Not everything can be connected with nails and screws. The process of repair and finishing work includes many technological operations that require glue that sticks tightly. In most cases, different types of adhesive mixtures are used for materials such as plastic, iron or drywall. However, there is a glue that can join almost anything - from fabric to ferrous metals. And it is produced under the general name “BF”.

Compound

The chemical composition may vary depending on the type of glue. The permanent component is polyvinyl butyral. The number immediately after the abbreviation “BF” indicates the proportion of the main active ingredient in dry form.

The adhesive mixture may also include:

- ethanol;

- phenol-formaldehyde resin.

Ethyl alcohol is necessarily present in BF medical glue. In other types it can be replaced with acetone or chloroform.

Externally, BF glue looks like a thick translucent mass of a reddish, yellow, brown or brown hue.

Instructions on how to make fabric glue with your own hands

If you prepare Mod Podge glue yourself at home, the product will have all the same qualities and properties as the industrially produced composition. For the procedure you need to prepare the following substances: 250 ml of glue, 250 ml of water.

The soluble composition is prepared according to this principle:

- Mix glue and water thoroughly in a container and shake well.

- As a result of mixing, a substance is obtained, which, after application to the surface, sets into a matte film.

Advice! In order to obtain an adhesive that forms a glossy film on the surface, you need to add water-based acrylic varnish to this mixture. After drying it becomes transparent.

You can also create your own dextrin glue for fabrics and other materials. Pour starch into an enamel container and place it in a drying cabinet for 2 hours, heated to a temperature of 160 degrees. After this you will get dextrin. Add this dried starch to boiling water in a 1:1 ratio and stir thoroughly until completely dissolved in water.

The finished dextrin composition tends to harden quickly, so after its preparation it must be used immediately.

You can easily prepare casein glue at home. To do this, you will need the following ingredients: casein and water in a ratio of 2 to 1. First pour the casein into a special container, then add water in a thin stream, stirring constantly to create a homogeneous adhesive mass. This mixture also hardens quickly and can no longer be used.

Note! Difficulties can arise when preparing casein. It can also be created at home from low-fat cottage cheese or milk. But to make life easier, it is better to buy ready-made casein in powder form.

Advantages and disadvantages

The main advantage of BF glue is its versatility. It is suitable for bonding non-metals to metals, repairing textiles, joining wound edges (in medicine). It is applicable to materials such as:

- ferrous and non-ferrous metals;

- stainless steel;

- plastic;

- tree;

- gypsum masses;

- textile;

- ceramics;

- glass.

BF glue is not subject to corrosion and rotting processes. It is waterproof, resistant to oil, gasoline and weather.

The main disadvantage of this product is that BF glue is flammable. In addition, if we compare it with specialized compounds, it loses to the Viam brand in terms of strength and to VS-10T glue in terms of heat resistance.

Criteria for choosing the strongest glue

If you urgently need durable glue, it is important to familiarize yourself with some of the features and characteristics of specific examples.

When choosing, it is important to consider:

- operating conditions of the glued product,

- ease of work,

- thickness of the adhesive seam,

- toxic properties of the solution,

- seam elasticity,

- the type of material is an important criterion. The materials have different structures.

For example, plastic has a fairly smooth and even surface. This makes it difficult to obtain the excellent adhesion required. If you need to glue vinyl wallpaper, then any wallpaper adhesive will not work. You will need to choose the strongest glue that can withstand a fairly large weight of the canvas.

Types and applications

Each variety differs not only in composition, but also in its scope of application. Some types contain toxic components, so they cannot be used to repair products that come into contact with food and drinking water.

BF-2

This type of butyralphenol glue is used for gluing static surfaces of metal, ceramics, wood, glass and marble. It can also be used when repairing acoustic equipment or during restoration work (used for impregnation).

To polymerize the composition it must be exposed to high temperature. The glue itself is heat resistant. Its limit is +180°C.

The percentage of viscosity of the composition changes depending on the storage temperature (the lower it is, the thicker the solution), therefore, before use, BF-2 is kept at room temperature for at least 2-3 days. The adhesive demonstrates good resistance to oil products, water, mold and acidic environments. At the same time, it is less resistant to alkali, alcohol and acetone.

BF-4

Just like BF-2, this variety is intended for joining parts and surfaces made of plastic, metal, leather, wood, and glass. The main difference from the previous type is that the mixture “works” on parts subject to bending and vibration. It is BF-4 that is most often used for joining metals and non-metallic surfaces.

BF-4 has a slightly lower heat resistance temperature (+175°C). Active use accompanied by multiple impacts on parts or surfaces can also reduce the strength of the adhesive seam.

BF-88

BF-88 is a universal adhesive for everyday use. It is also often used for repairing wood, glass, leather and plastic parts. BF-88 can be used on textiles, both natural and synthetic fabrics.

In addition to polyvinyl butyral, the product contains petroleum solvent, rubber (chloroprene) and ethyl acetate. Externally, BF-88 looks like a thick beige or greenish-gray mass, with a small amount of sediment.

BF-19

This type can be used in both hot and cold gluing processes. The first method usually combines wood, metals, ceramics and glass. The second is textiles, cardboard and paper, plastic and rubber parts.

BF-19 glue is a toxic type and is therefore not suitable for fixing parts in contact with food and water. It also cannot be used for medical purposes.

BF-2N, BF-4-N

Separately, it is worth mentioning the subspecies BF-2N and BF-4-N. Their main purpose is to connect parts made of ferrous metals, for example, iron.

Before use, you must wait until the glue has completely dried. With temperature changes below -60°C and above +80°C, the adhesive composition loses its strength.

BF-6

Medical-grade glue is unlikely to be useful during repairs, but it will not hurt in a home first aid kit. After use, BF-6 forms a film on the skin that has protective and disinfecting properties.

This type of glue can be used in the treatment of deep scratches, for healing burns, when suturing shallow wounds, and in dentistry. BF-6 should be used with caution, as it can provoke an allergic reaction.

What to do if the glue left a mark

Getting glue onto areas of fabric and plastic elements is a common occurrence that almost all needlewomen encounter. There is nothing dangerous in this situation or that could ruin the finished product. Even the simplest available materials are suitable for cleaning fabric.

We share some effective tips:

- To remove excess material, you can moisten a cotton pad with gasoline and then wipe the contaminated area with it.

- Regular talc also works well with glue - you need to sprinkle it on the glue stain, and then remove it with a regular cloth.

- Table soda works on the same principle.

- Vinegar is also suitable for getting rid of excess glue. They also need to wet a cotton pad or paper towel and then run it over the contaminated surface until completely clean.

Kak klej ubrat' s odezhdy

When using professional mixtures, be sure to follow safety precautions. Protect skin from contact with glue. If this is impossible to do for some reason, purchase environmentally friendly mixtures. This way you will avoid allergic reactions, irritation and chemical burns.

Bonding method

The choice of gluing method depends on the type of glue and materials used. Before use, the surface is cleaned of dust and dirt, sanded and degreased.

Hot way

With the hot method, an even layer of glue is applied to the prepared surfaces, after which they dry for an hour (for BF-2, 10 minutes is enough). Then a second layer of adhesive is applied and the parts are connected.

After this, the compound must be placed in an oven at + 150-170°C for 40 minutes (for BF-4) or for 1 hour at +130-140°C (for BF-2). The last stage is natural cooling to room temperature.

You can use the connected parts no earlier than 5 hours after the operation.

Cold way

Everything is much simpler here. The adhesive composition is applied to the surface of one part. After 3-5 minutes of drying, apply a second layer of glue and connect the parts, pressing them together as tightly as possible. You can use the result of your work no earlier than in a day.

What is the strongest glue in the world?

In many situations, the use of only high-quality products is required; for example, strong glue is needed to reliably connect and fasten different materials together. It must withstand significant loads.

You can pay attention to the glue with the following name Super Moment Maxi. It's great when working with plastic. Copes with smooth and slightly rough surfaces.

In order to avoid unnecessary difficulties, it is imperative to stock up on the following product: liquid nails. They will create a special layer that is particularly durable in use. It sets quite simply and quickly, withstands significant loads, and is easy to use.

You may be interested in: How to remove super glue from clothes

Composition with record strength anaerobic adhesive loctite

Among the rich variety of products, we can highlight the following option - this is glue that glues everything tightly and can cope with even the most difficult tasks at first glance. Glue

Loctite even managed to get into the Guinness Book of Records. Let's give a specific example: with the help of just nine drops of the selected super-strength product, it was possible to lift two cars weighing five tons.

This unique product was developed in Germany. Excellent quality German durable adhesive is used to quickly and easily glue different materials together. The adhesive solution is actively used; it is chosen by European companies in production.

It is definitely worth clarifying the following point: the special anaerobic composition of the product provides an excellent opportunity to obtain a compound that is super stable in all respects in a short period of time. The action is performed in the complete absence of air. Thus, we can conclude that a layer is obtained that does not react to lubricating oils.

Glue held a truck weighing 17.5 tons

Advantages and disadvantages

High-quality and correctly selected adhesive compositions for different materials have numerous advantages. These include safety in use, ease of operation, and excellent composition.

To achieve the best performance, it is important to carefully and thoroughly study the instructions for the selected product.

Other types of glue

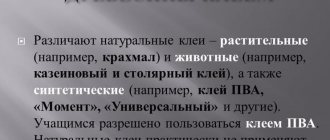

All adhesive mixtures can be divided into organic and inorganic. The BF series belongs to the latter. Organic glue is made from components of plant and animal origin: starch, resin, wax. Inorganic mixtures contain chemical elements and compounds: silicon, magnesium, formaldehyde, ethylene.

Adhesive is most actively used in the field of construction and repair work. It is used for fixing floor coverings, fastening drywall, heating and waterproofing equipment.

Tree

To fix parquet, as well as other woodworking derivatives, use:

- PVA glue;

- polyurethane glue;

- resin based product.

PVA glue is considered environmentally friendly and can be used even in rooms without exhaust ventilation. It is distinguished by:

- fast setting;

- high strength (able to withstand high static loads);

- long service life;

- versatility.

This type is often used for minor household repairs. You can increase the strength of the composition by adding wood dust to the mixture.

Polyurethane glue is a little more expensive, but it can withstand not only statistical, but also dynamic loads. It is also versatile, waterproof, heat resistant and UV resistant. Its use is advisable in extreme conditions.

Resin-based adhesives are in demand in furniture production. The main advantage of the composition is its resistance to chemically aggressive agents, so its use requires the use of protective equipment (gloves).

Clinker and gypsum tiles

For cladding with decorative gypsum tiles, a gypsum mixture is used. It has many advantages, among which it is worth highlighting:

- ease of preparation of the solution;

- increased strength;

- economical consumption;

- long service life.

If necessary, you can also use polyurethane foam, but since it expands when hardening, the parts should be additionally secured with dowels.

Drywall

When fixing drywall, 2 types of glue are most often used. The first type is aerosol. It is applied over the entire area of the slab every 25-30 cm, after which it is fixed in the desired position. The advantage of the aerosol composition is its rapid setting. Disadvantage: intolerance to temperature changes.

Classic mounting adhesive is cheaper. It is produced in dry form, so it requires dilution with water. Using plasterboard slabs you can level walls, door and window openings, as well as ceilings. Self-tapping screws will provide more reliable fixation of gypsum fiber boards.

Plastic

Plastic is widely used today in almost all industries. Products made from it are somewhat fragile, but can be easily repaired using the following types of glue:

- PVA;

- contact glue (Moment and BF-2);

- reaction glue (Second);

- hot melt adhesive.

If everything is clear with the first two types, then the reaction adhesive is made on the basis of epoxy resin. This type of glue has good water resistance. There are one-component and two-component varieties. The first ones dry quickly, the second ones are more durable.

Hot-melt adhesive is applied using a special device - a glue gun. It works great on plastic surfaces, as well as wood, metal and textiles.

Wallpaper

Despite the wide range of interior design possibilities, wallpaper is still the most popular means of wall decoration. When working with them, universal glue is most often used. Depending on the type of wallpaper (paper, vinyl, textile), the instructions for diluting it change. Light materials require a liquid composition; for dense wallpaper you will need to prepare a thicker mixture.

Iron

In situations where the integrity of metal parts cannot be damaged, a special type of glue is used - epoxy. It is sold complete with a hardener and, to increase the strength of the seam, requires thickening - adding metal shavings or silicate chips to the composition.

Another option is “cold welding”. It consists of a base and a catalyst, which, upon reacting with each other, harden. You can lock the threads on the metal and seal the flanges using machine glue or an anaerobic adhesive. In the absence of oxygen, the acrylic base of the adhesive polymerizes and sets tightly.

Rubber and PVC

Rubber parts and things, such as boots or a bicycle tire, can be repaired with a special adhesive compound - rubber glue. It is created on the basis of polychloroprene rubber, organic solvent and synthetic resins.

This variety is highly adhesive. With its help you can repair a tent, a PVC boat, shoes or children's toys. For the latter, it is better to choose brands based on natural rubber.

A second of adhesive gel will help you quickly repair a small tear. He will help out with a punctured tire and other minor troubles. However, it must be remembered that it has extremely low water resistance.

Glass

Glass is present not only in window structures. Decorative items, dishes, jewelry, lighting fixtures and furniture elements - you can find this beautiful but fragile material almost everywhere.

You can glue a broken vase using one-component varieties made on the basis of organic silicon. Unlike BF or Moment, this glue is more aesthetically pleasing and invisible on the surface of parts.

Polymer glue is actively used in restoration work, repairing jewelry, making stained glass and even expensive jewelry. It requires the use of UV radiation, so the polymer variety is rarely used in everyday life.

Silicone glue is environmentally friendly and non-toxic, so it can be used to repair dishes and other items that come into contact with food or drinking water. Silicone glue perfectly repairs not only glass, but also ceramics.

The main thing when selecting glue is to correlate its properties with the goals and tasks that it must accomplish. This is the key to an excellent result.

Choosing the best all-purpose glue

In order to choose and buy the best universal glue, you need to pay attention to its composition and features. The most proven and popular compositions, according to the recommendations of repair professionals, include the following product options:

- Epoxy adhesive. It is characterized by high strength. Provides and guarantees resistance to both mechanical and chemical influences.

- PVA is a common glue that has a variety of options with additives and concentration of substances. Easy to use at home.

- Montagekit Extreme Grip allows you to achieve high grip on any chosen surface.

Thus, we can conclude that there are a small number of universal glue options. All are of high quality, excellent adhesion to different materials.

How to use

When working with glass glue at home, you need to follow several rules. First of all, act carefully, as stains may remain on the transparent material. Hardened drops of glue are very difficult to remove from the front surface. Glass is a fragile material, so there is no need to subject it to unnecessary stress. Another important point is skin protection. It is necessary to use protective gloves and a mask, especially if the adhesive products contain toxic substances.

How to glue glass correctly :

- First of all, you need to prepare the surface. The result of gluing depends on its purity. Before starting work, the glass must be degreased: wipe with solvent, rinse with soapy water and wipe dry. Sometimes the surfaces are polished (for smooth joints).

- How to glue parts: both parts are covered with a layer of glue, if necessary, soaked, and then pressed tightly against each other for a while. Sometimes it is enough to lubricate only one part, usually a smaller one.

- For complete polymerization, you need to leave the item for a day in a dark place. If UV glue is used, the bonded product is placed under a special lamp.

- If excess glue appears, it can be cut off with a sharp construction knife or blade.

- Before use, the glued product should be wiped with a damp sponge and dried. If the packaging does not indicate that the composition has water-repellent properties, then it is better not to wash the glued object with water.

Advice! The glue is applied carefully and in a thin layer. Excess will be difficult to remove.

The exact drying time varies between different adhesive materials. The manufacturer indicates on the label the procedure for working with the glue, the speed of its setting and complete hardening. Working with glue depends on the type of packaging. If the tube is not equipped with a convenient nozzle, it is recommended to use a brush. To glue small decorative elements, they can be held with tweezers and immersed in a drop of glue.

The variety of adhesive products allows you to choose an option that will fully suit its purpose. With the right composition, work with large glass elements and small parts like beads will be performed equally reliably.

I collected this material myself personally and several other people helped me with this. It will be useful to everyone. Those who repair, those who want to and are engaged in tuning, or simply masters of their craft ;) Everything that is indicated here has found application in personal experience. I suggest adding your experience in the comments and creating a useful topic for everyone!

Hot glue, fast but unreliable

A quick fix might be hot. It is easy to use, but is not durable and can be used for temporary bonding. When using, be careful when applying to PLA, it may deform the plastic.

Surface preparation: sand, clean and degrease the surfaces to be bonded.

Suitable for PLA, ABS, TPU, not suitable for PETG and nylon.

A great option for gluing large models is to use a 3D pen. In this case, the thread for the handle can be selected from the same material as the printed 3D model.

Requirements for glass adhesive

Glass is a material with reduced adhesion, which makes it difficult to glue. Glass is also quite fragile, which also complicates the task. What properties should the glue have to make working with glass convenient and the result reliable and durable? Basic requirements for the material:

- High adhesion is a prerequisite, since glass is smooth and repels water; special adhesion strength is needed for gluing household items that are subject to stress.

- The glue should be transparent so that the seam remains invisible. For fastening small parts, this property is more important than strength.

- When working, the glue should dry quickly.

- High-quality material has a thick consistency.

- The seam must be elastic.

- Important characteristics are heat and cold resistance; it is highly desirable that the glue can withstand high and low temperatures, as well as their differences.

- Waterproof if the surface or object will be located outdoors or in a damp room.

- Safe for the environment, free of toxic substances and odor after curing, and ideally during operation.

Transparent glass adhesive is the best option for working with colorless materials of various types. This property is important for neatly joining small and decorative parts. When choosing an adhesive, you need to pay attention to the properties of the surfaces to be bonded. So, for smooth ones, regular compounds are suitable, for corrugated ones, reinforced ones. If you need to glue special glass, for example, for an aquarium, then buy a sealant without antibacterial additives, that is, safe for the water and its inhabitants. The strength of the adhesive is especially important when working with window glass or painted surfaces.

How to properly connect metal surfaces

When connecting components together, you need to consider how the structure will be used. If this is a fixed structure, you need a composition with strong adhesion. If it is constantly moving (for example, a staircase), an elastic component is needed.

IMPORTANT: each product has instructions that describe the properties, scope of application, and rules of use. They must be taken into account when using.

Proceed like this:

- Choose the appropriate adhesive for your situation (taking into account the scope of application, temperature, etc.);

- Read the instructions carefully;

- Prepare the surfaces. They need to be cleaned of rust and other contaminants. It is also important to degrease, for example using alcohol.

- Then, according to the instructions, apply the substance to the metals, combine, and hold until completely hardened. (The hardening time for each brand is different. It is indicated in the instructions).

In the video below you can see how metal is joined to metal:

Static rigid bonding of metals

Here adhesives are used that are capable of tightly bonding metal to metal. These are epoxy and cyanoacrylate glue. They have strong adhesion. Metal gluing must occur quickly. The entire area of the two parts of the material should be covered with an adhesive composition.

Deformation bonding of metals

If you need to glue two parts of constantly moving elements, you need fast-hardening metal glue. And at the same time elastic. Anaerobic, epoxy and heat-resistant glue are suitable.

In addition to gluing metal, which will be subject to constant deformation, there is “joining metals by deformation” - “cold welding”. This technology requires a special cold welding machine.

Epoxy resin

This adhesive composition forms a polymer, which is a fairly strong adhesive that tightly holds elements of two parts together. It is one of the best materials for gluing metal to metal.

Can be used for both interior and exterior work. It withstands temperatures well and is resistant to moisture. It hardens quickly, on average from one to five minutes, and complete hardening occurs within a day.

Epoxy adhesives, high strength

Usually these are two-component formulations, one bottle contains epoxy resin and the other contains a hardener.

Advantages:

- Resistance to aggressive chemicals, including oils, gasoline, non-concentrated acids and alkalis. Detergents and other household chemicals do not destroy the seam.

- Heat resistance. Tolerates temperature increases up to +250 C.

- Elasticity. Small displacements of glued fragments, drilling and grinding of the seam are possible.

- Completely waterproof.

- Good adhesion to various materials, including plastics, wood, cement, drywall, etc.

- Resistant to shrinkage and cracking.

- High seam strength.

Epoxy adhesives also have some disadvantages. The mixture cannot be selected to work with nickel, polyethylene, zinc, silicone, chromium and Teflon. It is prohibited to glue objects that come into contact with products with such compounds. Another disadvantage is the high speed of hardening, so you must work very quickly and accurately, otherwise it will be impossible to correct possible flaws. After hardening, such glue is very difficult to remove from the surface; all elements that have been stained must be thoroughly cleaned with a solvent (isopropyl alcohol is best) while the glue has a liquid consistency. In general, it is somewhat more difficult to work with than other types of adhesives.

After setting, the seam can be sanded and painted.

Surface preparation: sand, clean and degrease the surfaces to be bonded.

Suitable for: PLA, ABS, PETG, TPU, nylon, perfect for photopolymers and other resins DLP, LCD, SLA 3D printers.

How to glue shoe soles?

Before sealing your boots, you should assess the damage and choose the most optimal remedy to repair the damage. An effective shoe glue must have the following qualities:

- long service life;

- reliability;

- water resistance and frost resistance;

- reliable gluing regardless of the thickness of the materials used;

- minimal rigidity;

- elasticity.

It is true that, in the absence of more suitable means, shoes can be sealed with sealant. However, with its help you will not achieve the necessary adhesive strength. In addition, if used carelessly, it can ruin the appearance of the product.

Many types of glue have the necessary properties, but not all of them can glue leather to polyurethane, rubber or PVC. Therefore, before purchasing adhesive of a particular brand, carefully read the instructions for use.

Tips for use

The glue must be applied to a clean, grease-free surface.

Before applying glue for plastic and ensuring strong fixation of plastic to plastic or other material, it is necessary to carry out a number of preparatory measures:

- degrease the surface (you can use acetone);

- sand the areas of future gluing to ensure roughness;

- mix the glue in the required proportions (if required by the instructions);

- use brushes made of synthetic fibers rather than natural ones;

- apply the product in a thin layer to avoid the adhesive layer coming out;

- press the parts firmly, but without excessive load.

Valera

The voice of the construction guru

Ask a Question

To achieve the best gluing result, the specified curing time must be maintained before and after the compression process. If there is no marking on the plastic, you can apply a drop of glue to an inconspicuous area of the product and monitor the reaction.