To minimize friction of parts during operation of various robotic machines, special oil and high-quality lubricants are used for lubrication for their maintenance.

These CNC machines have ball screws (ball screws). They may differ in appearance and design, but they have one purpose - to convert movement from rotational to translational. With their help, it is easy to avoid sudden jumps when linearly changing the position of the housing and bearings. To keep friction to a minimum, the surface of the components in the machine is carefully ground. There are special requirements for its maintenance.

When is lubricant needed for CNC machines?

To ensure the longevity of your machines, it is important to maintain them regularly. Maintenance also includes periodic lubrication of all components of the device. The working surface should be cleaned after each use of the machine, and lubricated at least after every third use. You can do it more often, it will not harm the mechanics.

CNC care

The performance of the machine primarily depends on proper care. Main events:

- Automatic lubrication of the machine.

- Monitors the cleanliness and freshness of the cutting fluid.

- Particularly careful lubrication before prolonged inactivity.

- Regular cleaning of dust and chips with a brush.

- Protection against oil and other compounds getting into connectors, spindles, electronic control units, stepper motors.

- Correct shifting of gearbox levers when using a spindle with several mechanical gears.

- Cleaning the mounting holes of the collet and spindle before installing the cutter or mandrel.

It is very important not to neglect any of these rules, especially those relating to the automatic lubrication system of the machine, as well as those prescribed by the manufacturer in the instructions for a particular machine.

CNC machine lubrication systems

Lever

This option is the most common. Its popularity is due to its relatively inexpensive price and availability in stores. Can be used on any CNC machines that feature rail guides (profile).

The lubricant is presented in the form of a plastic container with a lever. This is where the oil is poured. As soon as the lever is pressed, the supply of the composition into the carriage begins, and it occurs along all the guides.

IMPORTANT! There is more pressure on the Y-axis compared to the X-axis, so over-lubrication may occur. To avoid this, it is recommended to do the following:

- tighten all adjustment screws before starting work;

- adjust the oil supply to all guides (the screws must be unscrewed gradually);

- 3-4 days after the first supply, all guides are cleaned of dust, then the lever is pressed again, and the lubricant is passed along all axes of the device;

- After all the steps, just press the lever every month.

Digital

This system is similar in many characteristics to the lever system and is distinguished by the presence of the following parts:

- a transparent plastic container for pouring oil;

- adjusting screws for adjusting the pressure level.

The main difference between the digital system is that the operator does not need to press the lever himself; lubrication occurs automatically. You can set the oil supply time on the electronic unit. Oil is supplied according to the established schedule.

The main advantage of the digital option is the minimization of the human factor and error (and this is the most common reason for machine malfunctions).

Centralized

The most effective and at the same time economical lubricant, since it does not require much attention and is absolutely unpretentious. It can also be used in CNC laser machines.

The operating principle of centralized lubrication is as follows:

- the oil is pumped into the pump (this happens using syringes);

- when the machine is operating, it independently regulates the amount of oil supplied to the units, and overflow is not allowed.

ATTENTION! The human role is to monitor the remaining oil in the pump. If the operator notices that the guides have become dry, the oil container must be refilled immediately. Otherwise, if there is no lubrication for a long time, the device may fail.

The Role of Ball Screws

All systems and types of linear motion also require lubrication: ball rail guides, cam rollers and ball bushings, and directly high-precision ball screws, which are used in new types of machines.

It is ball screws that provide high positioning accuracy (6 microns with a travel length of 300 mm). The high speed of processing parts and rotational speed, the influence of shock loads on the machine when cutting metal or durable wood, contribute to the wear of these components and lead to scuffing. The caliper begins to move jerkily, vibration appears, and this has a bad effect on the quality of the parts processed.

These units are difficult to manufacture and high in cost, so specialists usually treat them with exceptional care, spending considerable sums on lubricating oil.

What lubricant should I use for CNC machines?

Lubricants produced by domestic manufacturers are divided into lithium, hydrocarbon and barium. The optimal combination of performance characteristics for CNC machines is lithium. They gained popularity not only in Russia, but throughout the world.

Industrial oils are also used to lubricate milling machines, which are obtained by refining I-20 and I-30 oil. Such oils are characterized by a number of advantages:

- thickness and viscosity, which can change their properties under the influence of temperature;

- density - responsible for the transmitting properties of the oil;

- flash point - temperature indicators at which the oil can ignite (the higher the indicators, the more economically the lubricant is consumed);

- pour point - at this temperature the lubricant becomes motionless;

- ash content - characterizes the purity of the oil;

- percentage of sulfur content - the less sulfur, the higher the quality of the oil.

Additional protection for your milling machine

To prevent contamination of machine components, it is necessary to eliminate the cause of such contamination. Of course, you won’t be able to completely get rid of the chips. But there is an excellent opportunity to significantly reduce its spread throughout the equipment.

The most popular method is to install systems that catch chips. The design of such an element is not complicated: a special attachment is mounted on the spindle, which in turn covers the cutting area. What comes out is something similar to a “casing”. From this casing, the chips are pulled out by an additional unit - a vacuum cleaner. This happens through a special hole and a hose connected to this hole.

The simplicity of such a design does not mean anything. It has already proven its effectiveness in many industries. Another tip is to remove the chip “waste” immediately, without waiting for a large accumulation of “garbage” in the room. The rule is banal, but it is surprisingly often neglected. It is better to remove the “waste” from the cut than to subsequently spend a long and tedious time cleaning equipment components from it.

Frequency of lubrication of CNC machine components

Everyday lubrication includes the following steps:

- Cleaning the work surface. All guides and running gears are thoroughly cleaned of processing waste and dust.

- These parts, as well as components, are lubricated along their entire length. When lubrication, all axes must be taken into account. To do this, you can use a brush or rag, but it is better to do this with a syringe or spray.

- Run the machine portal several times to distribute the oil over the entire surface of the device.

IMPORTANT! Daily technical inspections are not recommended. Also, to maintain the functioning of the machine, you should not mix oils that differ in composition.

Twice a year the working surface is cleaned of lubricant residues. Particular attention should be paid to the lead screw and linear bearing. After applying the cleaning agent, this unit is moved until it stops. The new composition can be applied only after these manipulations have been carried out.

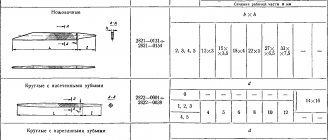

Lubrication of rack and pinion mechanisms of a CNC machine, bearings of linear guides and ball screws

Before carrying out maintenance, if there is dense contamination on the guides of the rack and pinion mechanisms, it should be cleaned with a napkin or a metal brush with bronze bristles . Then, using a brush , apply a thin layer of lubricant.

If the CNC machine is not equipped with an automated lubrication system, then the lubrication operation is typically performed using a lever plunger gun . It should be noted that the supply of lubricant per stroke of the lever for different syringes may differ from 0.4 to 2.0 grams . Therefore, before using the syringe, you should calculate how many strokes should be made in order to pump the required amount of lubricant.

The required amount of lubricant for linear guides, rack and pinion bearings and ball screws may vary depending on the size of the CNC machine table. For industrial woodworking CNC machines with worktable dimensions along the X axis up to 2.5-3.0 meters, the following volumes of lubricant per grease fitting (grease fitting, nipple) are recommended:

- X-axis gear mechanism – 6-8 grams or until lubricant begins to come out of the special hole;

- X-axis guides – 3-4 grams;

- Y and Z axes – 3-4 grams;

- Tool magazine moving devices – 3-4 grams;

- Workbench console bearings - 3-4 grams or until grease begins to come out on the sides of the bearings.

Mistakes and ways to avoid them

The main mistake of the machine operator is the lack of regular lubrication of the device. To fix this, you should thoroughly clean all components, and only then apply oil.

Mixing different oil compositions will also be detrimental to the machine. This deteriorates the design of the components and even peripheral materials. If this happens, you need to try to clean all the lubricated parts (most likely, this will have to be done several times, since the oil will not go away quickly), and then use oil of a homogeneous composition.

Another mistake is lubricating only a certain area of the machine and not distributing it throughout the entire device. In this case, the operator will be confident that the machine is serviced and can be fully loaded. But in fact, many parts will remain contaminated with dust and waste. Therefore, when lubricating, it is important to run all guides and axes.

Lubrication will help prolong the operation of the machine even under high loads. It is important to do this regularly in compliance with all the rules.

- November 09, 2020

- 1756

Lubrication of milling units: recommended compositions

Most often, it is recommended to lubricate the moving parts of the machine with a special compound called WD-40. However, it is worth noting that half of the composition of this substance consists of so-called white spirit, which is a solvent, but not a lubricant.

Therefore, the WD-40 mixture should be used for its intended purpose - to clean equipment components, but not for direct lubrication. This substance copes well with various types of dirt, fatty deposits, and removes moisture. But at the same time, it completely removes the lubricating layer, which subsequently leads to the appearance of rust and deterioration in the functioning of the machine.

Accordingly, this composition cannot be used to “lubricate” components. To do this, use a special lubricating oil, and wipe the nodal surfaces dry before processing. The most popular substances are so-called lithium greases. The best option would be No. 2. Another proven method is to treat the nodes using Mobil Vactra#2.

Sliding guide oil

Sliding guide oil is an EP 0 lubricant. It is a liquid dispersion of a base oil to which a viscous thickener is added to obtain the desired parameters. An example of such an oil is Mobilux EP 0. Products of this class have the following set of features:

- excellent grip on vertical surfaces;

- lack of contact between surfaces under increased loads;

- providing protection against corrosion.

The oil used to lubricate the guides forms a thin film, which protects parts from wear. Much depends on the level of loads under which the unit operates. Oil for lubrication of elevator guides differs from analogues for other applications due to the characteristics of operation.

The catalog contains oil for linear guides of all types from the most significant Russian and global manufacturers. You can buy products from TNK, Gazpromneft, SHELL, Mobil. Each brand is represented by several types of lubricants, which allows you to choose a product with optimal parameters.