Many construction and repair operations are simply impossible without a hammer drill. But for this power tool to be as effective as possible, it needs to be maintained in good condition. And for this you need lubricant for the hammer drill. Moreover, different parts of the device require only their own composition of oils. Let's figure out what needs to be lubricated in a hammer drill and how often it needs to be done. And most importantly, we’ll find out how to coat the working parts of the tool.

Coating the gearbox with lubricant Source mtdata.ru

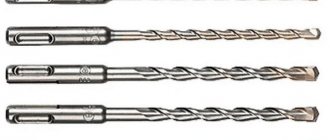

Rotary hammer working equipment

The instructions for the mechanism always contain an urgent requirement to lubricate the shank of the replacement tool. The drill absorbs high dynamic loads at the level of thousands of blows per minute.

During continuous operation, the operator should regularly coat the drill shank with lubricant - without this, the attachment will overheat and break. Caring for a rotary hammer is a painstaking task.

Boer

Correct application is carried out in the grooves into which the cartridge wedges fit. It is important to clean them of debris and sand, and then apply a small amount of lubricant to them. When removing a drill or bit, you should always renew the layer of lubricant - a fraction of a gram is enough.

Hammer chuck

Initially, this unit does not have its own protective coating. It is required to add 1-2 grams of lubricant before starting work.

Cartridge

Place of processing – seating surfaces for replaceable tools. This is where colossal friction and shock loads arise that can damage the cartridge. In addition to active protection, this also achieves passive protection: a layer of substance will cover the internal device from the penetration of dust and small particles.

Hammer gearbox

This mechanism is key in an electric tool (after the motor, the rotation of which it transmits to the working attachment). Operating conditions of the gearbox: constantly changing rotation speed and torque, strong friction and increased heating from it. To this should be added penetrating dust and small contaminants - the gearbox is under constant tension.

Hammer gearbox

Lubrication of the rotary hammer gearbox is carried out by applying a substance to the internal surfaces - especially after long-term operation. Bearings and shafts are protected in the same way. It is important to lubricate the rotary hammer gearbox during long-term operation.

Leading lubricant manufacturers

Before wondering how to lubricate a hammer drill, you need to choose the right product. Having understood the crankcase design and choosing either liquid or grease lubrication, you need to choose the manufacturer. And here you can go one of two ways.

The easiest thing to follow is a brand. Bosch, Makita, Lubcon, AEG are widely popular. In this case, you need to use lubricant from the same manufacturer that manufactured the tool. This ensures that all of the above requirements will be met.

In addition, such lubricants often have accompanying documents, which even indicate specific models that are best compatible with the product. Sometimes there is even a list of other brands whose equipment can use this product. But you still need to be extremely careful in your choice.

Lubricant products from Bosch Source allegroimg.com

You can also use universal lubricants from leading manufacturers. Companies such as Castrol, Xado, Ravenol and Shell produce a line of oils that are equally suitable for any equipment. And the only condition for proper use is that there is an indication on the product packaging that this is indeed a lubricant for the gearbox of a power tool.

The owner can only choose the consistency. And the technical documentation included with the hammer drill will help you do this correctly. There is always complete information there, including recommendations for lubrication of working units.

Lubricant for drills

High-quality models are sold with the volume of lubricant produced for processing drills. Its intended application is the mating surfaces of the shank. Moreover, the provided viscosity characteristics depend on the brand of the substance.

You should use exactly the brand recommended by the manufacturer. The reason is that the chemical composition is selected to match the construction materials and ensure their integrity during prolonged “hot” work.

It is optimal to purchase consumables of the same brands as the tool.

Briefly about the main thing

To increase the service life of power tools, it is necessary to use only high-quality lubricants. In particular, for uninterrupted operation of the rotary hammer, it is better to opt for specialized compounds that the manufacturer supplies with its products. This will guarantee the correct selection of the necessary lubricant components for this particular model.

You can also use products from leading manufacturers of oils and lubricants. Their universal materials are of high quality and are not much inferior to specialized products. The only condition in this case is the need to change oils more often than usual.

Gearbox lubricant

Lubricating the gearbox of a newly purchased hammer drill is not required. The factory has already placed the calculated amount of oil inside, so its presence there is often missed. However, during operation it decomposes, becomes dirty and ceases to fulfill its role.

After some time, it is recommended to replace the oil with one that is designed for harsh operating conditions and high heat. Friction occurs inside the gearbox during rotation, characterized by frequent and sharp squeezing of fluid from the friction pairs. Therefore, specialized oils are used that can:

- protect metals from oxidation;

- capture and remove pollution;

- stick to surfaces to protect them;

- be water-repellent;

- do not be afraid of strong heat,

- as well as self-healing.

How often should you lubricate the tool?

Drill and blade shanks must be lubricated at each installation after removing dust and other contaminants. If the work is intensive, it is necessary to visually monitor the degree of lubrication of the seat of the nozzle used.

The hammer drill works for different users with different intensity - some use it every day, while others use it only occasionally. Therefore, there is no clear answer regarding the regularity of adding or replacing lubricant. To determine the need to change the lubricant in general, you need to focus on the following:

- intensity of tool use;

- recommendations made on this matter in the instructions for the hammer drill;

- guarantee period.

The most comprehensive recommendations from manufacturers for lubrication of tool assemblies are contained in the operating instructions. Parts not listed do not require lubrication.

Top 4 lubricants for rotary hammer drills

Lubricant for hammer drills is individually selected for the brand of the tool itself, but there are several universal formulations. They stand out from the crowd, but the application remains up to the decision of the hammer drill operator.

The following are good for construction and domestic conditions, therefore they are used quite widely.

Hammer lubricant: makita 196804 7

Origin: Japan.

Purpose: processing of the shank and the inside of the chuck.

Release form: soft tube, 95 g.

Pros:

- lack of decomposition and transformation into wax;

- operational reliability and high level of surface protection;

- Convenience of storage containers.

Minuses:

- decent price;

- the chemical composition is a secret of the manufacturer.

Impression: smooth operation even after long hours of use.

Hammer lubricant: arsenal ar 401 100 g patriot

Origin: USA.

Purpose: processing of any replaceable drills used when rotating up to 4 thousand revolutions per minute.

Release form: flexible tube, 100 g.

Pros:

- retention of dusty contaminants – at a height;

- protection power – just right for intensive work with minimal consumption of tube contents;

- sufficient initial fluidity for fast and reliable processing of complex configurations;

- practical container that allows you to get a minimum amount of the composition.

Minuses:

- heated liquid has increased fluidity, which slightly reduces performance characteristics;

- the tube sometimes produces strong splashes, the price of which is lost composition and contaminated surfaces;

- There is no usual relief - it is problematic to open without removing gloves or with wet hands.

Impression: a decent lubricant at a not too high price, which lasts for a long time. How to use is intuitive.

Lubricant for rotary hammer: bison zsb 125

Origin: Russian Federation.

Purpose: replaceable tools with difficult working conditions (bit, chisel, drill), for cartridges of any configuration.

Release form: soft tube, 125 g.

Pros:

- enhanced chemical composition to withstand extreme loads;

- resistance to moisture and the formation of aqueous emulsion;

- reliable corrosion protection and high tribological properties;

- relatively low price;

- significant operating temperature range: from -50 to +130 degrees.

Minuses:

- relatively rapid acquisition of a liquid state;

- possible ejection from the rotating cartridge;

- does not rub off well from absorbent materials.

Impression: a semi-synthetic substance, packaged in a convenient tube, does its job efficiently, but you need to get used to its slightly lower viscosity.

Hammer lubricant: elitech 2006 000100

Origin: Russian Federation.

Purpose: to counteract friction and corrosion of replaceable tools and chucks.

Release form: tube, 60 g.

Pros:

- powerful operating temperature range: from -55 to +140 degrees;

- there is no scattering of individual drops;

- versatility of use - suitable for any type of tool and any working conditions.

Minuses:

- Possible strong darkening when working too hard and drying out when stored for too long;

- relatively small volume.

Impression: reliable material at an affordable price that will not turn into liquid oil.

Top 3 lubricants for rotary hammer gearboxes

The most loaded parts of the gearbox are the gear teeth and bearings. For them, substances are manufactured with capabilities designed to resist water and high temperatures.

Hammer gearbox

Lubrication of the rotary hammer gearbox can be done well with one of the three products listed above. How to lubricate the gearbox is up to the operator to decide.

Hammer lubricant: makita p 08361

Origin: Russian Federation.

Purpose: high-power rotary hammers and jackhammers (with SDS-Max chuck).

Release form: tube, 30 g.

Pros:

- easy to use with viscous consistency;

- coloring indicates untreated areas;

- minimum storage space.

Minuses:

- the manufacturer hides the chemical composition, so it is difficult to replace with an analogue;

- will leak from models without an oil seal;

- small volume, which is enough for only a couple of uses;

Impression: reliable composition for models with a shock mechanism and high vibration.

Lubricant for rotary hammer: ultra 50 g vmpavto et 110005

Origin: Russian Federation.

Purpose: removal of contaminants and removal of heat in gearboxes with gear and hypoid transmissions.

Release form: transparent rectangular package, 50 g.

Pros:

- high wetting of metals;

- self-distribution in work;

- the consistency is equally viscous and liquid;

- low cost.

Minuses:

- ability to exit from any gap if the loading quantity is exceeded;

- practicality suffers from a strong odor;

- packaging may seem inconvenient;

- the amount of content is enough for a couple of refills.

Impression: the lubricant has high fluidity, which increases its functionality - penetration into far corners and between all teeth is carried out independently.

Hammer lubricant: ultra 200 g vmpavto

Origin: Russian Federation.

Purpose: transmissions with gear and planetary gears used at high speeds.

Release form: tube, 200 gr.

Pros:

- easy and quick distribution over the surface;

- additives to improve tribological properties;

- heat removal at high speeds;

- A decent volume is sufficient for long-term use.

Minuses:

- not the best results for rotary hammers with low operating speeds (less than 1500 rpm);

- relatively high price.

Impression: the dark-colored composition is convenient for the hammer drill gearbox and has high performance properties.

Causes of equipment overheating

If the housing in the gearbox area constantly overheats, it is imperative to find the cause of the overheating and eliminate it. The most common causes of overheating:

- Excessive gearbox lubrication. Excess must be removed;

- Lack of gearbox lubrication. Occurs during prolonged continuous use in shock mode. Add grease to the gearbox;

- Ventilation holes are clogged. In this case, air cooling stops working. Clean the holes with a wooden stick or blow with compressed air;

In any case, work should be stopped and the mechanism allowed to cool.

If the cause is eliminated, you must first run the device idle to ensure uniform distribution of lubricant on the rubbing parts.

How else to lubricate the rotary hammer gearbox

How to lubricate in the absence of special equipment? Contrary to recommendations regarding specially developed mixtures, the use of solid oil or lithol is allowed for a short period of time. These proven materials are cheap and widely available, unlike hammer drill lubricant.

They allow for short-term protection of nodes in the absence of other means. The disadvantages of this solution are some braking of the mechanisms and low heat removal. What kind of lubricant is available in the field is a question, so using them is the best solution if you are empty-handed.

Features of oil selection

Before lubricating Bosch rotary hammers, you should select the appropriate oil. When purchasing it, you need to pay attention to the viscosity . High-quality compounds are expensive, but you shouldn't skimp. Such an expensive tool as a rotary hammer requires constant care. What types of lubricant and how much can be used are indicated in the instructions. If such information is not available, specialists from a retail outlet or service center will help you select the best composition. There are universal compounds on sale for processing various models of rotary hammers.

Many people prefer to use graphite lubricants , which have:

- high quality;

- good viscosity;

- affordable price.

If there is no lubricant, you can use lithol or grease . But they cause slight braking of the rotating parts and contribute to increased heating of the tool during operation. It is advisable to buy a special composition in the near future, remove the lithol and apply a new composition.

Before lubricating a rotary hammer drill, you need to make sure that the oil you use is suitable for it. The compounds used for gearboxes are not suitable for lubrication. For the latter, use more liquid products ; they must fill the free cavities and completely cover the parts that are in contact with each other. If there are plastic elements in the gearbox, use silicone grease. It is suitable for processing cartridges.

The transmission mechanism can be lubricated with plastic compounds . But not all tools will work smoothly when using products of this consistency. Thicker mixtures are suitable to reduce tail tip wear. The packaging indicates their purpose for processing drills. If you don’t have them, you can take graphite ones, but they dissipate heat worse.

Manufacturers of electric tools produce their own branded lubricants . They are also produced by enterprises that specialize in the production of lubricant mixtures.

The most popular products include:

- Bosch - for tail nozzles and gearboxes.

- Makita – for processing drills.

- Interskol - for the Boers.

- Nanotek – for shanks.

- Turmogrease - universal formulations.

- Lubcon Thermoplex – for gearboxes.

- Kress – for lubrication of drills.

- PRORAB – for processing the seats of tail nozzles.

Lubricant for hammer drills from the Makita brand