Mechanical processing of metal is a physical impact on a metal workpiece in order to obtain a product of the desired geometry with the desired surface quality. You can influence the workpiece using a cutting tool (drill, cutter, cutter, etc.) or using pressure or impact. It is on this principle that mechanical processing of products is divided into two main groups - operations performed without removing and with removal of metal. In the first case, this is pressing, rolling, forging (for non-ferrous metals) and stamping (usually for ferrous metals). In the second case, this is the mechanical processing of parts on machines - cutting. This group includes the following operations:

- turning;

- milling;

- grinding;

- drilling;

- countersinking;

- deployment;

- planing;

- stretching;

- chiselling.

Basic processing methods

The basics of metalworking are necessary for any novice craftsman and foundry worker to know. Knowing how certain metals behave under different processing methods, you can avoid mistakes when carrying out the technological process.

Modern metalworking includes several main areas of processing:

- Electric. Using this method, you can make holes in metal sheets for sharpening tools and working with hard types of steel.

- Mechanical. An extensive group of methods for processing metal workpieces. They are processed using special equipment.

- Chemical. Creating an artificial chemical reaction using acids, alkalis and other components.

- Working with pressure. In order not to violate the integrity of the workpiece and change its shape, equipment is used that creates powerful pressure. To change the shape of a workpiece made of hard steel, the material is initially heated.

- Thermal. To improve the technical characteristics of the material, various methods of temperature processing of workpieces are used.

Metalworking technology is developing and improving every year. New equipment and options for working with metals are emerging.

What determines the type of processing?

Types of metalworking involve different ways of working with metals. Each method is selected depending on the hardness of the material and its other characteristics. This is also influenced by what needs to be done with the workpiece. For example, heat treatment is used to change the technical characteristics of a material. To change the shape of the workpiece, a mechanical method or injection pressure equipment can be used.

Importance of processing in the food industry

Compliance with the rules of food processing is of great physiological, sanitary, hygienic, and epidemiological importance. Food industry enterprises are constantly inspected by regulatory authorities.

Violation of food processing rules can lead to mass poisoning, diseases of the gastrointestinal tract, etc.

In addition, in the process of food processing, its taste characteristics improve, nutritional value changes, and hazardous factors are eliminated. Food has a pleasant smell and taste, which promotes the active functioning of the gastrointestinal tract. Thanks to this, people buy and consume more food.

Electrical processing

Metalworking technology using electric charges involves processing the material using special equipment. They partially destroy metal workpieces.

Technological process:

- A high voltage is applied to an electrode made of graphite or brass.

- It comes into contact with the surface being treated.

- A spark appears and the metal begins to melt.

To prevent metal particles from scattering, special oil is poured into the space remaining between the electrode and the surface being treated. It traps metal particles.

Mechanical restoration

There are various types of mechanical processing of metals. This is the largest group of material processing methods that use special tools and equipment. Mechanical force allows you to remove a layer of metal from the workpiece.

Mechanical restoration

Drilling and turning

Drilling is the processing of metals using special equipment. Drilling technology is divided into several stages:

- The workpiece is secured to the work table using clamps or a vice.

- An accessory is fixed in the working tool chuck - a drill or a sword for cutting threads.

- After turning on the electric motor, the spindle spins the chuck. The equipment makes a hole of the required diameter in a metal workpiece.

When choosing equipment, it is necessary to take into account the characteristics of the material being processed. Drills can withstand different loads.

Another common type of metal machining is turning. Using this technological process, cylindrical and cone-shaped parts are created. Drilling method:

- The workpiece is fixed in a movable spindle.

- After turning on the engine, it spins the workpiece.

- The master brings the cutters to remove the layer of metal.

The classic principle of working with the drilling method is used when working with lathes. Using such equipment, you can make internal and external threads, as well as change the shape of the workpiece. Various cutters are used for this. To avoid harm to your health, you must use safety glasses.

Grinding and milling

Another popular method of metal processing is milling. It looks like drilling. Using a cutter, you can make various recesses in metal surfaces, create threads, and process the ends of workpieces. When the spindle rotates, the equipment removes a layer of metal.

Abrasive materials are also used in the processing of metal and wood. The coated circle is fixed on a movable shaft, which is spun by an electric motor. The type of processing depends on the choice of abrasive fraction. To clean a surface from a thick layer of rust or metal, you need to use abrasive wheels with large particles. A fine fraction is suitable for finishing work.

Grinding processing

Equipment used

Mechanical processing is used at specialized enterprises provided with a sufficient amount of production space and the necessary equipment.

To remove surface layers, the product is processed on a lathe and milling machines. The most popular among them are:

- CNC turning centers;

- vertical milling machines.

New models of working fixtures make it possible to maintain high geometry accuracy and surface roughness.

Equipment that allows you to process material mechanically is available in a wide variety. Each enterprise independently decides on the need to purchase a particular device. For example, some industries have rotary machines capable of processing products up to 9 meters in diameter.

The standard equipment that is equipped with any enterprise that processes metal products mechanically includes the following devices:

- milling;

- gear hobbing;

- radial drilling;

- horizontal drilling;

- vertical drilling.

Pressure treatment

If mechanical types of metal processing are not suitable and it is necessary to maintain the integrity of the workpiece, craftsmen can use equipment that works with pressure. Technological processes in this case are divided into two groups:

- Stamping. This method uses two key elements - a punch and a die. The workpiece being processed is placed between these parts. Then, with the help of force, it moves. The workpiece takes the form of a matrix. There is hot and cold stamping. In the first option, the part is initially heated.

- Forging. In ancient times, blacksmiths forged weapons and armor. To do this, the workpiece was heated in a forge, and after that it was struck with a hammer. This changes the structure of the material and improves its characteristics.

Nowadays, forging uses pneumatic hammers and industrial furnaces.

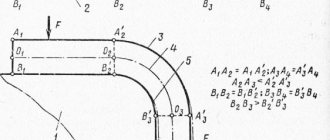

Metal planing cutting

Scheme of a longitudinal planing machine for metal

Processing of metal by cutting in a planing method involves removing the top layers of the surface of the part that is being processed. This type of processing involves the use of specialized machines:

Cross-planing machine You can machine blind and through shaped holes by chiselling

- planing-slotting;

- cross and longitudinal sections;

- edge planers.

The machines differ in the way the cutting mechanism moves, in productivity, and in the quality of metal processing.

A special feature of planing installations is the use of only straight planing cutters; they are installed at short overhangs, since they are not vibration resistant, but are quite simple to operate.

The disadvantage of such cutters is the impossibility of obtaining the most accurate cutting results. To eliminate this drawback, some machines have the ability to mount several cutters.

When working with planing machines, it is important to take into account that the cutting parts are quite powerful and are capable of plunging into the metal to a great depth from the first press, which can damage the product.

Chemical treatment

To understand how chemicals affect the workpiece, you need to know how to process the metal. Chemicals are used to clean metal surfaces from rust and dirt. Also using a galvanic process to apply a protective coating to the workpiece. Chemicals improve resistance to corrosion processes. There are several methods for treating material with chemicals:

- Cementation - the metal is saturated with carbon.

- Boriding - when a material is saturated with boron, its wear resistance increases.

- Chrome plating - only the top layers of metal are saturated with chromium. Resistance to corrosion processes increases, but strength does not change.

- Nitriding is used to increase the resistance of metal to moisture and mechanical damage.

The materials can also be coated with a protective layer of aluminum.

Heat treatment

Metal processing technology using increased temperature is used to improve the characteristics of the material. In addition to proper heating, the part must be cooled at a certain speed. Heat treatment is divided into several operations.

Heat treatment of metal

Annealing

To improve ductility and malleability, an annealing process is applied to the workpiece. Its essence is to heat the material to a certain temperature and then leave it to cool in the oven. This process is most often carried out after casting. This way internal tension is relieved.

Hardening

First of all, the material is heated to the melting point. Then it is kept in this state for a certain period of time. During this time, the structure of the material changes. It becomes stronger. After heating, the workpiece is immersed in water or oil for rapid cooling. Metal processing by hardening is carried out in order to increase the hardness of the material. However, this reduces its viscosity and increases fragility.

Vacation

This technological process is performed after hardening. During tempering, the material is heated to a certain temperature and then slowly cooled. The fragility of the part is reduced.

Aging

It is considered one of the ways to decorate material. The workpiece is slowly heated to a certain temperature. After this technological process, the metal changes to such a visual state as if it had aged for a long time under natural conditions.

Normalization

To increase the malleability of the material without compromising the hardness index, the workpiece is normalized. During this process, the metal takes on a fine-grained structure.

General overview of the types of processing of machine parts used

Manufacturability of the design of machines and parts

1 Manufacturing of machine parts blanks is carried out:

a) casting metals in various ways: in earthen molds, in metal molds (molds), centrifugally, under pressure, investment casting (precision casting), in shell (crust) molds, by vacuum suction (casting of non-ferrous alloys);

b) processing of metals by pressure (plastic deformation), forging, stamping (hot and cold), pressing (extrusion), rolling, drawing,

c) plastic molding;

d) stamping of plastics.

2 Processing of blanks of machine parts by mechanical methods:

a) removing chips - cutting metal with blade tools and abrasives on metal-cutting machines;

b) plastic deformation (without removing chips) - metal compaction; rolling and rolling with rollers, punching - calibration of holes with a ball or mandrel; rolling (to obtain a corrugated surface);

c) cold straightening of metal parts;

d) shot blasting of metal parts, which consists of subjecting heat-treated parts in special installations to the impact of a stream of steel or cast iron shot ejected by a mechanical (or pneumatic) shot blaster. The essence of the process is that the surface layer of the workpiece is plastically deformed - hardened, due to which its hardness and strength increase;

e) plastic deformation of plastics.

3 Chemical-mechanical treatment:

a) finishing (grinding) with laps made primarily of cast iron, copper or brass and fine-grained abrasive powders, micropowders and pastes. The lap material must be softer than the material of the workpiece;

b) polishing with soft circles (from cloth, calico, felt, paper, leather) using polishing pastes containing (like lapping pastes) surfactants that chemically affect the material being processed;

c) processing (sharpening and finishing) of carbide tools in a solution of copper sulfate and using abrasive powder and a metal disk.

4 Electrochemical processing. The essence of electrochemical methods is the use of electrical energy in the form of electrolysis. One such method is electropolishing, which is carried out in conventional electrolytic baths using special electrolytes and appropriate current modes.

5 Heat treatment. Heat treatment is used to modify the structure of the metal to obtain its mechanical and physical properties that meet technical requirements.

Heat treatment of machine parts can be applied at the initial, intermediate and final stages of the technological process. The nature of heat treatment operations is determined by design and operational requirements, as well as the requirements of mechanical processing technology.

Chemical-thermal treatment of metal parts is used to improve the physical, chemical and mechanical properties of parts - to increase their heat resistance, wear resistance, etc. by changing the chemical composition of the surface layer of the metal, which is artificially saturated with nitrogen (the process is called nitriding), aluminum (alitizing ), carbon and nitrogen simultaneously with subsequent hardening (cyanidation) and some other elements. This also sometimes includes the widespread process of heat treatment - saturation of low-carbon steel with carbon followed by hardening (cementation).

6 Aging of parts blanks. Aging aims to bring the structure of the casting into a state of equilibrium, i.e., to free the workpiece from internal stresses that arise both during the solidification of the metal and during preliminary mechanical processing (grinding).

Aging can be natural or artificial. The natural aging method is that the workpiece after casting or after peeling is kept in the open air under the influence of the atmosphere for 0.5...6 months or more.

Due to the duration of this process, the method of artificial aging is more often used. Artificial aging is mainly carried out by heat treatment of the workpiece by heating it in a furnace (electric, gas, oil) at a temperature of 450...500 ° C, holding for 12...15 hours and cooling for 2.5...3 hours together with the furnace, after which the workpiece is finally cooled in air.

Sometimes artificial aging is carried out in other ways, for example, by tapping the part suspended on a block, shaking, passing an electric current, passing the part through a washing machine with cold and hot water, and grinding the untreated surfaces of the part with hand-held grinding wheels.

Aging is used primarily for large cast parts that require the greatest possible stability of shape and size, for example, for the beds of metal-cutting machines.

7 The electric spark method of metal processing consists in the fact that between two close metal electrodes under current (one of which, the anode, is the workpiece), an electric spark discharge occurs, as a result of which local directed destruction (electroerosion) of the metal, the anode, occurs.

This method of electrical machining is used to produce through and blind holes of various profiles in metal workpieces (for example, in dies) when processing hardened metals, hard alloys and other difficult-to-machine conductive materials.

8 The anode-mechanical method is that when direct current passes through the electrolyte and electrodes, the anode surface dissolves with the formation of a film, which is forcibly removed by a rotating disk.

The anodic-mechanical processing method is used for cutting difficult-to-cut metals, sharpening and finishing cutting tools made of hard alloys, and finishing grinding of hard magnetic alloys.

Anodic mechanical cutting of metal is carried out by a disk-electrode rotating at high speed. The electrode disk is connected to the negative pole (clamp), the workpiece is connected to the positive pole. An aqueous solution of liquid glass—an electrolyte—is supplied to the processing zone; An electric current continuously passes between the disk and the workpiece. The installation is powered from a DC source. The insertion of the disk is achieved by feeding it transversely. The disk is made of a material with a hardness lower than the hardness of the workpiece being cut - mild steel, copper, cast iron.

9 The ultrasonic method is that the energy of a vibrating tool in the form of ultrasonic air vibrations is transferred to particles of abrasive micropowder, which arrive suspended in water or oil under the end surface of the tool and destroy the material being processed.

This method allows you to process holes of any profile in parts made from difficult-to-cut materials, such as, for example, diamond, glass, ceramics, hard alloys, quartz, etc.

10 Coating of parts with metals and alloys. To coat the surfaces of parts with a layer of other metals, the galvanic method based on electrolysis is most widely used. This method is used to coat parts with a layer of chromium, nickel, zinc, copper, etc.

Chromium plating of the surfaces of parts is carried out in order to protect them from corrosion, increase resistance to mechanical wear, extend service life, restore the size of worn surfaces, to give parts a beautiful appearance and shine.

Nickel plating is used to give products a beautiful shiny surface and, to a lesser extent, to protect parts from corrosion.

Copper plating is applied to parts of the cemented part (not subject to subsequent hardening) to protect them from carburization in order to facilitate subsequent machining.

Metallization - coating by spraying (pulverization) of molten metal - is used to repair and restore worn parts, correct defects, increase the heat resistance of parts (for example, aluminum coating), and impart anti-corrosion properties (galvanizing). Coating with hard alloys in order to increase the wear resistance of parts is carried out by welding or surfacing hard alloys on the surface of parts.

11 Metal welding is one of the methods of joining metal parts; is divided into chemical (gas, thermite, etc.) and electrical (electric arc, contact, etc.). Welding can replace soldering, riveting, forging, casting; in many cases, with the help of welding, significant savings in metal are achieved (the labor intensity of manufacturing products is reduced, production is cheaper).

12 Balancing parts. To avoid vibration, parts rotating at high speeds must be balanced. A rotating part will be balanced or balanced when its center of gravity and main axis of inertia coincide with the axis of rotation. The reasons for the unbalance of parts and assemblies may be inhomogeneity of the material, inaccuracy in the size and shape of surfaces, asymmetrical arrangement of the metal mass relative to the axis of rotation, mismatch of the axes of mating parts rotating together.

Parts that perform reciprocating motion (for example, a piston with a connecting rod in an internal combustion engine) are adjusted according to weight (mass).

13 Cleaning, rinsing and coating parts with lubricant. During processing and after processing, parts are cleaned, washed, dried and coated with lubricant. Cleaning is carried out by mechanical or chemical methods, washing - in washing tanks or washing machines, drying - by blowing with compressed air. Parts are coated with lubricant to protect them from corrosion.

Manufacturability of the design of machines and parts

1 Manufacturing of machine parts blanks is carried out:

a) casting metals in various ways: in earthen molds, in metal molds (molds), centrifugally, under pressure, investment casting (precision casting), in shell (crust) molds, by vacuum suction (casting of non-ferrous alloys);

b) processing of metals by pressure (plastic deformation), forging, stamping (hot and cold), pressing (extrusion), rolling, drawing,

c) plastic molding;

d) stamping of plastics.

2 Processing of blanks of machine parts by mechanical methods:

a) removing chips - cutting metal with blade tools and abrasives on metal-cutting machines;

b) plastic deformation (without removing chips) - metal compaction; rolling and rolling with rollers, punching - calibration of holes with a ball or mandrel; rolling (to obtain a corrugated surface);

c) cold straightening of metal parts;

d) shot blasting of metal parts, which consists of subjecting heat-treated parts in special installations to the impact of a stream of steel or cast iron shot ejected by a mechanical (or pneumatic) shot blaster. The essence of the process is that the surface layer of the workpiece is plastically deformed - hardened, due to which its hardness and strength increase;

e) plastic deformation of plastics.

3 Chemical-mechanical treatment:

a) finishing (grinding) with laps made primarily of cast iron, copper or brass and fine-grained abrasive powders, micropowders and pastes. The lap material must be softer than the material of the workpiece;

b) polishing with soft circles (from cloth, calico, felt, paper, leather) using polishing pastes containing (like lapping pastes) surfactants that chemically affect the material being processed;

c) processing (sharpening and finishing) of carbide tools in a solution of copper sulfate and using abrasive powder and a metal disk.

4 Electrochemical processing. The essence of electrochemical methods is the use of electrical energy in the form of electrolysis. One such method is electropolishing, which is carried out in conventional electrolytic baths using special electrolytes and appropriate current modes.

5 Heat treatment. Heat treatment is used to modify the structure of the metal to obtain its mechanical and physical properties that meet technical requirements.

Heat treatment of machine parts can be applied at the initial, intermediate and final stages of the technological process. The nature of heat treatment operations is determined by design and operational requirements, as well as the requirements of mechanical processing technology.

Chemical-thermal treatment of metal parts is used to improve the physical, chemical and mechanical properties of parts - to increase their heat resistance, wear resistance, etc. by changing the chemical composition of the surface layer of the metal, which is artificially saturated with nitrogen (the process is called nitriding), aluminum (alitizing ), carbon and nitrogen simultaneously with subsequent hardening (cyanidation) and some other elements. This also sometimes includes the widespread process of heat treatment - saturation of low-carbon steel with carbon followed by hardening (cementation).

6 Aging of parts blanks. Aging aims to bring the structure of the casting into a state of equilibrium, i.e., to free the workpiece from internal stresses that arise both during the solidification of the metal and during preliminary mechanical processing (grinding).

Aging can be natural or artificial. The natural aging method is that the workpiece after casting or after peeling is kept in the open air under the influence of the atmosphere for 0.5...6 months or more.

Due to the duration of this process, the method of artificial aging is more often used. Artificial aging is mainly carried out by heat treatment of the workpiece by heating it in a furnace (electric, gas, oil) at a temperature of 450...500 ° C, holding for 12...15 hours and cooling for 2.5...3 hours together with the furnace, after which the workpiece is finally cooled in air.

Sometimes artificial aging is carried out in other ways, for example, by tapping the part suspended on a block, shaking, passing an electric current, passing the part through a washing machine with cold and hot water, and grinding the untreated surfaces of the part with hand-held grinding wheels.

Aging is used primarily for large cast parts that require the greatest possible stability of shape and size, for example, for the beds of metal-cutting machines.

7 The electric spark method of metal processing consists in the fact that between two close metal electrodes under current (one of which, the anode, is the workpiece), an electric spark discharge occurs, as a result of which local directed destruction (electroerosion) of the metal, the anode, occurs.

This method of electrical machining is used to produce through and blind holes of various profiles in metal workpieces (for example, in dies) when processing hardened metals, hard alloys and other difficult-to-machine conductive materials.

8 The anode-mechanical method is that when direct current passes through the electrolyte and electrodes, the anode surface dissolves with the formation of a film, which is forcibly removed by a rotating disk.

The anodic-mechanical processing method is used for cutting difficult-to-cut metals, sharpening and finishing cutting tools made of hard alloys, and finishing grinding of hard magnetic alloys.

Anodic mechanical cutting of metal is carried out by a disk-electrode rotating at high speed. The electrode disk is connected to the negative pole (clamp), the workpiece is connected to the positive pole. An aqueous solution of liquid glass—an electrolyte—is supplied to the processing zone; An electric current continuously passes between the disk and the workpiece. The installation is powered from a DC source. The insertion of the disk is achieved by feeding it transversely. The disk is made of a material with a hardness lower than the hardness of the workpiece being cut - mild steel, copper, cast iron.

9 The ultrasonic method is that the energy of a vibrating tool in the form of ultrasonic air vibrations is transferred to particles of abrasive micropowder, which arrive suspended in water or oil under the end surface of the tool and destroy the material being processed.

This method allows you to process holes of any profile in parts made from difficult-to-cut materials, such as, for example, diamond, glass, ceramics, hard alloys, quartz, etc.

10 Coating of parts with metals and alloys. To coat the surfaces of parts with a layer of other metals, the galvanic method based on electrolysis is most widely used. This method is used to coat parts with a layer of chromium, nickel, zinc, copper, etc.

Chromium plating of the surfaces of parts is carried out in order to protect them from corrosion, increase resistance to mechanical wear, extend service life, restore the size of worn surfaces, to give parts a beautiful appearance and shine.

Nickel plating is used to give products a beautiful shiny surface and, to a lesser extent, to protect parts from corrosion.

Copper plating is applied to parts of the cemented part (not subject to subsequent hardening) to protect them from carburization in order to facilitate subsequent machining.

Metallization - coating by spraying (pulverization) of molten metal - is used to repair and restore worn parts, correct defects, increase the heat resistance of parts (for example, aluminum coating), and impart anti-corrosion properties (galvanizing). Coating with hard alloys in order to increase the wear resistance of parts is carried out by welding or surfacing hard alloys on the surface of parts.

11 Metal welding is one of the methods of joining metal parts; is divided into chemical (gas, thermite, etc.) and electrical (electric arc, contact, etc.). Welding can replace soldering, riveting, forging, casting; in many cases, with the help of welding, significant savings in metal are achieved (the labor intensity of manufacturing products is reduced, production is cheaper).

12 Balancing parts. To avoid vibration, parts rotating at high speeds must be balanced. A rotating part will be balanced or balanced when its center of gravity and main axis of inertia coincide with the axis of rotation. The reasons for the unbalance of parts and assemblies may be inhomogeneity of the material, inaccuracy in the size and shape of surfaces, asymmetrical arrangement of the metal mass relative to the axis of rotation, mismatch of the axes of mating parts rotating together.

Parts that perform reciprocating motion (for example, a piston with a connecting rod in an internal combustion engine) are adjusted according to weight (mass).

13 Cleaning, rinsing and coating parts with lubricant. During processing and after processing, parts are cleaned, washed, dried and coated with lubricant. Cleaning is carried out by mechanical or chemical methods, washing - in washing tanks or washing machines, drying - by blowing with compressed air. Parts are coated with lubricant to protect them from corrosion.

Features of artistic processing

The basics of metalworking include not only changing the shape and size of the workpiece, but also their decorative processing. The master can create individual products, or decorate ready-made metal structures. There are 4 metalworking processes that allow you to change the appearance of a part:

- casting;

- forging;

- minting;

- welding.

All types of decorative work with metal involve initial heating of the workpiece. The higher the plasticity, the easier it is to work with parts.

Welding technology is considered new compared to others. Its active development begins in the second half of the 20th century. Using a welding machine, you can cut metal sheets and connect the parts together.

Metal is a hard material, when working with it you need to use special equipment and heat the workpiece. Processing allows you to change the size and shape of a part, as well as improve its technical characteristics. Using methods of decorative work with material, you can decorate products, improving their appearance.

Why should you contact us?

provides:

- Prompt production - from 7 days. The warehouse program includes more than 5,000 tons of rolled metal from domestic and foreign manufacturers.

- High-quality work. Our staff consists of specialists with more than 7 years of experience in the field of machining.

- Competent logistics. We organize delivery to any point in Moscow and other cities of the Russian Federation and the CIS.

For more detailed information, please contact us using the feedback form or by calling the phone number listed on the website.