Due to such qualities as strength, hardness and low cost, cast iron is widely used in the manufacture of a wide variety of parts and products, often complex and massive, while being subjected to various types of processing, one of which is milling. This process is a complex, high-tech type of metalworking, which is carried out on various machines, including CNC. Programming the process greatly simplifies the work of milling operators and allows them to produce products of the highest quality.

Types of cast iron

All known cast irons can be divided into three groups. White

Carbon is included in this material not in pure form, but as cementite. This alloy has two seemingly contradictory properties - strength and brittleness. This is the most difficult object for CNC milling of cast iron. White cast iron is highly abrasive and quickly dulls the tool it comes into contact with. And if the intervention is too rough, it can crack.

Hence the purpose of the material - usually it is used to make castings that are ready for use and do not require machining.

Grey

In addition to the main component - iron - it includes silicon with a content of no more than 3.5% and carbon in the form of graphite. Despite its fragility, it is often used as a structural material. CNC milling and turning of this type of cast iron takes place without consequences for the material: it does not overheat.

The problem of tool wear when working with gray cast iron workpieces can be solved by choosing cutters made of particularly strong alloys and coated. The crumbling problem will be negated by reducing the feed. To reduce the risk of cracking at the treatment site, it is better to carry out the operation “dry”, without coolant. High strength

In this cast iron, carbon is contained in the form of nodular graphite. This increases its strength and makes it difficult to process, especially milling, a cast iron plate. However, the result is parts that are practically in no way inferior to steel ones, although they will cost less. In addition to excellent rigidity, the material has impact strength. Its disadvantages are low thermal conductivity and instability to vibration, which makes the use of gray cast iron undesirable in mechanical engineering.

Classification of cutters

In factory workshops you can find milling machines for a wide variety of purposes. They differ in their design, direction of tool feed, original parts, which are divided into several types:

- Straightforward.

- Rotational.

- Screw.

In principle, the equipment consists of several cutters, which are made of very hard metal.

Its wide variety allows you to choose the desired shape and material to mill the most inaccessible parts of the part. When classifying, certain technical characteristics are taken into account:

- Location of incisors.

- The design of the teeth and their direction.

- Type of cutter: solid, prefabricated.

- Fastening of cutters.

- Cutting part material.

Features of cast iron milling

As you can see, there is no ideal alloy for milling cast iron.

Each requires its own approach depending on its properties. However, there are several “rules of good manners” that should be followed in relation to all cast iron. For example, cutting fluids are recommended to be used only during continuous tool exposure. If, when CNC milling cast iron, the cutter comes into contact with the workpiece periodically, you can and should do without coolant. When selecting tools and processing modes, you should first analyze the composition of the material. For example, power parameters will directly depend on it. You can “fight” high wear of cutters for processing cast iron by purchasing tools with a resistant coating. It was noted that the cutter coated with aluminum oxide applied by spraying is the slowest to wear.

Processing of cast iron by milling.

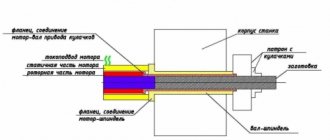

Complex massive body parts (for example, machine beds) with many holes, planes and grooves are often made from cast iron. These parts will subsequently be joined to the rest of the machine parts, and the mounting surfaces for them must have high precision processing.

However, it makes no sense to manufacture the entire massive part of the frame with high precision, and it is not economically profitable. Usually they proceed as follows - the mold into which the cast iron is cast has a relatively low accuracy, and critical casting areas are processed additionally at the next stage of production. For example, using milling.

Cast irons are alloys that can be easily machined. The presence of graphite in the alloy structure greatly facilitates the processing of cast iron, since graphite allows:

- get short crumbly shavings

- has a certain lubricity

In this case, a tool (end mill) for machining cast iron usually has a negative rake angle of the cutting edge (or a small positive value). This allows you to keep the cutter teeth intact when processing uneven surfaces with large allowances.

When processing cast iron, the abrasive type of wear on the cutter cutter predominates, so it is recommended to use cutters with a wear-resistant coating - for example, with an altin coating (ALTiN). In most cases, cast iron is processed without coolant.

Since cast iron workpieces are in most cases produced by casting, the following difficulties most often occur when milling cast iron:

- large quantities and unevenness of allowance on castings

- the presence of a casting crust on the workpieces (the crust interferes with processing)

- the presence of sand inclusions (sand enters the cast iron from the casting mold)

Note that sand is a strong abrasive and increases the degree of wear on the cutting edges of the cutter.

Selecting cutters for processing cast iron

For each operation when processing cast iron workpieces, you should select the most suitable type of cutter. Our consultants will always tell you in which case which cutters are best to use.

To get advice on choosing cutters, as well as purchasing questions, call or write to us through the order form on the website. Receiving competent advice is guaranteed.

High-quality cutters are the key to the smooth operation of your production! CNC Motors Company.

Technology of processing cast iron on CNC machines

CNC milling and turning of cast iron is notable for the fact that it not only eliminates the human factor, but also strictly observes cutting conditions, and also warns the operator about possible problems. But it should be understood that before the practical stage, the project goes through several important stages:

- creating a sketch in a computer modeling program;

- creating a drawing using drawing software;

- writing a working program for the machine;

- choice of processing scheme;

- selection of cutters;

- determining the time it will take to process one workpiece and a batch of ordered products.

The last point is especially important, as it allows you to tell the customer the exact timing of the project. Even if it is a simple milling of a cast iron slab, the work should not be postponed until later. Although the speed and serial production of CNC equipment simply will not allow the performer to work slowly.

Bronze milling

Bronze is a metal with a very ancient history. It’s not for nothing that the whole era is called the Bronze Age. In the 17th century, a tool appeared in China in the form of a rotating board with inserted teeth - the prototype of modern milling cutters. Such cutters were used to process the ends of bronze rings.

Currently, milled bronze products are widely used both in advertising and souvenirs, and in industry.

In terms of processing features, milling bronze is similar to working with copper.

Setting cutting modes

When choosing a cast iron milling scheme, technologists determine the processing parameters of a specific workpiece. These include:

- type of tool;

- the method of feeding it into the working area, the position of the cutter for processing cast iron relative to the surface being processed;

- cutting force,

- speed of operation,

- the thickness of the layer to be removed by the cutter in one pass.

If all these parameters are calculated accurately, defects are completely excluded.

Factory milling of cast iron

By offering you CNC milling of cast iron, we guarantee professional and fast completion of all the above stages. Your future parts can be born in the design bureau of our workshop, and then arrive to you completely ready. The work of our company’s specialists is distinguished by:

- diligence;

- attentiveness to the wishes of the customer;

- high quality confirmed by multi-stage control;

- strict adherence to deadlines.

And, of course, the most favorable prices for your business. Not only will we complete the task flawlessly, but we will also reduce our prices if you entrust us with a large order. Contact us!

Copper milling

Copper has a number of unique characteristics, which is why it is widely used in modern industry. In addition, copper has outstanding aesthetic qualities. For example, a sign on the door, made by milling a copper billet, will give respectability to the owner of the office and emphasize his social status.

Copper has high electrical and thermal conductivity, and as a result it is used in electrical appliances and electronics. By milling copper, various types of electrical busbars and radiators are obtained. Switching boards are produced by milling copper-coated insulators. Milling cutting of sheet copper allows you to obtain precise cutting of domes, air ducts, waveguides, etc.

When milling copper, it is necessary to take into account a number of specific features of its processing:

- Copper is a very viscous metal. When working with it, carbide cutters are used, which require maintaining a high degree of sharpness (otherwise a “binding” effect is possible).

- The use of coolant is mandatory.

- Sometimes you have to use cutters with a so-called chipbreaker, take measures to remove chips from the cutting zone and prevent clogging of the spiral grooves of the cutter.

- It is forbidden to exceed the recommended feed rate and spindle speed (you cannot “force” the processing speed).

A special composition WD40 is used as a coolant. The use of water-based solutions is not sufficient due to their poor lubricity.

Titanium milling

The extraordinary properties of titanium allow it to be used in the most demanding ortas. Lightweight, corrosion-resistant and durable titanium is also used in medicine (even joints are made from it to replace worn ones), in the space and aviation industries, and in nuclear energy.

Compared to the production of steel parts, titanium milling is much more complex. Before milling titanium, it should be subjected to nitriding or oxidation. The thinnest film will serve as protection against possible scuffing of the material. Due to the hardness and toughness of titanium, special requirements are placed on the rigidity of workpieces and cutters. To secure the work cutters, it is necessary to use a spindle with an ISO 50 taper with a short tool overhang. This condition will significantly reduce the vibration level of the equipment, and hence the accuracy and quality of processing.

Titanium retains its hardness and strength at high temperatures and is also a poor conductor of heat. As a result, when milling titanium, powerful forces and loads are applied to the cutting edges of the cutter, generating a significant amount of heat. There is a danger of strain hardening of the part. Therefore, for successful milling of titanium parts, careful selection of the alloy grade and cutting insert geometry is important. Fine-grained grades of hard alloys without coating have proven themselves to be excellent.

Mechanical factors are also important for milling titanium. So the minimum recommended feed is usually 0.1 mm per tooth. The spindle speed can also be reduced to return to the original feed rate. At the same time, an incorrectly selected spindle speed can reduce service life by 95% at minimum feed.