Using a manual milling machine, you can perform a very large number of operations with wood - select a groove and a tongue, a fold on a frame, an edge, make a rounding, embed a lock or a hinge on a door - this is not even half the list. Different types of cutters are used for different operations.

Within the framework of the article, their classification by design, purpose and criteria for selecting cutters will be given depending on the tasks performed and the material being processed, as well as photos of sets of cutters as an illustration.

Tail Diameter Standards

Important! There are two types of standards - inch and metric. They do not coincide with each other, so you should not experiment by clamping the cutter half an inch into a 12 mm collet.

The cutter rotates at breakneck speed, and when it escapes from the milling cutter collet, it is not very different from a bullet. If hit in the head, it will definitely kill or seriously maim.

For the metric standard there are 6.8 and 12 millimeter collets. The inch standard comes in two sizes - a quarter inch (6.35 mm) and half an inch (12.7 mm).

Set of milling drills 3/4/5/6/6.5/8 mm. for wood and metal

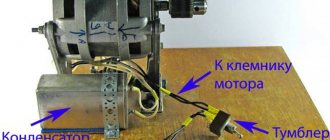

Hi all. In today's review we will talk about another set of drills (or, to be more precise, drill bits) from China, which I bought on eBay. Unfortunately, the store where I made the order no longer has this product, so the link above leads to another one, the first one I came across. So, my seller turned out to be adequate and prompt. For a small surcharge, the parcel was sent with a full track, so if anyone is interested, you can find out detailed information about its route along the China-Belarus route here.

The product was sent in a small paper envelope, inside of which were the drills I ordered. There is no original packaging; all the drills are placed in a small plastic bag, which was “sealed” using a regular office stapler.

The set includes 6 drills of different diameters: 3, 4, 5, 6, 6.5 and 8 millimeters. Outwardly they look quite nice. The cutting part is covered with a yellow coating, which, according to the seller, is nothing more than titanium nitride and is designed to extend the service life of the tool. Unfortunately, it’s not so easy to check whether this is true or not at home, so you’ll have to take the seller’s word for it. But these are not my first drills with such a coating, and I want to say that hydrochloric acid does not damage it, it does not wear off during operation, so the statement that the drills are “titanium” seems to be true.

The drill bits have cylindrical shanks, so they will fit 99% of chuck types. On the shank of each drill there is a marking indicating the diameter of the drill and the material from which it is made. Here it is HSS steel.

HSS (High Speed Steel) is a general definition of a group of high-speed steels. HSS steel is used to manufacture a large number of different cutting tools. Typically, these are drills, cutters, taps and dies, less often - knives and saw blades. HSS steels are high carbon and some contain a large proportion of tungsten. Typically, HSS steel tools have a hardness of 62-64 HRC. The main advantage over carbide tools is the durability and lower cost of the tools. Therefore, HSS performs well in interrupted cutting. A limitation of the use of HSS is the low cutting speeds compared to carbide.

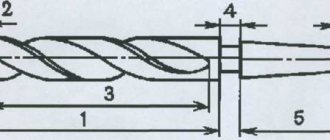

As you can see in the photo, the drills have an unusual appearance. They combine two types of cutting tools - a regular drill and a milling cutter. If everything is clear with the tip of the drill (it is needed to make a hole), then the main part is a cutter used to mill the resulting hole.

The recommended rotation speed of this tool is 1000 - 2000 rpm, and it is used for milling contours of any shape in thin-walled materials (wood, plastic, etc.) and sheet metals (up to 2 mm). It can also be used as an ordinary drill for making holes.

In principle, there is nothing more interesting in the appearance of the drills, which means we can move on to their practical tests. To begin with, I decided to try them out as the most common drills and see how they cope with making ordinary holes. As expected, there were no problems:

The holes are smooth and neat. Wood and plastic can be drilled effortlessly. The inner surface of the hole is flat, smooth, and without burrs. If you move the drill back and forth several times, the milling part will remove all unnecessary material.

After making a couple of holes, as well as milling them, the appearance of the drills did not change at all. The only thing is that the whole drill was covered with sawdust.

The next stage is to check the functionality of the drills on metal. A duralumin corner was taken, the wall thickness was 2 mm.

To begin with, I simply drilled a hole in it.

This was done using a cordless screwdriver. I wouldn’t say that everything went as quickly as in the case of the tree, but there were no special problems here either. Metal can be drilled without any problems. Next is milling the hole.

In principle, with the help of these drills, a round hole can be turned into anything you want (or need). Starting from oval and ending with an asterisk or some other figure. A couple of seconds and a beautiful, even hole turns into this:

Moreover, there were no problems with milling a hole even in a duralumin corner, and it was not even clamped in a vice, that is, it had to be held with one hand and the tool held with the other. That's why the heart turned out crooked

As for processing wood, plastic and other soft materials, everything goes quickly, without serious effort.

After the test was completed, the drill was not much different from what could be seen immediately after receiving the package (sorry for the focus gone wrong):

So, to summarize everything that has been written here, I can say that these milling drills turned out to be a working tool that copes well with its functions. Their main area of application is changing the shape of a hole. With their help, you can make a hole in wooden floors for a socket or switch, you can make the hole oval or square, or you can use them as regular drills.

That's probably all. Thank you for your attention and your time.

Types of cutters

End mills - designed for rolling the edges of products. They are equipped with a bearing as a guide, which allows the cutter to cut to the same depth. End mills also include spiral cutters.

Grooves with a flat end - for cutting a rectangular groove in wood. Without a stop, it is extremely difficult to work with such a cutter, so they are used together with a template.

Fillet – allow you to choose round and V-shaped grooves along the length of the product. By adjusting the position of the cutter, it is possible to select grooves of different depths. A V-shaped cutter allows you to make a groove, the walls of which are located at right angles to each other.

Spike with a reverse cone - designed for dovetail parting. This groove is used for reliable tongue-and-groove connection of parts to each other.

Conical - for rolling the edges of the product, for decorative purposes or due to its design features. Equipped with a bearing as a stop.

Moulder - just like a cone cutter, it is equipped with a stop and is intended for processing the edges of a product, but the resulting edge has a rounded shape, and when the cutter is lowered to the maximum, you can also get a straight line on the edge.

The quarter cutter is designed for selecting rectangular rebates on door and window frames. In some cases, the fold is selected in several passes, depending on the material being processed.

Disc cutters are used to cut a groove, and the working part of the cutter is not only its end, but also its entire peripheral surface. Used for cutting narrow deep grooves, for example, under glass or hardboard.

A combination cutter is used to perform two or more functions in one pass, for example, mortise and tenon.

Although the listed cutters are made with the expectation that they will process wood, in principle they can also work with plywood, plasterboard, oriented strand board, chipboard and some other materials.

Filler drills for drilling and filler machine

Filler drills are professional tools most in demand in furniture production. They are used on filler (drilling and filler) machines and allow high-precision drilling of blind or through holes intended for screws, screws, pins, handles, canopies, supports.

Modern furniture production involves automated lines and CNC equipment. And its effectiveness directly depends on the quality of the tool used.

We offer original tools from the CMT, Nordutensili and DIMAR brands, since they have already proven themselves to be a high-quality modern product that is successfully used in continuous production and has a competitive price.

Filler drills are high-tech tools, usually designed for industrial use. Therefore, their wear resistance is given special attention by production specialists.

Our range includes reinforced and solid filler drills. The first ones have a steel body and a carbide cutting tip, the second ones are completely made of tool hard alloy.

Features of the design of filler drills.

Structurally, a filler drill consists of a shank, a body with a chip removal spiral and a cutting end.

The shank with a flat allows you to quickly and reliably fix the drill in the machine chuck, the body with a chip removal spiral ensures effective removal of chips from the cutting zone, and the cutting part at the end of the drill is its most important part, responsible for strength and wear resistance, and therefore for long-term and high-quality operation of the tool.

Not counting the different standard sizes and direction of rotation, CMT, Nordutensili and DIMAR filler drills are divided into “blind” and “through” - they are responsible for drilling “blind” and “through” holes, respectively. Due to different tasks, the design of their cutting parts also differs.

Filler drills for blind holes have a flatter cutting bit. But drills for through holes have a pointed design, which ensures, firstly, easy passage through the material (solid wood, chipboard, veneer panels, MDF), and secondly, it maintains smooth edges without creases and chips at the exit from the material. This is an important point in furniture production, since the manufactured parts must not only have high precision execution, but also a decent appearance.

There is another type of “blind” filler drills – “cup” drills. This is a tool designed to form a “bowl” for installing a furniture hinge. It is characterized by a wide range of working diameters: from 15 to 80mm.

All types of CMT filler drills, Nordutensili and DIMAR, have a unified tail section with a diameter of 10 mm with a flat, which allows them to be quickly installed and securely fixed on modern woodworking equipment.

Why should you buy filler drills from us?

We offer only original filler drills from the CMT, Nordutensili and DIMAR brands, which are of high quality and have a long-term successful history of operation in mass production conditions.

In our online store you can profitably buy filler drills wholesale and retail with delivery throughout Moscow and the Russian Federation.

We supply only original tools from the most reputable brands and have a flexible pricing policy. We will offer wholesalers significant discounts on the entire range.

Our specialists have practical experience working with woodworking equipment and know the nuances of its operation and the selection and use of cutting tools for it;

Our prices for CMT, Nordutensili and DIMAR filler drills are among the lowest on the market. Our goal is long-term mutually beneficial relationships;

A wide warehouse program allows you to avoid long waits for tools to become available for sale;

If you need to quickly buy filler drills, our couriers will promptly deliver your order. If necessary, we will deliver it to a transport company convenient for you.

Optimal selection of cutters

The minimum that is included in a good set of cutters is:

- two edge cutters, one metric, the other inch;

- end mills with diameters of 6, 12 and 18 millimeters;

- a simple groove cutter, and for dovetail cutting;

- figured molding cutter;

- disk cutter.

This is the required minimum, but for professional work you may need a much larger arsenal.