During operation or processing, parts made of metal often lose their original configuration. The same phenomenon can be observed if they are not stored carefully. But in order for the parameters of the finished product to meet the requirements of the technical specifications, for the correct implementation of all further stages of processing, it is very important that the dimensions of the workpiece and its shape match the values specified by the project. To do this, an intermediate preparatory technological operation is performed, called “metal straightening”.

Types of editing

A cylindrical workpiece may bend under the influence of an external load, and one with a sheet configuration may become wrinkled. Products in the form of axes that do not even transmit torque, as well as shafts, can bend. The technological operation of straightening metal is understood as a series of actions, upon completion of which the workpiece made of metal returns to its original shape. Defects/flaws come in a variety of forms. The most common ones are:

- convex. It appears on flat products in the form of an increase in thickness - the size of the cross-section of the sheet - from the edges towards the center;

- dent. A recess on the surface of a metal plate, framed by flat edges;

- wave. This is a deviation of the shape of the sheet surface from straightness.

There are two types of editing:

- manual. It is carried out when home craftsmen produce uniquely shaped products. Although the set of tools used is quite simple, high demands are placed on the worker’s skill level;

- mechanical. Used in industrial production conditions. The equipment is very complex, large-sized and heavy. But it is characterized by a high level of productivity, and its design makes it possible to automate the straightening process.

It is not allowed to perform such an operation at subzero temperatures. In this case, the level of ductility of the material decreases and it becomes brittle. Moreover! Sometimes it is necessary to heat the workpiece to a temperature of 140°C to 400°C. After this, its plasticity increases

1.5. Filing

Filing –

is a method of processing workpieces with a file to obtain the required shape, size, and surface roughness.

Filing

metal is produced with a file, in a vice and is based on the destruction of the surface layer of the workpiece material by the cutting elements of the tool (file).

Files

(GOST 1465-93) are a multi-blade cutting tool whose teeth are located on the surface of hardened steel bars having different cross-sectional profiles and lengths. Files are divided according to the cross-sectional shape into flat, square, triangular, hacksaw, rhombic, semicircular and round, and according to the number of notches per unit length - into bastard files, which have from 4 to 12 notches, personal files - 13 - 24 notches and velvet files, which have 30 -80 notches per 10 mm length.

File length from 100 to 450 mm (every 50 mm).

Brushed files are used to remove a layer of metal up to 0.7-1 mm from a part; personal files are used after bastard files.

Files are made from steel grades U12, U12A, U13, U13A, 14ХФ and 13Х, as well as from high-speed steel.

Mechanization of the filing operation is achieved by using filing machines, grinders, and special devices.

Editing metal sheets

The complexity of this operation depends on the type of defect detected. But special difficulties arise when their combination is revealed. For example, a convexity in the center of the plate and at the same time a wavy edge.

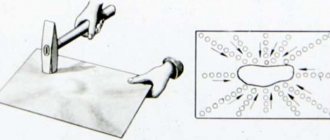

Convex

When straightening a convexity, blows should be applied around the circumference. You need to start with the line framing the defect. As work progresses, the radius of the circle must be gradually reduced, moving from the edge of the convexity to its center. As you progress, the frequency of strikes increases, and their strength, on the contrary, becomes less.

A special approach is used when there are several such defects on the sheet. In this case, by striking with a hammer, you need to ensure that the convexities are combined into one common one, after which the editing is carried out according to the method described above.

Waviness

Editing a metal sheet with wavy edges is carried out starting from its edges and then moving towards the center. The waviness of the edges is smoothed out after the plate is stretched in the middle.

Thin sheets

Processing of workpieces with a small thickness in order to return them to a flat configuration using strikers is not carried out. The reason is that metal creases may occur as a result of unforging. A thin sheet is straightened with long, even planes of smoothing bars made of wood or steel. Smoothing is done in different directions with gradually increasing pressure.

Classic or regular straightening

Traditional straightening is carried out with the support of specialized hammers, spoons, jacks, mandrels, levers and other devices. In some cases, resistance welding devices are necessary.

A similar technique is usually used to correct local damage to the body. It means:

- Applying intense alternating blows with wooden, iron or rubber hammers;

- Displacement with special hooks, spoons, sticks;

- Leveling with slabs;

- Use of other scientific and technical methods, as well as devices.

Straightening of hardened metal products

In this case, hammers equipped with soft strikers are not used for straightening. For this purpose, a tool with similar elements made of steel with high strength characteristics is used. In this case, the sharp part of the striker - the nose - is rounded, that is, it is given a rounded configuration.

Straightening of hardened metal is carried out by applying pulsed point effects on a concave fragment of the workpiece. As a result of impacts in this area of the workpiece, a stretching of the material structure is observed, due to which the surface becomes more and more flat. This operation is carried out:

- on a straightening/straightening headstock, characterized by a hemispherical surface;

- with alternating movement of the workpiece from bottom to top and top to bottom. Straightening a hardened square whose right angle is broken is carried out in one of the following two ways (see figure):

- if the angle has become acute, the direction of the blows is the internal section of the surface of this part closest to the point of intersection of the rays/sides;

- when the angle has transformed into an obtuse one, the place of striking is the zone close to the top of the outer angle.

The metal in the affected area is subject to tension, as a result of which the 90° angle is restored.

Safety requirements during plumbing work

When performing metalworking work, which is carried out in a production area, and especially when metalworking is carried out at home, the following safety requirements must be observed:

- on the workbench you need to put only those tools and parts that will be necessary to complete this work;

- metalworking of metals should be performed only after they have been securely secured in a vice;

- remove shavings and dust from the workbench only with a brush;

- do not perform drilling work or sharpen tools with bandaged fingers or mittens to avoid them being caught by the drill;

- while the machine is operating, it is prohibited to open or remove protective covers, guards and safety devices;

- when chasing, riveting, chopping and other work in which there is a possibility of metal particles flying off, it is necessary to use safety glasses or a mask with safety glasses, while fencing off the workplace with nets and portable shields to avoid injury to people working nearby or passing by;

- pneumatic tools must be used with flexible hoses. It is strictly forbidden to use hoses that are damaged.

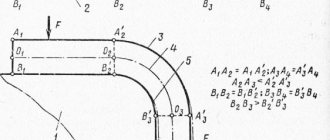

Straightening rounded metal parts

The method for performing editing in this case is practically the same as when processing a strip. Irregularities must be marked with chalk, and the workpiece must be placed so that the bulge is on top. Impacts should be applied in the direction from the peripheral areas of the defect to the central ones.

After correcting the main flaw:

- the part turns around its axis;

- the force of the blows decreases.

This is done in order to prevent deformation of the workpiece in the opposite direction.

A similar approach is also relevant when working with rectangular or square rolled metal.

Plumbing and repair work

There are plumbing and repair work, which consists of replacing or correcting damaged and worn parts, manufacturing missing parts, assembling components, mechanisms and even the whole machine, performing fitting work and adjusting assembled mechanisms and testing the finished machine. Each mechanic has his own workplace - a small section of the workshop's production area, where there is all the necessary equipment: hand tools for metal processing, instrumentation, auxiliary devices.

The main equipment of the workplace for metalworking is a bench with a vice attached to it and a set of necessary working and control tools and devices. In order for the workplace to be able to move parts or components weighing more than 16 kg, it must be serviced by cranes or lifts. To perform assembly or disassembly work, workplaces are equipped with stands, conveyors, roller tables, special carts or other transport devices.

Equipment for straightening/straightening

Manual straightening/straightening of metal sheets and structural elements made from them is carried out using hammers on special equipment - straightening headstocks, as well as straightening plates.

Straightening headstocks

For the manufacture of these devices, heat-treated steel alloys are used. The working surface of the straightening head can be:

- in the form of a flat circle on a cylindrical base, the radius of which (designation R) ranges from 150 mm≤R≤200 mm:

- spherical. This is the lateral surface of a cylinder truncated along the plane of symmetry and along the edges.

Also, in home workshops, a railway rail, cut to a length of 0.5 m to 1 m, is often used as a straightening headstock. It is convenient to move it along the slab. In addition, the rail is not subject to deformation and remains practically motionless when the workpiece is struck with a hammer.

Correct slabs

Straightening slabs are available in two modifications.

- Manufacturing material – cast iron. Execution – design with side ribs or solid.

- Manufacturing material – steel.

The slab must be heavy and sufficiently stable so that hammer blows do not cause it to shake. As for the requirements for the condition of its surface, they are standard: it must be perfectly smooth, and without the presence of foreign particles in the form of dirt and remnants of metal fragments that interfere with obtaining a high-quality result of straightening work.

The slabs must be installed on supports. They can be either metal or wood. But the most important thing is that these stands provide, in addition to stability, the required horizontal position. To make straightening easier, you need to have enough space around the slab.

There is another interesting option for such equipment. The material used to make the correct slab is dense rubber with many small protrusions, or rather, even tubercles with the same height. Under the influence of impacts, the metal itself determines its place. As a result, there is a significant increase in the productivity of the straightening process when compared with the use of a conventional leveling plate made of steel.

Hammers

The following key requirement is imposed on hammers used for straightening: they must be softer than the material of the workpiece being processed. In view of this, for straightening sheet steel, an impact tool with lead or copper strikers is usually used. Moreover, these elements should be characterized by a rounded shape. A square-shaped firing pin will leave nicks on the metal plate upon impact. When it comes to processing soft metals or non-ferrous alloys, it is necessary to use hammers equipped with rubber or wood strikers.

Convenience of work will be ensured if the ratio of the weight of the impact tool and the same parameter of the correct plate is equal to 1:100.

1.6. Hole machining

Holes in the metal body for fasteners (bolts, studs, screws), as well as for subsequent processing (drilling, countersinking, reaming, threading and boring) are achieved by drilling. Standard high-speed steel drills with a diameter of 0.3 - 80 mm are used as a tool for drilling. According to the design and nature of the work performed, drills are divided into feather, spiral, centering, drills for deep holes, etc.

Feathers

-(flat) are easy to manufacture, durable, but do not provide high accuracy and cleanliness of the hole. Used for drilling shallow holes.

Spiral –

perfect in design, easily remove chips through screw channels, low friction force on the hole wall, do not require additional processing of the hole, allow a large number of regrinds.

Drills are made with cylindrical (up to d=12 mm), conical (6 – 60 mm) shanks. Drills are made of high-speed steel grades P18, P9, U10-U12 (small drills) and with hard surfacing of carbide plates.

Reaming

designed to increase the diameter of the hole in workpieces and is used when processing holes with a diameter of over 30 mm. First, drill a hole with a diameter of (0.2 - 0.3) D, and then drill this hole to the specified diameter D.

Countersinking –

used for chamfering holes, producing cylindrical and conical recesses for screw heads and rivets.

Countersinking –

used for boring a hole and preparing it for reaming. Standard high-speed steel countersinks machine holes with a diameter of 3–100 mm. A countersink has a larger number of cutting teeth than a drill, so processing with it is more productive than drilling, and the quality of countersinking is higher than with drilling.

Deployment –

used for finishing a pre-drilled hole and obtaining precise geometric shape, dimensions and high purity

surfaces using cylindrical or conical reamers. Standard reamers are used for machining holes with a diameter of 1–300 mm in workpieces made of various materials.

For mechanical processing of holes by drilling and countersinking, pneumatic-electric machines and machines are used.

Hot straightening

If it is not possible to eliminate body defects using simple methods, the hot straightening technique is used.

- For this, as a rule, a gas burner is used.

- But in inexperienced hands it will cause more damage than benefit.

- It is possible to heat an element made of thin sheet steel with the help of a special hair dryer with an air flow temperature of several hundred degrees.

This action will make it possible to prevent the destruction of paint coating. In addition, a hair dryer is much safer than a gas burner.