A metal corner is a popular device in construction. However, it has found application only in this area. Metal corners are used in the national economy, industry and design work. There are several types of products, each of which is used in certain situations.

What is a metal corner?

The shape of the structure is made in the form of the letter “G”. Iron angles are small in size, but they are made from durable rolled products, so they can be used in construction without fear. Structures based on metal corners will be strong and reliable. The alloys from which building materials are made contain:

- carbon steel;

- types of metal that are resistant to rust and corrosive processes;

- high alloy steel.

Why do you need a metal corner?

The products are used every day due to some qualities: durability. Strength and resistance to destructive processes. Angles are used in construction for the construction of floors, spans and load-bearing structures. A product in which both sides are equal is well suited for window and door openings. Options with uneven axes are better suited for building arches.

Perforated metal corner is used to equip furniture or strengthen its frame. Stainless steel galvanized profiles can even be used for interior decoration. Another area where products are in demand is mechanical engineering. They are used to make carriages, cars and large equipment. Metal corners are suitable for electrical installation work: for fastening equipment or cables.

What is the easiest way to level the corners of the walls?

Aligning the corners is the final stage of finishing before wallpapering or painting the walls.

This is a very labor-intensive process that takes a lot of time and effort, since it is difficult to manually make exactly 90-degree angles. In this article we will tell you how to make this job easier.

Corner Alignment Methods

Today this can be done in 3 ways:

- manually using putty and a spatula;

- plasterboard;

- metal corners.

Types of metal corners

Designs are divided into several types depending on the manufacturing method and areas of application. There are products with unequal sides. They call the corner itself a shelf. Large industrial enterprises produce equal-flange structures, and those with unequal sides are made only on individual orders. All geometric parameters of the corners and their dimensions are regulated by technical documentation. According to it, there are several classifications of products:

- Equal angle made by rolling metal method - GOST 8509-93.

- Equal angles made by bending - GOST 19771-93.

Bent metal corner

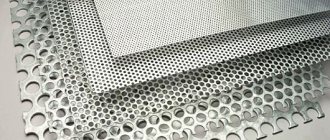

Products are created using the cold bending method. For this purpose, special equipment is used that is capable of exerting significant pressure and physical impact on the metal. The decorative metal corner is created exclusively from rolled sheets, which have a small width in cross section.

The technology under consideration significantly speeds up the production process. It produces more defects than when using the hot-rolled method. When making bent structures, it is possible to more accurately maintain the size of the canvas, so the range of such products is larger. Bent metal corners are lighter in weight, which gives them a definite advantage in construction.

Equal metal corner

Products can be made not only by the bent method. Another option for their production is hot-rolled. It makes the metal harder and changes its structure, even without hardening. A metal corner for slopes is suitable for decorating interior design and for creating engineering systems. The only disadvantage of equal-flange structures is that not all stores sell them in a standard size - 12 m in length. In the production of angles using the hot-rolled method, the following grades of steel are used:

- 15HSND;

- 09G2S;

- 17G1S.

Unequal metal corner

It is used for the construction of structures that are subject to increased rigidity criteria. In the interior, a metal corner is used for shelves and furniture decoration. In shipbuilding and automotive industry one cannot do without this element. The wide range of applications of the product is due to the fact that it is made only by the hot-rolled method, which ensures the strength of the entire system. Numerous grades of steel are used in the production process:

- for equal angles;

- 08G2S;

- 12GS;

- St0-St6;

- st4ps;

- 14HGS.

Standards for products with unequal angles are described by GOST 8510-86. It describes the following options:

- ratio of the larger and smaller sides;

- radius of curvature of ends;

- shelf thickness;

- ordinary and centrifugal moment of inertia.

Methods for leveling room corners with plaster

The issue of smooth walls is one of the most important when it comes to finishing work.

But it is equally important that the corners in the rooms are even at 90°. Therefore, the question of how to level the corner of a wall with plaster is one of the most frequently asked questions on the pages of construction forums. Rooms always have both internal and external corners. Therefore, it is necessary to understand two alignment processes, which are slightly different from each other. Please note that leveling with plaster is best done if the size deviation from straight is not very large (87°-92°). If this indicator exceeds the standards, then it is best to use drywall for leveling.

Aligning an outside corner

Aligning the outer corner

Let's start with the question, how to align the corners of the walls (external)? They are usually located near doors, rarely when there is a column or architectural protrusion into the room. But in any case, they must be adjusted to a straight line.

- First of all, the deviation is determined. To do this, apply a square to the corner. The long part of the tool should lie on the main wall, which should already be plastered. Usually a protrusion is adjusted to fit it.

- If the corner is sharp, then the adjacent surface must be leveled.

- First, plaster beacons are installed - evenly over the entire height.

- After which plaster is applied to the adjacent wall. That is, the surface of the wall and the outer corner are leveled at the same time.

Most likely, small deviations will still remain. Therefore, it is necessary to wait until the plaster layer has dried, after which the corner must be treated with a primer. When it dries, final leveling can be carried out with putty (a thin layer) using an angled spatula.

Aligning an inside corner

Aligning the inner corner

The solution to the question of how to align the inner corner of the wall is more complex. Sequence of work:

- On one of the walls, at a distance of the width of the angle spatula blade, a metal profile is installed, which is secured to the wall with three metal dowels. Installation must be carried out strictly vertically, for which a level is used.

- A plaster solution is applied to the adjacent wall with a flat small spatula. The plaster is applied in small strokes to the entire height of the corner to be leveled.

- Now, using an angle spatula, you need to level the mortar so that the gap between the tool blades and the wall surfaces is completely filled with plaster.

- The profile is dismantled, wait until the applied layer dries, after which it is necessary to prime the corner and carry out additional leveling with a thin layer of putty.

As you can see, plastering the corners of walls with your own hands is not the easiest process. But if you look into it, it turns out that doing it yourself is not a problem.

Counterschultz

Modern way

Construction technologies today are rapidly changing, moving into the “easy to implement” category. Therefore, the question of how to plaster the corners of walls can be solved in a simpler, modern way. To do this, you will need a special part - a metal counter. Essentially, it is a straight angle made of aluminum to which a mesh is attached. Konrashultz is used to form corners.

In order to install it, you need to apply a thick layer of plaster directly into the corner. It's better if it's thick. After which this mesh corner is installed on top of the not dried plaster. Please note that the vertical installation of the konrashulets is the main requirement. The metal corner itself is a soft part, so to press it down to the corner of the room it is best to use a long rule.

In this case, part of the plaster mortar will be squeezed out from under the leveling device, which must be removed. Now it takes time for the solution to dry thoroughly. The rest of the corner alignment process is carried out using standard technology. In fact, this is the usual alignment of walls adjacent to each other. That is, first one wall is leveled, then the other. In this case, the konrashulc mesh will be inside the applied layer of plaster, which will make the solution stronger. And the metal angle will provide 90º.

Conclusion on the topic

So, this article answered the question of how to make an even corner of a wall with plaster (external and internal)? To finally understand this issue, we suggest watching the video posted on this page of the site.

Metal corner - dimensions

The width of structures with different side parameters ranges from 20 to 200 mm, and the thickness is up to 16 mm. The weight of an iron corner is calculated in kilograms per 1 m. The weight of steel products with a minimum thickness of 3 mm and the smallest thickness of 20 mm is 0.9 kg/m. The weight of a metal corner with parameters 200 mm by 16 mm is about 37 kg/m. Depending on the compliance of actual dimensions with standard ones, all products are divided into high-precision (class A) and conventional (class B). In a large-volume batch, up to 15% of unmeasured blanks are allowed.

The weight of the minimum unequal corner is 900 g, and the maximum - 39 kg. The length of the strip can be from 4 to 12 m. In this case, as in the case of equilateral structures, slight deviations in dimensions according to GOST are allowed. For products 4 m long, an error of 30 mm is allowed, for corners 4-6 m - 50 mm, from 7 m - 70 mm.

Installation of a metal corner on a vertical corner – Blog Stroyremontiruy

Below we will tell you how to correctly install a metal corner on a vertical corner of a wall, which will be useful for those who are used to working at home themselves, without calling a master finisher for every little thing (I would go again).

The need to install a metal perforated corner is not due to the whim of the owners, but to the fact that this element allows:

- — Align the corner of the wall faster and with higher accuracy,

- — Additionally strengthen the corner, protecting it from accidental mechanical damage.

What is needed for installation

To perform the installation, you do not need to prepare much material and tools. You will need:

- — Gypsum-polymer mixture Rotband,

- — Level (from 1 meter),

- - Several metal spatulas,

- — Plastic container for kneading.

Corner installation

Many are accustomed to thinking that the main thing in the process of installing a corner is the accuracy of its vertical installation, however, it is necessary to control the accuracy of the work along the plane of the adjacent walls (photo 3), because otherwise holes or bumps will appear on the wall.

The Rotband mixture is mixed to a medium consistency (first water is poured into the container, then the mixture is poured) and applied to the base of the outer corner with a spatula (8-12 cm) after 10-15 cm. The corner is applied to the corner without pressing, then a level and corner are taken in hand straightened vertically and laterally.

It is important not to try to completely align it along one vector at once, since there will be no margin left for editing along other planes. Slightly align the corner vertically, then press it with a level along the line of the wall, then accurately align the vertical. Deviations should not exceed 2 mm per linear meter, but this is the maximum; see the table for the full list of permissible deviations (quality indicators).

Leave the leveled corner to fix (20-40 minutes), then use the remainder of the mixture (Rotband does not set for an hour) to zero its side edges. When removing the sidewalls, use a wide metal spatula, which should go from bottom to top, this way you will avoid the appearance of holes in the saddle of the outer corner, and vertical accuracy will be ensured by the corner itself (its outer edge will act as a guiding beacon).

After a day, the corner can be puttied in one or two layers, depending on the type of further finishing (1 layer for wallpaper, 2 layers for painting).

Questions and answers

Is it possible to attach a paint corner during plastering work?

Theoretically it is possible, but there are several “buts”. Firstly, this is a more labor-intensive process, especially when working with classic lime-sand plaster. Secondly, the paint corner will not adhere well to the plaster mixture, since its perforation is made for putty (there is a mesh underneath the plaster).

Is it necessary to buy corners with reinforcing mesh on the sides?

No, not necessarily, but due to the mesh, the corner is held more securely on the corner and is difficult to knock down even with accidental physical impact.

The most important indicator of quality when installing beacons is the accuracy of their vertical installation?

No, the metal corner must be precisely fixed not only vertically. Pay attention to the second photo - the corner must be even along the wall; often for this you have to either knock down the upper part of the corner, or run the corner above the level of the wall and then smooth out the unevenness with plaster.

How to bend a metal corner?

To do the work yourself, it is better to use the hot method of processing the material. To obtain the optimal bend radius, it is advisable to use a template. It needs to be prepared in advance. Algorithm for how to bend a metal mounting angle with your own hands:

- Heat the material evenly along its entire length. The temperature is selected so that it is half the melting index of the metal.

- The product is evenly bent according to the template. To correct unevenness during work, use a sledgehammer or hammer.

- The fold will be in the form of a semicircular angle.

If you need to get a clear bend, then use another method:

- Use a grinder to cut out a triangle in the place where the corner should be. Its sides should be at an angle of 45°.

- The cut area is carefully heated with a burner and bent. This section is then electrically welded.

How to fasten and bend

A metal corner in Orenburg is often used for fixing building and design structures, and the service life of the system and safety for people will depend on the reliability of the fastenings. It can be captured using:

- Self-tapping screws – when you need to attach furniture or designer shelves;

- Dowel nails - they are used for fixing heavy building structures;

- Anchors - they can withstand weights of over 100 kilograms and are used in construction and industry;

- Rivets are for decorative purposes.

To bend the product yourself, you should subject the material to the hot processing method. You should use a template to obtain the desired bend radius. The template must be prepared in advance.

To bend a product, you first need to heat it evenly along its entire length. The required temperature is selected so that its value is equal to half the melting temperature of the metal.

The metal corner is evenly bent according to the template, and in order to level out any existing unevenness, a sledgehammer or hammer is used during the operation. The result is a semicircular fold.

If you need to get a clear bend, you should use a different technique. In the place where the corner should be, use a grinder to cut out a triangle with sides at an angle of 45 degrees. Then, using a torch, the cut area must be heated and bent, after which this area must be welded using electric welding.

How to straighten a metal corner?

Work of this type is called straightening. During this process, unevenness and other imperfections in metal workpieces are eliminated. The metal corner can be straightened manually or by machine. In the first case, manipulations are performed on a flat surface and a hammer is used. They look for places on the workpiece that, when struck, will straighten the entire structure.

To carry out the work better, you can also heat the surface of the metal corner. The maximum temperature to which the workpiece can be heated is 850°C. Otherwise, cracks will appear on the metal and it will be impossible to use it for further purposes. Algorithm for aligning a corner curved in a plane:

- The product is placed on a wooden board to create less noise during operation.

- The workpiece is positioned so that it touches the anvil at two points.

- Strong blows with a hammer are applied to the more curved places. As correction progresses, the force on the corner is gradually reduced.

- The blows are applied from both sides of the parts, periodically turning the workpiece over. Do not knock on the same place several times in a row.

How to drill a hole in a metal corner?

Metal products are characterized by increased hardness. Work with them must be carried out according to a special algorithm, following the technological process. In order to drill a metal mounting angle, you will need:

- protective glasses;

- hand or electric drill;

- center punch;

- hammer;

- drill.

The peculiarity of the work is that you need to independently set the direction of the drill in order to correctly make a hole in the metal. Step-by-step algorithm of actions:

- The workpiece is clamped in a vice.

- Pre-marked locations for holes on the metal corner of the core. The procedure will prevent the drill from moving from the specified point.

- The drill is installed strictly perpendicular to the metal corner. If this rule is not followed, it may break.

- The pressure on the drill is gradually reduced as the drill penetrates the workpiece. This will prevent the formation of metal burrs in the workpiece.

How to attach a metal corner?

If you use the structure for construction or design purposes, then it must be fixed. The more reliable the fastenings are made, the longer the entire system will last. Otherwise, the structure will not only fall apart, but will also threaten the safety of people. Popular options for fixing a metal corner:

- self-tapping screws

- needed when attaching designer shelves or a metal furniture corner; - dowel-nails

– designed for fixing heavy structures used in the construction industry; - anchors

- used for construction and industrial purposes and can support structures weighing more than 100 kg; - rivets

- for decorative purposes.