Wood carving has an ancient history. And although few examples of such products have survived, they exist, for example, ancient Egyptian wooden sarcophagi. In those days, craftsmen used mechanical tools. Nowadays, this ancient art has received a second life, and modern power tools for wood carving have significantly expanded the capabilities of the ancient craft.

In this article, we will consider in detail the types of electric tools, the purpose of the devices, the best manufacturers and the cost of the devices.

Electric chisel

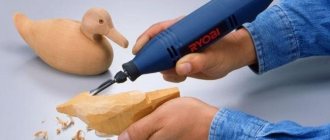

The classic hand chisel was recently replaced by an electric analogue. The wooden handle was replaced with a plastic case in which the electric drive is hidden. The device has a power button, an indicator of operating and locking modes, as well as a nozzle lock.

Very often, an electric chisel is called an electric scraper or an electric chisel. It combines many functions and allows you to perform a large number of jobs:

- removing old coating, traces of technical fluids or adhesive base from the surface;

- performing, including the most miniature, wood carvings;

- complete or partial removal of the thin top layer from the material being processed.

The main advantage of this tool is its versatility. Thanks to the power control system, both rough processing of the material and fine finishing, including wood carving, are performed. The downside is that during work you need rest periods to cool down. Working surfaces require regular sharpening.

Electric chisels perform both rough processing of material and fine finishing, including wood carving.

When choosing a chisel, decide what and how often it will be used. If from time to time, a device with a minimum number of functions is sufficient. For frequent professional activities, a powerful, multifunctional device with a large number of attachments is suitable.

For small jobs, a miniature device is suitable; for large, large-scale jobs, the tool must match.

But in all cases, when choosing, they focus on:

- The body must be light and strong, without loose parts.

- The tool should fit comfortably in your hand.

- The presence of a lock button and a regulator of operating modes is mandatory.

- The attachments should be held tightly in the retainer and can be easily removed.

- Nozzles must be made of durable steel.

The manufacturer also plays an important role in choosing an electric chisel. Below are the main companies and the characteristics of their tools.

- Makita TM 3000С

Electric chisels have a proprietary set of attachments that allow you to perform a wide range of work. The tool is easy to use. There are practically no vibrations in the body. Has 12 fixed positions for interchangeable attachments. It has a power of 320 W, engine rotation speed is from 6000 to 20000 rpm. The package includes a chip remover with a vacuum cleaner.

Prices fluctuate around 13,000 rubles.

- Bosch Pmf 190 e set – 7489

It is characterized by the accuracy of the work performed, minimal noise and vibration. Ideal for household chores. Convenient, lockable start button. The attachment of the attachments at different angles to the device is reliable and does not allow slipping. Power 190 W, motor rotation speed from 15,000 to 21,000 rpm. Includes 2 segmented and 3 immersion elements, a set of sandpapers, a mounting screw and a key.

The cost is around 8000 rubles.

- Skil Masters 1490 NA – 4850

Designed for finishing wood, plastic, metal and drywall. Allows you to sand difficult areas. Has a speed control function. It is characterized by low weight and a comfortable key. Power 220 W, engine rotation speed from 12,000 to 19,000 rpm. It has a set of replaceable attachments, a sanding pad, a set of sandpapers, and a key.

Price 4500 – 5000 rub.

Waterjet cutting

The unique technology “TECHTRAN” , developed by Soviet scientists for the defense industry, and only relatively recently became available to the general public.

The principle of operation is to cut any sheet materials with an ultra-fine jet of water. Mixed with abrasive, it is fed under very high pressure to the cutting head, where it turns into the finest hair. The jet output speed allows you to cut even metal, not to mention wood.

Nowadays, a CNC system has been introduced into the technology, which makes it possible not only to cut, but to program the processing of material according to any sketch. Cutting accuracy – 0.1 mm. At a speed of up to 100 m/hour, the cut of wooden material is cold, the part does not heat up and does not deform. The cut edges are clean and do not need any finishing.

Vladislav Permin, specially for Equipnet.ru

Jigsaw

Universal device. Used for wood carving and straight cuts. Suitable for working with plastic, metal, plasterboard and wood. The versatility of a jigsaw is its main advantage; unlike mechanical tools, it does not require frequent replacement of saw blades and allows you to increase the speed of work. The disadvantages include the thick canvas compared to a hand-held device, which does not allow the creation of miniature patterns.

Jigsaws are divided into two large groups - household and professional. The first ones are suitable for small household work and rare finishing works. The latter are intended for large-scale, voluminous work.

Different materials require saw blades with different characteristics.

Choosing the right file will improve quality and speed up work

On wood

- fast cutting – elongated blade, with large and widely spaced teeth;

- clean cut – average spread and tooth size;

- figured cut - a narrow blade with small teeth that are beveled towards the back.

For metal

Saw blade made of durable metal with wavy teeth.

For polymer materials

Saw attachment with exceptionally fine teeth.

There is a large selection of jigsaws on the market; the most popular are models from three companies:

- Makita. The company's best-selling model is 4350ST.

Tool power 720 W, suitable for working with material up to 135 mm thick. It has a pendulum stroke and can be connected to a vacuum cleaner. There is a keyless replacement of nozzles. The tool is well assembled, has a low noise level, and has the ability to perform work at different angles.

The price is around 10,000 rubles.

- Bosch GST 850 BE

Power 600 W. It has a pendulum stroke and quick-release fastening of the saw blade. Cutting depth up to 85 mm. The handle is staple-shaped. Built-in sawdust blower. The advantages are low noise level, speed adjustment by changing the force of pressing the button, smooth cutting line. Connecting to a vacuum cleaner will get rid of dust. Cons: no cutting light, no storage case included.

The price is around 10,000 rubles.

- DeWALT DW 333K

Power – 701 W. Cutting depth of wood up to 130 mm, metal up to 30 mm. Has a four-stage pendulum stroke. The frequency of the blade movement is 3100 movements per minute. Characterized by fast and accurate cutting, convenient speed adjustment. The sole is adjustable up to 45 degrees in two directions. The downsides are weak sawdust blowing and lack of lighting.

Pros and cons of laser cutting

Laser cutting devices have the following advantages:

- Versatility. Devices for cutting plywood sheets using a laser can be used when processing leather products, fabric, organic glass, plastic polymers and other materials with low thermal conductivity and combustion temperature.

- Multifunctionality. The laser device is used for cutting wooden blanks, engraving, welding and milling. Depending on the speed of movement of the mechanisms, the machines are capable of creating patterns of various thicknesses and shapes.

- Minimum cut width. Laser devices provide high precision manufacturing of parts. Thanks to laser focusing, the cut width is 0.01 mm, which allows you to detail the image applied to the surface of the plywood.

- Contactless. Laser devices do not come into contact with the surface being processed, which reduces the risk of workpiece deformation.

- Hygiene. During laser cutting, large amounts of dust, chips and other types of dirt are not generated.

The main disadvantage of a laser machine is its high cost. The devices consist of expensive tubes and laser diodes. The average price of medium format machines is 225,000 rubles.

Plane

Indispensable for leveling the surface, removing knots and irregularities. Used for tongue-and-groove and quarter cutting. Often used as a planing device. When using an additional ruler and square, it is used to level the workpiece and give it a square shape.

The advantages of using planes include:

- ease of use - no physical strength required;

- high productivity;

- used as a rimming or jointing tool.

Minuses:

- not used for treating floor coverings;

- traumatic;

- After using a power tool, manual processing with a mechanical device is necessary.

You will find useful tips on choosing a plane in this video:

The choice of electric planer is determined by the scale of the work. Accordingly, a suitable optional tool is selected. And in order not to make a mistake with your choice, you must adhere to the basic rules:

- Power tools for woodworking are purchased in specialized stores, from sellers who have the appropriate certificates. A quality device should have a warranty of at least two years.

- When purchasing, both the tool and its equipment are carefully checked.

Below are the models of electric planers, their characteristics and prices.

- Metabo ho 26-82

Designed for processing and chamfering wood, suitable for cutting quarters. The handle is equipped with a non-slip nozzle. Aluminum casting sole.

The price varies around 8500 to 9500 rubles.

- Makita KP0800

Equipped with a powerful motor, which allows you to work with hard wood. It is lightweight and has a convenient blade replacement system.

Price from 8000 to 9000 rubles.

- Hitachi P 20ST

Suitable for wood processing. Easy. Equipped with a lightweight non-slip handle. There is a button for fixing the start mode.

The price is around 5000 rubles.

Capabilities of laser cutting machines

Using a laser machine you can perform the following operations:

- Cutting out various blanks, models and stencils of arbitrary shape from plywood.

- Burning simple designs onto the surface of wood.

- Creating chamfers, slots, recesses, slits, grooves and other openings.

- Cutting three-dimensional plywood products.

Thanks to the powerful emitter, this device can be used for processing wood of high hardness. The device has a closed body with a transparent lid and ventilation, which allows it to burn parts without charring the edge of the cut. The number of machine functions is determined by its cost, size and quality of components.

Circular Saw

The electric circular saw is a universal tool; it allows you to work with wood, laminate, and metal. Replaceable saw blades allow you to work with almost any material. The main disadvantage of the tool is the risk of injury and high cost.

Pros:

- ability to perform any type of cut. The exception is figured cutting;

- the weight in the structure is distributed evenly, this reduces physical stress during work and increases work efficiency;

- the design of the tool ensures precision work.

An important parameter when choosing a circular saw is comfort during use. Before purchasing, you need to hold it in your hands for a couple of minutes and, if possible, make a cut.

When purchasing, it is important to pay attention to the complexity of setting cutting parameters.

It is important to choose tools from well-known companies that have specialized service centers.

The most popular models are:

- Makita HS 7601

The device has a power of 1200 W and a rotation speed of 5200 rpm. Suitable for working with wood, plastic, plasterboard, metal. Has a low noise level. It is possible to connect a construction vacuum cleaner. The downsides are the lack of a dive indicator and the soft rip fence.

Price from 7,000 to 10,500 rubles.

- Hammer CRP 1500 D

Power 1500 W. Equipped with a laser, has a mode lock button. Can be connected to a vacuum cleaner. Powered by battery. Suitable for cutting wood. If you have a specialized disc, it is suitable for metal and plastic. It can be used outdoors for cutting down trees. The disadvantages are the large mass and inconvenient fixation of the depth of cut.

Price 5,000 – 6,000 rubles.

- DeWalt DWE560/

Power 1350 W. Rotation speed 5500 rpm. Has a low noise level. Allows you to make the most accurate cuts. It is possible to connect to a vacuum cleaner. The downside is a weak rip fence.

Price 7300 – 10800 rubles.

CNC plasma cutting

Plasma machines are the latest generation of CNC milling and engraving technology. Equipment of this type is intended for plasma arc cutting and milling of wood.

The machine looks like this: a supporting frame, including connecting elements and two drawers for water. Cutting is carried out with a milling spindle to a thickness of up to 16 mm. The maximum operating speed is 2.5 m per minute.

The units have a very stable design, allowing processing to be carried out with high precision. One of the best models of this type is the German machine High-Z PlasCUT-1350 . In addition to working with wood, he excels at cutting, milling and engraving metal, plastic and other materials.

Sander

This is a tool that allows you to process the surfaces of wood, metal elements and stone. Indispensable for grinding and polishing. Used in professional and household work.

The choice of an electric grinder depends on the work for which it is chosen. A consultant from the store will help you decide on the type of tool.

When choosing, focus on:

- ease of use – weight, comfort of the handle, cord length;

- quality of materials;

- power - the higher, the greater the productivity;

- additional functions.

Popular sanders are:

- Bosch PBS 75AE

Belt type grinding tool. Power – 750 W. The belt rotation speed is 350 m per second. Working surface – 76*165 mm. Has a dust bag. Provides quick belt replacement and a large sanding area. The downside is that there is no way to properly process the corners.

The cost fluctuates around 9,000 rubles.

- Ryobi ROS300A

Orbital type model with a power of 300W. Has a built-in ventilation system. The machine is durable and equipped with a shockproof housing. The device is compact and light weight. The controls are smooth. Equipped with light indication. The downside is an inconvenient dust bag.

Price – 3500 – 5000 rub.

- Bosch PEX 300AE

Orbital sander with a power of 270 W. Number of revolutions – 12000. Copes perfectly with a large area of the processed surface. Leaves little dust. Built-in vibration control system. The presence of micro Velcro makes it easy to change the sandpaper. The downside is the high noise level. Headphones are required during operation.

The cost is about 5000 rubles.

Types of equipment

The following types of laser machines are distinguished according to their functional features:

- Engraving machine. This device emits a weak beam of light. It is used for engraving and burning thin plywood sheets. If you increase the wavelength, then using this installation you can completely cut a wooden workpiece.

- Laser milling machine. This device is capable of emitting a high-power beam of light, which allows you to create additional holes in the plywood. Using a CNC laser milling machine, you can engrave the workpiece. To do this, you need to correctly configure the laser parameters.

Based on the type of control, the following types of laser cutting devices are distinguished:

- Manually operated machines. These devices are low cost and easy to use. With their help you can cut out unique models and stencils. The disadvantage of these devices is the low accuracy of drawings and shapes.

- Automatic machines. These types of CNC machines ensure high quality manufacturing of products. For the operation of automatic machines, it is necessary to specify the operation algorithm. Based on the specified program, the devices will independently create the necessary patterns. During operation, a person can control the state of the CNC machine.

There are the following types of laser cutting devices in terms of power and size:

- Tabletop engraving machines. The power of these devices is 80 W. They are distinguished by their compactness. Tabletop devices can be placed in small spaces. They are used in making souvenirs and cutting thin plywood sheets.

- Professional laser machines. Their power is no more than 195 W. These devices are large in size and are installed at large woodworking enterprises. They are also used in furniture factories for the production of serial products and cutting out precise patterns.

- Industrial machines. The power of these devices is 380 W. They are installed in large factories specializing in woodworking.

The choice of laser cutting device depends on the scale of production, the physical properties of the surfaces being processed and the function of the device. Modern enterprises use universal CNC laser devices. They are multifunctional and can process both plywood and structures made of non-ferrous metals and polyvinyl chloride (PVC).

Surface grinder

Unlike a sander, it is a vibrating tool with a flat sanding platform. Consumables for performing surface treatment are attached to it. These tools are designed for large-volume work, without a lot of time. Abrasive consumables are attached to the working surface using Velcro. The machines are comfortable to use as they are light in weight – maximum 3 kg. Motor power starts at 110 W and reaches 600 W. The shaft rotation speed reaches 25,000 rpm. The level of vibration of the sole depends on the speed of rotation.

The choice of machine depends on the upcoming actions - for fine work, a tool with a displacement amplitude of 1.5-2.5 mm is suitable. For coarse – up to 5 mm.

Used for work in workshops, for surface restoration. Allows you to level the surface, remove dirt and oil traces from materials. Prepare walls and floors for painting or covering.

Below are examples of popular surface grinding tools.

- Interskol PShM-115/300E

Surface grinder with a power of 300W. Suitable for household work. Equipped with a dust collection system and a speed control system. Has a reliable wear-resistant sole. Equipped with a rubberized comfortable handle. The downside is the noise level.

Price – 2000 – 2500 rub.

- Makita BO3700

Power 180 W. Platform oscillation – 20,000 per minute. Has a dust collector and vibration damping system. It has a low noise level and can work with any sandpaper. The downside is a lot of dust after work.

Cost from 3500 to 5000 rubles.

- Hammer PSM 300

Power 300 W. Platform oscillation – 12000 per minute. Equipped with a speed control system and a power button lock. Has an additional handle. Spare brushes and sheets included. Made from quality materials. Suitable for frequent use. The downside is that it sometimes overheats during operation.

Price – 2000 – 3000 rubles.

Laser cutting

Today this is the fastest and most economical way to cut wood material. It is carried out with a gas CO2 laser, that is, without mechanical contact with the workpiece. This allows cutting along the most complex contours and with the smallest detail. It is impossible to achieve such precision with any other tools or machines. And the use of computer programs makes it possible to turn work into the most waste-free production possible.

Any wood material can be cut by laser. Even the veneer is only 0.6 mm thick. In general, technology opens up very great opportunities, allowing you to cut out original stories. The work of decorators and furniture makers cannot do without this installation.

True, the principle of operation requires high qualifications. Wood is a flammable material and therefore requires constant cooling. To do this, the machine blows into the cutting zone, which is controlled by the operator. In this way, maximum purity of processing is achieved (no carbon deposits are formed) and at the same time heat treatment of the part is carried out (it looks more contrasting and lasts longer).

Different types of wood are cut with a certain beam power and blowing force. And, if the workpiece is knotty, then this complicates the process even more. “Aerobatics” requires cutting plywood, because... glue layers burn hotter than wood. Yueming CMA series machine is perfect .

Safety rules when working with power tools

Tools require attention and compliance with safety regulations:

- Before starting work, check the serviceability of the tool, the integrity of the electrical wiring elements, and the reliability of fastening the elements:

- check the surface for the presence of foreign objects - nails, staples;

- Work with power tools should be performed in a comfortable position. The instrument is held with both hands;

- replaceable elements are used only those recommended by the manufacturer;

- When working, use protective glasses and gloves.

This video clearly shows why you need to know and follow safety precautions.

Instrument care

To ensure that the power tool is always in working order and in good working order, it is necessary to care for it and perform the following actions:

- Regularly sharpen and change removable working parts.

- The tool is stored in a protective container in a dry place - this will prevent rust from appearing on the elements.

- Regularly inspect the instrument to ensure its integrity.

- It is important to regularly lubricate the tool mechanisms with specialized oil.

- If necessary, seal the device with sealing paste.

- Cleaning internal cavities from dirt.

Wood carving is impossible without the use of hand tools; read about what you may need in your work in the article: “Basic tools for wood carving.”

Device selection

When choosing a laser CNC, the following indicators must be taken into account:

- Precision parameter. It determines the quality of production of texture elements.

- Power. This indicator determines the performance of the device. Machines with high power are capable of processing a large number of parts in a short period of time.

- Functionality. When purchasing a machine, it is important to find out whether the machine is suitable for engraving or milling plywood.

- Material. The working mechanisms and corner parts of the machine must be made of stainless steel.

When purchasing a laser device, it is important to pay attention to the manufacturer's brand. As of 2022, the most popular devices among buyers are the following brands: Kokie, Mazak, Trumpf, ESAB and Bystronic. They are distinguished by their high service life and versatility. Laser installations are also assembled in Russia. The leading Russian manufacturer is the research and production center “Lasers and Equipment”, located in the Moscow region.