Painting metal stoves, fireplaces and stoves built of brick is not a problem. Because on the market today you can buy three types of paint and varnish products for these heating devices. It is a fire-resistant paint for metal, heat-resistant and heat-resistant. The last two can also be used for painting brick structures. Let's understand these paints, determine their temperature conditions and application methods.

How to paint a brick oven Source gidkaminov.ru

Classification of paints for fireplaces and stoves

So, the first type is fireproof. It is necessary to note one subtlety associated with this material. Its purpose is to cover metal surfaces that are constantly or temporarily in contact with fire. That is why the operating temperature of such paint is up to 1800 °C.

Therefore, industrial-type equipment or units are painted with it. That is, this paint and varnish material did not find its use in everyday life. Of course, the point here is not only that the temperature in home ovens is much lower. It’s just that such paint is an expensive material.

But heat-resistant, also known as heat-resistant paint, has found its application in everyday life. It is used to paint metal stoves or metal parts of fireplaces and brick stoves. For example, doors and grilles. Depending on the type, these paints can withstand temperatures ranging from 600-1000 °C.

If you need to paint a brick or concrete stove, then it is better to use the third type - heat-resistant paint. It can withstand temperatures well, but not higher than +400 °C. Therefore, it is used to treat the walls of stoves and chimneys.

Heat-resistant enamel for painting stoves Source diy.obi.ru

Rating of the best thermal paints

The list below contains compounds that can easily be found in hardware or specialty stores.

All of them, according to user reviews, are of good quality.

1st place – Alpina Heizkoerper

The paint produced by the German DAW group is made on the basis of alkyd resin with the addition of titanium dioxide. The product is of good quality - it fits tightly, and the resulting coating is scratch-resistant. The price is quite high, but you need a little of this paint due to its insignificant consumption.

The heat-resistant composition Alpina Heizkoerper can be applied to any type of metal from which heating radiators are made: steel, cast iron, aluminum and copper

Main parameters:

- color: white (with the possibility of tinting);

- gloss type: glossy;

- permissible surface temperature (0C): 100;

- type of packaging and volume (l): can (0.75, 2.5);

- country of origin: Germany.

The main purpose is to process elements of a water heating system. The possibility of tinting allows you to create an original color scheme and diversify the interior of the room.

The short-term temperature of a painted object can reach 1800C. The paint can be applied by brush, roller or spray gun to steel, cast iron, aluminum, copper and other metals. Consumption ranges from 90 to 120 ml/m2.

2nd place – Elcon

After the tinting process, Elcon products are available in 250 shades. But pigmentation reduces the maximum temperature that paint can withstand. Thus, classic black enamel retains its properties up to 10000C, copper – up to 7000C, and blue – only up to 6000C.

Using Elcon colored enamels, you can create exclusive custom coloring for radiators, stoves, fireplaces, boilers and barbecues

Main parameters:

- color: black, graphite, gold, copper, etc.;

- gloss type: matte or semi-gloss;

- maximum temperature (0C): 1000 (black), 700 (graphite, gold, copper);

- type of packaging and volume (l): can (0.52), jar (0.8), bucket (25);

- country of origin: Russia.

The presence of a large number of color solutions allows the use of Elcon enamels for complex interior designs. With its help you can create simple patterns using stencils.

In addition to painting metal products, this enamel can protect other types of surfaces - concrete, asbestos or brick. After application and drying, it is necessary to perform a thermal hardening procedure.

3rd place – Tikkurila Termal Silikonimaali

Silicone resin paint from the Finnish company Tikkurila is used to coat metal surfaces.

Small packaging (0.1 liter) is convenient if there is a need to paint a small metal product. No need to think about where and how to store leftover enamel

Main parameters:

- black color;

- gloss type: semi-matte;

- maximum temperature (0C): 400;

- type of packaging and volume (l): can (0.1, 0.33);

- Country of origin: Finland / Russia.

One liter of paint is enough for a single-layer treatment of 16-20 m2 of surface, depending on its roughness. The fine structure of the solution allows you to use the sprayer without the risk of frequent clogging of its nozzle.

The quality of the products is very good, but the price is also high - this is due to the promotion of the brand. The disadvantages include the need for thermal hardening, which must be carried out for 1 hour at a temperature of 2300C.

4th place – Bosny Hi-Temp

This heat-resistant paint from a famous British brand is produced in Thailand. It is distinguished by its volume, which is atypical for Russia, and is characterized by good quality and a slightly high price.

Bosny Hi-Temp aerosol is often used to treat hard-to-reach areas such as car mufflers or metal pipe fittings.

Main parameters:

- color: silver, black;

- gloss type: matte;

- maximum temperature (0C): 650;

- type of packaging and volume (l): can (0.4);

- Country of origin: Thailand.

Made on the basis of alkyd resins, this thermal paint can be used not only for metal, but also for wood, plastic, ceramics and other materials. It adheres well to untreated surfaces, including rusty ones.

5th place – Tikkurila Termal Silikonialumiinimaali

Tikkurila Thermal paint (silicon-aluminum) from a well-known Finnish manufacturer is distinguished by its excellent quality and high price due to the popularity of the brand.

Paint from the advertised Tikkurila brand is aluminum in color. It is used for painting boilers, furnaces and other metal objects exposed to extreme heat.

Main parameters:

- color: aluminum;

- gloss type: semi-gloss;

- maximum temperature (0C): 600;

- type of packaging and volume (l): jar (0.33);

- Country of origin: Finland / Russia.

Heat-resistant paint based on silicone resin, aluminum color with a slight metallic sheen. Its consumption (for one layer) depends on the type of surface being painted and is 16 m2/l for rough areas and 20 m2/l for smooth areas, which is a very good indicator.

To harden the paint, it is necessary to heat the surface to a temperature of 2300C. A month after application, you can clean the painted surface with mild detergents.

6th place – Bosny Hi-Temp (color)

Acrylic-based paint with silicone pigmentation from Bosny has a lower permissible temperature than black or silver. It is characterized by good quality at an average price for products of this class.

Due to the lower permissible temperature, the scope of application of Bosny Hi-Temp color paints is slightly different than that of black or silver composition

Main parameters:

- color: red, orange, yellow, green, blue;

- gloss type: matte;

- maximum temperature (0C): 205;

- type of packaging and volume (l): can (0.4);

- Country of origin: Thailand.

The most common area of application is painting pipes and heating radiators. It is also used for decorative painting of car parts. It dries quickly, does not peel off, but requires thermal hardening. Thus, it is better to paint the batteries a day or two before turning them on.

One can is enough to paint 1.5-2 m2 of surface in 2 layers. In addition to sanding, it is advisable to prime the surface. This will significantly increase its resistance to physical damage.

7th place – Veslee

Heat-resistant, high-quality metal paint on an acrylic-epoxy base is in the middle price range.

Small capacity cylinders (0.1 l) are used for painting automotive parts. To treat the heating system, it is financially more profitable to take a standard volume (0.52 l) packaging

Main parameters:

- color: black, white, red, silver;

- gloss type: matte;

- maximum temperature (0C): 400 (black), 250 (all others);

- type of packaging and volume (l): can (0.1, 0.52);

- Country of origin: China.

The composition is intended for painting heating circuit elements (excluding fireboxes) and automotive parts (mainly the exhaust system). The availability of small-volume cans for sale is a definite plus when you need to paint a surface with a small area.

The paint is quick-drying - the drying interval between layers is 2-3 minutes.

8th place – MagicLine

Spray paint made in China, based on synthetic resin, is located in the middle price range. According to consumer reviews, the temperature indicated on the label is not the maximum allowed for an indefinite period of time, but acceptable for a short-term period.

The most ordinary paint made in China, without any significant pros and cons. Available as an aerosol can

Main parameters:

- black color;

- gloss type: matte;

- maximum temperature (0C): 600;

- type of packaging and volume (l): can (0.4);

- Country of origin: China.

Medium quality products designed for processing metal parts. Not suitable for application to high temperature objects such as the firebox door of a steel oven or hob.

9th place – Thermoxol

Russian-made paint is intended for metal surfaces. It is distinguished by good quality, four main colors, packaging of varying volumes and an average price.

If you need to process a lot of radiators and pipes, then it is better to take paint in buckets - it will be much cheaper

Main parameters:

- color: black, white, red-brown, gray;

- gloss type: glossy;

- maximum temperature (0C): 160;

- type of packaging and volume: jar (0.9), bucket (3, 10, 20);

- country of origin: Russia.

The paint contains formaldehyde resin and an acid thinner, so the area must be well ventilated. It can be used for processing ferrous and non-ferrous metals, as well as alloys. The composition can be applied to tightly adherent rust.

Short-term (up to 5 hours) heat resistance – 2100C. The main purpose is painting heating radiators and pipes.

10th place – Decorix

This enamel can often be found in stores and retail outlets. It has a low price and acceptable quality.

This cheap enamel is best used for painting sauna stoves and other metal products whose appearance is not particularly important.

Main parameters:

- color: white, aluminum, black;

- gloss type: glossy;

- maximum temperature (0C): 800;

- type of packaging and volume (l): can (0.52);

- Country of origin: China.

Decorix enamel is available in the three most popular colors for metal coating. The mass fraction of paint for such a volume is insignificant - only 0.315 kg (usually 0.34 - 0.36 kg).

The sprayer leg is soldered into the can, so if the composition dries out, it will not be possible to replace the mechanism. Therefore, it is better not to leave partially used paint for a long time.

Requirements for paints

Primarily, these compositions were made to decorate heating surfaces. But at the same time, the heating devices and units themselves do not lose their technical and operational characteristics. Therefore, there are special requirements for paint and varnish products of this type. Namely:

- High security . That is, during the heating process, the painted surface should not release substances harmful to humans into the air.

- Thermal conductivity . The paint layer applied to the stove or fireplace should not interfere with the release of heat into the room. That is, the heat exchange between the stove and the air inside the rooms must be sufficient.

- High elasticity of the material . It would be easier to say this: the paint applied to the surface of the stoves should not crack during operation. Especially with temperature changes.

- The material should easily withstand the negative effects of household chemicals . That is, so that painted stoves and fireplaces can be easily washed and cleaned using various detergents. In this case, the surfaces must withstand repeated cleaning.

- Covering power . This indicator should guarantee even application of paint to the surface. It is optimal if there are no more than three layers.

Good hiding power of heat-resistant paints Source orchardo.ru

See also: Catalog of companies that specialize in paints and varnishes and related work

Alkyd heat-resistant coating

Alkyd heat-resistant enamels can withstand heating temperatures up to 150 degrees. Based on this, they can be used for exterior finishing of stoves in places where there is no risk of fire, or indoors for painting radiators.

It is important to consider that alkyd compounds have a pungent, unpleasant odor, so they must be applied to a cooled surface. Among the advantages of this type of thermal coating:

- Can be used on any surface, high level of adhesion;

- service life up to 10 years;

- protection of the surface from external influences.

The alkyd composition should be applied to the surface in two layers so that the color is more uniform. It is convenient to use a brush to work with it, but some manufacturers produce an alkyd aerosol. Although it can be used to quickly paint hard-to-reach places, the material consumption in this case increases significantly.

Types of heat-resistant paints

The range of paints for stoves that domestic and foreign companies offer today is huge. It will satisfy the requirements of even the most capricious buyer. This is especially true for the color palette. That is, in this regard there are practically no restrictions.

As for the types, they are divided depending on the components. Essentially, like any other paint and varnish product. Next, we will consider the classification of heat-resistant paints for brick stoves.

Wide color palette Source uastal.com

Silicon organic

Typically, such paints are used to cover building facades. And they are based on organic resins. But recently, manufacturers have begun to produce heat-resistant analogues for painting stoves and fireplaces. Please note that on containers of such material you can often see the inscription - moderately heat-resistant. They cannot be used for painting heating devices, because such material can withstand temperatures of no more than +100 °C.

Note that today silicon and organic compounds are increasingly being used for finishing heating devices. Firstly, this is the cheapest paint material of all those offered. Secondly, it has excellent characteristics. For example, here are the advantages of this paint:

- excellent heat resistance;

- high elasticity;

- good strength of the film that forms on the brick surface;

- excellent moisture resistance, which makes it possible to use paint to coat sauna stoves;

- excellent adhesion, allowing the material to be applied not only to brickwork, but also to plaster and concrete.

Silicon organic composition for coating the surfaces of stoves and fireplaces Source gidpokraske.ru

Acrylic heat-resistant coating

Acrylic compounds are the safest for treating indoor surfaces. But such materials do not have very good resistance to high temperatures. They usually withstand temperatures up to 100 degrees.

Acrylic compositions are used to coat elements of heating systems, for example, metal radiators, gas boilers. Their advantages include:

- no pungent odor;

- good adhesion to the surface;

- rust protection;

- uniform application, no smudges;

- wide selection of colors;

- resistance to moisture and dust.

Apply acrylic heat-resistant finishing materials to degreased and dry surfaces using a brush. Since they dry very quickly, it is better to do this on a cold surface.

Metal paints

Let’s immediately make a reservation that heat-resistant paint for metal stoves is not used for painting brick. But their classification is exactly the same. And they are made on the basis of the above compositions. True, there are other varieties:

- epoxy , which can be used for painting metal products heated to +200 °C;

- single-component ethyl silicate and epoxy ester , withstand temperatures up to +400 °C;

- silicone one-component – withstands up to +650 °C;

- compositions to which liquid glass or composite materials are added , they can withstand temperatures up to +1000 °C.

Heat-resistant silicone paint, black Source gdematerial.ru

Do-it-yourself thermal paint, can it be done and how?

You can make heat-resistant paint yourself. The best option would be to prepare it from liquid glass and aluminum powder. The main thing is to understand that after the first fire, strong smoke may appear; the shelf life of such a coating is up to five years.

You can also use heat-resistant varnish; aluminum powder is added to it to obtain the desired effect. This option can withstand up to 350 degrees, and receives an anti-corrosion coating. Making paints is not difficult, the main thing is to get the necessary ingredients.

You can use heat-resistant varnish; aluminum powder is added to it to obtain the desired effect.

High-temperature paints and varnishes for metal make it possible to create a reliable coating against various influences. Metal products will be protected from corrosion and the harmful effects of elevated temperatures, which will extend the shelf life of the product itself. There are different types of similar materials on sale; when choosing, it is important to pay attention to the purpose of the paints. The dyeing process itself is easy, you can do it yourself, the main thing is not to neglect the preparatory work. If you wish, you can prepare the composition with your own hands; the recipe was described in the article.

Rules for applying paint

There are no special requirements for painting bricks and metal. With brick surfaces everything is quite simple. They are dusted off and painted using either a brush, a roller, or a spray gun. It is better to use the first two tools; the layer of applied material will be thicker and, accordingly, stronger.

As for metal furnaces, manufacturers offer paints that do not require preliminary preparation of the metal. But for some varieties, preparation is still needed. Namely:

- rust is removed, if any;

- the metal surface is cleaned from dirt;

- degreasing is carried out using a solvent: gasoline, white spirit, etc.

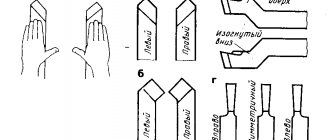

As for the painting process itself, in some cases one layer is enough. If they fail to paint well, then apply a second layer. Only it is applied in a perpendicular direction relative to the first one.

Attention! Before painting, it is recommended to study the instructions for use from the manufacturer. Here you will find useful information about the temperature at which the paint should be applied, in what conditions the painted product should dry, how much time should be left between applying layers of material, and so on.

Features of painting a metal stove

To get maximum efficiency from using high temperature paint, the painting process should be carried out according to the rules. First of all, study the instructions on the package. And then the metal stove is prepared, and only then proceed to painting.

To get maximum efficiency from using high temperature paint, the painting process should be carried out according to the rules.

Can or spray can - what to choose

Heat-resistant paints are produced in the following packaging:

- aerosols (sprays) in 400-500 ml cans (very convenient to apply by spray);

- liquid paint, packaged in cans from 1 kg, in buckets of 20, 25 and 30 kg and in drums from 40 kg.

Aerosol paint is available in spray cans.

Advantages of aerosol paints:

- When painting, it is evenly distributed over the surface.

- Spray cans are convenient for working in hard-to-reach places.

- The paint does not need to be diluted and there is no need to wash the tools after work.

- The cans are easy to use and can be painted by a person even without painting experience.

- Aerosol paint will never thicken, so you can reuse it even after a long time.

Paint packaged in buckets and jars quickly thickens and becomes covered with a film, so it cannot be stored for a long time. But if you need to paint a large surface, buying a can is the preferable option.

Other barbecue processing options

An alternative treatment option is chemical oxidation. This is a rather complex process, and it is often done in factories in specialized baths, especially if you do not have a large collapsible grill.

Chrome grill

First, the grill is cleaned. Then a sulfuric acid solution is used to completely remove the oxides. Then a solution is made, where laundry soap is added and the product is boiled. And only then does oxidation itself occur. At a temperature of 140°C in a sodium solution, place the grill itself for an hour and a half.

Colors - what they are, what to choose

The most common heat-resistant paints are black and silver. But there are any other color options. They are usually a little more expensive.

A stove painted in a dark color will warm up faster than a light one, so if heating speed is a factor for you, use dark paint, if possible matte, as it transfers heat better. But if you want a beautiful, cheerful and shiny fireplace, feel free to paint it in red gloss - it will also be good!

The importance of anti-corrosion treatment

Without anti-corrosion coatings, industrial, construction and even household technological facilities, pipelines, equipment and structures are exposed to the negative effects of the sun, solar radiation, air oxygen, rain and snow. Oxygen contained in the atmosphere, together with moisture, destroys metals, concrete and mineral building materials, and temperature changes and ultraviolet radiation accelerate corrosion processes.

Corrosion, affecting materials, makes them more fragile, which is why structures can collapse, pipelines can break, leak, equipment can fail. This entails not only financial losses, but also worsens living conditions and even poses a threat to its safety. Anti-corrosion compounds are designed to solve these problems.

Anti-corrosion coatings prevent oxygen and water from oxidizing metals. As a result, thinner and more fragile areas do not form inside pipes, tanks and equipment. Protective compounds also prevent sediment from settling inside containers, which maintains throughput and extends the life of pipelines and machines that handle liquids.

Moisture contained in the atmosphere penetrates through the pores of concrete and other mineral building materials. When it freezes, it crystallizes, which leads to the appearance of cracks. Gradual destruction occurs even without exposure to low temperatures. The consequences of these processes are also eliminated by anti-corrosion compounds.

Corrosion protection allows:

- reduce the frequency of maintenance;

- improve safety;

- give surfaces a more aesthetic appearance.

eliminate the costs of repairs, restoration work, replacement of equipment or structures;

As a result, the service life of structures, pipelines, equipment and surfaces is significantly increased.

Matte or glossy, enamel or paint - what are the differences, what to prefer

The protective properties of paint do not depend on its type - matte or glossy. This is purely a matter of taste. Some buyers think that glossy ones look nicer.

Others prefer matte ones, which look better on uneven surfaces and mask imperfections well. After painting the stove with heat-resistant enamel, a hard, opaque film forms on the surface to be painted. It will perfectly protect against high humidity, but it will not protect against exposure to open fire.

Heat-resistant enamels as opposed to paints:

- more elastic;

- create a more durable coating;

- have the best decorative properties;

- Can be applied to surfaces even at sub-zero temperatures.

However, if there is a risk of fire, if it is important to prevent the possibility of fire spreading through painted structures, use heat-resistant paints.

Sequence of actions when painting

The very first thing to do is dry the surface so that it is completely dry. It should also be free of dust, oil or any other debris. If the grill is already painted and the paint is peeling off, or you think it needs to be removed, use a drill with a special attachment or just sandpaper. A wire brush will also work.

The next thing to do is treat the surface with a solvent to degrease it. The paint itself must be mixed thoroughly so that there are no lumps. Then apply some paint and see if it is the right thickness. If the degree of thickness is high, add a little solvent there. There are several painting options:

- Roller or brush;

- Complete immersion in paint in a larger container;

- Use a spray paint.

In any case, the painting method depends on the design, size and condition of the grill, so that the grill is completely painted.