According to Wood Mackenzie, copper use will increase in three energy-related sectors due to the replacement of traditional and energy-intensive technologies with energy-saving and clean energy generation technologies. Renewable energy, electric vehicles and energy-efficient equipment are recognized as key components of the clean energy transition. All of these sectors offer significant opportunities for future growth in copper consumption. According to CRU analysts, global consumption of refined copper in 2023 will exceed 26 million tons, which is 10% higher than the result of 2022. At the same time, a deficit of approximately 245 thousand tons is predicted. In such conditions, Russian mining and metallurgical companies specializing in the extraction and production of copper have a chance to strengthen their positions in the international market: possessing the fourth largest metal reserves in the world, Russia ranks third in the top ten countries in terms of copper production.

Content:

The Russian metallurgical complex is a vast industry that includes enterprises that smelt ferrous and non-ferrous metals.

The latter occupies a very important place in the economy of our country. Today we have several centers of non-ferrous metallurgy, which extract and enrich non-ferrous ores, rare and precious metals. Non-ferrous metallurgy deals with several types of metals - these are basic or so-called heavy. These include copper, light, small, alloying, noble, rare and scattered.

Let's take a closer look at copper production. Copper production centers are concentrated in different regions of our country. The location of such enterprises is determined by a number of factors, among which it should be noted:

- raw materials;

- energy and fuel factor;

- consumers.

Metallurgy in the North-West region of Russia

The North-Western region is rightfully one of the largest industrial centers of the republic. And it is no coincidence that the metallurgical industry occupies 2nd place in the total volume of industrial output. It was the capabilities of metallurgy that determined the degree of development of mechanical engineering and other types of industrial production.

St. Petersburg, the educational, innovative and industrial core of the region, plays a special role in the development of metallurgy.

Metallurgy is characterized by the consolidation of industrial zones. Large metallurgical plants operate in the Leningrad, Vologda, Novgorod regions, Karelia, the Komi Republic, the cities of Cherepovets, Olenegorsk, Kandalaksha. Most of the metallurgical products produced are exported. It contains not only rolled steel, but also a wide range of non-ferrous metals: aluminum, copper, nickel, tin, gold.

The limiting factor in the development of metallurgy is the insufficient pace of development of mechanical engineering and, as a consequence, slow technical re-equipment.

It is necessary to accelerate the introduction of energy and resource-saving technologies, otherwise, the products of foreign manufacturers will gradually dominate the domestic market. The development of the metallurgical industry requires comprehensive measures: such as closer cooperation with the banking sector, active introduction of innovative leasing equipment, accelerated development of research and development, and the use of tax incentives at the government level.

In addition, more attention needs to be paid to the development of enterprises in the coal, chemical and energy industries.

These recommendations are applicable in almost all regions of Russia.

The strategic development of basic industries, of course, requires a government approach similar to the adopted national projects.

The main copper centers of Russia.

Copper ore in our country is mined in different regions. The richest ore deposits are located in Kazakhstan, although copper is also mined in other areas, for example, there are rich deposits in the Urals. It is worth noting that Russia today ranks first in the world in copper ore mining.

The main centers of copper production are located in the Urals. This region ranks first in copper production.

Copper plants are most often located near mines. The raw material factor is key due to the low content of concentrates in the raw materials. Today, copper producers widely use copper pyrites, mined in deposits located in different regions of the Urals, as raw materials. Therefore, copper production enterprises are also concentrated in this region, although they also use imported Kazakh ores in their activities. This industry also has its own raw material reserve in the form of cuprous sandstones, which are located in Eastern Siberia.

Chern copper in the Urals is produced by such enterprises as Sredneuralsky, Kirovograd, Krasnouralsky (“Svyatogor”), Mednogorsky and Karabash plants. The Verkhnepymensky and Kyshtymsky plants are engaged in refining copper.

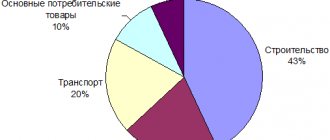

In total, there are 11 copper enterprises in the Urals, which produce 43 percent of all copper in Russia.

Enterprises of the Urals are also characterized by waste disposal. Thus, factories in cities such as Revda, Kirovograd and Krasnouralsk use sulfur dioxide gases generated during production to produce sulfuric acid, which is subsequently used for the production of fertilizers.

Large centers of copper production are located not only in the Urals, but also in other regions of the country. The table shows where the raw material and industry centers are located.

Refining.

Almost all blister copper is refined sequentially by two methods - fire (pyrometallurgical) and electrolytic. Fire refining in reverberatory furnaces removes impurities Fe, Zn, Co, Ni and sulfur in the form of oxides from blister copper, and then dissolved gases, after which the copper is deoxidized. Previously, to remove dissolved gases from copper and restore Cu2O, raw wooden poles were immersed in the metal bath, the wood of which emits gaseous hydrocarbons that vigorously stir the melt. Now raw wood is being replaced by natural gas, oil-steam mixtures, and hydrocarbon by-products of other industries. After fire refining, the copper is fed to casting machines to cast anodes - square plates with ears for hanging in the electrolyzer. The anodes are placed in baths with an acidified copper sulfate solution. The cathode is a thin sheet of pure copper. During electrolysis, copper and other base metals (iron, zinc, lead and nickel) dissolve, leaving a slurry of silver, gold and platinum at the anode. The difference in electrical potential between copper and other basic impurity metals is large enough for copper in an acidic solution to be selectively deposited on the cathode with a purity of about 99.9%.

Sredneuralsky plant: characteristics.

As mentioned above, the Sredneuralsk Copper Plant (SUMZ) is one of the main copper smelting centers in our country. This plant is located in the city of Revda, in the Sverdlovsk region. SUMZ belongs to the Ural Mining and Metallurgical Company, and is also a member of the regional industrial chamber.

At SUMZ, copper is smelted from primary raw materials, which are taken from the Degtyarskoye deposit.

The Sredneuralsk Copper Smelter has a large copper smelting workshop, an enrichment plant, as well as xanthate and sulfuric acid workshops. The plant also has a number of auxiliary enterprises that serve the needs of the copper smelter.

SUMZ produces about one hundred tons of blister copper annually. Copper concentrates at this plant are processed by firing in fluidized bed furnaces, and the method of converting and reflective smelting of the cinder is also used.

The products of the Serdneuralsk plant are supplied to all large Russian enterprises operating in the metallurgical, mining and chemical industries and located in different regions of the country, as well as abroad.

No harm

has been part of RMK since 2004. At that time, the enterprise and the city were in decline: outdated equipment, accumulated environmental and social problems turned Karabash into an unattractive territory from the point of view of investment. However, the regional authorities managed to convince the company management to save and revive the city-forming plant.

Over the past 15 years, RMK has allocated over 20 billion rubles for the development of Karabashmed. Comprehensive modernization took place at all technological stages. Along with increased productivity, it ensured an increase in the environmental safety of the enterprise. Outdated shaft furnaces were replaced with a modern high-performance copper smelting furnace Ausmelt, powerful gas purification systems were installed to effectively capture metallurgical gases, and a sulfuric acid workshop was built to utilize the gases. To reduce the volume of industrial waste generated, a processing plant was built to process metallurgical slag with the production of copper concentrate and construction sand. In addition, a closed water circulation cycle has been organized and a modern industrial wastewater treatment plant has been built.

The complex of implemented projects and activities made it possible to reduce emissions by more than 20 times compared to 2000 levels.

The results achieved in the field of improving the environmental safety of production made it possible and expedient to take measures to eliminate the environmental damage accumulated in the 20th century. They decided to start with the reclamation of ownerless tailings of the former copper smelter. Thus, this fall the company presented to the public a five-year project for the reclamation of one of these sites with an area of 45 hectares. A similar facility adjacent to the plant site was previously reclaimed and today there are green lawns in its place.

Kirovograd copper smelting plant: characteristics.

Another large copper smelting enterprise in the Urals is the Kirovograd plant. It is engaged in the processing of copper and copper-zinc ores, as well as their mining.

The plant began its activities in 1957, it was created on the basis of a copper smelting plant and a number of other small enterprises. Today the plant is a member of Tyazhtsvetmet LLP.

The plant in Kirovograd operates in several directions - mining, processing, beneficiation of ores containing copper, smelting copper from raw materials, both primary and secondary. The plant also processes metallurgical dust, gold concentrates, scrap and waste that contains copper and other metals.

In 2008, the plant in Kirovograd produced almost seventy thousand tons of blister copper, which was sent to various enterprises in our country.

Metallurgy in the Siberian region

Compared to other regions of the country, Siberian metallurgy is the youngest. However, thanks to rich reserves of iron ores, coal, cheap energy and intensive development, about 20% of all Russian pig iron is produced in Siberia. The foundation of Siberian metallurgy is formed by the West Siberian plant operating in Kuzbass and the Novokuznetsk metallurgical plant.

Non-ferrous metallurgy is not far behind, although its share in total industrial production is only about 10%. In the industrial region formed on the basis of Norilsk, the production of nickel, cobalt, copper, and platinum group metals has been launched.

Global demand for zinc is growing steadily, which contributes to the development of lead-zinc ores in the Krasnoyarsk Territory.

The most important component of the non-ferrous metallurgy of Siberia is the production of aluminum at plants in Irkutsk, Bratsk, Krasnoyarsk, Sayanogorsk. Their capacity allows them to produce over four and a half million tons of aluminum per year. A large share of non-ferrous metallurgy products is exported.

In terms of development plans, Siberian metallurgy has great prospects compared to other regions. Development is hindered only by the relative territorial remoteness of Siberia and the insufficient development of transport infrastructure.

Name the major copper production centers in Russia.

They are mainly located in the Urals. Chern copper in the Urals is produced by such enterprises as Sredneuralsky, Kirovograd, Krasnouralsky (“Svyatogor”), Mednogorsky and Karabash plants. The Verkhnepymensky and Kyshtymsky plants are engaged in refining copper. In total, there are 11 copper enterprises in the Urals, which produce 43 percent of all copper in Russia.

There is also the Norilsk copper deposit, a production complex for smelting copper from nickel ores in Monchegorsk, and the leader in copper reserves is Kazakhstan.

Sredneuralsky plant.

Sredneuralsky Copper Plant (SUMZ) is one of the main copper smelting centers in our country. This plant is located in the city of Revda, in the Sverdlovsk region. SUMZ belongs to the Ural Mining and Metallurgical Company, and is also a member of the regional industrial chamber.

At SUMZ, copper is smelted from primary raw materials, which are taken from the Degtyarskoye deposit.

The Sredneuralsk Copper Smelter has a large copper smelting workshop, an enrichment plant, as well as xanthate and sulfuric acid workshops. The plant also has a number of auxiliary enterprises that serve the needs of the copper smelter.

TOP 10 copper producing countries

The Russian metallurgical complex is a vast industry that includes enterprises that smelt ferrous and non-ferrous metals. The latter occupies a very important place in the economy of our country. Today we have several centers of non-ferrous metallurgy, which extract and enrich non-ferrous ores, rare and precious metals.

Wood slime can usually be found near copper mines and is protected from legislation as an ancient monument. Underground and surface mining methods were used to extract the ore. The main underground methods that were used were horizontal successive pieces or levels followed by roof falling as top cutting and basement trimming, or filling voids with stone filling or hydraulic filling as cut, fill and cross cut.

The main surface method was the closed bench method, primarily due to the topography of the mountainous areas. Initially the work was done by hand, but gradually the underground mines were partially mechanized by pneumatic and electric machines such as jackhammers, scrapers, forklifts and locomotives. Surface mining took place with wagons, bulldozers, loaders and tracks, which they gradually upgraded.

Non-ferrous metallurgy deals with several types of metals - these are basic or so-called heavy. These include copper, light, small, alloying, noble, rare and scattered.

Let's take a closer look at copper production. Copper production centers are concentrated in different regions of our country. The location of such enterprises is determined by a number of factors, among which it should be noted:

Today there are about 25 abandoned sulphide mines near Troodos Mountain. Some of the mines are partially restored for access purposes, preventing acid drainage and reducing visual impairment. Several copper mines have been restored or are under restoration by landowners to reuse their land.

It is very interesting to note that this intensive mining has not stopped Cyprus from becoming a significant tourist destination. In contrast, the proceeds from mines were used to develop tourism, and the mines became a source of inspiration for many people to develop new types of tourism, such as geoscience sites and museums or sites for heritage exhibitions. Mining areas can also be developed into tourist areas, such as excursion areas or country clubs and golf courses.

- raw materials;

- energy and fuel factor;

- consumers.

The main copper centers of Russia.

Copper ore in our country is mined in different regions. The richest ore deposits are located in Kazakhstan, although copper is also mined in other areas, for example, there are rich deposits in the Urals. It is worth noting that Russia today ranks first in the world in copper ore mining.

Copper deposit Treasure in Luzhatia

Geologists have known about two million tons of copper in the soil near Cottbus for decades. Now metal must be extracted from thousands of tunnels. The treasure map has been around for a long time. However, no one tried to lift the treasure at the bottom. It is hidden deep in the earth. There is no copper mined in Germany yet. Now the treasure must be removed. Three were used to raise the Lugat copper. The two defeated applicants have until May to sue for the decision. However, since they have already failed twice with controversy, their chances are slim. Eight million tons of rocks are mined annually in Lužatia.

The main centers of copper production are located in the Urals. This region ranks first in copper production.

Copper plants are most often located near mines. The raw material factor is key due to the low content of concentrates in the raw materials. Today, copper producers widely use copper pyrites, mined in deposits located in different regions of the Urals, as raw materials. Therefore, copper production enterprises are also concentrated in this region, although they also use imported Kazakh ores in their activities. This industry also has its own raw material reserve in the form of cuprous sandstones, which are located in Eastern Siberia.

World copper market

Therefore, copper production enterprises are also concentrated in this region, although they also use imported Kazakh ores in their activities.

This industry also has its own raw material reserve in the form of cuprous sandstones, which are located in Eastern Siberia.

Chern copper in the Urals is produced by such enterprises as Sredneuralsky, Kirovograd, Krasnouralsky (“Svyatogor”), Mednogorsky and Karabash plants. The Verkhnepymensky and Kyshtymsky plants are engaged in refining copper.

In total, there are 11 copper enterprises in the Urals, which produce 43 percent of all copper in Russia.

Enterprises of the Urals are also characterized by waste disposal. Thus, factories in cities such as Revda, Kirovograd and Krasnouralsk use sulfur dioxide gases generated during production to produce sulfuric acid, which is subsequently used for the production of fertilizers.

Large centers of copper production are located not only in the Urals, but also in other regions of the country. The table shows where the raw material and industry centers are located.

Melting.

The concentrate, to which sand or calcium carbonate has been added, is heated until it melts. In this case, part of the iron is removed in the form of iron silicate, and sulfur is partially oxidized into sulfur oxide. The molten copper matte is collected on the hearth of the furnace; it is poured into a barrel-shaped cylindrical converter with a side row of tuyeres and purged with air. Upon completion of the process, metallic copper, formed as a result of sulfur oxidation (Cu2S + O2® 2Cu + SO2), is poured into molds. When this blister copper (with a Cu concentration of ~98%) is cooled, dissolved sulfur dioxide is released from it, so its surface has a bubbly appearance. Sulfur dioxide released during smelting and converting processes is captured and converted into sulfuric acid, which is either sold or used to leach oxide ores from rock dumps.

Sredneuralsky plant: characteristics.

As mentioned above, the Sredneuralsk Copper Plant (SUMZ) is one of the main copper smelting centers in our country. This plant is located in the city of Revda, in the Sverdlovsk region. SUMZ belongs to the Ural Mining and Metallurgical Company, and is also a member of the regional industrial chamber.

Copper deposits and mining

But before you start mining, the substrate will need to be examined more closely. With further drilling and sound waves, the best production sites should be explored by next year. According to von der Linden, 700 million euros will be invested in the construction of the mine. The operating company hopes to promote copper worth at least €300 million per year for 20 years. Shiny metal plates emerge from the black rubble. The copper sheets from the dining table, each weighing more than 100 kilograms, are eventually sold to industry. It is much more common in jewelry making than copper. Often you think about magnetic bracelets made of copper, which are supposed to have a healing effect. However, many people know that copper is also used as a material.

At SUMZ, copper is smelted from primary raw materials, which are taken from the Degtyarskoye deposit.

The Sredneuralsk Copper Smelter has a large copper smelting workshop, an enrichment plant, as well as xanthate and sulfuric acid workshops. The plant also has a number of auxiliary enterprises that serve the needs of the copper smelter.

Everyone will get it

So far, the company's main raw material base is concentrated primarily in the Chelyabinsk region. To ensure the utilization of basic metallurgical capacities, which also operate in the region, RMK is developing several mining projects at once. These are the Mikheevsky Mining and Processing Plant and the Alexandrinskaya Mining Company. In addition, the Tominsky GOK is in the active phase of construction.

Over 15 years, the company has invested more than 155 billion rubles in the construction of new and technical development of existing enterprises in the Southern Urals. One of the largest projects already implemented is the development of the Mikheevskoye copper deposit and the construction of a mining and processing plant on its basis. The deposit was discovered back in the 1980s. But despite the impressive reserves, until recently it remained without the attention of investors: the whole point is the low content of the useful component in the ore, which made mining unprofitable using existing technologies. But RMK managed to select the technology and the most advanced equipment.

As a result, in 2014, the Mikheevsky GOK produced the first batch of copper concentrate. The enterprise has become the largest project for the extraction and enrichment of copper ore in the post-Soviet space.

The Tominsky GOK will surpass Mikheevsky in its scale. The processing capacity here will be 28 million tons of ore per year, productivity - about 500 thousand tons of copper concentrate per year. As a result, the company will be guaranteed to be provided with raw materials for the long term. At the same time, RMK will be able to supply concentrate to third-party consumers in Russia, who, due to a shortage, are forced to import raw materials.

[edit] Production

: Copper production in Russia

There are only four notable producers of refined copper in Russia - Norilsk Nickel, Uralelectromed (part of the UMMC holding), Kyshtym Copper Electrolyte Plant and Novgorod Metallurgical Plant (owned by the Russian Copper Company). Norilsk Nickel is the leader in terms of copper production, producing a total of almost 50% of this metal in our country. The growth of this production in 2005 was (according to the company) 1.1% compared to 2004. The volume of copper production in 2005 at MMC Norilsk Nickel almost coincides with 2003 and is inferior to 2002.[1]

The largest copper producers in Russia (according to 2005 data):[2]

- Norilsk Nickel - 452 thousand tons

- Uralelectromed - 353 thousand tons

- Kyshtym Copper Electrolyte Plant - 82.6 thousand tons

In total, 861 thousand tons of copper were produced in Russia in 2002, in 2003 - 855 thousand tons, in 2004 - 909 thousand tons, in 2005 - 929 thousand tons.[3]

Kirovograd copper smelting plant: characteristics.

Another large copper smelting enterprise in the Urals is the Kirovograd plant. It is engaged in the processing of copper and copper-zinc ores, as well as their mining.

The plant began its activities in 1957, it was created on the basis of a copper smelting plant and a number of other small enterprises. Today the plant is a member of Tyazhtsvetmet LLP.

During the Bronze Age, after the Copper Age, copper was used primarily for alloys, especially with other metals such as tin and lead. These alloys were more stable and harder than metals alone. The most famous alloy is copper and tin brass with a golden yellow color. Copper has excellent fusible properties and is therefore particularly suitable for the manufacture of alloys of all types. In addition, once melted, it combines well with other molten metals, which can further enhance the quality of the alloy.

Where did copper get its name?

In ancient times, especially in Cyprus, copper was mined and then associated as a type of ore.

Application.

Copper has a unique combination of properties that have ensured its widespread use - high electrical and thermal conductivity, good corrosion resistance, high ductility and an attractive natural color. More than 70% of all copper consumed goes to electrical products, 15% to elements of building structures, 5% to parts of machines and mechanisms, 4% to transport structures and 4% to other types of products, including the manufacture of artillery weapons. . The construction industry consumes about 40% of all copper produced, electrical engineering and electronics about 26%, general engineering - about 14%, transport engineering - about 11%, consumer goods industry - the remaining 9%. Cables, electrical busbars, transformer windings and other electrical products are made from different types of copper. In cases where maximum electrical conductivity is required, “oxygen-free copper with high electrical conductivity” is used; in other cases, “technically pure” copper containing 0.02–0.04% oxygen is suitable. A small addition of arsenic increases the strength of red copper (a product of fire refining), but such copper, which contains oxygen, is difficult to weld. Copper with a reduced oxygen content has good casting properties and is used for the manufacture of chemical-technological equipment, copper pipes, automobile radiators, ship condensers, household water pipes, roofing material and other technical products.

Copper alloys are a group of common alloys whose properties vary widely. Some copper alloys containing cadmium, chromium, silver or tellurium have high strength with high processability and good electrical conductivity. The most famous and widely used copper alloys are brass (alloys with zinc) and bronze (alloys with tin).