With the increase in the number of road transport as a result of an increase in the volume of waste, the issue of the environmental situation has become acute. Every year, thousands of tires are taken to landfills and landfills, where they become a source of negative impact on the environment.

Car tires belong to class 4 hazardous waste due to the carcinogenic and toxic substances released during decomposition that destroy the biosphere . In recent years, waste disposal requirements in large cities have become more stringent, and compliance with rubber product recycling techniques is regularly checked.

Fire safety regulations prohibit storing tires due to the possibility of spontaneous combustion. An active person with basic knowledge of physics and carpentry skills can turn rubber waste recycling into the main source of income. Crumb rubber obtained during the recycling process acts as a secondary raw material in the manufacture of goods.

We make crumb rubber with our own hands using a homemade crusher

Every year, thousands of tires are lost in landfills and landfills, despite the fact that for an enterprising person they are a free resource from which crumb rubber can be produced.

If you need it only once, you can buy it in the required quantity from the manufacturers.

But where can you get crumb rubber if you need it on an ongoing basis and in large quantities?

It is worth considering purchasing your own tire recycling equipment.

However, not everyone can afford a full-fledged installation , and not everyone will find such an investment profitable. The solution is to create equipment with your own hands and use it to produce crumb rubber from tires at home.

Business prospects

The benefits of the tire recycling business can hardly be overestimated. The constant appearance of new cars on the market allows for a practically inexhaustible source of raw material - tires that must be recycled.

But for them there is an alternative option - obtaining crumbs, which, with the right approach, can be used to make many useful items both for the home and garden, and for many branches of human economic activity.

Experts have calculated that with an available initial capital of 160 thousand dollars, the payback period will be about a year, and then the profit per month will be more than 15 thousand dollars.

If you are interested in equipment for mechanical processing of rubber, then read our material about machines, lines and factories.

Recycling small amounts of rubber at home

If you need very little raw material, you can do without equipment at all.

All you need to do this is scissors and a cutter .

The metal cord is first removed from the tire, then divided into strips and crushed into smaller fractions to the required size .

At this point the process is considered complete.

The material for decorating paths, flower beds or a separate playground is ready for use.

But in order to obtain a larger volume of raw materials or to have income from processing tires at home, you need the appropriate equipment.

Room

The production premises must be located at a distance from the residential sector - no closer than 300 m. It is recommended to rent a suitable workshop on the outskirts or in an industrial area of the city. The rent here is cheaper, the location suits all requirements.

According to our business plan, the equipment will require a room with an area of 150 square meters. m. It should be divided into the workshop itself with equipment, premises for storing raw materials and finished products, rooms for workers, a bathroom, and the director’s office.

The workshop must have:

- flat floor;

- high ceilings (5 m);

- ventilation systems, air purification, fire safety, heating, electricity (380V);

- redecorating;

- stable air temperature 15-18°C.

Construction of a tire crusher

There are three main methods for producing crumbs:

- Crushing tires after cooling them with liquid nitrogen to –190 degrees.

- Production of crumbs using full-cycle industrial equipment with cord removal and subsequent rubber grinding.

- Processing using universal crushers, which can be done at home yourself.

The first two methods require large investments. The third option is available to everyone

who has the opportunity and desire to make a crusher at home.

The necessary units can be made independently in a workshop or at a production site - where there are metal-cutting machines (lathes, milling) and a welding machine for the manufacture of component parts.

If you cannot perform mechanical processing of the workpieces yourself and you have to order them according to your own drawings, the cost of tire processing machines will still be several times cheaper than similar purchased units.

The main component on the tire conversion line is a shredder (rubber shredder). Let us consider in more detail the purpose of the components of this machine.

Unit design

The machine consists of the following main components:

- electric motor 5 kW – 2 pcs;

- housing with disk shafts;

- lattice;

- worm gearbox – 2 pcs.;

- shredder frame;

- loading hopper;

- guide tray;

- control cabinet.

The installation parts are mounted on a powerful frame welded from channels.

Box with cutting discs

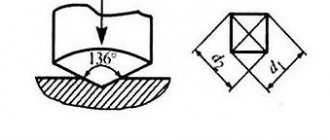

The main unit of a rubber crusher is a housing with milling rolls.

At the same time, the cutting knives are made of high-strength steel and heat-treated, which significantly reduces their wear. They practically do not require sharpening during operation .

The calculation of the box openings, shafts and cutting elements must be accurate, so it must be done by a specialist in this field (designer).

Grid for calibrating crumbs

In order to obtain a calibrated fraction of tire raw materials, shredders are equipped with a special grid, which is installed under the rolls.

Worm gearbox

The rotation of shafts with disk cutters is carried out separately, directly from worm gearboxes connected to electric motors through couplings.

Business organization

When considering recycling used tires as a business, it is worth weighing all the pros and possible cons.

As a model, we will take the proposed site ALFA TIRE RECYCLING 500 - an electromechanical production line for processing tires of different diameters, including truck tires.

Cost of equipment

Starting capital to purchase the necessary equipment:

| N p./p. | Name of equipment, other expenses | Cost, rub |

| 1 | Basic equipment | 11 750 000 |

| 2 | Scales | 20 000 |

| 3 | Bag packing machine | 10 000 |

| 4 | Bags for crumbs | 20 000 |

| 5 | Delivery to any region of Russia | 100 000 |

| 6 | Installation, assembly and commissioning of equipment | 150 000 |

| 7 | Costs for starting the line (keys, oil, etc.) | 30 000 |

| Total: | 12 080 000 |

Below is a table with the name of the equipment within the ATR 500 tire recycling line:

| N p./p. | Name of equipment | Quantity |

| 1 | Knife for cutting tires | 1 |

| 2 | Belt conveyor | 1 |

| 3 | Primary shredding system (shredders) | 2 |

| 4 | Fan | 3 |

| 5 | Small cyclones | 2 |

| 6 | Pneumatic conveyor | 1 |

| 7 | Magnetic separation | 3 |

| 8 | Crusher | 1 |

| 9 | Sieve with vibration impact | 2 |

| 10 | Cyclones are big | 1 |

| 11 | Vacuum cleaner | 1 |

| 12 | Electrical equipment | 1 |

| 13 | Metal structure | 1 |

| 14 | Belt conveyor for cord | 1 |

You can learn a little more about this line by watching the video:

It is worth paying attention to the following points:

- prices for individual equipment items must be clarified with the seller (supplier);

- all obligations for warranty repairs and the conditions for their provision are specified in the supply contracts.

The cost of delivering equipment throughout Russia may fluctuate upward depending on the remoteness of the region.

A more detailed description of this line is here.

You can also ask prices for equipment from other suppliers, for example, from this one.

Requirements for production premises and warehouses

Space will be needed for:

- placement of equipment;

- storage of raw materials;

- storage of the finished product.

To install the line you will need at least 200 square meters.

An outdoor unheated hangar or a fenced-in area for unloading recyclables is suitable for storing old tires.

Purchasing the necessary premises can be an overwhelming burden for a new entrepreneur.

Staff

Let's consider the number of service personnel and the monthly payroll.

For uninterrupted operation of the production line with a finished product output capacity (crumb rubber) of 150 tons/month. A staff of about 10 people is required.

The approximate monthly wage fund is RUB 350,000.

These calculations are presented in the form of an average plan and may differ depending on the region of Russia.

Other expenses

Production will be accompanied by other monthly expenses:

- Purchase of packaging bags (containers) for finished products. The price of a 30 kg bag will be 8 rubles, based on the monthly consumption we get the amount of 4,000 rubles.

- Communication – 10,000 rub.

- Unforeseen expenses - 10,000 rubles.

- Average data on energy consumption of a production line, designed for the production of finished products of 150 tons/month. equal to about 100,000 rubles/month.

- Maintenance – 50,000 rub.

- A separate expense item should be considered the replacement of cutting elements (knives) - 35,000 rubles.

- Garbage truck services – RUB 20,000.

License for acceptance and disposal

Contrary to information on most websites, tire recycling as a business requires a license.

Tires have the fourth hazard class. According to the legislation of the Russian Federation, the reception and disposal of this type of waste requires obtaining a license.

Before submitting documents, an entrepreneur must have:

- production area;

- industrial site with a sanitary zone;

- equipment;

- permits from Rosprirodnadzop, Rospotrebnadzor, fire inspection.

The cost of the license is 7,500 rubles, the period for obtaining it is 45 working days. When using the services of intermediaries, be prepared to pay many times more.

Profitability calculations

Project profitability and revenue generation plan:

- Finished products in the form of rubber granules, average price 15 rubles/kg. 100 tons = 1,500,000 rub.

- Metal cord 30 tons at a price of 3,000 rubles/ton = 90,000 rubles.

- Textiles based on the resulting material being 20 tons and the average market price of 2,000 rubles/ton = 40,000 rubles.

The presented business plan has average calculations and does not take into account some factors:

- location;

- territorial affiliation;

- availability of a sales market in a particular region.

It cannot be taken as a formula, but even so, the benefits are obvious.

Under favorable conditions, the payback for the production of crumbs from old tires will occur within 1.5-2 years after the launch of the line.

How to shred tires?

The technological chain consists of several preparatory stages before the product of the required fraction is obtained.

- Inspection and removal of foreign objects from the tire cavity.

- Cord cutting.

- Cutting tires into strips measuring 50-80 mm.

- Grinding of raw materials using a shredder.

- Separation and separation of metal parts from textile parts.

- Calibration of crumbs into fractions using a vibrating sieve.

Equipment performance

The operation of these two main units when processing tires is done in a semi-automatic mode .

For normal operation of this line, a room of about 150-200 sq. m is required. meters. This is due to the fact that you need a place to locate not only equipment, but also to store used tires, finished tire products and metal waste.

The production of crumb rubber on this equipment per hour will be approximately 200-800 kg and up to 100 kg of metal scrap; 2-3 unqualified workers will be needed to service the machines.

In addition to tires, this equipment can process other rubber (conveyor belt, inner tubes, gas masks). The output is crumbs with dimensions from 0.7 to 4 mm, while it makes up 65-85% of the total mass of raw materials.

Business plan

Based on the current business plan, you can open a tire recycling plant. At the planning stage, an entrepreneur needs to develop a business plan with calculations to launch the production of crumb rubber from tires. It consists of:

- Brief summary.

- Descriptions of the goals and objectives of the project.

- Descriptions of the enterprise.

- Analysis of the direction of processing and ways of further development.

- List of potential buyers of crumbs.

- Assessments of competition in this area.

- Assessment of possible risks.

- Marketing plan.

- Technological and organizational plans.

- Personnel composition.

- Financial plan.

- Social and environmental responsibility.

- Conditions for leaving the business.

Several aspects of the business plan have been touched upon above. Project development requires the entrepreneur to be attentive, foresighted and have a sufficient amount of time. Below we will look at examples of some points of a business plan.

Staff

Processing tires and tires into crumbs is a simple process from a technological point of view. Highly skilled workers may only be needed when troubleshooting and servicing equipment (for example, sharpening knives, changing conveyor belts and electric motors). A small production facility can be serviced by 3-4 employees.

So, to open a business you will need personnel:

- 3-4 plant operators;

- accountant (possibly part-time);

- storekeeper who receives raw materials;

- Sales Manager;

- truck driver.

Total: 7-8 people.

Financial plan

Initial investment (RUB):

- registration of an organization – 10 thousand;

- a number of consumables, printing – 10 thousand;

- production equipment – 6 million 200 thousand;

- advertising and other – 50 thousand.

Total: 6 million 270 thousand rubles.

Expenses for each month (rub.):

- to the lessor – 80 thousand;

- utilities – 5 thousand;

- wages to employees - 120 thousand;

- communications and other – 10 thousand;

- electrical energy – 20 thousand;

- packaging materials – 6 thousand;

- taxes – 55 thousand;

- transport (gasoline) – 30 thousand.

Total: 326 thousand rubles.

Income

The production line, whose capacity is 400 kg of raw materials per hour, ensures the processing of 80 tons of tires per month. As a result of the process, you can get in a month: 55 tons of rubber crumbs, 10 tons of textile material and 15 tons of metal cord.

The cost of 1 kg of crumbs of different sizes is 16-17 rubles, 1 kg of textile fiber - 2 rubles, 1 kg of metal fraction - 2.5 rubles.

Thus, monthly income will be (rub.):

- acceptance of tires for recycling – 120 thousand;

- sale of crumbs – 895 thousand;

- cord sales – 37 thousand;

- textile sales – 20 thousand.

Total: 1 million 72 thousand rubles.

The payback period for a business with maximum use of production capacity is 8.5-9 months. In order to cover operating costs, it is necessary to process at least 170 kg of raw materials per hour.

Risk assessment

Processing tires into crumb rubber, like every other industry, has certain risks. Some of them can be reduced through regular and proper maintenance of the equipment; other risks are unforeseen and may arise:

- in case of failures in the supply of raw materials;

- in case of breakdown of installations and their downtime;

- when problems arise with the sale of products;

- in case of damage to the final product as a result of violation of storage requirements;

- when prices for crumbs fall.

To minimize risks, it is necessary to duplicate the supply channels for raw materials and sales of finished products, cooperate with Russian and foreign companies, and expand the scope of business activities. For example, it is possible to completely process tires into crumbs and then into floor coverings used in the construction of sports grounds, stadiums, etc.

It cannot be said that the business of processing tires into crumb rubber is simple and inexpensive. However, with the right approach to business, this area of business activity will bring good income. In addition, the government can help you start this environmentally beneficial business if you have a solid business plan.

Where to use the resulting raw materials?

- apply for your own needs;

- sell wholesale and retail to the population and enterprises;

- use for the production of goods or open a custom rubber coating business.

The price of the crumbs will depend mainly on the quality of the raw materials, and secondarily on the fraction.

The most popular is crumb, the fraction of which is 2-4 mm .

It's great for creating:

The popularity of such crumbs is due to the fact that a minimal amount of glue is used to glue these granules together. And a polyurethane binder is sometimes 5-8 times more expensive than crumbs.

Features of preparing the working composition

Regardless of the rubber coating manufacturing technology you choose, you will need:

- rubber crumb;

- adhesive composition;

- coloring pigments.

Rubber crumb

The degree of grinding of rubber tires determines their further scope of use.

- crumbs less than 2 mm in size – the formation of two-layer floor coverings for sports fields and stadiums, running tracks, swimming pools, industrial workshops, car washes, livestock buildings;

- granules 2-5 mm in size - filling sports equipment, creating a base for children's, sports and playgrounds.

When purchasing crumb rubber, pay attention to the following conditions:

- quality of product cleaning;

- sorting by size;

- crumb shape.

For 1 m2 of coating, an average of 8 kg of rubber will be required.

The cost of finished crumb rubber starts from 10-12 rubles. per 1 kg of product and depends on the volume of purchase and seasonal demand for products.

Adhesive composition

For the manufacture of seamless rubber flooring, predominantly one-component compounds are used, less often - two-component ones.

One-component

Bitumen or polyurethane is used as a binding element in the adhesive mixture. The choice of adhesive is determined by the performance properties of the future coating and the work conditions.

Adhesive for rubber coatings on a polyurethane basis has the following properties:

- Water permeability. Water does not linger on the surface of a coating made with polyurethane, but passes through it. The finished coating can be used both indoors with high humidity levels and outdoors.

- High abrasion resistance. Suitable for making floors subject to high mechanical loads.

- Elasticity. Allows you to create an injury-proof covering for sports.

- Environmental friendliness. The absence of harmful fumes makes it possible to use rubber floors in play areas for very young children.

- Long service life due to resistance to ultraviolet radiation and sudden temperature changes.

Another feature of the polyurethane binder is hardening at a fairly high level of humidity - 60-70% and an ambient temperature of 20-25o.

Compositions with bitumen are less suitable for making a seamless rubber surface.

Cost 1 kg. one-component glue – from 185 rub.

Two-component

Two-component adhesive is sold in separate containers containing an epoxy-polyurethane binder and a chemical hardener.

Both components are mixed directly at the time of work.

When choosing a two-component adhesive for crumb rubber, you should take into account that the finished composition should be used in the first 30-40 minutes after its preparation.

This feature of the glue requires careful calculation of the need for it to carry out work in this period of time. The advantage of the two-component composition is high chemical inertness.

The cost of 1 kg of glue is from 165 rubles.

Requirements for work

The formation of a high-quality seamless rubber coating is possible only with strict adherence to the proportions recommended by the adhesive manufacturer.

Another condition for uniform polymerization of the working composition is maintaining the required level of humidity and temperature at the work site.

Pigment compositions

The coloring of the future rubber coating is given by coloring pigments added to the working composition.

What should you pay attention to when choosing paint?

- production from inorganic components;

- presence of iron oxides.

This component composition of the dye makes it resistant to precipitation and ultraviolet radiation, extending the aesthetic life of the coating.

The dosage of the dye depends on the desired color intensity of the surface being formed and averages 62 g per 1 kg of crumb rubber.

The uniform consistency of the working composition is achieved by strictly following the manufacturer's recipe.

The cost of 1 kg of dye is from 110 rubles.

Primer material

A polyurethane-based primer is another component without which high-quality installation of a seamless rubber coating is impossible.

The price of a primer ranges from 10 rubles. for 1 kg. and depends on the volumes purchased.

How to make crumb rubber at home without professional equipment

We will send the material by email

Since I always deal with the arrangement of the local area on my own without the involvement of specialists and expensive materials, I decided to puzzle myself with the question of how to make crumb rubber at home. In the future I will need it for landscape design. I offer two options for manufacturing raw materials: simple and complex.

An elementary method for making crumbs in small quantities

To decorate a small area with rubber crumbs, I only needed two car tires, scissors and a cutter. There were no difficulties in implementing this method. The only caveat is that it is extremely difficult to grind rubber to a minimum fraction. The whole process consisted of the following steps:

- I took two worn tires from a car that were no longer suitable for use.

- I examined them for the presence of nails, thorns and other unnecessary objects, then cut out the cord (metal reinforcement).

- Next, using large scissors, I cut the workpieces into strips of the same width, then, using a cutter, I crushed them to the maximum possible size.

As a result, I got black rubber crumbs with my own hands. Next, I used it to decorate flower beds, after soaking it in paint to add pigment.

Recycling

Crumb rubber is widely used in various areas of production, sold to the public or used for personal purposes. An excess of worn-out car tires and rubber products ensures the constant availability of consumables.

The cost of crumb rubber depends on the diameter and quality of the granules. Powdered crumbs and granules with a diameter of 2-4 mm are in great demand. The popularity of this size is due to lower production costs and lower consumption of adhesive, the price of which is several times higher than the cost of recycled materials.

Crumb rubber is used to make the following products:

- Roll coverings

- Rubber Shoes

- Paving slabs

- Fuel

- Rubber insulation and seals

- Three-dimensional figures cut from used tires

- Paths for private houses, gardens and summer cottages

- Waterproofing and noise-absorbing coatings for children's and sports grounds

- Rubber technical products

- Asphalt mixtures

- Seamless rubber coatings

Currently, the recycling industry is considered promising for starting your own business due to low competition and growing demand for waste recycling services. Even with a small amount of work performed, the financial investments spent on equipment pay for themselves in a short time. Recycling tires in a crusher is recognized as the most environmentally friendly method of disposal, allowing you to make a profit with a small financial investment.

Complex method using equipment

This manufacturing option is reliable, but requires the preparation of special equipment. I did not buy equipment for grinding, since I also decided to assemble a structure from parts available on the farm. I'll tell you step by step what followed.

Detailed design of the unit

At this stage, I will explain what parts a homemade crusher should consist of and where I got them from. If you still have to buy something from the components, then believe me it will be much cheaper than purchasing an industrial device. So, the design should consist of:

- two electric motors (I took them from two old home mills, power 5 kW each);

- a housing in which disc shafts are built in (the latter had to be ordered to fit your dimensions);

- regular grille;

- worm gearbox (at least two pieces are required);

- do-it-yourself shredder frame for rubber crumbs;

- bunker for loading material for processing;

- guide channel;

- cabinet with control buttons;

- device for preparing tires for shredding;

- powerful frame for installing equipment.

The last structural element will also have to be ordered from professional welders. The frame must be made from channels. But, if you have skill in this matter, then you can think through the support yourself. Next, I propose to consider the main components of the device in more detail.

Box with built-in cutting discs

This element includes a housing equipped with small milling shafts. The knives themselves, which are used for chopping, are made of high-strength steel. They also have high thermal stability, as they can become very hot during operation. Thanks to heat treatment, cutting structures last longer and do not require periodic maintenance.

Calibration grid

This DIY tire shredder design is installed directly under the rollers. It serves to obtain a calibrated fraction from processed raw materials. This element is mandatory, as it allows you to obtain a uniform mixture.

Worm gear

It serves for separate rotation of disk cutters. The gearbox itself is connected using couplings to the provided electric motors. To cut rubber at a sufficient speed, you will need to select the correct gear ratio - from 25 to 35.

Making crumbs using a built grinder

When the DIY rubber shredder was ready, I couldn’t wait to use it. I found a few more old tires in the cellar and got to work. The whole procedure was a step-by-step algorithm, which I describe below:

- Visual inspection and removal of interfering parts for recycling (garbage, pieces of dirt, glass and other sources of damage). I advise you to focus your attention on this, since the presence of a foreign body can negatively affect the operation of the constructed unit.

- Cord cutting. This manipulation is also mandatory, since there is metal wire inside it, which cannot be processed in a crushing apparatus. Due to the presence of such reinforcement, the crushing machine may jam.

- Preparation of belts from tires up to 80 mm wide and their further shredding using a shredder installed in the machine.

- Separation. The process of separating the remaining metal parts directly from the rubber takes place.

- Calibration. At this stage, the finished crumbs are changed into fractions using a built-in vibrating sieve.

At this stage, the option of professional grinding into rubber crumb can be considered complete. I would like to note that after the first processing, it seemed to me that the crumbs turned out to be quite large, so I decided to pass them through the crusher again. The second result impressed me. The result was a raw material of uniform consistency.

Recycling

Recycling is also economically beneficial. From car tires you can obtain various types of valuable recyclable materials, as well as produce a huge amount of finished products. From waste rubber powder of a very fine fraction (about 0.2 mm) new car tires and rubber shoes are produced ; this secondary resource is popular in Russia and the CIS countries.

Powder from waste of larger fractions is used in the production of composite roofing materials, rubber-bitumen mastic, waterproofing materials, and rubber coatings. Scrap metal is obtained from metal cord, which is also used by Russian entrepreneurs. Also, textiles and rubber are obtained from tires.

Recycling at home

Particularly active and advanced people have the opportunity to recycle rubber with their own hands. What is needed for this? Used tubes, tires, tires and a little ingenuity. Recycling tires into crumbs at home is quite a complex undertaking. In terms of their properties, tubes from old tires are more suitable. They are softer and more easily susceptible to external influences.

Let me sum it up

Do-it-yourself rubber crumbs can be made at home in two ways. Small volumes can be obtained quite simply, but if you need a lot of crumbs, then additional equipment will be required. Accordingly, the first question that needs to be decided is what volume of output raw materials is required.

Write in the comments whether you used one of the methods given or are you still inclined to buy crumbs from an industrial manufacturer?

Source