08/31/2021 Author: VT-METALL

Issues discussed in the material:

- Basic requirements for a welding table

- Materials for welding table

- Dimensional drawings for welding tables

- An example of manufacturing a welding table from a profile pipe

- Ready-made drawings of a welding table for laser cutting

Drawings of a welding table will allow you to think through the dimensions and make the workplace as comfortable as possible for the welder, which will have a positive impact on the quality of the finished products. The main material for making the table is metal. Profile and perforated sheets can be used.

In addition to the dimensions of the table, the drawing allows you to think through additional details - take into account grounding, the location of the lighting, shelves for storing accessories, a waste tray and other elements. Read more about the types of welding table drawings in our material.

Basic requirements for a welding table

First of all, the welding table must be durable, made from materials that are not subject to combustion and can cope with high temperatures. You also need to understand that the properties of the table largely depend on the nature of the operations that are planned to be performed using welding equipment.

When preparing an individual drawing and further manufacturing a welding table, it is important to consider the following factors:

- Structure height. Craftsmen carry out welding mainly while standing, which is why, if there is a difference in height or the habit of carrying out a number of operations while sitting, it may be necessary to change the height of the table. According to the standards, it should be in the range of 650–800 mm.

- Tabletop dimensions. Small parts can be welded on a table with a working surface of 60x60 cm, while when working with very bulky objects, even a table of 2x1.5 m will be small.

- Load capacity. We are talking about a distributed load on the tabletop and a maximum load on the legs, of which there are four in small products, and their number can reach up to eight in large ones. The tabletop is made of thin sheet metal only on the condition that it is planned to weld only compact parts of low mass on it. However, in this case it will be necessary to provide an additionally reinforced support area for the welding machine. Tabletops made of layered structures or profile pipes with a large cross-section have proven themselves best.

- Possibility of moving the table. It happens that you have to move it around the room and even use it outside. Then it is recommended to include wheels with a stopper in the drawing of the welding table.

- Additional elements. We are talking about shelves, tool hangers, drawers for consumables. Shields, specialized lamps, hoods, etc. can also be installed.

The welder himself chooses a specific table model based on his needs and the intricacies of the planned operations.

Photo

Taking into account the tasks set, the materials used and creative impulses, you can even get the following results:

Materials for welding table

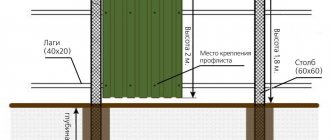

The power frame is usually made of metal. For a mobile model, a rigid welded structure consisting of a profile pipe with a cross-section of 60x60 mm and a wall 2 mm thick is suitable. The side parts of the frame are reinforced with reinforcing bars. It is recommended to make the tabletop from a profile with a section of 60x140 mm. The result is a product weighing 150–200 kg - this mass provides the required load capacity.

It must be emphasized that to create a welding table design according to the drawing, only pipes with a wall thickness of 2 mm or more can be used. The fact is that a product with a wall of 1.5 mm is not strong enough when welding large workpieces.

VT-metall offers services:

Both a closed profile and a channel and other similar type of rolled product can be used.

Most welding tables do not have a monolithic tabletop - the working surface must have gaps. The latter allow you to fix parts with clamps and other mechanisms during operation.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

The tabletop can either consist of strips or have perforations. In the second case, it is made from a steel strip or sheet with a thickness of 8–10 mm, but it is better if this figure is even greater. The optimal hole diameter is considered to be 10–25 mm. Due to the thicker metal, the weight of the structure increases, which ensures its stability and better distribution of the load over the working surface area. However, as the thickness of the tabletop increases, it is necessary to choose a larger cross-section and wall thickness of the profile for the legs, which is also important to consider when preparing the drawing of the welding table.

Small workpieces are usually not secured, so for welding them the working surface can be made of metal sheets 8–20 mm thick. To make shelves and the bottom of drawers for relatively light objects, choose a metal mesh or a solid or perforated sheet of metal of less thickness than that of the tabletop.

Sometimes OSB, thick plywood for non-essential shelves can be used. It is worth clarifying that the latter means shelves that do not receive sparks and do not place hot objects.

If you plan to store materials or equipment under the table that may suffer from excessive heat, it is recommended to provide the tabletop with thermal insulation. Non-flammable basalt or mineral wool, basalt cardboard, and asbestos are suitable for these purposes.

To prevent shelves and drawers made of wood or other flammable materials from being damaged by sparks and scale, they are covered with metal sheets up to 5 mm thick.

The legs of mobile tables are equipped with a stopper; in addition, the supports themselves must be selected in accordance with the weight of the structure. On small products that are rarely used in the welding process, non-locking wheels can be installed.

Original and easy manufacturing methods

Idea by Sarah Melloni

The aluminum structures designed by Sarah Melloni look like easily folded sheets of paper. The designer called her collection “Simple Things.” Furniture can be made with your own hands without any scraps; it does not require additional parts for assembly. The items are created from 2.5 mm aluminum sheets, each of which is folded 4 times. White powder coating protects the surface from fingerprints and scratches.

From water pipes

Various combinations of interesting materials make it possible to create a unique design. For example, you can make a table with legs from water pipes.

A table like this with a top made of high-quality wood or glass has not only an exclusive look, but also that enviable strength that guarantees it a long life. Making furniture this way with your own hands, using recycled materials, is a sign of skill and ingenuity.

- First, taking into account all individual needs, you need to make drawings.

- Then, before purchasing pipes and materials for the countertop, it is worth calculating the dimensions and number of components.

- At the nearest plumbing store you need to purchase all the necessary parts: pipes, fittings and couplings.

- If you paint the pipes in a noble black color, it will seem that the table was created a century ago. You can use spray paint designed for painting metals. It is sold in auto and hardware stores.

- The wooden tabletop is processed and varnished in several layers. By applying wood stain, you can give it any shade.

- A DIY table can be of any size; it can be made into a dining table, a desk table, or a coffee table table.

Dimensional drawings for welding tables

The following models and drawings of welding tables with photos have different manufacturing complexity, layout, and materials.

- The simplest table for welding work.

This design has a small size and load capacity, but allows you to process small parts if they need to be secured in a vice or with clamps.

The supports of the product consist of a corner with parameters 60x60x670 mm. For strapping or drawers, use a strip with a cross-section of 20x100 mm. The length of two fragments (on the longer side) is 1,000 mm, the other two (on the short side) – 620 mm. The strips are welded to the outer part of the corner so that the top edge of the strip is 20 mm above the top edge of the corner.

Inside the rigid frame, which is formed by the table supports with strapping, strips 20 mm thick, 580 mm long and 100–150 mm wide are laid and welded. The last indicator may vary, since such a run-up is not critical. To strengthen the structure, cross members are sometimes added 200–300 mm from the floor. They can be made from a corner so that, if necessary, a shelf can be placed on top of them.

Finishing

After making a practical and convenient welding table, you should worry about its appearance. It is best to paint the finished product with metal paint . This will not only decorate the table, but also extend its service life.

Tip : You can also increase the functionality of your workplace by making a folding table for the garage, a simple table made of boards or pallets, or a tool cabinet.

An example of manufacturing a welding table from a profile pipe

A step-by-step description of the table production process allows you to better understand the design features and its assembly. Next we will talk about a relatively simple product with shelves provided, the tabletop of which consists of sections of profiled pipe with a rectangular cross-section.

Manufacturing involves the following steps:

- Cutting pipes for further assembly of the tabletop in any way, welding the ends. Cleaning burrs left after cutting, grinding seams.

- Fastening the workpieces to the drawer - the drawer pipes themselves must be cut at the corners and butt-joined in accordance with the drawing of the welding table.

- Metal polishing, which is most important for welded joints.

- Fastening the shelves and sides with self-tapping screws through pre-prepared holes.

- Placing a sheet of metal 1–3 mm thick on the top shelf - it is designed to protect the OSB board from fire and excess dirt. If the sheet becomes dirty, remove it and shake off debris and metal particles.

- Fastening previously prepared tabletop elements to pins rather than directly to the frame. In this way, it is possible to reduce heat transfer and provide greater convenience for fixing products along the edge of the structure.

- Reinforcement of the frame with braces in the corners and along the central post if you plan to process large, heavy parts.

- Attaching hooks to the legs necessary for fixing equipment and wires.

- Reinforcing corners with L-shaped parts, if it seems that the required level of reliability has not been achieved when attaching the wheels.

- It is possible to use an I-beam to make support-beams for a stacked table top instead of an angle and a rectangular pipe. In this case, the closed rectangular frame can be replaced with two separate beams.

- To make a table that will be attached to the floor, it is important to prepare plates with holes on the bottom plane of the legs in advance - this is how the structure will be attached to the anchor bolts.

Regulating mechanism of general ventilation

- If less than 0.2 g/h of welding materials is consumed per 1 m3 of room, the arrangement of general ventilation may not be carried out.

- The fresh flow rate cannot exceed 0.9 m/s.

- In the absence of a local ventilation system, mechanical ventilation should ensure the elimination of 2/3 of the air masses from below and 1/3 from above.

- If welding work is carried out inside a product (container, barrel), the air speed should be more than 0.7 m/s at temperatures not lower than 20 degrees.