Types and purpose of jewelry rollers

Such machines are used in any modern enterprise for the production of cone, oval, and cylinder shaped products from metal sheets. The process of creating such structures is called rolling. Rollers make it possible to produce any pipes, blanks for further stamping, and various finished products from metal sheets.

Before manufacturing a rolling machine, you should make a drawing of it

Simple rollers are also used in everyday life when you need to do it yourself:

- Gutters;

- Chimneys;

- Pipes;

- Air ducts;

- Other products for roofing and construction.

Modern equipment makes it possible to work with almost any metal sheet. They bend sheet material made of stainless steel, alloy and carbon alloys, aluminum and cast iron sheets without any problems. There are also roller models that operate with polycarbonate workpieces.

All equipment for working with metal sheets can be divided into the following groups:

- Handmade (jewelry);

- Electromechanical;

- Hydraulic.

The manual machine can be installed on a stand (on the floor) or on a workbench (on a table). It does not have an electric drive, so bending on it requires sufficient human strength. Manual jewelry machines are very easy to use. Their design creates the highest reliability of operation of special equipment over a long period of time.

Manual equipment is intended for producing pipes and other products from metal sheets up to 1.5-2 mm thick.

Manual machines are small in size, which makes it possible to transport them and use them directly at the site where repairs are being carried out. It should also be noted that such units do not require electricity. The cost of a manual floor or table machine is always cheaper than an electromechanical one. Machine equipment for bending sheet metal with an electric motor equipped with a gearbox is most efficient in operation. On such machines the work goes faster. The electromechanical machine is mounted permanently in the required workshop of the enterprise and is used for processing metal sheets up to 4 mm thick.

Hydraulics belong to the heavy class. Such machines are required for the creation of pipes and other structures on a large industrial scale at plants:

- Power engineering;

- Shipbuilding;

- Mechanical engineering.

In terms of potential, hydraulics are superior to mechanical and manual designs to a significant extent. It is possible to make pipes yourself from metal sheets up to 8 mm thick. Often such special equipment is equipped with program control.

Main technical parameters

How to make a sheet bending machine with your own hands? To do this, it is necessary not only to develop drawings of such a device, but also to determine its technical characteristics. It is best to take the design of a serial model as a basis and independently adapt it to your own needs.

Assembly drawing of a factory-made three-roller machine (click to enlarge)

Considering the fact that you are going to install your rollers in a certain room, you should immediately decide on their dimensions. This parameter, which directly depends on the length of the installed shafts, will determine what width of sheet blanks you can process on a device made by yourself. When deciding on the size of hand rollers, you should also take into account the fact that processing sheet blanks with a width of more than 1.2 meters using them will be quite difficult physically. The weight of a homemade machine will affect the ability to move it around the room and transport it.

Drive shaft. Drawing (click to enlarge)

Folding shaft. Drawing (click to enlarge)

Pressing shaft. Drawing (click to enlarge)

Drawing of three-roll plate bending rollers with electric drive (click to enlarge)

In addition to the dimensions and weight of future rollers, it is necessary to determine the following characteristics of such equipment:

- the diameter of the rolls - the main working parts of the device (this parameter, which is quite important, will determine the maximum radius with which you can bend the metal sheets being processed);

- the maximum distance at which the upper thrust roll can be located from the lower ones;

- the maximum distance to which the lower rollers can move apart;

- the speed at which the processed sheet material can move between the rolls.

Studying the technical parameters of factory models will help you decide on the size and design of the machine.

An important parameter that you should pay special attention to when developing a drawing of future rollers is the rigidity of their design. When processing metal sheets, significant mechanical loads are experienced not only by the rolls, but also by all other components - bed, drive mechanism, etc. That is why the choice of the roller operation scheme, as well as the selection of materials for its implementation, should be done with particular care.

Most often they are used for the manufacture of 3-roll rollers, since an increase in the number of working parts of such low-power manual devices leads to an increase in the level of load exerted on its drive mechanism.

Operating principle of a metal rolling machine

The main component of the machine equipment is the cast frame. It can be steel or cast iron. A special deformation mechanism is installed on the frame, which consists of 3-4 rollers. Three-rollers are usually used. Two rollers do not move; the third roller rotates during operation.

In addition, the movable shafts can move vertically.

The roller is fixed on top of the frame according to a scheme that allows you to quickly remove it if necessary or quickly adjust it for the production of pipes with different cross-sections. This structural element is adjusted using a single thumbscrew.

The metal rolling machine has a long service life

If the work rollers have grooves , you can bend them:

Manual metal bending equipment traditionally has 3 rollers, but there is a type of pipe bender with 4 rollers. But hydraulic machines are always created with 4 rolls.

Making pipes on any unit is quite simple:

- Clamping the sheet with a special handle on the machine equipment between the shaft in the middle and at the edge.

- Pressing the workpiece with the third roller.

- Rotate the roll manually or start the engine.

Characteristics of the rolling process

The fundamental feature of sheet metal rolling is that the deformation process occurs over the entire contact surface . This slightly reduces productivity, but increases the durability of the rolling work rolls. The advantages of metal rolling include:

Reduced operating costs for tooling and equipment.- Increasing the service life of tools and machines.

- Effective use in single and small-scale production.

- Reducing losses from marriage.

- Low cost of a rolling machine compared to a hydraulic or mechanical press. The cost of its acquisition pays off within six months of active use.

During the rolling process, the operator can change the rate of metal deformation. With other forming and stamping operations this is not always possible.

Rolling a sheet of metal can be done in several ways:

- in the transverse direction of the workpiece feed;

- in the longitudinal direction;

- with screw feed.

The first option is used to obtain short pipes, the second - long ones.

The sheet rolling process is characterized by the following features:

Deformation is produced by torque, not force. The value of the torque depends on the conditions of contact friction, the diameter of the working rollers and the physical and mathematical characteristics of the material.- When performing an operation, the rolling speed does not affect energy costs; on the contrary, as the indicator increases, the working force of the process decreases.

- The friction between the rollers depends directly on the surface. Reduced roughness leads to reduced friction. Therefore, during continuous operation of rolling machines, it is necessary to periodically grind the surface of the equipment.

When rolling a steel product up to 6 mm thick, the original metal is processed in a cold state. If you are working with parts made of thick sheet material, preheating is used. In such cases, the rolling machine is installed near furnaces with a non-oxidizing heating system. Due to this, the formation of surface scale is reduced.

If hot-rolled sheet metal is deformed, the sheet is straightened before rolling. This is stipulated by the technical requirements of GOST.

Rules for strengthening profile pipes

It is almost impossible to do without a device such as pipe rolling equipment in cases where you need to carry out repairs yourself, which will require the use of curved pipes.

To do this, you need to purchase a unit of this type or use homemade profile benders, the design of which is quite simple.

It also makes sense to ask the question of how to make a machine for bending metal because store-bought products are expensive, so buying them (especially if they are needed only for home use) is not always rational. In order to make high-quality homemade rolling, you can study the theory, watch a video on this topic, but the main thing is to listen to the advice of those who have already achieved excellent results.

When using the machine, please follow safety instructions

Naturally, to build your own rollers, you need:

- Have relevant knowledge;

- Have certain skills in manufacturing and using various technical devices;

- Prepare drawings and materials.

Do-it-yourself rollers can even be created from improvised building materials, which are almost always available in any garage or workshop at home. Moreover, such equipment, if everything is done taking into account all the recommendations, will work no worse than products from the store.

Application area

The sheet metal rolling process is a deformation method that is performed using a non-profiled rotating tool. This is a cold forming operation in which the metal takes the shape of a cone. After processing in this way, the structure of the workpiece becomes denser and its basic properties improve.

Metal deformation is used in many cases and for different materials. For example, rolling is a preparatory step for stamping the finished product. The same technology is used for primary processing of blanks.

This procedure can be applied not only to sheet metal, but also to pipes, rods and other profiles, products made from rubber compounds and plastics. It is important that the material is sufficiently ductile.

Metal rolling is often used to compact, compress and flatten workpieces, to give them a uniform gloss and thickness. The process can take place both in a cold state and in a heated state. It is possible to heat the rolls and change the speed of passage of the workpiece.

Today, metal rolling is carried out not only in production, but also at home, for which they use a special tool of the same name. In enterprises these are large machines with electric and hydraulic drives. Simple designs, often made by hand, are more suitable for repair shops.

The technological process of metal deformation using this method consists of several stages:

- Preparation of equipment - rollers.

- Rolling a bar or sheet.

- Intermediate annealing.

- Treatment of burrs and cracks.

- Final annealing and rolling.

The absence of burrs and cracks is one of the main conditions for high-quality rolling. Such defects can appear in the event of excessively strong compression of the bar by rollers or from uneven stress and annealing. Defects are identified and eliminated at the fourth stage of work after intermediate annealing. If this is not done and rolling continues, the cracks will increase.

Eliminate defects by rubbing cracks with a file and sawing off, biting off burrs. Then, in order to relieve stress from the metal, the workpiece is annealed and metal rolling continues. The resulting depressions are leveled.

This is interesting: Metal drill: types, markings, selection rules, manufacturers

Making equipment yourself

Anyone can make such machine equipment on their own.

Before using the metal rolling machine, you should watch the training video

What building materials and how can this be made:

- The first step is to take a frame made of pipes or a bent metal profile, which will play the role of a frame.

- Next, you need to prepare a U-shaped metal profile (it is best to use hardened steel for this) to create a vertical support for the machine.

- The deforming unit of the rolling unit must be installed in the open (top) part of the metal profile. You can secure it using a clamp with a thread.

- Under the bed you need to secure the bottom of the metal profile P.

- Next, you need to take the transmission chain, without which the machine will not function, and mount it on the stars. It is necessary to tension the chain very well and check the ease of its movement.

- Now you need to mount the feed handle and attach the entire mechanism to the frame using rolling bearings.

The machine is ready. It is important to properly think through a special mechanism in its design that will make it possible to regulate the gap between the rollers. Then it will be possible to process metals of various thicknesses. You can make the most complex rollers yourself. The main thing is to prepare drawings of the machine equipment and follow the instructions.

Having studied the drawings of homemade machines, it is not difficult to make equipment that is ideally suited and will help solve the tasks.

Standard profile pipes of square or rectangular cross-section, due to their high bending strength and low weight, are widely used in construction. In cases where the permissible load values are exceeded, which occur during strong bending, the products become deformed and break. The use of pipes with a reinforced profile allows you to eliminate negative consequences.

General information

sheet bending machine Enkor Corvette-503

The first metal bending equipment was developed in the United States of America more than two hundred years ago. It, like the knee-bending machine, worked on manual traction and did not find widespread use, since the quality of the products was quite low and operation was dangerous. The manual device was replaced by a pneumatic one. The compressed air equipment operated slowly and was not highly efficient. In the second half of the last century, a hydraulic sheet bending machine appeared - reliable, productive and safe.

The principle of operation of all sheet benders is similar, they differ in the type of traction: a sheet of metal is fixed by a pressure beam and pressed down by a bending crossbeam. The worker monitors its operation using a sensor system. The machine is often supplemented with a back stop, the position of which is set depending on the width of the strip to be bent. Metal sheets are fed manually or automatically for processing.

Machine for strengthening profile pipes

Reinforcement means the formation of ribs at the corners of a square or rectangular profile during rolling on specially shaped rollers.

Pipes with a reinforced profile are characterized by high bending strength and are used to create curved structures of any degree of complexity.

The profile is strengthened using specialized equipment.

Application area

To obtain the desired configuration, profile pipes are sequentially processed on profile strengthening machines, a forging block and a pipe bender.

A pipe bender allows you to bend profile pipes along a longitudinal section along a given radius. Such products are used when installing canopies, gazebos, and canopies.

Price

The cost of factory models of jewelry rollers, which can be equipped with either manual or electric drive, depends on their functionality and is in a fairly wide range. The most budget models, which in their functionality resemble homemade devices, cost about 6 thousand rubles. As a rule, such models are miniature desktop devices without additional functions that allow processing products of limited width and a certain configuration. Naturally, on the working surfaces of such devices (which, as a rule, have manual drives) there are no grooves, which are called streams.

Professional electric rollers with a cast iron gearbox will cost about 200 thousand rubles

Rollers for jewelry production, which are in the middle price range, cost 20–30 thousand rubles. These devices are the most popular. Thanks to the larger number of working shafts, such models, in comparison with the most budget-friendly ones made by hand, are distinguished by a longer working surface, due to which the impact on the workpiece is ensured. If for rollers made by yourself and belonging to the budget category, the length of such a surface is about 30 cm, then for more functional models this parameter reaches 1 meter.

The cost of the most expensive and truly functional roller-type devices used in jewelry can reach up to 1 million rubles, and on average it is in the range of 100–300 thousand rubles. An alternative to purchasing them, which also involves quite large expenses, is the services of specialized companies that have such equipment at their disposal.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Making a machine yourself

It doesn't always make sense to purchase a professional machine. For one-time work, simple DIY installations are more suitable. The main thing is to have drawings, carefully study the design principle and operation of the machine, select high-quality materials for the workpieces and the necessary tools for assembly.

Scheme

Schematic diagram of a machine for rolling 2 types of profile sections in section. Based on it, you can get an idea of the design and interconnection of the main components and the principle of pipe processing. In this case, the upper shaft is the driving one.

Machine diagram

Accessories

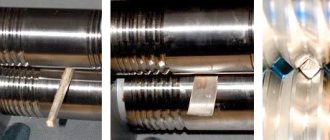

Rolling roller components must not have chips or gouges, have a decent margin of safety, and be made from certain grades of steel.

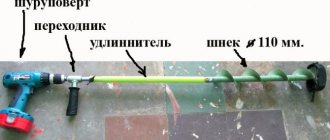

Shafts and axles are turned on a lathe. Some components can be bought in a store or removed from other mechanisms, for example:

- self-aligning rolling bearings (4 pcs.);

- stars (4 pcs.);

- chain from a bicycle, moped.

To assemble the frame (base), you will need rolled metal (channels, pipes), sheets 5-10 mm thick. The base ensures stability of the installation during operation.

Frame assembly

To strengthen the profile, it is better to make rollers (2 pieces of each type) from alloy steel; for a small amount of work, St3, St10 are also suitable. Roll blanks are subjected to hardening.

IB2222 Procedure for operating the machine when bending a cylindrical shell

- The sheet is inserted between the top and side rollers. In this case, the edge of the sheet should be aligned parallel to the generatrix of the front roll

- The rear side roller moves to its lowest position

- The front side roller moves to the uppermost position and the sheet is clamped

- The rear side roll moves upward and the leading edge of the sheet is hemmed

- Side rolls are installed in a symmetrical pattern (at the same level relative to the top)

- The sheet moves to the extreme forward position

- The second edge of the sheet is hemmed, similar to the first

- Side rolls are installed in a symmetrical pattern

- The sheet is bent into a cylinder. The bending radius depends on the position of the side rolls relative to the top, which are controlled using indicators located on the right column of the machine

- The left support of the upper roll is folded back and the shell is removed

Attention

Because When bending the edges of the sheet is carried out according to an asymmetrical pattern, in this case greater radial forces arise than with a symmetrical pattern. For this reason, the machine can bend edges of smaller thickness (see Table 1).

When working, more attention is required to the correct adjustment and installation of the workpiece in the rolls, as well as monitoring the movement of the workpiece during the bending process. After each transition, you should check the parallelism of the edge of the sheet forming the roll

The flat workpiece must be pre-corrected because the presence of curvature causes its distortion and displacement of the end edges of the shell.

The displacement of the edges is corrected by reverse skewing of the shell in the rolls. Editing is possible if the shell is not completely bent.

Recommendations

Special requirements are placed on the alignment of the rollers: they must be located in the same vertical plane and be strictly parallel. Any misalignment will lead to uneven compression of the profile, which will significantly reduce the quality of the rolled product.

A machine made at home specifically for strengthening profile pipes should not pose a danger to humans during operation. During assembly you should:

- Fix all moving parts as reliably as possible. Prevent them from bouncing during operation.

- Provide protective flaps.

Properly assembled home-made installations are not inferior to professional models in terms of the quality of their products.

Design Features

Rollers (also called sheet bending machines) allow controlled plastic deformation of sheets made of metal. Operating on the rolling principle, such a device is equipped with several shafts, which, when a metal sheet or pipe passes between them, changes their configuration. Serial models of such sheet bending equipment and homemade rollers work on the same principle and, accordingly, have a similar design. Let's look at the main elements of the machine.

Device of manual three-roll rollers

Bed-base

This is a load-bearing element that ensures the stability of the rollers, as well as the correct relative position of all their components.

Two vertical support posts

In their bearing units, shafts are installed, of which there can be only two (two-roll machine), three (three-roll machine) or even four. In the design of most rollers equipped with three working bodies, the two lower rollers can change their position only in the horizontal plane, and the third, a thrust roller located on top, is also adjustable in height. In addition, the upper roller for removing the finished part is equipped with a quick tipping mechanism.

Upper pressure roller lifting mechanism

Rolls

In the process of processing a sheet blank, the rolls must rotate, for which any rolling machine is equipped with a drive mechanism, which can be chain or gear. The operation scheme of such rollers is such that only the lower rollers are driven into rotation, and the upper one, tightly pressed against the surface of the workpiece, rotates under the influence of friction forces.

Roll operation diagram

Rollers can be equipped with various types of drives. Thus, depending on this parameter, rolling devices of the following categories are distinguished. Manual

These are the simplest rollers, which are most often made by hand. To drive such devices, chain and gear drives can be used, the parameters of which should be selected depending on the characteristics of the material being processed. Hand rollers, taking into account the fact that significant physical effort is required to operate them, are used primarily for processing small workpieces.

Electrically driven

In terms of their performance, such rollers belong to the average category. Electrically driven three-roll rollers, due to the sufficiently high power of the drive mechanism, make it possible to process workpieces of considerable size.

Electromechanical rollers are often a modification of a manual machine to which a motor and control panel have been added.

Hydraulically driven

This is the most powerful of all rolling equipment on the market today. Due to the fact that the hydraulic drive with which such rollers are equipped allows their working bodies to act on the workpiece with great force, such a device can effectively process metal sheets of even very significant thickness.

Among industrial hydraulic rollers there are even such giants

The quality of processing performed on rollers is primarily influenced by the characteristics of the rollers. Since the rolls experience significant mechanical loads during operation, high-strength tool steel is used for their manufacture. In addition to the mechanical impact, when processing sheet blanks of considerable thickness, which are preheated to give them greater plasticity, the rollers also experience thermal impact. It should be noted that such an impact, which can be very significant, has a rather negative impact on the operational characteristics of the rolls.

The quality of processing performed on rollers can be improved by equipping them with CNC systems, the tasks of which include coordinating all operating modes of the machine (the relative position of the rollers, the amount of pressure exerted on the workpiece, etc.).

Industrial rollers

The industry produces machines for self-rolling profile pipes for the needs of private construction.

The cost of such devices starts from 25 thousand rubles. These are portable, compact machines:

- with manual drive;

- electrical devices.

Standard rollers for home use consist of:

- Three hardened metal rollers. The bottom two are servers. The upper pressure roller presses on the pipe, deforming it.

- Threaded clamping device.

- Stable bed.

- Sturdy metal case.

- Handles for driving the chain drive.

It is easy to equip a manual machine with an electric drive. For some industrial rollers, this modification is provided by the manufacturer. At the consumer's request, the electric drive is installed upon purchase.

However, purchasing an industrial machine for home use is a luxury for most consumers. It is possible to make such a device yourself, provided you have some skills and the availability of component parts.

Design Features

Jewelry rollers, unlike the rubberized rollers of old washing machines, are made of metal, but work on the same principle. Such devices, the distance between the shafts of which can be adjusted, can operate either manually or electrically. There are also combined models, the design of which implements both options.

Rollers used in jewelry production are designed to compress and bend items made of metal. By setting the distance between the working bodies of such rollers less than the thickness or other cross-sectional size of the workpiece, it is possible to change not only its original thickness, but also its width and length.

Manual roller device

Unlike the squeezing devices of old washing machines, jewelry rollers can have in their design not only 2, but also 3, 4 and even 5 crimping shafts. The use of a large number of shafts allows not only efficient rolling of metal products, but also bending them at different angles. Because of their versatility, three- and four-roll rollers are more popular among jewelry makers, which, if desired, can be made with your own hands.

On the surface of the working elements of factory-made rollers, there may be streams - special holes through which the rod material is driven.

Powerful machines allow you to use several strands for rolling at the same time

It is problematic to make such grooves on the surface of crimping shafts made by yourself. To do this, you need to have fairly complex metal-cutting equipment at your disposal or contact metalworking specialists. This is why many jewelry craftsmen refuse to use homemade rollers, preferring more efficient and functional factory equipment.