ASSORTMENT

2.1. Galvanized steel is manufactured with a width from 710 to 1800 mm inclusive, and a thickness from 0.5 to 2.5 mm inclusive.

2.2. Dimensions, maximum deviations and other requirements for the assortment must comply with the requirements of GOST 19904-90.

Galvanized steel of the highest quality category is produced:

with a crescent shape of rolled steel no more than 6 mm per 3 m length;

with flatness PV and PU and permissible thickness deviations according to the standards of increased rolling accuracy;

with telescopicity of rolls with a steel width of up to 1000 mm, no more than 30 mm.

Examples of symbols

Galvanized steel 0.8 thick, 1000 wide, 2000 mm long, normal rolling accuracy B, normal flatness PN, snow-edged edge NO group OH, with crystallization pattern KR, first class zinc coating according to GOST 14918-80:

Galvanized steel coils 1.2 thick, 1000 mm wide, increased rolling accuracy A, with cut edge O, grade 08kp, very deep drawing VG, without MT crystallization pattern, with reduced thickness variation UR, second class coating according to GOST 14918-80:

Galvanized rolled steel with a differentiated coating 0.5 thick, 710 mm wide, increased rolling accuracy A, with a cut edge O, grade BSt3kp, for PC painting, without a crystallization pattern MT with a reduced thickness difference UR, with a first-class coating on one side and a second-class coating on the other GOST 14918-80:

Note

. The steel category XSh is not indicated in the order, and the drawing ability index (N, G or VG) is indicated in the designation.

Chapter. 2. (Changed edition, Amendment No. 2).

CLASSIFICATION

1. CLASSIFICATION

1.1. Galvanized thin sheet steel (GTS) is divided into:

by appointment to groups

for cold stamping - KhSh, for cold profiling - KhP, for painting (trained) - PK, for general purpose - OH;

by drawing ability (steel group XSh) into category

normal drawing - N, deep drawing - G, very deep drawing - VG;

by uniformity of zinc coating thickness

with normal thickness variation - HP, with reduced thickness variation - UR. (Changed edition, Amendment No. 1).

1.2. By agreement between the consumer and the manufacturer, galvanized steel can be produced: with a crystallization pattern - KR, without a crystallization pattern - MT.

1.3. Depending on the thickness of the coating, galvanized steel is divided into three classes in accordance with those indicated in Table 1.

Table 1

| Thickness class | Weight of 1 m of coating layer applied on both sides, g | Coating thickness, microns |

| P (increased) | up to 855 incl. | Over 40 to 60 inclusive. |

| 1 | » 258 » 570 » | » 18 » 40 » |

| 2 | 142,5 » 258 » | » 18 » |

When producing steel with a differentiated coating, its thickness on one side of the sheet must correspond to class 2, and on the other side to class P (for sheets) or class 1. (Changed edition, Amendment No. 2).

TECHNICAL REQUIREMENTS

3.1. Galvanized steel must be manufactured in accordance with the requirements of this standard technical documentation approved in the prescribed manner.

3.2. Galvanized steel is made from carbon cold-rolled coiled steel with a surface quality in accordance with GOST 16523-97. Steel grades must correspond to those given in table. 1a.

Table 1a

| Cink Steel | Cold rolled steel grade for making galvanized steel | ||

| Group | Hood category | first quality category | highest quality category |

| XSh | N, G | Steel grades with chemical composition according to GOST 380-94, GOST 9045-93 and GOST 1050-88 | Steel grades with a chemical composition in accordance with GOST 9045-93, as well as GOST 1050-88 with a sulfur content of no more than 0.035% and phosphorus - no more than 0.020% and GOST 380-94 with a mass fraction of sulfur no more than 0.035% and phosphorus - no more than 0.025 % |

| XSh | VG | 08ps, 08kp, 08Yu according to GOST 9045-93 | 08ps, 08kp, 08Yu according to GOST 9045-93 |

| 08ps, 08kp, 10 cl according to GOST 1050-88 | 08ps, 08kp, 10kp according to GOST 1050-88 with a mass fraction of sulfur no more than 0.030% and phosphorus no more than 0.020% | ||

| HP, PC | — | 08ps according to GOST 9045-93 | 08ps according to GOST 9045-93 |

| 08, 08ps according to GOST 1050-88 | 08, 08pa according to GOST 1050-88 | ||

| BSt0, BSt1, BSt2, BStZ of all degrees of deoxidation according to GOST 380-94 | BSt0, BSt1, BSt2, BSt3 of all degrees of deoxidation according to GOST 380-94 with a mass fraction of sulfur no more than 0.04% and phosphorus no more than 0.035% | ||

| HE | — | Steel grades with chemical composition according to GOST 380-94, GOST 9045-93 and GOST 1050-88 | Steel grades with a chemical composition in accordance with GOST 9045-93, GOST 1050-88, GOST 380-94 with a mass fraction of sulfur no more than 0.045% and phosphorus no more than 0.040% |

(Changed edition, Amendment No. 2).

3.3. For galvanizing, zinc of grades Ts0 and Ts1 according to GOST 3640-94 is used with the addition of aluminum, lead and other metals to the bath. Alloying with lead is allowed by introducing zinc of grade Ts2.

3.4. The surface of galvanized steel must be clean and completely coated.

3.4.1. Violations of the continuity of the coating in the form of cracking on small beads located on defects in the steel base, the classification and dimensions of which are provided for by GOST 16523-97, are not allowed.

3.4.2. On sheets and strips with unedged edges, edge flaws with a depth exceeding the maximum deviations in width are not allowed.

3.4 — 3.4.2. (Changed edition, Amendment No. 2)

.

3.5. For galvanized steel of groups ХШ, ХП and ОН, small sagging (sagging, layering), grains and uneven crystallization of zinc, traces from bends of the strip and control rollers, local roughness of the coating (rash), light scratches and abrasions that do not violate the continuity of the zinc coating, light and matte spots are allowed , uneven coloring of the passive film.

3.6. For galvanized steel of the PC group, dark dots and tracks (traces) from deformed small beads (sagging, layering), grains and local roughness of the coating (rash), a matte and blurred pattern of zinc crystallization, traces from strip bends, light scratches and abrasions that do not violate the continuity of the zinc are allowed. coatings, light matte spots, uneven coloring of the passive film.

3.7. At the request of the consumer, the passive film must have a uniform color.

(Changed edition, Amendment No. 2).

3.8. The reduced thickness difference of the UR zinc coating should be no more than 16 for class P, no more than 10 for class 1, no more than 4 microns for class 2. Galvanized steel of normal thickness HP must have a coating thickness within the limits specified in the table. 1.

Galvanized steel of the highest quality category is manufactured with different thicknesses of the zinc coating for steel groups XSh, HP and PC of class P - no more than 12, class 1 - no more than 8 and class 2 - no more than 3 microns.

(Changed edition, Amendment No. 1,2).

3.9. In the place of bending of galvanized steel with a thickness of up to 1.0 mm inclusive, when testing the adhesion strength of the coating to the base metal when bending 180°, there should be no peeling of the zinc coating exposing the steel surface. A network of small cracks along the entire length of the bend and peeling of the coating at a distance of up to 6 mm from the edges of the sample are allowed.

3.10. The mechanical properties of galvanized steel must comply with the standards specified in Table 1b.

Table 1b

| Cink Steel | Temporary tensile strength sВ, MPa | Yield strength sT, MPa, not less | Relative elongation d4, %, not less, at l 0 = 80 mm for steel thickness, mm | ||||

| groups | hood categories | up to 0.7 | St. 0.7 to 1.5 | St. 1.5 to 2.0 | St. 2.0 | ||

| N | 300-490 | — | 21 | 22 | 23 | 24 | |

| XSh | G | 275-430 | — | 23 | 24 | 25 | 26 |

| VG | 255-410 | — | 26 | 28 | 29 | 30 | |

| HP, PC | — | — | 230 | 20 | 22 | — | — |

| HE | — | — | — | — | — | — | — |

Note

. The values of temporary tensile strength and relative elongation for galvanized steel of group XIII of drawing categories N and G, relative elongation for steel of groups KhP and PK were optional until 07/01/89.

When calculating the tensile strength and yield strength, the thickness of the zinc coating is not taken into account.

3.10.1. The depth of the spherical hole of galvanized steel of group XSh must comply with the standards given in table. 1st century

Table 1c

| Thickness of galvanized steel | Depth of spherical hole for hood categories, not less | ||

| VG | G | N | |

| 0,5 | 8,5 | 8,0 | 6,9 |

| 0,6 | 8,9 | 8,5 | 7,2 |

| 0,7 | 9,2 | 8,9 | 7,5 |

| 0,8 | 9,5 | 9,3 | 7,8 |

| 0,9 | 9,9 | 9,6 | 8,2 |

| 1,0 | 10,1 | 9,9 | 8,6 |

| 1,1 | 10,3 | 10,1 | 8,7 |

| 1,2 | 10,5 | 10,3 | 8,8 |

| 1,3 | 10,7 | 10,5 | 8,9 |

| 1,4 | 10,8 | 10,6 | 9,0 |

| 1,5 | 11,0 | 10,8 | 9,1 |

| 1,6 | 11,3 | 11,0 | 9,5 |

| 1,7 | 11,4 | 11,1 | 9,6 |

| 1,8 | 11,5 | 11,2 | 9,7 |

| 1,9 | 11,6 | 11,3 | 9,8 |

| 2,0 | 11,7 | 11,4 | 9,9 |

Notes:

1. For galvanized steel of intermediate thicknesses, the depth of the spherical hole must correspond to the standards established for the next smaller thickness.

2. The depth of the spherical hole for galvanized steel with a thickness of over 1.5 mm was optional until 07/01/89.

3. When tested on devices such as MTL-10 g, the norms for the depth of the spherical hole are reduced by 0.3 mm.

3.10.2. For galvanized steel of group XIII of the highest quality category, the relative elongation should be 1 unit. more than the norms of the table 1b, and the depth of the spherical hole is 0.2 mm greater than the norms in the table. 1st century

3.10 — 3.10.2. (Amended edition, Rev. No. 2).

3.11. Galvanized steel of the XSh group is manufactured with a ferrite grain size of points 7, 8,9, 10 according to GOST 5639-82 for exhaust category VG and not lower than point 6 for exhaust category G.

For galvanized steel of category VG, grain unevenness is allowed within two adjacent numbers, for sheets of category G - within three adjacent numbers.

3.12. For galvanized steel of group XIII, category hood VG, the presence of structurally free cementite is allowed within points 0, 1, 2 and 4 of scale 1 according to GOST 5640-68. For categories G and N, the presence of structurally free cementite is not standardized.

3.13. The number of bends without fracture of galvanized steel of the HP, PK, OH groups must comply with the standards established in table. 1 year

Table 1d

| Thickness of galvanized steel, mm | Number of bends |

| Up to 0.8 incl. | 8 |

| St. 0.8 "1.2" | 5 |

| » 1,2 » 2,0 » | 3 |

| » 2,0 | 2 |

Note

. The norms for bending galvanized steel with a thickness of more than 1.5 mm were optional until 07/01/89.

(Changed edition, Amendment No. 2).

3.14. (Deleted, Amendment No. 2).

Technical specifications - GOST 14918-80 - galvanized steel from continuous lines

GALVANIZED THIN SHEET STEEL WITH CONTINUOUS LINES

TECHNICAL CONDITIONS GOST 14918-80

STATE COMMITTEE ON STANDARDS Moscow DEVELOPED by the Ministry of Ferrous Metallurgy of the USSR EXECUTORS: V. I. Dovgopol, B. N. Papulov, V. M. Kukushkin, A. A. Tarasova INTRODUCED by the Ministry of Ferrous Metallurgy of the USSR Member of the Board V. V. Lemnitsky APPROVED AND INTRODUCED INTO EFFECT by Resolution of the USSR State Committee on Standards of March 31, 1980 No. 1465

STATE STANDARD OF THE USSR UNION

| THIN SHEET GALVANIZED STEEL WITH CONTINUOUS LINES Technical specifications Continuously galvanized sheet steel. Technical conditions. | GOST 14918-80 Instead of GOST 14918-69 |

By Decree of the USSR State Committee for Standards dated March 31, 1980 No. 1465, the validity period was set from 01.07. 1981 to 01.07. 1986

Failure to comply with the standard is punishable by law

This standard applies to sheet and coil cold-rolled steel, hot-dip galvanized in continuous galvanizing units, intended for cold profiling, for painting, production of stamped parts, utensils, containers and other metal products. The technical level indicators established by this standard meet the requirements of the highest and first quality categories. (Changed edition. Amendment No. 2).

1. CLASSIFICATION

1.1. Galvanized thin sheet steel (GTS) is divided into:

- by purpose into groups: for cold stamping-XSh,

- for cold profiling-XP,

- for painting (trained) - PC,

- general purpose-ON;

- normal hood-N,

- with normal thickness variation - NR,

(Changed edition. Amendment No. 2). 1.2. By agreement between the consumer and the manufacturer, galvanized steel can be produced:

- with crystallization pattern-KR,

- without crystallization pattern-MT.

1.3. Depending on the thickness of the coating, galvanized steel is divided into 3 classes in accordance with those indicated in the table. 1. Table 1

| Thickness class | Weight of 1 m2 of coating layer applied on both sides, g | Coating thickness, microns |

| P (increased) | St. 570 to 855 incl. | Over 40 to 60 inclusive. |

| 1 | St. 258 to 570 incl. | From 18 to 40 incl. |

| 2 | From 142.5 to 258 inclusive. | From 10 a.m. to 6 p.m. inclusive. |

When producing steel with a differentiated coating, its thickness on one side of the sheet must correspond to class 2, and on the other side - class P (for sheets) or class 1. (Changed edition. Amendment No. 2).

2. ASSORTMENT

2.1. Galvanized steel is manufactured with a width from 710 to 1800 mm inclusive, and a thickness from 0.5 to 2.5 mm inclusive. (Changed edition. Amendment No. 2). 2.2. Dimensions, maximum deviations and other requirements for the assortment must comply with the requirements of GOST 19904-74. Galvanized steel of the highest quality category is produced:

- with crescent shape of rolled steel no more than 6 mm per 3 m length;

- with flatness of PV and PU and permissible thickness deviations according to standards of increased rolling accuracy;

- with telescopic rolls with a steel width of up to 1000 mm no more than 30 mm.

(Changed edition. Amendment No. 2). Examples of symbols: Galvanized steel with a thickness of 0.8, a width of 1000, a length of 2000 mm, normal rolling accuracy B, normal flatness PN, with an uncut edge NO group OH, with a crystallization pattern KR, first class zinc coating according to GOST 14918-80: Galvanized rolled steel 1.2 thick, 1000 mm wide, increased rolling accuracy A, with a cut edge O, grade 08kp, very deep drawing VG, without MT crystallization pattern, with reduced thickness variation UR, second class coating according to GOST 14918-80: (Modified edition. Change No. 2). Galvanized rolled steel with a differentiated coating 0.5 thick, 710 mm wide, increased rolling accuracy A, with a cut edge O, grade BSt3kp, for PC painting, without a crystallization pattern MT with a reduced thickness difference UR, with a coating on one side of the first, and on the other another second class according to GOST 14918-80: (Changed edition. Amendment No. 2). Note. The steel category XIII is not indicated in the order, and the drawing ability index (N, G or VG) is indicated in the symbols.

3. TECHNICAL REQUIREMENTS

3.1. Galvanized steel must be manufactured in accordance with the requirements of this standard according to technical documentation approved in the prescribed manner. 3.2. Galvanized steel is made from carbon cold-rolled coiled steel with a surface quality in accordance with GOST 16523-70. Steel grades must correspond to those given in table. 1a. Table 1a

| Cink Steel | Cold rolled steel grade for making galvanized steel | ||

| Group | Hood category | first quality category | highest quality category |

| XSh | NG | Steel grades with chemical composition according to GOST 9045-80, GOST 1050-74 and GOST 380-71 | Steel grades with a chemical composition in accordance with GOST 9045-80, as well as GOST 1050-74 with a sulfur content of no more than 0.035% and phosphorus - no more than 0.020% and GOST 380-71 with a mass fraction of sulfur no more than 0.035% and phosphorus - no more than 0.025 %. |

| XSh | VG | 08ps, 08kp, 08Yu according to GOST 9045-80 08ps, 08kp, 10kp according to GOST 1050-74 | 08ps, 08kp, 08Yu in accordance with GOST 9045-80 08ps, 08kp, 10KP in accordance with GOST 1050-74 with a mass fraction of sulfur no more than 0.030% and phosphorus no more than 0.020% |

| HP, PC | — | 08ps according to GOST 9045-80 08, 08ps according to GOST 1050-74 BSt0, BSt1, BSt2, BSt3 of all degrees of deoxidation according to GOST 380-71 | 08ps according to GOST 9045-80 08, 08ps according to GOST 1050-74 BSt0, BSt1, BSt2, BSt3 of all degrees of deoxidation according to GOST 380-71 with a mass fraction of sulfur no more than 0.04% and phosphorus no more than 0.035% |

| HE | — | Steel grades with chemical composition according to GOST 9045-80, GOST 1050-74, GOST 380-71 | Steel grades with a chemical composition in accordance with GOST 9045-80, GOST 1050-74, GOST 380-71 with a mass fraction of sulfur no more than 0.045% and phosphorus no more than 0.040% |

(Changed edition. Amendment No. 2). 3.3. For galvanizing, zinc grades Ts0 and Ts1 are used according to GOST 3640-79 with the addition of aluminum, lead and other metals to the bath. Alloying with lead through the introduction of zinc grade Ts2 is allowed. (Changed edition. Amendment No. 2). 3.4. The surface of galvanized steel must be clean and completely coated. (Changed edition. Amendment No. 2). 3.4.1. Violations of the continuity of the coating in the form of cracking on small sagging on defects in the steel base, the classification and dimensions of which are provided for by GOST 16523-70, are not allowed. (Changed edition. Amendment No. 2). 3.4.2. On sheets and strips with unedged edges, edge flaws with a depth exceeding the maximum deviations in width are not allowed. (Changed edition. Amendment No. 2). 3.5. For galvanized steel of groups XSh, HP and OH, small sagging (sagging, layering), grains and uneven crystallization of zinc, traces from bends of the strip and control rollers, local roughness of the coating (rash), light scratches and abrasions that do not violate the continuity of the zinc coating are allowed. light and dull spots, uneven coloring of the passive film. 3.6. For galvanized steel of the PC group, dark dots and tracks (traces) from deformed small deposits (sagging, layering), grains and local roughness of the coating (rash), a matte and blurred zinc crystallization pattern, traces from strip bends, light scratches and abrasions, not violating the continuity of the zinc coating, light and dull spots, uneven coloring of the passive film. 3.7. At the consumer's request, the passive film must have a uniform color. (Changed edition. Amendment No. 2). 3.8. The reduced thickness difference of the UR zinc coating should be no more than 16 for class P, no more than 10 for class 1, no more than 4 microns for class 2. Galvanized steel of normal thickness NR must have a coating thickness within the limits specified in table. 1. (Changed edition. Amendment No. 1). Galvanized steel of the highest quality category is produced with varying thicknesses of the zinc coating for steel groups XIII, HP and PC of class P - no more than 12, class 1 - no more than 8 and class 2 - no more than 3 microns. (Changed edition. Amendment No. 2). 3.9. At the point of bending of galvanized steel up to 1.0 mm thick inclusive, when testing the adhesion strength of the coating to the base metal when bending 180°, there should be no peeling of the zinc coating exposing the steel surface. A network of small cracks along the entire length of the bend and peeling of the coating at a distance of up to 6 mm from the edges of the sample are allowed. 3.10. The mechanical properties of galvanized steel must comply with the standards specified in table. 1b. Table 1b

| Cink Steel | Tensile strength, MPa | Yield strength, MPa, not less | Relative elongation, % not less, at L0=80 mm for steel thickness, mm | ||||

| groups | hood categories | up to 0.7 | St. 0.7 to 1.5 | St. 1.5 to 2.0 | St. 2.0 | ||

| XSh | N | 300-490 | — | 21 | 22 | 23 | 24 |

| G | 275-430 | — | 23 | 24 | 25 | 26 | |

| VG | 255-410 | — | 26 | 28 | 29 | 30 | |

| HP, PC | — | — | 230 | 20 | 22 | — | — |

| HE | — | — | — | — | — | — | — |

Note. The values of temporary tensile strength and relative elongation for galvanized steel of group XSh of drawing categories N and G, relative elongation for steel of groups KhP and PK are optional until 07/01/89. When calculating the tensile strength and yield strength, the thickness of the zinc coating is not taken into account. (Changed edition. Amendment No. 2). 3.10.1. The depth of the spherical hole of galvanized steel of group XSh must comply with the standards given in table. 1st century Table 1c

| Thickness of galvanized steel | Depth of spherical hole for hood categories, not less | ||

| VG | G | N | |

| 0,5 | 8,5 | 8,0 | 6,9 |

| 0,6 | 8,9 | 8,5 | 7,2 |

| 0,7 | 9,2 | 8,9 | 7,5 |

| 0,8 | 9,5 | 9,3 | 7,8 |

| 0,9 | 9,9 | 9,6 | 8,2 |

| 1,0 | 10,1 | 9,9 | 8,6 |

| 1,1 | 10,3 | 10,1 | 8,7 |

| 1,2 | 10,5 | 10,3 | 8,8 |

| 1,3 | 10,7 | 10,5 | 8,9 |

| 1,4 | 10,8 | 10,6 | 9,0 |

| 1,5 | 11,0 | 10,8 | 9,1 |

| 1,6 | 11,3 | 11,0 | 9,5 |

| 1,7 | 11,4 | 11,1 | 9,6 |

| 1,8 | 11,5 | 11,2 | 9,7 |

| 1,9 | 11,6 | 11,3 | 9,8 |

| 2,0 | 11,7 | 11,4 | 9,9 |

Notes: 1. For galvanized steel of intermediate thicknesses, the depth of the spherical hole must correspond to the standards established for the next smaller thickness. 2. The depth of the spherical hole for galvanized steel with a thickness of over 1.5 mm is optional until 07/01/89. 3. When tested on devices such as MTL-10 g, the norms for the depth of a spherical hole are reduced by 0.3 mm. (Changed edition. Amendment No. 2). 3.10.2. For galvanized steel of group XIII of the highest quality category, the relative elongation should be 1 unit. more than the norms of the table 1b, and the depth of the spherical hole is 0.2 mm more than the norms in the table. 1st century (Changed edition. Amendment No. 2). 3.11. Galvanized steel of the XSh group is manufactured with a ferrite grain size of points 7, 8, 9, 10 according to GOST 5639-82 for exhaust categories VG and not lower than point 6 for exhaust categories G. (Changed edition. Amendment No. 2). For galvanized steel of category VG, grain unevenness is allowed within two adjacent numbers, for sheets of category G - within three adjacent numbers. 3.12. For galvanized steel of group XIII, drawing category VG, the presence of structurally free cementite is allowed within points 0, 1, 2 and 3 of scale 1 according to GOST 5640-68. For hood categories G and N, the presence of structurally free cementite is not standardized. 3.13. The number of bends without fracture of galvanized steel of the KhP, PK, OH groups must comply with the standards established in table. 1 year Table 1d

| Thickness of galvanized steel, mm | Number of bends |

| Up to 0.8 incl. | 8 |

| St. 0.8 to 1.2 incl. | 5 |

| St. 1.2 to 2.0 inclusive | 3 |

| St. 2.0 | 2 |

Note. The norms for bending galvanized steel with a thickness of more than 1.5 mm are optional until 07/01/89. (Changed edition. Amendment No. 2). 3.14. Canceled. Change No. 2.

4. ACCEPTANCE RULES

4.1. Galvanized steel is accepted in batches. The batch must consist of sheets or rolls of one group of galvanized steel, one size, one type and class of coating thickness, type of preservation, one grade and melt (steel of groups XSh, XP and PK) and drawing category (steel of group XSh), must be registered and be accompanied by a quality document in accordance with GOST 7566-81 with the addition of values of optional quality indicators. (Changed edition. Amendment No. 2). The batch weight should not exceed the shift production of the unit. 4.2. In the quality document, test results and chemical composition data are indicated at the request of the consumer. For galvanized steel, which has been assigned the state Quality Mark in accordance with the established procedure, the state Quality Mark is affixed to the quality document in accordance with GOST 1.9-67. 4.3. To control the size and quality of the surface, 6% of the sheets or one roll from the batch are selected. 4.4. To control the adhesion strength of the coating and the mechanical properties of the microstructure, one sheet or one roll from the batch is selected. 4.5. If unsatisfactory test results are obtained for at least one of the indicators, a re-check is carried out in accordance with GOST 7566-81. (Changed edition. Amendment No. 2).

5. TEST METHOD

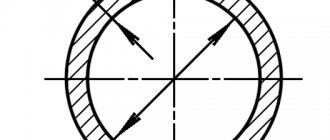

5.1. The quality of the surface of sheets and rolls is checked by external inspection without the use of magnifying devices. 5.2. To carry out tests, samples are cut from each selected sheet or roll in accordance with the requirements of the drawing and table. 2. Scheme of cutting samples for testing (b-sheet width) Table 2

| Sample number | Sample dimensions, mm | Test methods | |

| width | length | ||

| 1, 2 | 50 | 150 | On the adhesion strength of the zinc coating to the base metal |

| 3, 4, 5 | 50 | 50 | To determine the mass of zinc coating and thickness variations |

| 6 | 20 | 150 | To the bend |

| 7 | 90 | — | For drawing out a spherical hole (x-test location) |

| 8 | 30 | 180-300 | Tensile |

| 9, 10 | 30 | 40 | Microstructure assessment |

Note. Samples are cut with maximum size deviations of ±3 mm. 5.3. To determine the mass of the zinc coating, the test sample is degreased, weighed, immersed in a solution of antimony oxide (Sb2O3) or antimony chloride (SbCl3) in hydrochloric acid and kept until the violent gas evolution stops, then the sample is removed from the solution, thoroughly washed with cold and then hot water, dried with filter paper and weighed. Degreasing is carried out with synthetic technical ethyl alcohol (GOST 11547-80). (Changed edition. Amendment No. 2). A solution of antimony oxide or antimony chloride is prepared in the following way: 20 g of antimony oxide (or 32 g of antimony chloride) is dissolved in 1000 ml of concentrated hydrochloric acid (GOST 3118-77) for the second and first classes or 50 g of antimony oxides for class P. (Modified edition. Change No. 1). The mass of zinc coating applied on both sides of the sheet, in grams (t) per 1 m2, is calculated using the formula (1) where m1 is the mass of three samples (3, 4 and 5) before the zinc coating dissolves, with an error of 0.01 g, g ; t2-weight of three samples (3, 4 and 5) after dissolution of the zinc coating, with an error of 0.01 g, g; S is the actual surface area of the samples with an error of 1.10-6 m2, m2. To determine the mass of zinc coating, it is allowed to use other methods that provide the necessary accuracy. The method specified in this standard is used when there is disagreement in assessment. (Changed edition. Amendment No. 2). 5.4. The difference in coating thickness in the transverse direction of the sheet is determined as the absolute difference between the maximum and minimum values of the coating thickness on samples 3, 4 and 5 according to formula (2) for which the thickness of the zinc coating on each of the samples is first calculated using formula (3) where T3 is the coating thickness corresponding sample, µm; t3 is the mass of the sample before removing zinc, g; t3/-weight of the sample after removal of zinc, g; 7.13—zinc density, g/cm3; S3-surface area of the zinc coating, cm2 (Changed edition. Amendment No. 1). 5.4.1. The average thickness and variation in thickness of the zinc coating on the surface of a sheet with a differentiated coating are determined and calculated for each side. To do this, after degreasing the sample, one side is covered with a dense layer of rubber glue or paraffin and zinc is removed from the opposite side, as indicated above. After re-weighing, the glue or paraffin is removed mechanically or in hot water. Removal of the zinc coating on the other side of the sample is carried out in the same way. (Changed edition. Amendment No. 2). 5.5. The bend test is carried out according to GOST 13813-68. 5.6. The spherical dimple drawing test is carried out according to GOST 10510-80. Make two measurements in the test area and determine the arithmetic mean. (Changed edition. Amendment No. 1). 5.7. The tensile test is carried out according to GOST 11701-66. 5.8. Determination of the grain size of ferrite is carried out according to GOST 5639-82 and structurally free cementite - according to GOST 5640-68. (Changed edition. Amendment No. 2). 5.9. Bending testing of galvanized steel up to 1 mm thick at an angle of 180° is carried out according to GOST 14019-80. A sample of galvanized steel is tested on a mandrel equal to the thickness of the rolled product. (Changed edition. Amendment No. 1). Galvanized steel of the highest quality category must withstand 180° bending tests without mandrel until the sides touch. (Changed edition. Amendment No. 2). By agreement between the consumer and the manufacturer, the bending test can be replaced by a double roof lock test in accordance with GOST 13814-68, and for galvanized steel of the PK group by testing on the U-1A device in accordance with GOST 4765-73. Galvanized steel with a thickness of over 1.0 mm is tested at the request of the consumer according to a method agreed upon in the prescribed manner. 5.10. To control the quality of galvanized steel, it is allowed to use non-destructive control methods.

6. LABELING, PACKAGING, TRANSPORTATION AND STORAGE

(Changed edition. Amendment No. 2). 6.1. Labeling, packaging, transportation and storage - in accordance with GOST 7566-81 with additions. (Changed edition. Amendment No. 2). 6.2. To protect the surface of galvanized steel from corrosion, preservation is carried out: passivation, oiling or passivation and oiling. At the request of the consumer, galvanized steel is not preserved. When shipping to the Far North and hard-to-reach areas, conservation is required. (Changed edition. Amendment No. 2). 6.3. Sheets of galvanized steel are formed into a stack, placing one sheet on top of another. For sheets with differentiated coating, the side with the 2nd class of coating thickness should be facing the bottom of the pack. The end and side surfaces of the bundle are covered with channels made of annealed steel sheet with a thickness of at least 0.4 mm in accordance with GOST 17715-72 or other regulatory and technical documentation. Wooden bars in accordance with GOST 8486-66 and GOST 2695-83 with a cross-section of at least 80×80 mm or metal bars in accordance with regulatory and technical documentation must be attached to the bottom of the pack. The number of wooden and metal bars with a pack width of up to 1200 mm is 2 pcs.; over 1200 mm - 3 pcs. and 2 pcs. (Changed edition. Amendment No. 2). 6.4. Rolls of galvanized steel with differentiated coating are rolled so that the side with the 2nd class of zinc coating thickness is located inside the roll. (Changed edition. Amendment No. 2). 6.5. Packs and rolls must be tightly tied. The number of strappings must comply with the requirements of GOST 7566-81. When shipping to the Far North and hard-to-reach areas, the minimum number of strappings must be one more than the norms established by GOST 7566-81. For strapping, a metal tape with a thickness of 1.2-2.0 mm and a width of 30 to 40 mm is used in accordance with GOST 3560-73, GOST 6009-74 or other regulatory and technical documentation. The outer diameter and width of the rolls should not exceed 2 mm, the length, width and height of the bundles, respectively, should be 6.2 and 1 m. (Changed edition. Amendment No. 2). 6.6. The weight of one package must be at least 3 tons and must not exceed 10 tons. Until 01/01/88, at the request of the consumer, the weight of a pack of galvanized steel sheets should not exceed 5 tons. (Changed edition. Amendment No. 2). 6.7. Transport marking of packages must be applied in accordance with GOST 14192-77 with dark paint on the end surface of the pack and the side surface of the roll and contain basic, additional and informational inscriptions. (Changed edition. Amendment No. 2). 6.8. Transportation of galvanized steel by rail is carried out by open rolling stock in accordance with the rules for the transportation of goods in force for transport of this type and the conditions for loading and securing cargo, approved by the Ministry of Railways. (Changed edition. Amendment No. 2). 6.9. Storage of galvanized steel must comply with the conditions of ZhZ in accordance with GOST 15150-69, excluding joint presence with chemically active substances. (Changed edition. Amendment No. 2).

ACCEPTANCE RULES

4.1. Galvanized steel is accepted in batches. The batch must consist of sheets or rolls of the same group of galvanized steel, the same size, one type and class of coating thickness, type of preservation, the same grade and melt (steel of the KhSh, KhP and PK groups) and drawing category (steel of the KhSh group), must be registered and accompanied by a document on quality according to GOST 7566-94 with the addition of values of optional quality indicators.

The batch weight should not exceed the shift production of the unit.

(Changed edition, Amendment No. 2).

4.2. In the quality document, test results and chemical composition data are indicated at the request of the consumer.

For galvanized steel that has been awarded the state Quality Mark, the designation of the state Quality Mark is affixed to the quality document.

4.3. To control the size and quality of the surface, 6% of sheets or one roll from the batch are selected.

4.4. To control the adhesion strength of the coating, mechanical properties, and microstructure, one sheet or one roll from the batch is selected.

4.5. If unsatisfactory test results are obtained for at least one of the indicators, a re-check is carried out in accordance with GOST 7566-94.

TEST METHODS

5.1. The quality of the surface of sheets and rolls is checked by external inspection without the use of magnifying devices.

5.2. To carry out tests, samples are cut from each selected sheet or roll in accordance with the requirements of the drawing and table. 2.

Scheme of cutting samples for testing ( b

- sheet width)

table 2

| Sample number | Sample dimensions, mm | Test method | |

| width | length | ||

| 1,2 | 50 | 150 | On the adhesion strength of the zinc coating to the base metal |

| 3, 4, 5 | 50 | 50 | To determine the mass of zinc coating and thickness variations |

| 6 | 20 | 150 | To the bend |

| 7 | 90 | — | To draw out the spherical hole (x -test location) |

| 8 | 30 | 180-300 | Tensile |

| 9, 10 | 30 | 40 | Microstructure assessment |

Note

. Samples are cut with maximum deviations in size - ± 3 mm.

5.3. To determine the mass of the zinc coating, the test sample is degreased, weighed, immersed in a solution of antimony oxide (Sb2O3) or antimony chloride (SbC13) in hydrochloric acid and kept until rapid gas evolution stops, then the sample is removed from the solution, thoroughly washed with cold and then hot water, dried with filter paper and weighed. Degreasing is carried out with synthetic technical ethyl alcohol.

A solution of antimony oxide or antimony chloride is prepared in the following way: 20 g of antimony oxide (or 32 chloride of antimony) is dissolved in 1000 ml of concentrated hydrochloric acid (GOST 3118-77) for the second and first classes or 50 g of antimony oxides of class P.

Mass of zinc coating applied on both sides of the sheet, in grams ( m

) per 1 m2 is calculated using the formula

| (1) |

where is the mass of three samples (3, 4 and 5) before dissolution of the zinc coating, with an error of 0.01 g, g;

— mass of three samples (3, 4 and 5) after dissolution of the zinc coating, with an error of 0.01 g, g;

S

- actual surface area of the samples with an error of 1·10-6 m2, m2.

To determine the mass of zinc coating, it is allowed to use other methods that provide the necessary accuracy.

The method specified in this standard is used when there is disagreement in assessment.

(Changed edition, Amendment No. 1,2).

5.4. The difference in thickness of the coating in the transverse direction of the sheet is determined as the absolute difference between the maximum and minimum values of the coating thickness on samples 3, 4 and 5 according to the formula

| (2) |

for which purpose, first calculate the thickness of the zinc coating on each of the samples using the formula

| (3) |

where is the coating thickness of the corresponding sample, μm;

— mass of the zinc removal sample, g;

— mass of the sample after zinc removal, g;

7.13 - zinc density, g/cm3;

S

3—surface area of the zinc coating, cm2.

(Changed edition, Amendment No. 1).

5.4.1. The average thickness and variation in thickness of the zinc coating on the surface of a sheet with a differentiated coating are determined and calculated for each side. To do this, after degreasing the sample, one of the sides is covered with a dense layer of rubber glue or paraffin and zinc is removed from the opposite side, as indicated above. After re-weighing, the glue or paraffin is removed mechanically or in hot water. Removal of the zinc coating on the other side of the sample is carried out in the same way.

5.5. The kink test is carried out according to GOST 13813-68.

5.6. The test for stretching a spherical hole is carried out according to GOST 10510-80. Make two measurements in the test area and determine the arithmetic mean.

5.7. The tensile test is carried out according to GOST 11701-84.

5.8. Determination of the grain size of ferrite is carried out according to GOST 5639-82 and structurally free cementite - according to GOST 5640-68.

5.9. Testing on bent galvanized steel with a thickness of up to 1 mm inclusive at an angle of 180° is carried out according to GOST 14019-80. A sample of galvanized steel is tested on a mandrel equal to the thickness of the rolled product.

Galvanized steel of the highest quality category must withstand 180° bending tests without mandrel until the sides touch.

By agreement between the consumer and the manufacturer, the bending test can be replaced by a double roof lock test in accordance with OST 1411-196-86, and for galvanized steel of the PK group, by testing on the U-1A device in accordance with GOST 4765-73.

Galvanized steel with a thickness of over 1.0 mm is tested at the request of the consumer according to a method agreed upon in the prescribed manner.

5.10. To control the quality of galvanized steel, it is allowed to use non-destructive control methods.