Rolling of various types of metals is considered a popular technological operation that is performed at metalworking enterprises. The most popular areas where this technology is used are construction and repairs. You can make rollers for sheet metal yourself. However, to do this, you need to become familiar with the operating principle of this equipment, its design, strengths and weaknesses.

Rollers for sheet metal bending

Varieties

A rolling machine is present at various enterprises that produce various rolled metal products. Using this equipment, you can make oval, conical, and cylindrical workpieces.

At home, craftsmen make parts for roofing structures, air ducts, drains, gutters. Models are divided by performance, design, type of drive:

- Manual models. Compact machines with low weight, which are used for processing sheet metal, the walls of which do not exceed 2 mm in thickness. They do not require an electrical connection and are inexpensive. Often made by hand.

- Electromechanical models. A gearbox is installed on them, which speeds up the technological process and facilitates human labor. Allows processing of rolled metal up to 4 mm thick.

- Models with hydraulic drive. They are used at large metalworking enterprises. Allows you to bend metal sheets up to 8 mm thick.

To further speed up production and perform work more accurately, hydraulic machines are equipped with CNC systems. This type of control is difficult to create at home.

A separate division refers to the number of rollers installed on the machine. The more working parts installed, the more complex the molds can be made.

Plate bending rollers

In this section “Plate bending rollers” we present a special type of bending machine, the name of which comes from the method of rolling sheet material - rolling, rolling, i.e. movement of the sheet through a system of shafts to change its shape (deformation). In most cases, rolling sheet metal makes it possible to obtain a workpiece or final product - cylindrical shapes, but options for rolling cone-shaped or elliptical shapes, unfinished hemispheres or spatial facing panels are also possible. The basic principle in the operation of rolling machines for sheet metal, they are called rolling bending machines, is the rotation of the shafts (movement forward and back), as well as the possibility of lifting - pressing, and longitudinal movement. Thus, with the help of lifting - clamping, the installation of sheet metal on the machine is ensured and the required bending radius is set, with the help of forward and backward movements, gradual or one-time rolling occurs, giving the required shape, and with the help of the possibility of longitudinal movement, the resulting cylindrical shell is removed from the machine.

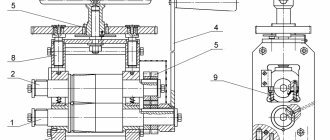

Depending on the model of the rolling machine, the design of sheet metal rollers includes: a bed, main drive and pressure shafts, a motor - drive gearbox (or drives), a control system with an electrical part. The process of bending sheet metal can be carried out with two, three, or four shafts arranged asymmetrically or symmetrically. Direct rolling (movement) of metal is ensured by the rotation of the main drive shafts (usually there are two of them, the placement type is horizontal or vertical), which is carried out using a manual or electric drive, and the pressure shafts (one or two, longitudinal or vertical movement) perform preliminary pressing of the sheet metal and adjustment bending radius, which is also ensured using a manual movement mechanism or an electric drive.

The main characteristics of bending machines of this type, according to the parameters of the material used, are the length and thickness of the rolled sheets, as well as the maximum and minimum values of the diameter of the resulting product (cylinder), which, as a rule, is determined by the outer diameter of the upper (rolling) shaft, while it is necessary to Depending on the brand and thickness of the metal, take into account the springing effect. Based on the type of drive device used for sheet bending machines, the following main subgroups of machines can be distinguished: manual, electromechanical 3-roll, electromechanical 4-roll and electro-hydraulic. Most of which are mainly intended for stationary use at production and construction sites, but there are also small models of rolling machines, which in their design imply sufficient mobility and the ability to operate in various climatic conditions.

Next, we will try to reflect the main types of sheet-bending products obtained with the help of rollers: various forms of round shells, casings, advertising structures, additional and facing elements, signs and decorative overlays; ventilation and drainage systems; various elements for the design of a more complex, composite product; conical shapes of sheet metal products, etc.

Moving directly to the choice of a rolling bending machine, in addition to the main technical characteristics, you should also pay attention to the most important nuances that arise during the work on machines of this type: the formation of a barrel-shaped workpiece, longitudinal creases on the sheet, straight sections on the edges of the circle, the springing effect, etc. d. Remember that well-formed technical requirements when choosing the bending machine you need will allow you to choose an indispensable assistant in your office work, thereby expanding the technological capabilities when working with sheet metal.

Design and principle of operation

A roller machine consists of several key elements, after studying which its operating principle will become clear. These include:

- The supporting element, or as it is also called, the frame. Can be made of sheet steel or cast iron.

- Rollers, which can be from two to 4. During self-production, craftsmen recommend installing 3 rolls.

- Drive - electric or hydraulic (on manual models a handle is installed to control the rollers).

- Control Panel. Various sensors and a monitor are installed on CNC systems.

Working principle step by step:

- Initially, a sheet of metal is prepared that will be rolled. It should be smooth, without cracks or grooves. It is placed on two lower rollers. They are separated in different directions in advance.

- After this, the master lowers the third shaft towards the sheet in order to securely clamp it between the working parts.

- The lower rollers begin to rotate under the influence of a drive or human manual force. The sheet is moving. As it begins to move, it begins to bend around the rollers.

Gradually, the metal blank passes through all the working parts according to the given configurations until the product of the required shape is obtained.

CNC rollers in production

Features of the metal rolling process

Rolling is used for pipes and sheet metal of the following types:

- stainless steel (some grades);

- aluminum and copper, as well as alloys obtained on their basis;

- Cink Steel;

- carbon steel alloys.

The sheet is rolled into a cone or cylinder, after which it becomes a blank for stamping the final product. Round and oval configurations are obtained in a similar way, and gutters are also made.

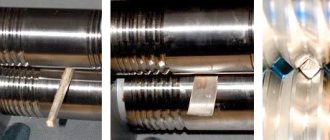

There are such technological procedures as rolling and flaring. They are used on pipe ends to change their geometric shape or diameter. This allows them to be used for the manufacture of prefabricated structures: collectors, other pipeline systems, heat exchangers.

Plastic deformation is achieved due to mechanical action. The equipment may not have rollers - this depends on the requirements for the product.

Manufacturers

The following manufacturers are especially popular:

- Metalmaster - models from this company stand out for their reliability and durability. They make it possible to work with metal sheets, fittings, and pipes. Well-known models are MSR 1215 and MSR 1315.

- Stalex is another well-known company whose equipment is valued by customers. It is used when processing sheets of different thicknesses. The housings of this equipment are made of durable steel grades that have an increased corrosion resistance.

- Anchor Corvette. Not suitable for mass production due to low reliability, but for a small workshop they are a good option.

At the same time, buyers highlight companies such as JET, PRINZING, SAHINLER, SCHWARTMANNS. It is important to consider the technical characteristics and capabilities of the equipment.

How to make an order

You can buy three-roll manual rollers by calling the office. You can purchase the required model by using the website service: adding the product to the cart.

Detailed information about the technical characteristics and price of three-roll plate bending rollers can be obtained from the managers of X-Profile. Delivery of goods is carried out by a transport company to the destination city. If you decide to buy three-roll rollers, we will help you calculate the favorable cost of transportation.

X-Profile cooperates both with cities of the Russian Federation and with neighboring republics: Belarus and Kazakhstan. Three-roll rollers will be an excellent purchase that will pay for itself in the near future.

Areas of application of machines

Rolling machines are installed at many metalworking enterprises. Among the areas in which they are used are:

- Jewelry production.

- Manufacturing of water drains and roofing elements.

- Utilities.

- Manufacturing of billboards and stands.

At the same time, different types of metals are used to produce different products. Machines for rolling sheet metal simplify construction and repair work.

Bending sheet metal on a machine

Characteristics of the rolling process

The fundamental feature of sheet metal rolling is that the deformation process occurs over the entire contact surface . This slightly reduces productivity, but increases the durability of the rolling work rolls. The advantages of metal rolling include:

- Reduced operating costs for tooling and equipment.

- Increasing the service life of tools and machines.

- Effective use in single and small-scale production.

- Reducing losses from marriage.

- Low cost of a rolling machine compared to a hydraulic or mechanical press. The cost of its acquisition pays off within six months of active use.

During the rolling process, the operator can change the rate of metal deformation. With other forming and stamping operations this is not always possible.

Rolling a sheet of metal can be done in several ways:

- in the transverse direction of the workpiece feed;

- in the longitudinal direction;

- with screw feed.

The first option is used to obtain short pipes, the second - long ones.

The sheet rolling process is characterized by the following features:

- Deformation is produced by torque, not force. The value of the torque depends on the conditions of contact friction, the diameter of the working rollers and the physical and mathematical characteristics of the material.

- When performing an operation, the rolling speed does not affect energy costs; on the contrary, as the indicator increases, the working force of the process decreases.

- The friction between the rollers depends directly on the surface. Reduced roughness leads to reduced friction. Therefore, during continuous operation of rolling machines, it is necessary to periodically grind the surface of the equipment.

When rolling a steel product up to 6 mm thick, the original metal is processed in a cold state. If you are working with parts made of thick sheet material, preheating is used. In such cases, the rolling machine is installed near furnaces with a non-oxidizing heating system. Due to this, the formation of surface scale is reduced.

If hot-rolled sheet metal is deformed, the sheet is straightened before rolling. This is stipulated by the technical requirements of GOST.

Types of rollers for bending sheet metal

Based on drive availability:

- Manually

devices process sheet metal up to 2 millimeters thick. - Electromechanical

sheet bending models – up to 5 millimeters. - Hydraulic

machines (the most expensive options) are capable of rolling sheet material up to 30 millimeters thick.

Depending on the number of rolls, the equipment can be either two-, three-, or four-roll.

What affects the cost of sheet metal rollers? The main thing in this matter is the design and type of drive. Bending mechanisms with hydraulic and electromechanical drives are more expensive because they are more complex and operations on them are performed better than on manual ones. But, unlike the latter, they significantly improve production characteristics and generally automate the production process.

Ours offers to buy a sheet metal rolling machine with convenient delivery, after-sales service for each buyer and a guarantee. From us you can buy exactly the sheet bending equipment that you need for your production.