The development of industry and construction is impossible without the use of various steel products. Metal corners are a universal product that has found wide application in various industries. It would be difficult to do without them. Distinguished by its light weight and simple configuration, angle bars are a desirable product both in construction, industry, and in everyday life.

In cross section, the steel angle, depending on the type, resembles the Latin letter “L” or “V”.

Production technology

The performance characteristics of this type of rolled steel depend on the method of its production. In accordance with manufacturing technology, equal angle angles are divided into two categories:

- Hot rolled.

- Cold-formed.

The production of hot-rolled profiles is subject to GOST 8509-93, and special carbon or low-alloy steels are used as raw materials for their production. The process of creating products using hot rolling technology includes several stages:

- A steel billet , heated to the recrystallization temperature, is processed by rotating shafts of various diameters to ensure the required profile dimensions. In the production of equal flange profiles, square steel ingots are used, with which it is possible to create profiles with flanges of equal width.

- The workpiece prepared after passing the shafts is passed through a rolling mill, where the product takes on its final shape under the influence of high pressure. During the manufacturing process, twisting the profile along the axis is unacceptable, since the maximum permissible parameters of its curvature should not exceed 0.4% of the length, and the maximum possible deviation from the length is 0.75%.

The use of the hot rolling method ensures high strength of the corners, bending resistance and a clear right angle, due to which they can be used for any type of construction and repair work, including the arrangement of load-bearing elements and structures.

The second production technology is the cold bending method, and the range of such angles is regulated by the requirements of GOST 19771-93.

To form bent corners, rolled sheets are used, which are processed on roll forming presses. Products obtained as a result of bending are characterized by lower strength, and they can be visually distinguished from hot-rolled angles by their rounded corner.

Marking

Any rolled steel has its own specific marking for its correct identification and avoidance of discrepancies.

On the metal corners you can find the following designations:

- Class of rental products;

- Her number;

- Angle length (measured);

- The grade of steel used.

Advantages

Equal steel angles are in demand due to a number of important advantages:

- High strength with low metal consumption. The production of angles requires less materials than the production of I-beams and channels, while the sufficient strength of the profile in some cases makes it possible to successfully replace these types of rolled products in various structures.

- High resistance to bending loads and mechanical stress, ensured by good corner rigidity.

- Maximum manufacturing precision. Even products with normal accuracy are characterized by fairly small deviations in length and slight curvature.

- Long service life while maintaining all operational characteristics, especially when using galvanized profiles that are well resistant to all types of weather conditions.

- Light weight, ensuring the possibility of using products in critical structures without significantly weighing them down.

- Significant resistance to distortion and deformation due to high rigidity and the ability to withstand significant loads for a long time.

- A huge assortment, including products with various dimensional parameters and characteristics.

- Possibility of using any fastening schemes, from bolted connections to welded fixation.

- Easy to process using all kinds of technologies.

- Possibility of improving performance properties through the use of galvanization or through the application of paint and varnish coatings.

- Minimal susceptibility to moisture and temperature changes.

- Versatility of application, ensuring the demand for rolled products in various fields.

- Affordable price.

Specifications

All operational and geometric characteristics of equal-flange angles are regulated by current requirements, according to which hot-rolled products according to GOST 8509-93 are divided into two types according to rolling accuracy:

- Normal accuracy with marking B.

- High precision with marking A.

To perform most of the work, profiles of ordinary precision are used, but when arranging critical structures that involve a high level of load, it is more advisable to give preference to high-precision rolled products. It must be taken into account that the permissible deviations of dimensional parameters depend on the width of the walls and accuracy indicators. For equal-flange steel angles of normal accuracy, these parameters are:

- No more than 1 mm with a wall (shelf) width of up to 45 mm.

- Up to 1.5 mm if the wall parameters do not exceed 90 mm.

- Less than 2 mm, if the width of the walls does not exceed 150 mm.

- Up to 3 mm with widths up to 250 mm.

Classification of angles according to length indicators is carried out as follows:

- Measured: products 4-12 meters.

- Unmeasured: profile lengths from 3 to 12 meters.

- Limited unmeasured length.

Corner curvature:

- At accuracy level “B” no more than 0.4%.

- With accuracy level "A" up to 0.2%.

When producing equal angle angles, various grades of steel can be used. Their type is determined depending on the operating conditions in which the rolled metal will be used. Various low-alloy alloys (10KhSND, 15KhSND, 17G1S, 09G2S and others) are in greatest demand in production.

Peculiarities

Among the most important features of rolled products are the highest level of strength and rigidity with a relatively low weight of the profile.

As a result, such corners are used in almost any type of construction, from the creation of lightweight metal structures to the arrangement of capital structures that involve a high level of load.

The second important feature is the high precision of manufacturing, so the products are widely used in cases where it is necessary to obtain a perfectly even angle.

Storage and transportation

Maintaining the quality of rolled products is ensured by well-organized storage and compliance with all established rules during the transportation of materials.

Equal-angle corners are mainly stored in bundles, which are tied with wire. When forming bundles from profiles with a width of more than 100 mm, corners in the amount of 4-6 pieces are stacked on top of each other, after which two stacks of equal height are placed parallel close to each other and tied with steel wire. If the width of the shelves is less than 100 mm, it is permissible to use up to 20 profiles to form a stack and link four packs together at once.

To store bundled corners the following can be used:

- Metal racks . The use of this storage option ensures that the rolled products are raised above the floor level, due to which the products are as far as possible from places where moisture accumulates and are less susceptible to corrosion.

- Special pallets , wooden beams or runners equipped with cross supports. A practical and convenient option that is used most often.

It is advisable to place rolled metal products in covered warehouse areas, where the area is completely isolated from precipitation and the humidity level does not exceed 70%.

Transportation of hot-rolled steel angles is carried out either in open trucks or using gondola cars in the case of delivery by rail. The size of one batch in most cases is no more than 70 tons, and a separate certificate must be provided for any batch. To facilitate the process of delivery and loading and unloading, the products included in the batch are divided into separate packs. Each bundle is equipped with a tag that contains all the necessary information: steel grade, batch number, dimensions and number of profiles, total weight of the bundle. If necessary, it is also possible to place groove-to-groove profiles, the so-called “herringbone”.

Rolled steel on the market

Recommendations on how to choose the right metal corner. First of all, you should pay attention to the following.

Angles are supplied to the market in the form of batches, and the product must be marked. In addition, quality certificates are issued for each batch, confirming compliance with GOST and the service life of the product.

Each marking must reflect what steel the rolled product was made from, what batch it was supplied in, all the dimensions of the angles, how much product was in one batch, and the heat number of the rolled product must be indicated.

Other types of corners

In addition to equal-flange corners, there are also unequal-flange profiles, characterized by different widths of the shelves. The production of such products is carried out using hot rolling technology (GOST 8510-86) and by bending from sheet materials (GOST 19772-93). Unlike universal equal-flange corners, unequal-flange profiles have a narrower scope of application and are used to strengthen various structures, in interior design, household, furniture production and other industries. In addition, due to their configuration, unequal angles are often used in complex structures, for example, when forming arches.

Advantages and disadvantages of bent corners

Bent corners also have their advantages and disadvantages. Pros:

- are the best option for small and medium-sized manufacturers;

- inexpensive;

- attractive appearance;

- compactness.

The disadvantages will be limitations in thickness and other parameters.

Application in construction

Strength, durability and a high level of reliability have ensured the widest possible popularity of equal-flange angles in the construction industry. They are used:

- During the construction of low-rise and large-scale objects, frame high-rise construction.

- As elements for creating heavily loaded and load-bearing structures: spans, trusses, floors, etc.

- When forming architectural elements for which it is important to obtain a perfectly even and clear angle: the formation of openings and slopes.

- Construction of overpasses and bridges.

- Construction of reliable frames for various objects: warehouses, bus stops, gazebos, shopping pavilions, change houses.

- Arrangement of screeds for metal structures.

- Manufacturing of canopies and canopies, stairs.

- When performing repair and finishing work.

- Decoration of building structures, creation of various architectural elements.

- Fastening of cables, pipes and various equipment during the construction of metal structures.

- Strengthening building structures, as well as concrete reinforcement.

- Improvement of local areas.

It is quite difficult to list all the possibilities of angles when used in the construction industry, since they are involved in the construction of buildings and structures of various types and purposes.

Buy from metal depot

A huge range of high-quality hot-rolled equal-flange angles at competitive prices is sold from the warehouse.

The entire range of this category of rolled metal meets the requirements of GOST 8509-93. We offer products with various geometric parameters and lengths, made of high-quality steel alloys.

In addition to equal flange profiles, we also offer unequal flange angles and other rolled metal products, represented by the following types of products:

- Fittings.

- Steel mesh.

- Profiled sheeting.

- Pipe and sheet metal.

- Channel.

- I-beams.

- Steel squares and circles.

- Wire.

- Stripe and more.

Rental products are sold at competitive prices and can be supplied both at retail and in wholesale quantities. As additional services for customers, we offer professional performance of work in the following areas:

- Welding of reinforcement in the required manner.

- Cutting rolled products and sheet materials to order. Please note that when cutting metals, the resulting materials are sold without any leftovers.

Advantages and disadvantages of hot-rolled angles

Hot rolled steel has a number of advantages, which include:

- scope of application – including at large enterprises for bulk and regular orders;

- Sizes are not limited;

- performance characteristic - maximum speed;

- Products with thick walls can be processed.

In addition to the advantages, hot rolled steel also has several disadvantages. Firstly, the high cost of equipment. Secondly, installing such equipment will require a large amount of free space.

GOST 8509-93

You can familiarize yourself with the GOST requirements and the range of hot-rolled and bent equal-flange steel angles by downloading the relevant documents in pdf format.

This standard applies to hot-rolled equal flange steel angles.

The dimensions of the corners, cross-sectional area, reference values for the axes and the weight of 1 m of the corners must correspond to those indicated in Figure 1 and Table 1, and for export deliveries - to Appendices A and B.

Legend to Figure 1 and Table 1

- b – shelf width;

- t – shelf wall thickness;

- X0, Y0 – distances from the outer edges of the corner flanges to its center of gravity;

- R – radius of curvature;

- r – radius of curvature of the edges of the shelves;

- I – moment of inertia;

- i – radius of gyration;

- F – profile cross-sectional area;

- Ixy is the moment of inertia that is developed by centrifugal forces.

Table of assortment of steel level angle

Equal-flange steel angles can be of normal precision (marked with the letter “B”) and high-precision (marked with the letter “A”). GOST allows the following deviations in the width of shelves:

- for products No. 2–4.5 – ±1 mm;

- No. 5–9 – ±1.5 mm;

- No. 10–15 – ±2 mm;

- No. 16–20 – ±3 mm;

- No. 22–25 – ±4 mm.

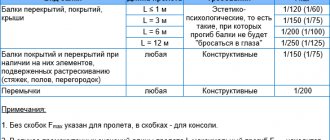

The thickness of the flange of an equal-flange steel angle in accordance with GOST may have the following deviations, measured in millimeters (see table).

The customer of a batch of equal-flange steel angles can agree with the product manufacturer that instead of permissible deviations in wall thickness, a tolerance for deviations in the mass of the product will be used, which can be for profiles:

- No. 2–7.5: from –5 to +3% (classes “A” and “B”);

- with No. over 7.5: ±2.5% (class “A”), from – 5 to +3% (class “B”).

Deviations in corner sizes depending on class

According to the provisions of GOST, steel angles belonging to the category of equal flanges can be supplied to the customer with a length of 3–12 m. By prior agreement between the customer and the manufacturer, these products can be supplied with a length exceeding 12 meters. Thus, GOST stipulates the possibility of tempering equal-flange steel angles of the following sizes in the longitudinal direction:

- measured length;

- measured size with the inclusion of products of unmeasured length in the batch (the number of such corners should not exceed 5% of the total volume);

- length, which is a multiple of the measured length;

- a length that is a multiple of the measured length, when the batch contains angles of unmeasured length (their number should not exceed 5% of the total volume);

- unmeasured length;

- length, located in an unmeasured interval.

To get advice, clarify the current cost and characteristics of rolled metal, contact us by phone or send a request using the online form on the website. When ordering materials in St. Petersburg, we provide delivery using our own vehicle, and in the case of making a purchase from other regions, we send rentals using reliable transport companies.

How to choose steel angles?

So, how should you choose the right metal corners?

The first is accuracy. You can recognize it by the letter in the marking. If there is a letter A, then this means that the corner has high accuracy. If Latin B is indicated, this means that this product has normal accuracy.

What can this parameter actually affect? It shows the parameters of the finished product (evenness, accuracy, thickness, as well as any deviations).

For small rolled metal products, high accuracy is an important characteristic. But for large products, completely different characteristics are important.

The second is the manufacturing methods. There are two types of manufacturing - cold rolling and hot rolling. That is, during hot production, products are rolled in special forms through hot machines (or the finished product is bent).

If we compare a cold-rolled product with a hot-rolled one, the former have low strength. Therefore, if high strength is required, then this steel angle will not work; it is better not to purchase it.

The third thing you should pay attention to is the shelves. There are two types - equilateral and non-equilateral. Option No1 is a metal strip that has an angle of 90% in the middle. The second No2 resembles the letter G because one side is longer than the other.

Corners that have equal sides are stronger, so they are used more often. But if it is necessary to individually calculate the length of both shelves, then non-equilateral corners are used here. This option also has high reinforcing properties.

And fourth is the steel from which the corners are made. In the manufacture of metal corners, more than one type of steel is used. If ordinary steel was used in the manufacture of the corner, then its price will be lower.

If in construction it is necessary for the structure to be reliable, so that it is not affected by the environment and temperature changes, then you should opt for products made of low-alloy steel.