Certification of welding equipment is mandatory for all production facilities where welding work is expected to be carried out. This procedure allows you to determine whether existing devices can produce welds of the required quality. The issuance of certificates of its completion can be issued exclusively by official certification centers that are not involved in the production of such devices and do not use them in their activities.

Application for certification of welding equipment

Why is the procedure mandatory?

The requirement that welding equipment must be certified is established by law. The provisions of the Federal norms and rules in the field of industrial safety interpret it as a test, during which the level of compliance of the devices available at the enterprise with technological standards is determined. Its key task is to determine whether there are unsafe and faulty devices in production, the use of which can cause injury to workers and (or) poor quality of seams.

Certificate of certification of welding equipment in accordance with the requirements of RD 03-614-03

Kinds

The presence of a huge number of methods and technologies used in welding and in the industrial sector and in construction has expanded the range of work of certification centers.

NAKS certifies:

- materials and equipment (welding inverters according to NAKS, power supplies, semi-automatic devices, transformer devices, etc.);

- methods of welding work (plasma, RDS, automatic, etc.);

- individual technical processes used in production.

What is the validity period of the Certificate of Completion of Certification of Equipment for Welding Work? The following frequency of inspections has been adopted:

- for equipment produced in large quantities – 36 months;

- for small batches of industrial equipment, if more than 6 years have passed since the start of use - 18 months.

If, according to the documents received from the manufacturer, the service life of the equipment is more than 6 years, then it will be subject to periodic certification every 36 months until the end of the service life specified in the documentation.

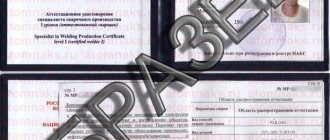

What document confirms the completion of the inspection?

Companies that successfully complete the procedure are issued a certificate of NAKS certification of welding equipment. This document confirms that welding machines can be used in hazardous industries. Its presence not only ensures that employees are safe, but also allows them to participate in tenders. The issued certificate of certification of welding equipment is valid for 3 years (if its service life does not expire during this period). For expired equipment that has been in use for over 6 years and has a serial number assigned by a certification center, this figure is 1.5 years. This document is issued in accordance with RD 03-614-03 “Procedure for the use of welding equipment in the manufacture, installation, repair and reconstruction of technical devices for hazardous production facilities.” The entire set of regulatory, organizational and methodological rules is developed by NAKS. He also initiates inspections and examinations, carries out accreditation of certification centers, and also implements a number of other functions.

About the system

An evaluation system for equipment used in welding work was developed in 2009 by several scientific and technical organizations .

The newly created organization was named NAKS - National Agency for Welding Control and is self-regulatory. The full designation looks like SRO NP "NAKS". The System employs only specialists and experts who perform certification services in all constituent entities of the Russian Federation.

284 Centers have been opened throughout the country, the main purpose of which is to assess the conformity of technologies, welding equipment and materials (for example, wire , electrodes, technological equipment), upon completion of which a NAKS certificate of the established type is issued.

When carrying out certification activities, the welding quality declared by the equipment manufacturer is checked . The effectiveness and compliance with the instructions and standards of the manufacturing, repair or installation processes of welding products used at critical facilities and high-risk sites is determined.

What types of welding equipment certification are there?

There are several types of certification of NAKS equipment:

- Primary. This is carried out when it comes to devices supplied from abroad. And also for previously unproduced mechanisms.

- Periodic. It is carried out after the period of primary examination has expired.

- Additional. Appointed in cases where new requirements for devices are introduced.

- Extraordinary. Performed in relation to modernized, repaired, not used for a year or more, or showing faulty mechanisms.

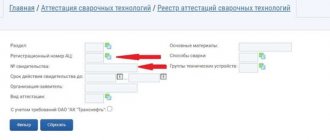

Samples for testing are selected from a batch of similar equipment. In accordance with the standards, their number should be 5% or more of the total number (in this case, at least 2 samples should be selected). In order for periodic certification of NAKS welding equipment to be scheduled, the owner must submit an application completed in accordance with the requirements of the technical regulations to the certification center. It indicates exactly what equipment is available and in what quantity. RD certification is carried out during the period when the units are in working condition. Mechanisms that are out of order and have not passed technical diagnostics cannot be used in operation. It is possible to issue a certificate under an abbreviated program, but only in cases where no comments or failures have previously arisen during the operation of the devices.

Employee certification

Certification of welding production specialists by NAKS is a mandatory procedure that must be carried out in production. It should be carried out in different situations - during changes in welding technology, during advanced training, during a short-term cessation of activity of one or more employees. But you definitely need to consider the main nuances of employee certification.

How is certification carried out?

To undergo certification, the employee must independently come to the NAKS center. The center conducts examinations, based on the results of which the person being checked is given an identification document. He assigns him the necessary degree of qualification. It can also be used to confirm a previously assigned qualification level.

For the test result to be valid, the following requirements must be met:

- The first step is to draw up an application; you can use a sample for this. Afterwards it must be submitted to a specialized certification center.

- The application must be accompanied by the required documents - copies of the identity card of the person being checked, diploma, documents including certificates of certification for welding-related professions, copies of the work book, employment orders. Photos taken in accordance with NAKS requirements.

- At the next stage, the time and place of the inspection is agreed upon. Certification of welding and workers under the control of NAKS are sent to training, which is based on a specialized program and an exam on knowledge of the required material.

- Passing final exams to confirm qualifications. There are usually two of them - practical and theoretical. But training must be done first.

- If all exams are passed successfully, the employee is issued a certificate of assignment of a certain level of qualification or renewal of an existing certificate.

It is worth noting! Applications can be submitted from legal entities, namely from an enterprise, as well as from an individual in situations where the welder has decided to apply for inspection independently.

If the welder’s documents are in full order, they are allowed to take the exams. There are only two of them - practical and theoretical. The second includes knowledge of the theory of welding, namely its technologies, principles of conduct and other important nuances. Practice comes first, and then theory. If a specialist cannot cope with the practice, then he is not allowed to take the theoretical exam. Retake is usually done after a month.

But for specialists of the second, third and fourth levels, only a theoretical exam is conducted. Engineers, technologists, and chief welders must know the standards of welding technologies, narrow areas, principles and other important nuances.

But in any case, you need to know what the NAKS register of certified welding materials and technologies includes, namely what stages of testing, required documents and types of certification. For the production audit process to be successful, it is necessary to adhere to established standards and follow the basic rules.

What is required to obtain a certificate of certification of welding equipment?

The certificate is issued only if, during the expert assessment process, the quality of welds made using the equipment fully complies with the established requirements. To check the seams, a non-destructive testing method is used. The welding machines themselves are also examined. Experts analyze whether the mechanisms are fully complete, how well they function, and whether their work meets labor safety requirements. In addition, research is carried out on systems and equipment components. The presence of this document will allow the company to increase its reputation in the eyes of partners and customers. It will also be a confirmation of the high level of quality of work performed by its employees.

What is it for?

The main task is to check the NAKS to the extent that the performance characteristics of the SM correspond to the characteristics given in the accompanying documentation, technical specifications, as well as other standards for the SM. In addition, this is confirmation of the suitability of certified products for repairs, reconstruction and other types of work at high-risk facilities.

After their successful completion, the customer receives a NAKS certificate, valid for 3 years - for mass-produced SMs and one year - for experimental samples and batches of SMs.

What is necessary

To pass certification, an enterprise must submit an application to NAKS. This document should indicate the passport details of the mechanisms. The application must be accompanied by a passport or a copy thereof, as well as a certificate of conformity. If we are talking about imported devices, then it is necessary to attach the instruction manual. Having received the application, NAKS creates a commission that goes to the production site. If such a need arises, additional information is requested from the applicant. Test days are agreed upon with company representatives. After their completion, the applicant is issued a certificate or a protocol of refusal is drawn up. Please note: there is a fee for this procedure. Its final cost is determined by the complexity of the task and the quantity, as well as the types of mechanisms to be examined. Some business owners are intimidated by the additional costs. However, they will fully pay off, since after passing the inspection the company will be able to perform a wider range of work, including welding structures that require high-quality connecting seams. Certification of welding equipment, the price

of which varies from several tens to hundreds of thousands, has special regulations for its implementation. In many ways, they have an active influence on the formation of the cost of work, because the type of permit—the type of access to the equipment—depends on the type of preparation. The latter can be divided into several categories:

- for welding building metal structures;

- for connecting lifting and transport type mechanisms;

- for work on boiler rooms, gas and gas distribution equipment;

- for welding at mining, metallurgical and metalworking facilities;

- for welding at oil and oil and gas facilities;

- to create an infrastructure capable of ensuring the safe transportation of special-purpose cargo.

The NAKS certificate for welding equipment

is divided into several types, each of which has an exact cost.

As a rule, it is formed based on the results of a completed questionnaire, and largely depends on the following criteria: the level of certification of welders and specialists; number of experts; established regulations for welding production. The final cost is discussed individually when submitting an application. For large companies and corporations, attractive offers and discounts are provided. Certification of welding equipment, the price

of which is largely determined by the needs of the customer, can be divided into several parts - for payment in installments or on credit. You can clarify the possibility of making payments in this way from the company manager by placing an order for the NAKS certification service in Moscow. In the near future, specialists will carry out calculations, doing everything necessary to begin productive and mutually beneficial cooperation.

How to get a certificate?

To undergo certification, contact our managers in any convenient way. You will need to prepare an application, provide a certificate of employment, educational documents and confirmation of the employee’s qualifications.

After receiving the documents, a date for qualification tests is set. If the exam results are unsatisfactory, a retake will be scheduled no earlier than a month later.

Leave a request for the service, we will contact you shortly and answer all your questions.

Need help? Contact us!

The key to successfully passing the test is thorough preparation. It is necessary to select the most suitable certification center, prepare a package of documents, and fill out an application. You can do this work yourself. But it is better to turn to professionals who know their business very well. The staff of the expert training center have extensive experience, so they will quickly and efficiently cope with the task. This will allow you to avoid bureaucratic delays and obtain a certificate in the shortest possible time. Do you want to know the cost, clarify any nuances or make an application? Just contact us in any way convenient for you. Our contacts are listed on the website.

Equipment requirements and procedure

Issuing a NAKS Certificate for welding equipment is an important point in the activities of any manufacturer. It is this that confirms the full compliance of the welding work performed with technical standards and requirements for the quality of seams of products and structures in the conditions of their operation at hazardous facilities.

To carry out certification activities, you must provide data regarding:

- basic parameters of workshops, compliance with technological equipment standards and conditions of facilities adapted for welding work;

- methods of conducting and certain types of welding work;

- characteristics of elements and parts to be welded;

- technological aspects and nuances, manufacturing conditions;

- timing and validity of personnel certification (welders and other workers directly related to the production of work);

- production conditions in which the welding equipment was manufactured.

Certification is carried out in the following order:

- Primary . For equipment that has not previously been tested or certified.

- Periodic . The maximum period is equal to the validity period of the Certificate and is 3 years.

- Additional . If there are changes and amendments to previously existing standards, technical specifications and other regulatory documents, as well as when planning to increase the scope of use of specific welding equipment.

- Extraordinary . Performed by special decision of technical supervision authorities.

Upon successful completion of certification, a Certificate of Equipment Conformity is issued, which is assigned a serial number and code.

National Welding Control Agency and its role in the certification of electrodes as a welding material

The control carried out by this organization is aimed, first of all, at identifying the correct adherence to the technologies of all welding processes carried out within the construction part. In order for these processes to be carried out without deviations from existing welding technologies, NAKS, as the main regulatory body, has quite serious mechanisms of influence.

One of these mechanisms, the purpose of which is to prevent the use of welding materials that do not meet the conditions of special welding technologies, is the certification of such materials. It is carried out in relation to welding electrodes, flux, wire and other filler elements that are used in welding processes.

Until the type of electrodes, as a welding material, passes the certification procedure with the assignment of a certificate of conformity, it will not be approved for use in production processes.

In the case of unauthorized use, this may result in the organization that has violated the NAKS requirements having to conduct an extraordinary certification to identify the percentage of defects.