Industrial equipment can sometimes not only maintain average temperatures, but also be useful in cooling liquids and climate systems.

Chillers are very often used in factories in conjunction with powerful refrigeration devices.

The compressor for the chiller system must be selected taking into account the characteristics and functions that it must perform.

Based on the cooling method

It can also be divided according to the method of cooling condensers on industrial climate systems into:

- Devices that cool capacitors with air. This happens in this way: fans are installed on the roof or walls of the structure to cool the condenser.

- Devices that cool the condenser using water. In such cases, the temperature depends on the water. It happens that systems are installed that supply water, but not as the main cooling method, but as an additional one.

Modern energy saving systems

Russian production is confidently switching to energy-saving technologies - less expensive and more environmentally friendly. Thanks to recuperative installations, recycled thermal energy can be used for production needs, rather than being discharged into the atmosphere using outdated methods. In financial terms, the purchase and installation of a recuperator pays off within 1-3 years; excess heat can be used:

- for air heating of nearby premises

- for heating water in the DHW network

- for heating water in the heating network

The selection of equipment for cooling systems for production processes has many nuances and can only be performed by a qualified engineer, after a detailed study of the production cycle and the necessary calculations.

Depending on the capacitor mounting

The following classification of chillers for water cooling is based on the installation of the condenser:

Systems that are mounted inside

If this type is used, then installation takes place indoors. But this method has two minor drawbacks, the first is that it steals space in the house, and the second is that as soon as you install such a system, there will be constant noise in the house.

A system that is mounted from outside

The installation of the capacitor body takes place from the street; you can attach it to the facade or to the roof. This installation method is the most common - the most advantageous thing is that you will not take up space indoors by installing a bulky condenser outdoors.

Installation rules

Installing a chiller is a complex job that requires highly qualified project developers and builders. Installation requires special equipment.

Chiller installation includes the following steps.

- Design - a specialist evaluates heat supply and coolant consumption, structural features of the building. He selects the appropriate type of installation and its execution.

- Choosing a location. For an outdoor monoblock chiller, the support frame must be welded. It should evenly distribute the load on the walls and roof and be high enough to protect the device from rain and snow. A special platform is prepared for indoor chillers. Since the device makes quite a lot of noise and vibrates, it should be placed as far as possible from rooms with people.

- Installation of the chiller - the device is brought to the installation site, unpacked, secured to the frame or placed on the site. Blowers and coolant pipes are fastened according to a pre-developed diagram.

- Connection to the power supply network and coolant system is carried out according to certain schemes. The algorithm is individual in each specific case. All factors are taken into account: device power, load, distance between air intake points and the working unit, operating conditions, etc.

- Commissioning work - after connecting the chiller, they start and check the operation of the system in all possible modes and with any permissible load. It is important to identify any shortcomings or errors at this stage.

All operating parameters must be adjusted to the design data. Only in this case can the installation of the chiller be considered complete.

What is the essence of the work

What is included in the chiller organization system for water cooling:

- Capacitor

- Evaporator

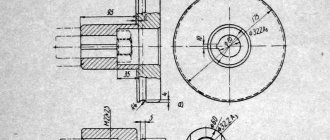

- Compressor module

The essence of the operation of a chiller with cooling using water: water moves through the evaporator, and the refrigerant also moves through it, this is a liquid that cools by eliminating warm energy.

In order for the water cooling process to start, the temperature of the refrigerant needs to rise to the maximum and then energy from the water begins to be absorbed.

And then the water begins to cool, and the liquid itself that cools the water, called freon, changes its state from liquid to gaseous and then moves to the module with the compressor.

When freon enters the compressor, its temperature rises to ninety degrees, and then goes to the condenser. And already there cold air blows on him, giving him a cold appearance again.

The refrigerant moves to the cooling part, and already there the temperature drops and a process occurs in which a transition from a vapor to a liquid state occurs.

When the freon continues to move and has already passed from the safety part to the thermal expansion part, the pressure drops, which makes the refrigerant vapor again.

The cooling liquid is again transported to the evaporator and the process starts from the very beginning.

Types of chillers and their descriptions

Based on the type of coolant, chillers are divided into:

- propylene glycol;

- ethylene glycol;

- aquatic.

The devices are equipped with a specialized microprocessor control system. For each chiller model it is always possible to select additional options. equipment, and this makes it possible to install the equipment anywhere.

Compressor-condensing devices are designed taking into account the latest technical and engineering developments, as a result of which they are equipped with microprocessor control, low-noise fans and special scroll compressors.

The refrigerant used (HFC-407°C) is absolutely harmless and does not have the slightest negative impact on the ozone layer.

An additionally developed evaporator in the form of a plate heat exchanger makes it possible to optimize the thermodynamic characteristics of the equipment as much as possible. The devices are equipped with a heater protection system against freezing during times when this equipment is not connected to operation.

Small-sized modules are mounted on a base frame, which includes all the components necessary for starting and operating the equipment.

Main components

The water cooling chiller consists of the following parts and systems.

- A compressor - its function is to combine steam and liquids that cool.

- The condenser performs the function of a heat exchanger. In this part of the system, heat is removed, which is used by freon. The system is equipped with fans that continuously cool the heat exchanger, preventing it from overheating.

- A system that automatically replenishes supplies. It works on the principle of semi-automatic replenishment of water into the general system. This is a necessary measure if the level of cooling fluid in the system has dropped below normal. The system is filled using a float chamber and valve. The float chamber pulls to the bottom, this in turn opens the shut-off valve. And when the spraying work is completed, and there is as much water in the system as needed, the valve automatically closes and the water no longer flows.

- High pressure switch - this is necessary to ensure that there is not too much pressure in the path when moving the refrigerant.

- Relay - it is necessary to ensure that the cooling water does not completely freeze

- A temperature limiter is a sensor that regulates the temperature in the system so that it is not very low or very high.

- Excess pressure gauge. It goes along with the relay, and has the same function - to keep the pressure normal.

- Sediment that cools liquids. Its function is to transport water or cooling liquids through the system.

- Liquid receiver - it has the function of transferring and storing cooled liquid

- The freon evaporator begins to boil, because of this it takes away the temperature of the water - this leads to cooling.

- The filter is its task to filter out any contaminants that can get into the freon as it moves through the system. If the freon is not filtered, this may adversely affect the operation of the chiller.

- Gas bypass valve. If this valve starts to operate and opens slightly, the refrigerant in a gaseous state moves into the evaporator part.

- Solenoid valve. This mechanism is controlled under freon pressure. The valve stops working when the compressor stops, this helps protect the system from temperature changes. And the tap resumes operation only when refrigerant enters the system.

- Thermostatic valve - the function of this valve is to prevent an excess of coolant that is transported to the evaporator. This function is extremely important because all the liquid that appears in this part could evaporate.

Liquid evaporation rate.

Unlike boiling , evaporation occurs at any temperature, however, as the temperature of the liquid increases, the rate of evaporation increases. The higher the temperature of the liquid, the more fast-moving molecules have sufficient kinetic energy to overcome the attractive forces of neighboring particles and fly out of the liquid, and the faster evaporation occurs.

The rate of evaporation depends on the type of liquid. Volatile liquids whose intermolecular interaction forces are small (for example, ether, alcohol, gasoline) evaporate quickly. If you drop such a liquid on your hand, you will feel cold. Evaporating from the surface of the hand, such a liquid will cool and take away some heat from it.

The rate of evaporation of a liquid depends on its free surface area. This is explained by the fact that the liquid evaporates from the surface, and the larger the free surface area of the liquid, the more molecules are simultaneously released into the air.

In an open vessel, the mass of liquid gradually decreases due to evaporation. This is because most of the vapor molecules disperse into the air without returning to the liquid (unlike what happens in a closed container). But a small part of them returns to the liquid, thereby slowing down evaporation. Therefore, with the wind, which carries away vapor molecules, the evaporation of the liquid occurs faster.

How not to make mistakes when choosing equipment

If you want your office or home to have an ideal climate for you, then you should choose liquid cooling.

This type of ventilation and cooling is the best option in those places where the temperature is always very high, without the ability to reduce it, and there is severe air pollution, as often happens in factories, factories and even small enterprises.

But remember that it is not enough just to find a recommended chiller for cooling water; the installation must be suitable for your office in many respects.

Reviews of the HUBER DC SERIES flow cooler

On sale you can find a flow-through water cooler of the above-mentioned brand. It belongs to one of the varieties of liquid cooling thermostats. According to users, this equipment is specially designed for use in undemanding and simple systems with circulating liquid. The unit is ideal for cooling running tap water. The chiller can serve to reduce the lower threshold of the temperature range. You will be able to precisely control the process temperature if you use this cooler in water baths that are equipped with circulation adapters.

In this case, the entire system does not have to be replaced, it will only be necessary to add an in-line cooler to get a thermostat in the bathroom and cooling and heating functions. This water cooler has compact dimensions, which are limited to 190x250x360 mm. The temperature range can vary from 30 to 50°.

Temperature parameter

Simply deciding to purchase a chiller for cooling water is not a bad first step, but now you need to approach the process of choosing it responsibly.

First, determine what is the average temperature in your room and what is the recommended one, we cannot say that there is a standard, since the factory may also be for the production of ice cream, where the recommended temperature is very low.

So first, decide what you want from this chiller.

If this is a factory, then remember that your machines, equipment, and belts remain one of the most active heat generators; they emit a lot of heat, which also needs to be taken into account.

So the chiller you choose must be able to convert hot air.

Characteristics of the FD200 flow cooler

This model is used in conditions below room temperature in combination with heating thermostats. A plus is reduced energy consumption and the ability to use drinking water. Among other things, the equipment is compact and easy to manage. The device has effective protection against hypothermia, takes up little space during installation, and does not require the use of tap water.

This immersion through-flow cooler can operate in an ambient temperature range of 5 to 35°. Its weight is 16 kg, which is very convenient even for self-installation.

Source

Cooling type

If you are choosing a water-cooled chiller, you need to decide which cooling component you will choose, what temperatures you expect from it, and what flow rate you are prepared for for this component.

All these indicators determine the process of heat energy transfer and the cooling itself directly. Also, different components have different characteristics.

Evaporation mechanism.

How does evaporation occur? The molecules of any liquid are in continuous and random motion, and the higher the temperature of the liquid, the greater the kinetic energy of the molecules. The average value of kinetic energy has a certain value. But for each molecule the kinetic energy can be either greater or less than the average. If a molecule with kinetic energy sufficient to overcome the forces of intermolecular attraction appears near the surface, it will fly out of the liquid. The same thing will be repeated with another fast molecule, with the second, third, etc. Flying out, these molecules form vapor above the liquid. The formation of this steam is evaporation.

How to cool water in an aquarium

Chillers that cool water come in different sizes; they can be huge production machines, or they can be compact devices. So the application is very wide, and one of the areas is cooling water in an aquarium.

Chillers are often used on fish farms, where it is necessary to bring the water climate closer to the native one for the fish, for better growth. They can also be found in pet stores, in large aquariums with fish, and even in grocery fish stores where they sell raw fish.

But it’s not a problem to find a chiller on the market for a regular home aquarium.

Here you also need to calculate what the temperature is in the aquarium, since the light lamps also emit their heat. But a chiller for cooling water should save the situation.

The principle of operation is the same as on huge industrial machines, just in a smaller body.

Making the right choice

Purchasing a chiller for ordinary household use is not very rational, since its prices are quite high, and, in principle, you can find other methods of cooling at home.

But if you still think that you need it and are going to buy it, then let's do everything right.

If you want a chiller for fish breeding, then this is a very right step; with the help of water climate control, the fish can go to spawn, which will significantly increase their population.

And when you stand at the counter with chillers for cooling water, pay attention to the following:

- How much

- What energy saving class is this chiller (in principle, you will not find unbalanced models; the manufacturer tries to combine both productivity and low energy costs. Even if you see a good price for a powerful chiller, you should not buy it if it does not suit your parameters.

- Noisiness, the larger the chiller, the more noise it makes.

- How simply is the device built, and can you find components for it on our market in case of a breakdown?

- Assess the size of the chiller to see if it will fit the size of your aquarium

- Visual assessment is also important to determine whether the aquarium design suits you

- How functional is such a chiller for cooling water?

Bottom line

Water cooling chillers are a very useful thing that will help you maintain the required climate; in production, it cools the air and purifies it. And at home you can use it for your fish.

Chillers are also used by farmers who want to increase the fish population.

If you choose a chiller correctly, it will stabilize the situation at your enterprise in a matter of days, and what’s nice is that it will reduce energy costs.