Making a matrix is a critical stage of the production process and is the most difficult and responsible work, since the quality of the future product depends on its quality.

Application of decorative coating (gelcoat)

Glass mat gluing process

Glass mat processing process

Checking the quality of connection of components.

Application of decorative coating (gelcoat)

Removing unnecessary components and protruding elements

Matrix of the future product

Matrix of the future product

Matrix of the future product

Fireplace Matrix

Bicycle helmet matrix

Matrix of the future product

If the matrix is made poorly, flaws will certainly appear in the product, which will ultimately lead to financial costs, delays in the production cycle, and defects in the final product.

By entrusting the production of the matrix (prototype) to us, you can be sure that you will receive a high-quality matrix within the agreed time frame.

Our company has experienced specialists and all the necessary equipment for the manufacture of matrices.

The matrix is made of carbon fiber or fiberglass

Fiberglass can be a material not only for this or that product as the final product of production, but also for special technological equipment when molding these very products.

If we are talking about small-scale production, then it is more economical to use fiberglass than, for example, metal. In addition, for a professional specialist it is quite simple and quick to lay out a mold from glass composite, which reduces production time and the cost of the resulting product.

The traditional method involves making a master model (prototype, punch, blank) of the future product. Then the matrix itself is built up layer by layer, the inner surface of which is a reflection of the surface of the master model.

Manufacturing a matrix from fiberglass - an ideal ratio of quality and price

The use of fiberglass in industry is the priority choice of many modern organizations. To produce parts from this modern synthetic material, fiberglass matrices are often used. Their forms are used everywhere: in casting, cold pressing, contact forming, spraying and injection.

The process of manufacturing such a matrix lays down the future properties of fiberglass. Therefore, work on its creation should be approached with special attention. In case of errors or shortcomings at the matrix manufacturing stage, further efforts will be a waste of time.

- own production and high-precision equipment

- a wide range of products made using cast marble technology

- high-precision master models, as well as matrices from master models for subsequent production of products

- wide choice of colors, possibility of fashionable design of products in onyx, marble, natural stone

- minimum time for completing all necessary work: the full cycle takes only 30 working days

- prompt delivery of products to the customer

- flexible pricing policy and system of discounts for regular customers

Doodle matrix:

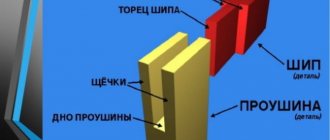

To make any matrix, you need a blockhead for it. This is a prototype of the future product, exactly repeating its shape. At the same time, the quality of the blockhead must be very high. Errors in size, shape, as well as unevenness and surface roughness are unacceptable.

The blank matrix is made either from the same material as the final product, but most often it is created from any rough material. For example, to make matrix blocks they often use:

- Tree;

- Gypsum;

- Metal;

- MDF;

- Expanded polystyrene.

After finishing, the blanks for the matrix must be puttied, painted and coated with special varnishes. This is necessary to create a perfectly smooth, non-porous surface, which will ensure a glossy surface of the product and eliminate the “boiling” effect.

To create complex dummies, CNC (computer numerical control) milling machines are used, which allow you to create exact copies with minimal dimensional errors, while working with various materials.

We make tools for pellets

What we need:

- A lathe or a ready-made blank for our matrix;

- Blank for matrix made of steel 45;

- Drilling machine;

- Drill with a diameter for a die;

On a lathe we process a blank with the inner and outer diameter we need. Set the thickness of the workpiece.

Next, we draw our blank with holes on the computer and print it on a printer at a scale of 1:1.

After that, we glue the drawing onto our workpiece, mark the holes and drill.

After the drilling operation, the dies must be countersunk so that the holes do not become clogged.

A few words about liquid crystal displays

LCD (Liquid Crystal Display) is a display made from liquid crystals that change their location when voltage is applied to them. If you come close to such a display and look closely at it, you will notice that it consists of small dots - pixels (liquid crystals). In turn, each pixel consists of red, blue and green subpixels. When voltage is applied, the subpixels are arranged in a certain order and transmit light through them, thus forming a pixel of a certain color. Many such pixels form an image on the screen of a monitor or other device.

Why do each type of wood require different equipment parameters?

Each type of wood has its own density, and in order to achieve high-quality pressing, you need to select your own tool for each type of raw material. Let's look at the example of pine to see how to select a tool.

Pine has a low density, so compared to other denser species such as birch or larch, the length of the die will not be long. For example, you can focus on 5 cm. This is a practical value, that is, it has already been selected.

Choosing a monitor in 2022 – which matrix is better TN, VA or IPS

A reward was awarded for the post

This material was written by a site visitor and was compensated for.

Buying a good monitor is very easy. You need to choose a more expensive model and pay several thousand dollars for it. But what to do if you don’t have that kind of money or you’re not ready to part with it. In this case, it is worth understanding the technologies that are currently on the market. So, monitors are represented by the following types of matrices: TN, VA and IPS. It is on their basis that the displays of laptops, smartphones and other gadgets are made. There are others, but they are not yet represented by several models for geeks.

The problem of choosing a monitor is especially relevant during the New Year holidays. Grandfather Frost strives to give the good boys some useful thing, and it is up to you whether the old man will make the right choice, or whether you will remember his rash step for a long time, wiping away your tears after an hour of sitting at the monitor. Let's get started. It's 2022. Which monitor to choose: expensive IPS, cheap TN or balanced VA. Let's go through the main characteristics.

announcements and advertising

RTX 3070 Ti Aorus at a non-Ti price

RTX 3080 for 288 tr in Citylink

RTX 3090 MSI for 539 TR

Earn money by participating in the content of our site

Another 3080 is even cheaper - see the price

Cool 3060 Ti Gigabyte Aorus fell in price 2 times

Viewing angles. The TN has terrible viewing angles with significant color and contrast shifts in both the horizontal and vertical directions. IPS have almost ideal viewing angles, which is why most professional monitors belong to this class. With VA, everything is not so simple: the most important thing here is to choose the right model. There are monitors on the market that are almost as good as IPS in this characteristic, and there are also those that are little better than their counterparts with a TN matrix.

Brightness and contrast. The good news is that there is almost no difference in brightness between the matrices. Unless, of course, your manufacturer decided to save on this characteristic. But the contrast ratio of TN is rather poor. Let's take a look at the table, everything is clearly indicated there.

Color quality. Everything is simple here, most TN monitors are 6-bit, which means you shouldn’t expect high-quality images from them. VA start from 8 bits, but some reach the coveted 10. As for IPS, they please with excellent performance and show the best picture.

Color spectrum. There are almost no differences between VA and IPS in this indicator. Both technologies offer up to 125% sRGB coverage and can perform well in DCI-P3. But we are talking about expensive high-quality monitors, because IPS has several trump cards in its pocket, thanks to which professionals can get 100% DCI-P3 and Adobe RGB coverage. TN trails behind, barely reaching 100% sRGB.

Prices. All this time you could see that TN matrices are simply disgusting. But when it comes to price, no technology can match cheap TN monitors. Moreover, only this technology allows the production of 240-Hz displays. VA reaches up to 200 Hz, IPS up to 165 Hz. Interestingly, expensive professional IPS monitors have a refresh rate of up to 90 Hz.

Response time. For a long time, this characteristic distinguished monitors built on a TN matrix. However, recently manufacturers have learned to make VA and IPS displays with very low response times, which allows you to feel comfortable both in single-player games and in high-speed multiplayer shooters.

We've got the basics figured out. Some experts suggest that TN should be considered the weakest technology. VA is the golden mean, and IPS is the matrix for aesthetes who prefer natural color rendition. Accordingly, according to these ideas, TN is for the cheapest monitors, VA is a compromise, and IPS is for those who have extra money. This is not to say that there is no sound grain in this statement, however, it is not so simple. Many of those who have never seen a 244-Hz matrix in operation say that it does not provide any visible advantages. Just like there is no difference between four milliseconds and 8 milliseconds. Supposedly the human eye does not see the differences. Let's take a look at a short video.

Have you already decided to run to the store for such a 240 Hz monitor? Wait, that's not all. There is such a useful thing as adaptive image synchronization technology. It currently comes in two variants: G-Sync and FreeSync. This is an extremely useful technology that allows you to create a “whole” picture, without unpleasant gaps and artifacts. Nvidia adherents unanimously declare that the most advanced and correct is, of course, G-Sync. However, recently FreeSync is not only gaining momentum, but can also become a unified standard, because Nvidia itself has opened support for red technology for its cards. See below how it works.

If you're impressed, there's one more thing to keep in mind: Each person's perception of color is different. Men are noticeably worse than women. At the same time, a very small number of people see the coveted 100% sRGB. This is where the two most important questions arise: price and purpose. If a user has the opportunity to pay for an expensive monitor with IPS technology, then he has every right to later tell how justified his purchase is, and also that he doesn’t need 240 Hz. A professional selects a monitor based on his needs, but a gamer must think carefully about whether to buy an inexpensive monitor in 2022, devoid of the technological bells and whistles of the last five years, or to get the maximum possible.

PS There is also an OLED matrix, which compares favorably with all competitors. But the prices for such monitors begin where the prices for the most advanced IPS analogues end. As many experts say on this matter: the main thing is to choose and bring the monitor home. It may look better or worse against the background of dozens of other models, but at home you will have nothing to compare with. The color scheme will quickly become familiar to you, and brightness, contrast (if they are at a good level) and dozens of other characteristics will immediately become familiar to you.

The post was rewarded.

This material was written by a site visitor and was rewarded.

My services

All information in this article is taken from my new book. You can get it by contacting SUPPORT.

In addition, there is the possibility of financing your pellet and biomass projects from abroad. You can find out about the selection of equipment and consultations, ordering a matrix and other components by contacting “SUPPORT”.

More and more people are turning to me for advice, for selection of equipment, and so far I have not refused anyone. I find both used and new cheap equipment, in addition, the operating technology of your future equipment will be at the highest level!