Markings on cutting discs

In order for owners of grinders to be able to correctly select consumables in accordance with the upcoming work with this tool, manufacturers of cutting discs apply special markings to them.

Abrasive discs

The following information can be gleaned from the labeling.

- The material from which the nozzle is made is indicated by the first letter: A – corundum, used for cutting metal; AS – electrocorundum (white), cuts stainless steel; C – silicon carbide, cuts stone and concrete well. Metal cannot be cut with this abrasive attachment.

- Next, after the letter indicating the material, there is a number. It means how many abrasive grains are in a unit area. Accordingly, the smaller the grain, the higher the number. If you need to cut steel, then choose a disk with a finer grain - 40 or 60. Coarse-grained disks are used mainly for cutting non-ferrous metals.

- The next parameter is the hardness of the ligament. Indicated by letters of the Latin alphabet (H, I, J, K, L, M, N, O, P, Q, R, S, T). The closer the letter is to the beginning of the alphabet, the softer the connective, and vice versa. For processing soft materials the bond must be hard, and for strong and hard materials it must be soft.

- The last letters indicate the type of ligament. Ceramic discs are marked with the letter V. Such discs are characterized by good water resistance, fire resistance and resistance to chemicals. The bakelite bond is designated by the letter B. Such wheels have good bending and compressive strength, but are destroyed when using alkaline coolant. Also, binders based on bakelite have low heat resistance. At a temperature of 200 degrees it becomes brittle, and at higher temperatures it begins to burn out. The third type of ligament - bakelite with increased strength - is labeled as BF or BU.

- The maximum speed that cannot be exceeded for this consumable. The linear speed of the edge can be specified in m/s or in revolutions per minute.

- Dimensions of the circle in mm: outer diameter, thickness and diameter of the seat.

- Date of manufacture. Usually indicated on a metal insert located around the mounting hole. It is not allowed to install an expired wheel on an angle grinder, since over time it may lose strength and fly apart during operation.

- Purpose of the nozzle. It is indicated what materials the tool is intended for cutting.

- Color coding: blue is used for cutting steel, green is used for cutting stone.

Color coding of diamond blades

Diamond wheels are marked with the following colors:

- orange – for cutting bricks;

- blue cuts concrete and marble well;

- green is used for cutting granite;

- gray cuts tiles, granite and ceramics;

- yellow – alabaster and tiles.

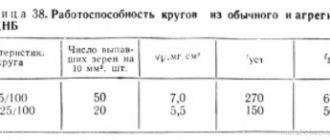

Grinding wheel grit

Grit size is perhaps the most important indicator, since the smoothness of the finished surface depends on the size of the abrasive. Based on the grain size index, you can clearly determine the thickness of the layer being removed, the degree of wear of the disc and the smoothness of the processing. Typically, tool manufacturers provide special tables that detail the characteristics of the wheel range, including grit size and purpose of the disc.

The grain of the wheel can be so small that it can be used for polishing glass. With its help, small scratches and chips are removed and the glass is returned to a perfectly smooth surface.

The most common types you can find are:

- grinding - the abrasive size ranges from No. 200 to No. 16;

- grinding powder - from No. 12 to No. 4;

- micro-grinding powder – M63-M14;

- fine micro-grinding powder – M10-M5.

Particle size is measured in micrometers. It is worth noting that the exact size of the abrasive can usually be determined only for artificial materials. When producing diamond wheels, it is impossible to choose the same size of chips, so when marking, two indicators are used, the minimum and maximum grain size.

Types of cutting discs

Cutting wheels for an angle grinder can be either made of abrasive material or all-metal. Depending on the type of material being processed, the type of cutting disc is selected.

For metal

If you need to cut metal, always use bakelite consumables with reinforcing elements. In this case, there must be at least 2 reinforcing meshes.

For ferrous metals, ordinary corundum is used, which contains, in addition to aluminum oxide, impurities of chlorine, iron and sulfur.

For cutting stainless steel, the presence of the above impurities in the cutting wheel is unacceptable, since they cause burning of the steel (overheating). As a result of this, alloying additives can burn out of the stainless steel, and it turns into ordinary steel, as a result of which the cut area begins to become covered with rust. Therefore, it is important to carefully read the information on it before purchasing a disc. A cutting disc for stainless steel is always marked with the letters “AS” and the word “INOX”.

For cutting non-ferrous metals, discs with large abrasive particles are used. For example, a cutting wheel for aluminum, in addition to coarse abrasive, contains special fillers that prevent clogging of the cutting edge.

Users of angle grinders often wonder: what cutting discs for metal are best to use? An ideal grinder disc should have:

- bakelite reinforced bond (RB);

- correctly selected type of abrasive: for stainless steel white electrocorundum (AS), for ferrous metal - ordinary corundum;

- disc thickness from 1.6 to 2 mm;

- outer diameter 125 mm;

- fine abrasive particles if cutting of steel structures is required.

It is not recommended to use abrasive wheels for cutting corrugated sheets, since the cut area overheats and the zinc, the main element that prevents corrosion, burns out of it. To reduce overheating of the material, some craftsmen use a circular metal grinder disc with fine teeth. But in both cases, the cut site must be treated with a special anti-corrosion compound, which can be purchased at a store that sells profiled metal sheets.

For cutting stone

For cutting stone at home, an abrasive disc made of silicon carbide (marked with the letter C) is suitable.

This cutting disc is used for small stone work, as it wears out quickly. But, due to its low cost, this consumable is quite popular among owners of grinders.

An abrasive disc for stone is not suitable for professional use. For these purposes, it is recommended to choose an all-metal cutting wheel with diamond coating.

On concrete

Discs for cutting concrete and reinforced concrete are made from high-strength hardened steel, with diamond chips applied to the cutting part. Also, these cutting wheels can be segmented or solid.

Before you start cutting concrete, you need to determine its type. It can be regular or reinforced (containing a metal mesh). It is also worth considering the age of the concrete.

- Young concrete has abrasive properties, so it quickly wears out the tool. To cut it, it is necessary to use segmented diamond discs for concrete of increased thickness.

- Old concrete is a very hard material. To process it, it is better to use a grinder wheel of moderate thickness.

For cutting reinforced concrete, install a universal diamond wheel.

For cutting tiles and porcelain stoneware

It is best to use solid diamond-coated cutting wheels for cutting ceramic tiles . These discs usually say “Wet cut”. As practice shows, this tool makes an excellent, smooth cut on tiles with a minimum of chips, even without the use of water, although this produces a lot of fine dust.

A solid diamond blade can also be used on porcelain tiles.

By the way, this wheel can be used not only for ceramics, but also for cutting thick glass.

On tiles, of course, you can use segmented (dry) and turbo discs, but the quality of the cut will be very low, since chips will inevitably form along its edges.

For cutting plastic

Plastic can be cut well with a regular abrasive metal tool. But there is also a special saw blade (three-toothed) designed for cutting wood, plywood and plastic. It can be used not only for cutting, but also for longitudinal cuts of material, especially thick ones.

When installing this tool, it is important to correctly determine the direction of rotation of the angle grinder spindle.

It is not recommended to use circular saws with many teeth on plastic and wood, due to the high probability of the tool kickback, which can lead to injury.

Structural density

The essence of the indicator of the structural density of an abrasive is the ratio of grains to the total volume of the disk, that is, grains and binder. The higher the grit density, the more material can be removed in one pass. Sometimes the lower the density, the better. For example, when sharpening. The disc self-cleans faster and does not overheat due to rapid heat dissipation, protecting the disc from deformation.

Typically the markings look like this:

- dense structure – from 1 to 4;

- average – from 5 to 7;

- open – 8, 9, 10;

- porous – 11, 12.

Ceramic, bakelite and vulcanite binders are usually used as binders. The first is the most common, it is based on sand, clay and quartz. These discs are highly durable, but they are also fragile. It is not recommended to use them for power processing.

Bakelite circles are based on resin. Such discs are highly resistant to temperature changes during operation. Volcanic bond is rarely used and usually in highly specialized areas; it is based on rubber.

Abrasive hardness degree

The hardness indicator is the degree to which the abrasive is retained on the surface of the wheel. There are several varieties of circles, from very soft (VM) to extremely hard (HH). The most universal are the circles of medium hardness, suitable for a wide range of materials, therefore they are usually used in everyday life.

This parameter should be treated with special care, since an incorrectly selected disc wears out faster, can be destroyed during processing, damage the material being processed, or fail to produce results at all, even after several repetitions of grinding.