Modern foundry is a complex technological method, in which blanks of metal parts are obtained by pouring a molten metal alloy into a specially prepared casting mold; inside it there is a cavity of the required configuration. After hardening, the resulting workpiece is removed and processed to the desired state. The modern foundry industry confronts specialists with the task of obtaining workpieces that best fit the shape, requiring minimal costs for their modification.

The following is a description of the most famous types of casting in modern industry.

Essence and Basics

In foundries, products are produced by melting a raw material, then pouring it into a mold, and then solidifying it. Foundries produce a wide range of products: from engine components to various containers for the food industry. All products made of cast iron, up to half of aluminum parts, up to 20% of steel products, etc. are produced by casting.

All foundry technologies are based on the concept of fluidity, when a material heated to a temperature above its melting point turns into a highly viscous liquid. In this case, the effect of continuity of its flow in the required direction must be observed. This makes it possible to form the required workpieces during the solidification process of the melt.

All casting metals have a complex structure, therefore fluidity is influenced by:

- Viscosity.

- Surface tension.

- The nature of the surface oxide film.

- Presence, content and composition of inclusions.

- Hardening method.

- Chemical composition of the base material.

- Physical and mechanical characteristics, primarily specific gravity and melting point.

Fluidity is established based on the results of chemical analyzes and technological tests in relation to a specific casting material.

If previously the process of liquid metal flow was poorly controlled, which led to various casting defects - uneven structure of the final product and porosity, now the situation has changed. In order to produce castings with optimal quality and minimize production costs, computer modeling processes have been mastered, as a result of which flow rates and the presence of various cooling effects can be predicted. They are the ones that cause porosity in the cast product.

3-D modeling allows you to adjust:

- Melt viscosity;

- Cooling intensity;

- Degree of porosity.

The spatial model of the casting developed by the technologist, taking into account the listed factors, allows even at the technology design stage to optimize the design of the part (ensuring its optimal configuration), design casting equipment, and also create the best sequence of operations performed.

Continuous casting

A process that allows metals and alloys to stretch, shape, and harden without having to interrupt the pour. At the same time, waste is reduced, the yield of finished products is increased, and the economic efficiency of production is improved.

Battery grids are manufactured using continuous injection molding. Using a water-cooled roller and mold system reduces the chance of impurities and provides a better thickness ratio.

Technology of foundry production of ferrous and non-ferrous metals

The casting properties of materials take into account not only fluidity, but also the decrease in volume that occurs during the cooling process of the casting. This phenomenon is called shrinkage; it is 1...3% of the original dimensions. Since all metals are anisotropic, a distinction is made between linear and volumetric shrinkage, which determine the final balance of the metal. The first parameter is important for castings with an increased length to width ratio, and the second is important for castings of complex shapes.

During the cooling process of the metal, segregation is observed in its structure - heterogeneity of grains, which is caused by the different properties of the components. Impurities and non-metallic inclusions are also formed. Liquation negatively affects the properties of the final product, so they try to reduce the heterogeneity of the structure by all acceptable means. In particular, the current GOST 26645-85 “Castings from metals and alloys” limits the content of phosphorus, sulfur (as well as their compounds - sulfides and phosphides), a number of gases - hydrogen, oxygen, as well as the amount of slag not removed from the metal.

Depending on the casting properties of metals, a decision is made on the choice of appropriate technology for producing castings. There are free casting in molds (sand or metal), injection molding, squeeze casting, centrifugal casting, as well as combined methods, for example, liquid stamping.

In shell forms

Shell casting is used to produce cylinder heads, connecting rods and other machine parts where increased precision is required. This process requires a sand mold, and a special type of resin-coated sand is used.

The process provides a number of advantages:

- the ability to create complex shapes with the highest precision;

- low labor costs;

- suitable for most metals and alloys;

- used for any scale of production;

First, the sand is thoroughly mixed with resin, which acts as a binder. Then the sand is poured into a heated mold, the temperature of which usually reaches 750...13000C. The heated mold initiates a reaction with the resin-coated sand. When sand comes into contact with a hot mold, a shell forms on the inner surface of the mold. Next, excess sand is removed from the mold, and then the shell itself is removed, for which ejector pins are used. The ejector is built into the mold itself, making it easy to remove the newly created shell without damaging it.

Injection molding

Injection molding is used to produce critical castings. The process requires the use of special equipment where the metal is melted and then put into a mold where it cools and solidifies.

Injection molding is used to produce thin-walled parts with a large number of ribs and undercuts. Such castings are used in household appliances, power tools, car parts, etc. Molds for injection molding are not limited in cross-section.

Advantages of the method:

- Possibility of obtaining parts with complex shapes and small sizes.

- High quality surface.

- Increased (compared to conventional foundry technologies) accuracy.

- Stability of casting metal characteristics.

- High performance.

Restrictions:

- High cost of equipment and accessories.

- Relatively low tool life.

- Increased level of initial financial costs.

Injection casting justifies itself with significant production programs, or with increased requirements for the quality of finished castings (in particular, to eliminate subsequent mechanical modification).

The injection molding process cycle is very short, typically 2 seconds to 2 minutes, and consists of the following four steps:

- Clamping parts of the mold, with one half fixed to the equipment, and the second being able to slide along the guides;

- Supplying the melt into the closed volume of the mold. The injection volume is determined by the volume of metal (taking into account its shrinkage), pressure and feed power;

- Cooling of the melt during contact of the metal with the walls of the mold. In some cases, shrinkage is taken into account by pressing the movable half of the mold against the surface of the hardening part;

- Removal of the formed casting from the tooling, the time of which is calculated based on the thermodynamic properties of the material and the maximum wall thickness of the part.

After an injection molding cycle, some post-processing is usually required. Thus, when cooled, part of the material located in the mold channels hardens. This excess metal must be trimmed using cutters. If necessary, it can be added to the melt, using it for casting the next batch of products.

According to gasified models

The mold is obtained using a non-removable model, and the metal is poured into a permanent mold. In this case, the model is produced from foam plastic by foaming at high temperature. When metal is cast into a mold, the foam model burns out completely, freeing up the internal volume.

If models for small parts can be obtained by foaming the composition, then large ones are cut out from glued slabs. Cutting is done by hand. Nichrome wire is used for this. The applied voltage heats the wire, which makes cutting easier.

The model can also be cut on milling or engraving machines with numerical control according to a given algorithm. The prepared model is painted and additionally coated with a heat-resistant compound.

Forming during lgm is carried out using two methods. In the first case, for castings of simple shapes, vibrating tables are used, on which the molding sand is compacted using flasks. Then the lid is placed on the flask and the sprue receiver is mounted.

In the second case, when the product has a complex geometry, molding is carried out under vacuum. To prevent the closed mold from collapsing, it is subjected to reduced pressure until the end of pouring. The vacuum pressure value is low - about 4-5 GPa.

Blanks for casting using gasified models

The temperature of the poured metal is significantly higher than the beginning of foam gasification (560 °C). The gases released by the foam are easily removed from the mold by a vacuum system. At the same time, there is no smoke in the working area.

The main advantage of this method is the high quality of castings, which can be obtained by casting into an ordinary or lined chill mold. This became possible due to the fact that the shape is solid.

Casting using gasified models

At the present stage, casting using burnout models is used for casting:

- large and medium-sized products in small-scale production;

- workpieces with complex configurations and weighing up to 50 kg, which are subject to increased dimensional accuracy requirements, in medium- and large-scale production.

Squeeze casting

The technology is used when constant compensation for material shrinkage is required, and is used for casting large castings with thin walls. To do this, the movable half-mold receives forced movement towards the surface of the melt - by rotation, screw or plane-parallel movement. The sequence of transitions is as follows. The metal is poured into the lower part of the mold, then its moving part is moved until it comes into contact with the melt, while the excess is poured into the receiving ladle of the installation. Since constant thermal contact is maintained between it and the base metal, heat loss is minimal, and the physical and mechanical parameters of the material are uniform in all sections. The form completion rate also increases. After solidification, the movable half-mold moves to its original position, and the finished casting is pushed out of the cavity.

Advantages of the process:

- Increased structural homogeneity of the casting.

- High uniformity of physical and mechanical characteristics of the material.

- High process productivity.

Press casting is mainly used to produce products from aluminum cast alloys.

Centrifugal casting

Centrifugal casting is a process that produces high-strength castings. This technology is chosen for products such as jet engine compressor housings, hydraulic wear rings, and many defense products.

The steps in the centrifugal casting process begin with pouring molten metal into a preheated die. The mold can be oriented along either a vertical or horizontal axis depending on the part configuration.

As the mold rotates while pouring molten metal, centrifugal force distributes the molten metal into the mold under pressure up to 100 times the force of gravity. The combination of this pressure, controlled solidification and secondary refining produces products of the highest quality.

As the mold begins to fill, the denser molten metal is pressed against the wall. Directional solidification of the strong metal occurs from the periphery of the mold towards the channel, while less dense material, including impurities, moves towards the inner diameter.

After the casting has hardened, the part is removed from the mold, and residual contaminants remaining on the surface of the casting are subjected to mechanical processing - cleaning.

A variant of the technology is centrifugal casting in a vacuum. It is used when part accuracy and control of atmospheric exposure are critical because some alloys, including nickel-cobalt alloys, are reactive to oxygen.

Important: Centrifugal vacuum casting provides very high reliability for products often used in the aerospace and military industries.

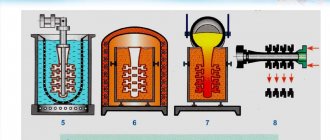

Equipment and forms

Arc or induction electric furnaces are used as melting equipment in foundries. The type of equipment is determined by the metals the foundry/site is working with: electric arc furnaces are ideal for working with steel or cast iron, while a foundry specializing in copper is more likely to use an induction furnace. Ovens can range in size from small tabletop units to those that weigh several tons.

Modern foundries are mechanized. Almost all operations of the cycle are subject to mechanization: from the production of cores to the actual casting. Molding machines are used in the serial production of castings. Manual molding is common only in small repair industries.

The main equipment includes:

- Melting furnaces;

- Pouring ladles;

- Loading and transport equipment - loaders, cranes, conveyors, etc.

- Control and automation equipment.

An electric arc furnace operates on the principle of periodic melting. The metal is melted by introducing electrical energy into the furnace through graphite electrodes. Additional chemical energy is supplied by oxy-fuel burners. Oxygen is introduced to remove impurities and other dissolved gas. When the metal is melted, slag forms and floats to the top of the melt; the slag, which often contains undesirable impurities, is removed before discharge.

An induction furnace transfers electrical energy by induction, where a high voltage electrical source induces a low voltage, high current in a secondary coil. Induction furnaces are capable of operating with minimal loss of raw materials, but are more used in the production of castings from non-ferrous metals and alloys.

All foundry equipment is specifically designed to operate reliably at elevated temperatures. The dominant trends in the production of this technology are scale, automation, rapid finishing of castings, increased safety and efficiency.

What lubricants are used? The choice depends on the brand of material and casting method. The initial concentrate in liquid form must be water-soluble, and in solid form heat-resistant pastes are used.

Die casting

All types of chill casting are a group of methods especially suitable for producing castings from non-ferrous alloys - aluminum, magnesium and brass. Before casting, the functional surfaces of the molds are treated with a special kaolin or similar coating, which will effectively separate the surfaces. Molds that cannot be removed from the mold are often made using sand cores. After casting, the cores are destroyed.

Compared to sand casting, the solidification of the mold occurs faster due to better thermal conductivity. A casting is formed with a relatively fine and dense material structure, which, at the same time, has better mechanical properties compared to a casting from the same material, but cast in a sand mold.

Advantages of die casting:

- due to faster solidification, chill casting has better mechanical properties and a relatively fine and dense material structure;

- slight surface porosity;

- high dimensional accuracy and reduced surface roughness;

- reduction of metal loss coefficient.

Chill casting is a good choice for producing medium-sized castings for runs of 1,000 to 10,000 pieces, with a minimum production run of 100 pieces.

The process is used to produce medium-sized castings of instrument housings, drive covers, racks, brass or steel sealing inserts (nuts, bearing housings, pins, etc.).

The main tool in foundry production

Foundry equipment includes models (templates), flasks and molds. What is a flask? This is a cavity into which molten metal is poured. The template is a replica of the object to be cast and is used to shape the casting. Models can be made of wood, metal or plastic. The main stages of obtaining equipment are:

- Obtaining a cavity;

- Dimensional processing of elements;

- Development and installation of clamping mechanisms.

Molds are developed taking into account metal shrinkage, for which compensators are provided. The walls of the molds have conical sections to facilitate ejection of the finished product from them. Hollow castings are created using a core, an additional volume of sand or metal that forms internal holes and passages in the casting. Each core is placed in the mold before pouring. To make it easier to remove the frozen casting from the mold, non-stick coatings are used.

There are two different types of casting molds: single-use and reusable.

The production of reusable pattern equipment is usually made from metal, disposable - from sand. To facilitate storage and use, the molds are always marked.

After the preparation of the molding sands is completed, the sand is placed around the model. Then the sample is removed, the rods are installed in place, after which the melt is poured. Casting tool design features are optimized for different metals and cavity complexity levels.

The cost of some types of foundry equipment and accessories is presented in the table:

| Name | Purpose | Approximate price, thousand rubles. |

| Kokili | For casting iron castings weighing up to 15,000 kg | 2 |

| Continuous casting line | For producing castings from non-ferrous metals and alloys | 7200 |

| Induction oven | Universal use | 800 |

| Injection Molding Machine | Same | 4500 |

| Induction melting complex | Same | 1500 |

| Continuous Vortex Mixers | For preparing sand mixtures | 13 |

| Centrifugal Casting Machine | Universal use | 25 |

| Mold | For casting iron | 1,5 |

| Knockout grid | To remove sand mold residues | 16 |

into the ground

Casting into the ground or into molds from a mixture of sand and clay is the oldest method of producing molten metal blanks. Over 80% of all castings come from it. It is distinguished by the simplicity and availability of the materials used.

The model and sprue kits are made from wood. After the model is ready, the molding mixture is mixed. The simplest ones include sand, quartz and clay.

Earth casting technology

Forming is done both manually and by machine. Manual mold making is used for the production of single or multiple castings and is considered unproductive. Machine forming is used on automated casting lines. Casting molds consist of two halves and are disposable. After pouring and cooling, the molds are destroyed. More than half of the waste material is returned to the molding operation after purification and recovery.

Defects in casting alloys

Before the casting production cycle is completed, the physical properties and structural integrity of the final product must be verified. Test methods can be destructive or non-destructive. The choice of defect detection method depends on the technological purpose of the part. Some purely aesthetic products require only a brief visual inspection to determine dimensional accuracy, presence of cracks, and quality of finish. For castings with industrial applications, all physical and mechanical properties of the metal (ductility, tensile strength, elongation, impact strength, hardness, etc.) are established during testing.

The most common casting defects are:

- Shrinkage defects. When metal hardens after being poured into molds or casting, it should shrink. When there is not enough metal, shrinkage of the cast iron will cause holes or voids to form in the casting. There are many types of shrinkage depending on its cause. With axial shrinkage, the material in the center takes longer to harden compared to the metal at the periphery, which leads to the formation of a cavity. This may be caused by the temperature at which the molten metal is poured, the speed of pouring, or the quality of the feedstock.

- Dispersive shrinkage. Dimensional changes in alloy elements can lead to a type of shrinkage where cavities form perpendicular to the casting surface. High nitrogen content or low carbon content can lead to this type of defect.

- Sometimes all foundry products may have the same type of defects in size. The reason is the different speed of solidification of different parts of the casting.

- Stitches or scars. This is a metallurgical defect, which is characterized by the presence of depressions on the surface of the casting. A defect is likely when graphite moves into shrinkage cavities during the melting process.

- Slag inclusions. They are small spots found on the surface of castings. Such inclusions are caused by contamination of the parent metal with carbides, calcites, oxides and sulfides.

- Failure to complete certain areas. Caused by the presence of gas in certain parts of the mold, reduced fluidity of the material. It will be necessary to increase its heating temperature and/or melt it in a vacuum.

Lost wax casting

Investment casting allows the production of precision components, minimizing material waste, reducing the energy intensity of production and reducing the cost of subsequent processing of finished castings, and of any degree of complexity.

Lost wax casting technology uses a shell of ceramic, plaster or plastic that is formed around a wax mold. This mold is then melted and removed in a furnace and the metal is poured into the shell to create the casting.

The lost wax casting process occurs in several stages:

- Creation of an initial sample that reflects the configuration of the finished part, adjusted for thermal shrinkage of the workpiece;

- Making wax samples and creating a wooden model. It is assembled in such a way as to ensure delivery of the melt to all hard-to-reach parts of the casting;

- Creating a mold shell, where the entire wax model is dipped into a ceramic slurry, covered with a sand shell and sent to dry. These cycles are repeated until a shell of the desired thickness is created, which is set to the dimensions and configuration of the finished casting. Once the ceramic shell dries, it is strong enough to hold the molten metal during casting.

- Removal of wax, for which the entire assembly is placed in a steam autoclave to melt almost all the wax (the remains, impregnated with ceramic composition, are burned in the oven). Then the sprues are also removed;

- Melting and casting. The mold is preheated to a certain temperature and filled with molten metal, creating a metal casting. The lost wax casting process can produce a finished product from any alloy. Depending on its chemical composition, melting in air or vacuum can be used. Vacuum melting is used when reactive elements are present in the alloy.

- Final operations. After the casting has completely cooled, the mold shell is separated from the casting by displacement. In this case, the remains of the channels and sprues are cut off, and, if necessary, sandblasting, grinding and mechanical finishing of the casting are performed to the dimensions specified in the product drawing.

The technology includes a non-destructive testing stage, for which fluorescent, magnetic particle, radiographic or other quality control methods are used.

Advantages of the method:

- A wide range of masses of the resulting castings - from small to 300...350 kg.

- Versatility and complexity of shape, including those that cannot be obtained by metal-cutting on machines.

- Minimization of subsequent mechanical finishing.

- High precision and low roughness of the finished surface.

Investment casting is a good alternative to welding because many components can be combined into one complex-shaped casting.

Since the tool is quite complex to manufacture, this technology fully pays for itself in serial and mass production.

Selection of specialists

This profession involves the production of cast iron, steel or non-ferrous metal parts through various casting processes, as well as periodic testing of materials to ensure quality. A specialist in a modern foundry - a cutter, a melter, a moulder - must know the various types of molds and materials, the processing of foundry tools, and the chemical processes occurring during casting.

Professional training includes:

- Theoretical vocational training;

- Internship in the company directly at the workplace;

- Internship or retraining courses.

The last stage is intended for foundry specialists who want to improve their skills. Among them may be production operators, engineers, managers, metallurgists, personnel of quality assurance departments, and labor protection specialists.

The mandatory training or retraining program includes:

- Fundamentals of metallurgical processes (materials, thermodynamics).

- Types of equipment.

- Secondary metallurgical processes (pouring, metal mixing, cooling).

- Molds, their design and maintenance.

- Casting defects.

- Modeling of foundry processes.

Metal casting in CTS

The acceleration of the casting process led to the development of cold-hardening mixtures (CMC), which have become widespread. They have certain disadvantages. For example, some self-drying oils create a form that requires long drying periods, especially when air access is prevented. Urea-based synthetic resins, which are also designed for use as CTS, have very low breakdown temperatures, which in turn limits the versatility of the resulting form. Sand mixtures containing furan-based acid-curing resins (another but relatively new cold-curing binder) also have certain limiting characteristics. For example, they tend to cause the mold to stick to the casting, and the outgassing that normally accompanies pouring molten metal into molds becomes very pronounced and turbulent.

Modern CTS compositions are formed using binders containing at least one diphenylmethane ethoxylin resin or diphenol derivatives, to which at least one organic compound containing many reactive amino groups is added as a hardener.

Very good results are obtained when ethoxylin resins are synthesized from para-substituted diphenylmethane derivatives, especially bisphenol. Moreover, their epoxy equivalent exceeds 170.

Among the organic compounds that can be used as hardeners, promising compositions are those having many reactive amino groups and especially polymers (linear or ring), which include from two to five = NCH CH groups.

Where do the supplies of raw materials and equipment come from?

Ferroalloys, alkali metal salts, boric acid, bentonite, etc. are used as the main chemical components. The main suppliers and delivery conditions are presented in the table:

| Provider | name of raw materials | Approximate price |

| MPI (Chelyabinsk) | Ferroalloys | 45…80 rub/kg |

| DOMINIK GEORG LUH TECHNOGRAFIT GMBH (Germany), Ekaterinburg | Graphite electrodes | 400…600 rub/t |

| BW KUNSTSTOFFE EK (Germany), Biysk, Belgorod | Electric foundry furnaces | On request |

| SMO Crl (Italy) | Press forms | 20000…30000 |

| SBM InfiSPA (Italy) | Mechanical and loading equipment | 80000…120000 |

Domestic raw materials are used, as well as those supplied from China, Sweden, and Ukraine.

Modern foundry technologies

Modern foundry is a complex technological method, in which blanks of metal parts are obtained by pouring a molten metal alloy into a specially prepared casting mold;

inside it there is a cavity of the required configuration. After hardening, the resulting workpiece is removed and processed to the desired state. The modern foundry industry confronts specialists with the task of obtaining workpieces that best fit the shape, requiring minimal costs for their modification. The following is a description of the most famous types of casting in modern industry.

Sand casting

This is the most cost-effective, yet very crude casting method. Due to its low cost, the method is the most widespread.

First, a casting model is made. Previously, wood was used for these purposes, but today it is much easier to make a model using a modern 3D printer from inexpensive polymer materials.

Making sand molds

The prepared model is installed on a kind of under-model plate, and a box without a bottom (flask) is placed on top of the model. The gap between the model and the nearest walls of the flask is filled with sand or a pre-prepared mixture of sand with a special binder.

For complex things, two half-forms (2 flasks) are used, the plane of their contact is the place of the connector. The model is removed, the resulting half-molds are connected and then casting is performed. To pour metal directly into the sand-molding mixture, sprues are made - special holes.

After hardening is complete, the workpiece is removed, the flash and sprues are removed, and the surface is processed to standard quality.

Currently, casting in disposable sand molds has made it possible to use vacuum-sealed molds made from dry special sand without the use of a binder.

Continuous casting technology

When making castings by continuous casting, the molten raw material from the metal receiver through a graphite hollow half-rod enters a crystallizer with mandatory water cooling, and when solidified, it is drawn out by a special device. Such blanks are later cut to the required dimensions.

Continuous casting is used to produce semi-finished cast iron, non-ferrous, and precious metals. metals The workpieces cannot have foreign inclusions, porosity, or cavities due to the creation of a narrowly directed flow of metal solidification. This feature makes this method unsurpassed for the production of high-quality wire.

Casting using gasified burnt models

With the method of casting using gasified models, it became possible not to remove the disposable model from the casting mold before pouring. Or such sources are removed by burning, dissolving, etc.

Due to the low cost of polystyrene foam, this method is often used to make castings for various artistic purposes.

It is good to use for single copies of elementary castings, for example, overlays with simple ornaments, branded boards, etc.

When making a model, polystyrene foam granules must be foamed for active growth. Next, the raw materials are placed in foam molds and heated again.

At the same time, the reactive process of expansion and sintering of the placed granules begins; as a result of the resulting pressure, polystyrene foam fills all the voids inside the mold.

The connection of various elements is carried out by simple gluing, using compositions that do not aggressively affect the chemical characteristics of the source and completely burn out when heated.

The molding of gasified models must be done in sand-clay, self-hardening, liquid-glass mixtures. The great advantage of this progressive method is the possibility of simple sand molding without a binder. In this case, the sand in the mold cannot mix with the metal that replaces the model.

Shell casting method

Shell casting is a technology for producing metal castings in molds made using model hot tooling from specially mixed sand-resin compositions. Such forms have strength, pliability, gas permeability, and non-hygroscopicity.

Shell forms have the following properties: sufficient strength, gas permeability, pliability, and non-hygroscopicity.

The shell casting process begins by coating a preheated platform with a thermosetting resin on which a grease-free metal model is mounted. When heated, the original composition melts, forming a semi-solid shell.

In order to remove excess resin, the mold with the model plate is turned over and then heated additionally. After hardening, the shell—the half-mold—is removed from the matrix and connected by gluing or bonding with the other half.

Then the finished shell mold is placed in a previously made flask and then filled tightly with the molding mixture. After pouring, this form is destroyed.

Injection molding

When producing a semi-finished product by injection molding, only metal molds are used, but the hot melt is poured into the prepared mold under pressure.

This method is quite highly productive, while providing a high quality surface structure. Non-ferrous metals are usually cast using this method. The range of casting sizes is very different - from one g to several, and sometimes tens of kg. This type of casting is used mainly for various mass production of hollow products, most often of simple configuration.

Centrifugal casting

The centrifugal method involves the formation of castings under the sharp influence of generated forces inside a spinning mold, freely filled with melt. This is how semi-finished products are produced from ferrous and alloys of many non-ferrous metals. Specialized installations have now been developed for gentle centrifugal casting of precious metals.

The main and main advantage of the presented method is the unsurpassed high, when analyzed with other types, density of the resulting crystalline structure of the metal used. This feature imparts excellent mechanical properties to the required workpieces.

This type of casting can be produced on machines with different axes of rotation - vertical or horizontal. For it, sand, metal, and shell molds or molds (flasks) based on wax models are used.

Die casting

Chill casting is considered to be the production of a workpiece by pouring the melt into a reusable metal chill mold. In this case, heat is removed quite quickly through the highly thermally conductive material of the mold, so the surface of the casting and its mechanical features are obtained at a significantly higher level than with the vast majority of other methods.

The most interesting feature of the presented method is the unique possibility of multiple use of a single-use metal mold.

Its significant strength can make it possible to very accurately copy the surface configuration, while simultaneously obtaining the highest quality metal.

Due to the high thermal conductivity of the mold, the product quickly hardens, and the speed of production of the semi-finished product increases accordingly.

Lost wax casting method

Today, lost wax casting is becoming the most popular method in the art industry.

Modern technology involves the preliminary production of a high-precision sample from any low-melting material, often wax. This model is filled with a special mixture - molding mass.

After hardening, wax blanks are melted out of it to obtain a casting mold. The melt must be poured into the resulting cavities. As it hardens, it forms blanks for future products.

Our readers can find a detailed description of lost wax casting in the section “Technological processes at VYUZ “Russian Silver”. This is the type we use.

Nowadays, casting technology has managed not only not to lose its dominant role in the jewelry industry, but, on the contrary, its new amazing possibilities have opened up.

This trend has become a necessary link between the unique art of the jewelry artist and modern jewelry production.

Technology for the production of casting molds using layer-by-layer 3D printing

October 24, 2019

Denis Bychkovsky, Ph.D. Sc., General Director of Additive Technologies LLC Alexander Netkachev, Technical Director of Additive Technologies LLC

Domestic foundry production is the main base of the machine-building complex. The prospects for the foundry industry are determined by the pace of development of mechanical engineering, the need for castings, the dynamics of their production, the level of development of foundry technologies and the competitiveness of domestic enterprises

According to recent data, there are about 1,250 enterprises in Russia that produce castings, equipment and related materials.

However, the level of automation of foundry production in our country is extremely low - 78% of castings are produced on mechanized lines and machines, as well as manually.

In this regard, the development of automated methods for creating foundry molds is becoming one of the priority areas for the development of the industry.

Problem and solution

In transport engineering today, high-tech internal combustion engines are widely used. Their design includes complex-shaped and often large-sized cylinder blocks and cylinder heads, which are manufactured by Russian enterprises using traditional casting technologies.

The first is casting into one-off molds made by hand using physical master models. This requires a long technological chain of making a master model, preparing the mixture, molding and drying parts of the mold, storage space for models, and so on.

Another technology - chill casting (metal mold) - is very time-consuming (from 6 months to 1-2 years), labor-intensive and economically unprofitable, and in addition, this method is associated with a high risk of defects in the manufacture of the chill mold. Both approaches have technological limitations on the complexity of the internal casting configuration.

Using the listed technologies, it is impossible or extremely difficult to create complex cooling channels, optimize the design and reduce the allowance for subsequent processing.

All this significantly limits the potential for developing new products and complicates the release of new models, increases the time for new products to enter the market and the cost of launching production, which, in turn, negatively affects the competitiveness of the final product. Problems with the inability to implement the best design design configurations using traditional methods lead to a decrease in product performance.

Recently, to overcome technological limitations and speed up design and production times, world leaders in mechanical engineering have been actively introducing additive technologies.

Creating casting molds using layer-by-layer synthesis methods allows you to bypass the technological limitations of traditional methods and shorten the production chain, eliminating such operations as making a master model from metal or composite materials, manufacturing a gating system and profits, molding parts of the mold (installation of a master model and gating system into the flask and filling with the mixture). This leads to a reduction in production time and an order of magnitude reduction in the cost of the mold.

As an example, consider the manufacture of a casting rod for forming internal engine cooling channels using various methods (Fig. 1). As can be seen from the above example, the cost of manufacturing a mold using the technology being developed is three orders of magnitude less than using any other technology.

A similar economic effect is achieved due to the fact that a 3D printer creates a casting mold directly from a digital model. This model is divided into layers and transferred to a 3D printer, in which the hardener is applied according to the digital model of the casting mold onto a pre-prepared layer of sand mixture.

As a result, a hardened part of the sand mixture is created in the construction area, which exactly replicates the digital model.

Product Volume of the rod Material Linear dimensions of the rod

| Casting rod for forming internal engine cooling channels | 300 cm3 | sand (gypsum) removed from the casting | 300×216×85 mm |

Rice. 1. Comparison of casting core manufacturing methods

SLA and SLS technology 3D printing CNC machine Sand-polymer 3D printing

| Cost, rub. | 46560 | 21560 | 45 |

| Time, days | 9 | 24 | 1 |

Rice. 2. Printed mold for casting the cylinder head assembly with casting cores

Printing technologies used for the production of foundry molds

For the production of casting molds using layer-by-layer printing, inkjet printing and clad sand sintering technologies are used.

Review of some options for turnkey production complexes

In addition to equipment that uses chill molds, there are other production complexes.

Press machine for metal casting. It is designed to work with molds and is most often used in the manufacture of non-ferrous metal parts. Characteristics:

Continuous casting machine

- created pressure – from 33 to 135 MPa;

- power consumption – 30 kW/h;

- maximum weight of one casting – 6 kg (aluminium);

- cost – 700,000 rubles.

The turnkey machine complex PR-1000 from AB Universal is designed for casting non-ferrous metals, characterized by complete melting, slag-free casting, and precise filling of molds - this ensures high quality of finished products. Characteristics:

Development of the design of a horizontal continuous casting machine for non-ferrous metals

- crucible volume – up to 2000 cm3;

- maximum weight of one casting – up to 5.4 kg (aluminum);

- maximum height of the flask – 400 mm;

- flask diameter – up to 500 mm;

- power – 30 kW;

- dimensions – 2000*1500*850 mm;

- cost – 1,500,000 rubles.

The turnkey production complex DTC-280 from the Global-Mash company is designed for the production of cast products from non-ferrous metals. Specifications:

Shot casting machines are designed for the production of cast steel and cast iron shot

- mold sizes – from 250 to 680 mm;

- pressing pressure – up to 188.4 MPa;

- casting area – up to 290 cm3;

- power – 18.5 kW;

- dimensions – 2560*1410*6420 mm;

- weight – 11500 kg;

- cost – 6,000,000 rubles.