The central element of a welder's workplace is the table. What it should be like and how to choose the right one are important issues in organizing a room for welding work. You will find the answers in the article.

- Welding and cleaning

- Siegmund

- Clamps

An integral element of any welding workshop is the table. Without it, doing work will be much more difficult and uncomfortable. It serves as a working platform where metal workpieces are joined, as well as a storage place for a large number of useful items and consumables.

Design

A large selection of welding tables is due to the need for diverse design solutions for specific tasks. But every product has elements that are mandatory and basic:

- tabletop. The working surface is made of durable, non-flammable material. It has many holes and grooves, which are used to secure workpieces during operation;

- frame. A frame to which a tabletop, pull-out shelves and various kinds of organizers are attached;

- adjustable supports. They make it possible to set the tabletop evenly and at the desired height;

- open and closed shelves. The first are used to place electrodes, filler wire and other consumables that should always be at hand. Tools are stored in closed shelves;

- pallet. It is located at the bottom of the table and serves to collect production waste, scale, shavings, etc.;

- brackets. They are located along the contour of the working surface. Hold the welding wire and ground loop;

- suction sleeve. An element of the ventilation system designed to remove exhaust gases and dust.

Tables are the central element of a welder's workspace. They are complemented by other elements for proper organization of space - cabinets, shelves, racks, mobile and stationary tool carts, as well as other equipment.

What does the welding table consist of?

Conventional welding tables have a standard height and simple design, so their cost is low. But they are reliable and quite suitable for the job.

We list the main elements of these products:

- durable steel frame welded from an angle profile;

- six supports with height adjustment;

- a cabinet located on the left with several drawers for various working tools;

- a tool plate on which there are T-shaped slots to secure the parts;

- stands or shelves on the right half of the tabletop for placing large equipment;

- dust collection tray;

- brackets for welding wires installed at different heights (different options may be provided);

- a container for water or a stand for placing it.

It is not difficult to prepare such a table for work. You just need to adjust the height of the legs, check the compliance with the horizontal and vertical directions using a level, carry out grounding, install the ventilation equipment at the desired angle, connect and check the reliability of the inverter.

If you plan to use another type of welding machine, then the workplace must be equipped with a trolley with a mobile fan, having a suction hose of about 2 m, and a magnetic holder for fastening to the frame. The fan must be equipped with an electric cable 4-5 m long. The fan power is adjusted in accordance with the required performance. If the volume of polluted air is 2000 m3/hour, then a unit with a power of no more than 0.8 kW and an inlet diameter of about 150 mm is required.

The design and configuration of welding and assembly tables is much more complex. Their height and other ergonomic characteristics are similar to conventional workbenches, but there are differences. They are additionally equipped with devices for mechanizing certain types of work; it is also possible to install equipment for drilling, milling, grinding, etc.

If necessary, you can equip the table with additional ventilation and air duct systems. The table rotation function eliminates the need for the welder to walk around the workpiece and allows welding seams with high precision. Maximum reliability of the structure is ensured by embedding the supports in the concrete foundation.

Modern models of welding and prefabricating tables usually include a quick-installed vice, a set of clamping clamps, and a rotating stand for the welding machine.

Peculiarities

The most important parameter of the equipment and accessories that a welder uses in his work is safety. This can be fully discussed in relation to such a harmless object as a welder’s table. It would be more accurate to say - to his workplace, the central element of which is the table. Among the mandatory conditions for arranging a workplace, several basic provisions should be highlighted:

- Forced exhaust over the table. Active ventilation is necessary to quickly remove harmful gases and dust accumulations from the room.

- They pumped in air. They are necessary for the ventilation to work as efficiently as possible, and for the specialist to continue working for as long as desired.

- Work area lighting. It is important to ensure optimal lighting levels. To do this, it is best to combine natural and artificial light sources.

- A place should be provided for storing work equipment.

An important condition for desktop materials is their complete environmental friendliness: they should not emit substances harmful to human health when exposed to strong heat. This leads to another mandatory requirement: the materials from which the table is made must be non-flammable.

Safety precautions when working at a welding table

Welding work is a dangerous and harmful to health process, which is accompanied by the following factors:

- high temperature;

- scattering of hot splashes;

- high-intensity ultraviolet radiation;

- danger of electric shock;

- falling of heavy workpieces and parts.

To minimize harmful effects, the following rules are required:

- Metal can be welded only in workshops that have forced-type supply and exhaust ventilation.

- The height of the welding table for sitting or standing work must meet safety requirements; it is also necessary to check the equipment and eliminate mechanical damage, insulation damage, and secure contacts.

- It is necessary to use personal protective equipment: a welder’s mask, a respirator, split-leaf protective gloves with gauntlets, fire-resistant clothing and shoes.

- There should be enough free space around the workbench for easy access to the welding area.

- The use of random supports is prohibited.

- During operation, parts must be secured using fastening devices.

- The storage of flammable materials and liquids and their use are prohibited near the workplace. A special storage facility no closer than 5 m must be equipped for them.

Application area

The table is used in the process of working on individual orders, which are characterized by a unique design, and for mass production. It should provide maximum comfort and at the same time promote work efficiency. It is not suitable for mounting large-sized products, but it is quite comfortable to assemble individual components of a large structure on a table.

An important advantage of the welding table is the ability to use guides with mobile stops. Additionally, they can be fixed with clamps and other clamps. For example, often the position of the workpiece is fixed using a standard ruler provided on the working surface.

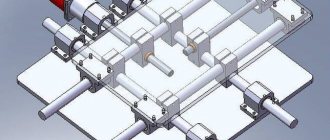

Assembling the upper frame

To assemble the upper frame of the welding table, place the workpiece on a flat surface. The crosspieces are inserted between the long frame blank, so they are made 80 mm smaller (taking into account 2 longitudinal profiles). The net size of the structure will be exactly 1100/660. When using another profile pipe or rolled metal, this factor must be taken into account.

Having laid out in a plane, grab all the corners with 1 tack, measure the diagonal and grab on all sides. After this, measure the diagonal again and check that all the parts are in the same plane. As experts say, “so that there is no propeller.” Only now they are scalding all the joints.

At a distance of the thickness of the plywood from the top, gussets are welded from the inside. They will strengthen the frame and serve as stops for the plywood tabletop.

Type overview

Today there are a large number of different models of welding tables. They can be divided into three groups:

- traditional workbench;

- Rotary table;

- universal tables with a set of additional features.

To understand in more detail the functionality of each group of tables, you need to take a closer look at their structure and features.

Crafting table

The simplest option for a mounting surface made of metal. Both the frame and the tabletop are made of metal, which ensures high structural strength. Additionally, the table is equipped with accessories - clamps, angles, clamps, bench vices and other accessories.

Rotary

The next class of equipment in terms of complexity. It has an electric drive, which provides the ability to position the surface according to the angle of inclination or move it along any axis. Such tables are in demand in the production of complex shaped structures. A slot table is a type of rotary structure designed for assembling, stripping and welding workpieces.

Universal

In addition to the functionality of rotary tables, such tables have additional equipment designed to optimize welding, grinding and other operations. The workplace is designed for intensive use, therefore it is equipped with hoods to remove dust and gases from the room.

Models and systems of assembly and welding tables: SSM-01-03, 1200 x 750 x 800, system 16 and others

Assembly and welding table made of cast iron plates with 28 mm holes. Photo TECHNOVELD

Let’s look at the names of the models using the example of the “VTO” (High-Tech Equipment Plant) equipment line. Assembly and welding tables have the abbreviation SSM . Further variety of digital designations is caused by different dimensions, shapes and conditions of the workpieces being welded:

- 01, 10 – designation of basic options;

- 02-xx, 09-xx - designation of modular tables, where “xx” highlights differences in dimensions and materials for the tabletop (here and in the following text);

- 03-хх – with a rotating work plate;

- 04-хх – with a rotary-extraction device;

- 05-хх – rotary tables;

- 06-хх – mobile;

- 07-хх – universal;

- 08-хх – with hydraulic drive;

- 01-07….01-10 – tables with a coordinate grid;

- 11-хх….15-хх – collapsible;

- 16 – placed on a rail track.

For mounting parts on countertops, there are three fixation systems : D16, D22 and D28(26). They differ in the diameter of the calibrated mounting holes, which are respectively 16 mm, 22 mm and 28(26) mm. The lowest load capacity and thickness of the tabletop sheet is for the D16 system, the highest for the D28(26). The D22 system occupies an intermediate position in these indicators.

Foreign companies, Demmeler and others engaged in the production of assembly and welding tables, have their own unique models with a set of equipment for any of the specified fixation systems.

Types of tables for welders and assemblers

The range of equipment sold is varied: from simple and compact ones, which are suitable for amateurs and home craftsmen, to serious installations with mechanized functionality. Some of the most common types are described below.

Welding and cleaning

The tables are equipped with a fan or a full exhaust system to remove dust and exhaust gases. The tabletop is made from high-strength structural steel that is wear-resistant. It has holes or is made in the form of a lattice.

Universal assembly and welding machines

Before starting welding work, the workpieces are attached to the surface using various devices. If necessary, the tabletop can be dismantled and moved to a position that best suits the task at hand. At the buyer's request, the tables are equipped with additional supports, which make the solution universal.

Transformers

The height, width, and length of the table can vary to suit the dimensions of the structure with which the welder has to work.

Stationary and mobile

There are models of tables that are firmly attached to the base and remain motionless all the time. These are stationary versions. Mobile ones are often equipped with wheels. They are installed on legs and easily rotate around the axis of the fastener. The wheels themselves are made of polyurethane and are equipped with a brake mechanism.

Simple and professional

The first group of welding tables is designed to perform simple operations and simple work on assembling structural components. Professional models are universal in use and have many options for fixing workpieces. They are equipped with an effective exhaust system and allow the installation of additional equipment - grinding, drilling and others.

With ventilation

During welding of metals, a lot of gases - combustion products - are released into the surrounding space. If the welder’s workplace is equipped indoors, then an effective system for removing exhaust gases and dust is needed. Local ventilation is most often used. The suction and removal of combustion products can be performed in the form of autonomous ventilation, or can be connected to a general exhaust hood.

3D

Such models are designed for precise positioning of workpieces in two planes: vertically and horizontally. The devices allow you to weld any parts with a three-dimensional configuration.

Folding, folding, folding

In order to save space indoors, transformable structures are installed. They take up little space and are folded until welding of workpieces or any structure is required.

Nitrided

Characterized by the fact that the surface is nitrided. This gives it special strength and resistance to wear. Scale and molten metal do not stick to the working surface.

Cast iron

Manufacturers offer table models with cast iron surfaces. Cast iron cooks very poorly. Therefore, the advantage of a cast iron surface is that the melt does not stick to it.

Final assembly

For final assembly, turn the frame face down and expose the legs of the welding table. You can use a building level, but a simple plumb line will do. They grab the legs and once again check the correct installation, hammer them to the desired position and weld all the joints. For greater reliability of welding, scarves are welded on the inside. They will serve as stiffeners.

Nickels from the strip are welded to the ends of the legs of the welding table. Then the table is turned over and the lower jumpers are welded at a distance of 150-200 mm from the bottom. Mark the places where the shelves are attached and weld the corners. The skeleton of a simple welding table design is ready. All that remains is to clean all the joints with a grinder and check the seams.

Next, all surfaces of the welding table are degreased with a solvent and the first layer of primer is applied. After drying, install the countertop. Before installation, plywood must be treated with impregnation. The top of the plywood is covered with a sheet of metal with curved edges. They grab the metal in several places to the frame.

After drying, if desired, you can paint the table with heat-resistant paint, or you can do without painting. At the last stage, the shelves are installed.

The entire manufacturing process is reviewed in the video.

Optimal sizes

The size of the working area is one of the key points that is very important for welders and affects the ability to perform certain jobs. It is this indicator that determines the size of the workpieces that the welder can subsequently work with. The dimensions of the table surface vary over a wide range of values: from small (approximately 70x70cm) to large (298x148cm). in height it should not exceed 1.4 meters.

Tables with a small workspace are used for working with small workpieces or assemblies. Tabletops of impressive dimensions provide more opportunities. You can place a corresponding structure or several nodes on them. Here you can leave the most frequently used equipment, which is easier to keep at hand.

Top brands

It is possible to weld metal workpieces without a special table, but it is very convenient. As a result, the specialist’s labor productivity decreases and the quality of the welded joint suffers. Therefore, a working surface is definitely needed. Today the market offers a large selection of such equipment from famous and unknown manufacturers. Of the total number of brands presented, several of the most popular ones should be highlighted.

Siegmund

The company supplies the market with products that fully comply with generally accepted requirements for welding tables. The manufacturer has equipped the working surface with quick-clamping devices, which helps to increase the welder’s productivity.

Forster

A company from Germany specializes in the production of modular options. The countertops are made of ferrite or cast iron and can be easily removed if necessary. This allows you to change the shape of the table in order to adapt it as much as possible to a specific workpiece. The brand supplies rotating, lifting and rotating type products.

Demmeler

The brand belongs to a German manufacturer specializing in the manufacture of welding tables and additional equipment for them. The main advantage of the products is the versatility of the solutions.

"WTO Plant"

The Ulyanovsk company produces a fairly large range of non-standard equipment and accessories. Prefabricated welding tables are practical and come with additional accessories to increase productivity and improve working conditions.

VTM

The Russian brand specializes in the production of standard welding equipment and custom-made metal structures. The main focus is the production of D16 and D28 systems, as well as the execution of individual orders. The parameters of the finished product exactly correspond to the customer's requirements. For the production of welding tables, only high-quality certified materials and components are used.

Evidence

The main direction of the company is the production of welding and installation equipment. The main advantage is the wide range of models offered, which allows you to find the option that best suits your needs.

ESAB

Perhaps the most recognizable brand on the domestic market. The Swedish brand supplies high-quality welding equipment, including tables. In addition, its assortment includes a large selection of other equipment, consumables and accessories.

Sovplym

A joint venture created by businessmen from Russia and Sweden. Production facilities are located in St. Petersburg and supply ventilation systems to the consumer market. One of the company’s areas of work is the production of filter and ventilation devices for welding tables.

TEMPUS

The German manufacturer supplies 3D tables to the domestic market. They are excellent for solving problems of welding and installation of frames, fences and a whole range of other products.

Table-Table

The Russian company specializes in the production of welding tables, the table tops of which consist of stacked plates. The typesetting elements themselves are made of cast iron and aluminum, to which molten splashes do not stick. The plates are easily removable, which allows you to transform the working surface to suit specific workpieces or structures. Production processes can be simplified. For this purpose, the table can be equipped with various hydraulic and electromechanical drives.

SIBAR

A young domestic company is creating its own range of products. takes into account the needs of customers as much as possible.

Required tools and materials

In a home workshop, they often try to make do with improvised materials. However, in order to meet the strength and stability requirements stated above, the following should be used for racks:

- profile with a cross-section of at least 60×60mm and a wall thickness of 4 mm;

- I-beam or angle 60×60, but already 4 mm thick.

The shelf and drawers can be made from a lighter profile.

Welding table drawing

The tabletop is assembled from rolled profiles. The gaps between them will be used to secure the parts to be welded with clamps or pliers.

For the protective screen use:

- base frame - light profile;

- the screen itself is a metal sheet 0.4-1.0 mm.

The protective screen also has side edges.

A welding table with a fastening system should be equipped with additional devices to help secure workpieces to the table and to each other:

- clamps;

- clamps;

- magnetic plate base for fastening small parts.

Welding table with clamping system

It is not possible to make this equipment for a welding table with your own hands; you will have to buy it.

How to choose?

Choosing the most suitable table for specific tasks is not so easy. After all, many factors have to be taken into account and it is possible that new circumstances may arise in the process of work. That is, if possible, it is necessary to provide for the maximum possible number of working moments.

Those who prefer comfortable working conditions and put them at the forefront should pay attention to round models of welding tables. They are usually rotating. Therefore, the entire range of problems (or most of them) can be solved without changing your location. Such equipment is mounted on a prepared concrete platform. If you plan to produce complex structures, you should choose a work surface with a set of additional equipment that would make it easier to complete the tasks.

Fortunately, manufacturers produce a wide range of welding tables and there really is plenty to choose from. Structures are often equipped with special equipment and equipment designed to perform highly specialized operations. And if you need universal equipment, then finding it will not take much time.

When choosing a welding table, experienced specialists advise paying attention to the following recommendations:

- The first step is to determine the optimal dimensions of the structure. They must meet production requirements and at the same time be comfortable for a specialist. If you lose sight of this point, welding work can become an unpleasant and even dangerous process.

- It is important that the work area is fenced. This is a kind of protective screen. It must be made of fire-resistant materials.

- The table should have a decent weight. At least 180-200 kilograms. Thanks to this, it will be rigid and quite stable.

- It is necessary to abandon energy-saving lamps. Their light creates glare, which is a source of discomfort while doing work.

- A big plus is the presence of a rotating platform. It is advisable to purchase just such models.

Sometimes the table lacks integrated ventilation. Then you definitely need to purchase it separately. As an option - a small exhaust device with magnets.

If it was not possible to choose something appropriate from the presented models, then you can order the manufacture of the structure according to individual drawings. Thanks to this approach, the owner will receive a welding table that will best meet his requirements. At the same time, you will not have to overpay for unnecessary functions or devices.

Comfortable working conditions cannot be created without the appropriate tools. You should pay special attention to his choice. It is important that fastening devices and clamps securely hold the workpieces in the desired position and make it possible to quickly change the position of the workpieces being connected.

When buying a table for a home workshop or small business, universal models are best suited. They are suitable for more than just welding work. On such surfaces you can fix a part for grinding, sharpening, drilling or performing any other technological operations.

Equipment

To speed up welding work as much as possible, you need to take care of purchasing special equipment and devices. Basic requirements for auxiliary equipment:

- must ensure the desired location of the joined workpieces. In this case, you will not have to additionally adjust the parts;

- during welding, the edges must be at a certain equal distance in relation to each other. This is easy to achieve with the right tools;

- auxiliary equipment should be placed on the work table and not interfere with the performance of various technological operations.

It is difficult to weld parts without fixing them in a certain position. Various types of clamps, clamps, clamps and clamps cope well with this task. There are several types of fixing devices, which are divided into groups according to the type of drive:

- mechanical;

- hydraulic;

- pneumatic.

Hydraulic and pneumatic clamps are equipped with strong links, which provide the ability to brake parts automatically. This design prevents unauthorized loosening of fasteners. It is important to ensure clear joining and fixed fixation of the elements before welding them. Otherwise, the seam may turn out to be of poor quality. It is noteworthy that the preparatory work very often takes more effort and time than the welding process itself.

In addition to the clamps supplied with the tables, other devices for fixing workpieces can be used.

Clamps

A separate subtype of clamps that holds workpieces at a given angle. There are many options for devices that differ in both shape and size. The design includes a pin on which there are clamps.

Prisms

Fixing devices designed to hold bulky workpieces. To keep the part stationary, it is fixed using prisms at an angle. The main disadvantage of this type of holder is the fact that marks of fixation often remain on the surface of the workpiece.

Cast iron plates

In budget models of welding tables, cast iron plates replace the tabletop. The main advantage of this solution is that if one of the plates fails, it can be easily replaced. Another plus that you should pay attention to is the low thermal conductivity of cast iron. Even with prolonged operation of the welding machine, it does not heat up to high temperatures. In addition, the metal is characterized by high resistance to static loads.

Vise

Mechanical unit for holding workpieces. They are used in the welding process, as well as subsequent (or preliminary) processing of workpieces. The main feature of the vice is the fact that the specialist has both hands free and it is easier for him to perform the necessary manipulations. There are several types of vices.

Plate

In fact, it is the same tabletop, but with a perfectly flat surface due to its thickness. The choice of plate size is determined depending on the size of the workpieces that will have to be worked with in the future. The advantages of the plate include markings for placing parts on the surface. The metal sheet has several holes that can be used to secure workpieces using other equipment.

Suction sleeve

A lot of welding work is now done indoors. It is important that they have active ventilation, which will remove combustion products and dust outside. A forced ventilation system is sometimes used as a primary or additional workpiece holding system. The suction pipe is located under the table and the air flow, passing through small holes in the table, presses the part to its surface.

Preparing parts

Let's look at two table options that you can make at home. The entire cycle of work is divided into several stages. Before starting work, make sure that cables, power tools and protective clothing are in good condition. In this case, special attention should be paid to safety glasses and a welding helmet.

The most universal and simplest design will be a structure made from a profile pipe. Let its height be 900 mm, length 1100, and width 660.

To reduce the cost of the design of the welding table, a tabletop made of plywood covered with thin metal is installed. The best countertop is, of course, a metal slab with a thickness of at least 8 mm. But this is a very expensive option.

To work you will need:

- profile pipe with a shelf 40 mm – 10 m;

- steel strip 40 mm wide, thickness not less than 5 mm - not less than 200 mm;

- sheet of plywood 1100 mm long and 660 wide;

- sheet steel no more than 2 mm thick for covering the tabletop. It needs to be made a little larger, taking into account the bends;

- gussets made of sheet steel 2 mm.

This version of the welding table has several shelves, but boxes can be made. For shelves you will need a corner with shelves 30 mm, length 600 mm. For 2 shelves you will need 4 blanks. It is better to make the shelves themselves from DSP sheets.

Use a grinder to cut the workpiece to size. The legs will require 4 pieces of 840 mm each from a profile pipe. For the upper frame, you need to prepare 2 sections of 1100 mm each and 3 sections of 580 mm each.

The lower jumpers of the welding table will require one piece of 1020 mm and 2 of 580 mm. For shelves, 4 pieces of 580 mm each are cut from the corner.

After the cut, a burr remains; it must be removed either with a grinder or a file. Having completed the preparatory work, we proceed to assembling the welding table.