To prevent fire or damage to the electrical network in the event of an accident, various technical means of protection are often used. A popular example of such a device is a copper ground bus. But where is it mounted and installed? What state GOST requirements regulate this equipment? What are the main types of copper bars? Below we will find out the answers to all these questions.

Selection of copper bars

The copper electrical busbar is a conductor with low resistance.

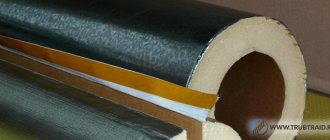

Copper electrical busbars are made with a rectangular cross-section. Visually, a copper electrical busbar is similar to a sheet, but thicker. UMMC-OTsM produces copper electrical busbars in a wide range of sizes: thickness 1.2 - 80 mm and width 8 - 250 mm. Tires are produced in pressed and drawn condition, in coils and sections. Cracks, cavities, blisters, transverse tears and dirty technological lubricants are not allowed on the surface of copper busbars. Deviations in cross-sectional shape, mechanical properties, crescent shape do not exceed the values established by regulatory documentation. It is possible to produce non-standard tire shapes. In this case, the shape is specified in the specification and a drawing of the future product must be attached.

The choice of copper busbar depends on the conditions of use. When choosing the current cross-section of copper busbars, take into account the maximum current that will flow through the busbar. Section - the ratio of width and thickness. Based on the value of the maximum current, the busbar cross-section is selected according to PUE and GOST 434-78.

Technical characteristics and GOST requirements

In Russia, copper busbars must be produced taking into account many technical requirements of GOST. The main regulatory documents are GOST 859-2014, GOST 18690-2012, TU 48-0814-105-2000 and some others. GOST requirements apply to many parameters - type of raw materials, mechanical properties, presence of defects, labeling, storage, and so on. Below we will briefly look at each option individually.

Recommended raw materials

Not all copper alloys are suitable for production, but only those that contain a minimum amount of impurities (no more than 1%). The oxygen content is especially critical in this regard, since this element negatively affects the strength and anti-corrosion properties, therefore the oxygen concentration in the alloy should be minimal (no more than 0.01%).

The optimal brand for the production of protective tire plates is M1, M2 and others. Copper that has undergone various primary processing can be used as a raw material - rolled, wire rod, ingot casting, pressing, and so on.

Presence of defects

Copper plates must be free from defects and various damages (cracks, corroded areas, holes, etc.). At the same time, the presence of lubrication and local oxidation, which was formed for natural reasons, is allowed.

A number of serious restrictions are also imposed on the straightness of copper bars. The minimum crescent shape is no more than 1.75 millimeters per 1 meter of product length. Also note that GOST allows for a higher crescent shape (up to 4 millimeters per 1 meter of length) - but only if there is a prior agreement between the customer and the contractor (that is, unauthorized excess of the norms without agreement with the customer is not allowed).

Mechanical properties

The copper busbar must meet certain requirements regarding elongation.

- With a plate thickness of 2.5 to 8 millimeters, the GOST copper busbar should have a relative surprise of no more than 37%.

- If the plate thickness is more than 8 millimeters, according to GOST it should have a relative elongation of no more than 40%.

This parameter is very important from the point of view of the safety of the copper bus. Why? The point is that if a short circuit occurs, the copper plate will be saturated with excess electrons, which can lead to cracking of the plate. The lower the relative elongation, the longer the plate can successfully “hold” the electric current. This is especially critical when working with high current or voltage.

Transportation and storage

We list the main state requirements:

- Each package must be labeled with all technical information. It allows you to uniquely identify not only the product, but also its manufacturer. Basic information - the name of the manufacturing plant, its sign, type (ShMT, ShMTV, ShMM), thickness and width of the plate, batch number, date of manufacture and others.

- The plates may be packed in uniform packs. The weight of one block of plates should be no more than 200 kg. Please note that products of the same brand can be placed in each package. M1 and M2 cannot be placed in the same package. For packaging, it is recommended to use regular wrapping paper, as well as wire wrap for fastening. By prior agreement with the customer, it is allowed to transport copper busbars without packaging using container delivery methods.

- By law, the manufacturer must provide a warranty. The warranty period depends on the type of product. In the case of ShMT and ShMTV - at least 6 months, ShMM - at least 1 year. Please note that the warranty is subject to the same rules as regular products.

Permissible continuous current for rectangular busbars

| Dimensions, mm | Copper bars | Aluminum tires | Steel tires | |||||||

| Current*, A, with the number of stripes per pole or phase | Dimensions, mm | Current*, A | ||||||||

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | |||

| 15 x 3 | 210 | 165 | _ | 16×2,5 | 55/70 | |||||

| 20 x 3 | 275 | — | — | — | 215 | — | — | — | 20×2,5 | 60/90 |

| 25 x 3 | 340 | — | — | — | 265 | — | — | — | 25 x 2.5 | 75/110 |

| 30 x 4 | 475 | — | — | — | 365/370 | — | — | — | 20 x 3 | 65/100 |

| 40 x 4 | 625 | -/1090 | — | — | 480 | -/855 | — | — | 25 x 3 | 80/120 |

| 40x 5 | 700/705 | -/1250 | — | — | 540/545 | -/965 | — | — | 30x 3 | 95/140 |

| 50x 5 | 860/870 | -/1525 | -/1895 | — | 665/670 | -/1180 | -/1470 | — | 40×3 | 125/190 |

| 50×6 | 955/960 | -/1700 | -/2145 | — | 740/745 | -/1315 | -/1655 | — | 50×3 | 155/230″ |

| 60×6 | 1125/1145 | 1740/1990 | 2240/2495 | — | 870/880 | 1350/1555 | 1720/1940 | — | 60 x 3 | 185/280 |

| 80×6 | 1480/1510 | 2110/2630 | 2720/3220 | — | 1150/1170 | 1630/2055 | 2100/2460 | — | 70 x 3 | 215/320 |

| 100×6 | 1810/1875 | 2470/3245 | 3170/3940 | — | 1425/1455 | 1935/2515 | 2500/3040 | — | 75 x 3 | 230/345 |

| 60 x 8 | 1320/1345 | 2160/2485 | 2790/3020 | — | 1025/1040 | 1680/1840 | 2180/2330 | — | 80 x 3 | 245/365 |

| 80 x 8 | 1690/1755 | 2620/3095 | 3370/3850 | — | 1320/1355 | 2040/2400 | 2620/2975 | — | 90×3 | 275/410 |

| 100×8 | 2080/2180 | 3060/3810 | 3930/4690 | — | 1625/1690 | 2390/2945 | 3050/3620 | — | 100×3 | 305/460 |

| 120×8 | 2400/2600 | 3400/4400- | 4340/5600 | — | 1900/2040 | 2650/3350 | 3380/4250 | — | 20×4 | 70/115 |

| 60 x 10 | 1475/1525 | 2560/2725 | 3300/3530 | — | 1155/1180 | 2010/2110 | 2650/2720 | — | 22 x 4 | 75/125 |

| 80 x 10 | 1900/1990 | 3100/3510 | 3990/4450 | — | 1480/1540 | 2410/2735 | 3100/3440 | — | 25 x 4 | 85/140 |

| 100 x 10 | 2310/2470 | 3610/4325 | 4650/5385 | 5300/6060 | 1820/1910 | 2860/3350 | 3650/4160 | 4150/4400 | 30×4 | 100/165 |

| 120 x 10 | 2650/2950 | 4100/5000 | 5200/6250 | 5900/6800 | 2070/2300 | 3200/3900 | 4100/4860 | 4650/5200 | 40×4 | 130/220 |

| 50×4 | 165/270 | |||||||||

| 60×4 | 195/325 | |||||||||

| 70×4 | 225/375 | |||||||||

| 80×4 | 260/430 | |||||||||

| 90x 4 | 290/480 | |||||||||

| 100×4 | 325/535 | |||||||||

What do copper grades affect?

Copper grades differ in composition and amount of impurities.

Under normal operating conditions, the oxygen content at the level of 0.08 - 0.001% does not affect the properties of the tires. The negative effect is noticeable only at high temperatures, therefore, for high-temperature operation, oxygen-free, refined grades of copper are chosen. Bismuth, zinc, lead, cadmium, other low-melting impurities and oxygen complicate welding and soldering. During the heating process, zones of fragility are formed. From a technological point of view, oxygen-free copper is preferable in this case.

A silver content of 0.05% reduces the creep of copper without loss of electrical conductivity, and also doubles the rectallization temperature of copper.

The content of phosphorus, iron, arsenic, tin and antimony reduces electrical conductivity.

Impurities directly affect electrical conductivity. Considering that a slight variation in the percentage of impurities is allowed, tires from the same manufacturer may differ in their electrical conductivity.

Advantages of copper busbars

Along with copper busbars, aluminum busbars are used in electrical engineering. Aluminum tires are valued for their affordable price and lightness of the metal. However, in the long term, copper bars will be a cost-effective solution.

Copper has high thermal conductivity. With the same cross-section, a copper busbar will withstand a percentage greater load than an aluminum busbar of the same size. The copper busbar minimizes energy loss during transmission. They are highly elastic and resistant to stretching. The copper bus bends easily without losing its technical properties. This allows smaller distribution and power units to be assembled. It is resistant to high and low temperatures and can withstand higher voltages. When choosing between an aluminum busbar and a copper one, preference is given to the latter.

Copper busbar sizes

Various copper-based alloys are used in industry. At the same time, metal with a purity of at least 99.7 percent is used in the production of tires. The advantages of the material include maintainability, ease of soldering and welding, ductility, and corrosion resistance. Tires are in demand due to their wide range of uses, excellent conductivity and ability to withstand electrical loads.

Copper bars of the following dimensions are available for order:

- the length of rolled metal varies from 2 to 6 meters;

- the minimum and maximum strip width is 15 and 120 mm, respectively;

- The thickness of copper strips can be from 2 to 30 mm.

Depending on the dimensions of the tire, you can easily calculate its weight and cost. The density and specific gravity of the material are given in the tables of regulatory documents.

How to choose the main grounding bus - section, copper or steel, connection.

As we all know, voltage is a potential difference. If the potentials are equal, then there is no voltage between these points, which means you won’t get an electric shock here.

For this purpose, a potential equalization system (EPS) is installed in buildings. It can be basic (OSUP) and additional (DSUP).

Before undertaking this, it is necessary to check with the management company whether the entire building is covered by CSUP or not. Here is a clear picture of what can happen to pipes in high-rise buildings in the absence of general grounding and potential equalization.

As a rule, in new buildings there are no problems with all this, and DSUP is mandatory. But in the old housing stock there is no BPCS. Therefore, in such cases, no amateur performances!

Otherwise, you will kill your neighbors at the first current leak or insulation damage.

The main potential equalization system connects the main utilities at the entrance to the building and other conductive parts of the equipment.

The system must meet the requirements of two regulatory documents:

The circular was issued to clarify some of the provisions and recommendations of the PUE in order to harmonize these recommendations with the requirements of GOST R51321.1-2000 and GOST R51732-2001. Some PUE recommendations really require clarification, since for some reason most of them are interpreted differently.

The basis of the OSUP is the main grounding bus - GZSh. What should it be like and what material should it be made of?

PUE 1.7.119 states that the function of the main switch can be performed by a PE bus inside the switchgear. This is often done.

And if the GZSh is taken outside the panel room, separately from the ASU and mounted on the wall, what rules should be followed when choosing and making calculations?

First, let's decide on the material of manufacture. Paragraph 8 of the circular states that it is recommended that a separately installed main frame be made of steel.

At the same time, the PUE states the opposite, that the GZSh should first of all be copper.

Aluminum is strictly prohibited!

Who to believe in this situation and what to ultimately choose, steel or copper?

The choice is always yours, but experienced professional electricians still prefer copper. This is explained by the fact that energy inspection inspectors, during inspections, are more willing to sign all the papers if there is a copper gas shield.

There are no unnecessary questions or heated debates.

The main grounding bus must connect such elements as:

A metal corner or strip that is buried in the ground on the street or in the basement of a house.

And now the main question is - what cross-section should the grounding bus be? What does it depend on, where to install it and how to connect it?

Let's look at the documents again. The PUE says that a bus installed in a switchboard room, that is, where there is access only for specially trained personnel, can be:

That is, no more than one conductor or tip is allowed under one bolt.

At the same time, the circular says a little differently. According to it, the GZSh section is selected according to the following table:

As you can see, here the choice is made not based on the PEN cross-section of the supply cable, but based on the phase conductor!

We all know that a Pen conductor can be either equal to a phase conductor or have a smaller size. For example, if you have a cable of 35 mm2 or more, then you have every right to take a cross-section for PEN that is half the size of the phase one.

Although most often the supply cable from the substation comes with the same cores (4*120mm2, 4*150mm2).

It turns out that if your cable is too thick, then according to the above table it is not at all necessary to select the same large copper busbar. The main thing is that it has a cross-section half the size of the phase conductor.

But in practice, both situations should be taken into account. That is, make sure that your GZH meets both conditions:

In this case, there will be no claims against you regarding the grounding and potential equalization system.

It is not always clear who will accept the finished object. How competent he will be in his field. If you do what is called for yourself, then choose the most optimal and economical option, without looking at possible inspectors.

When calculating the cross-section, do not forget about the difference in materials and cable brand.

Power input cables are usually made of aluminum. And we decided to make the tire out of copper!

Accordingly, you will have to convert the useful cross-sectional area of aluminum to copper. The PUE tables for permissible long-term currents of copper and aluminum wires will help in this matter.

Specialized calculators for calculating the weight of rolled metal

Also on our website you can buy an electrical copper busbar ShMT or use other calculators to calculate weight:

Reference materials on electrical busbars

Also in our “Directory” section you can study the calculation tables for electrical buses:

Send your applications for the purchase of rolled aluminum to our email address. Your email address is being protected from spambots. Javascript must be enabled in your browser to view the address.

At Nevskaya Aluminum Company you can buy aluminum from a warehouse in St. Petersburg or order delivery throughout Russia.

The warehouse of the Nevskaya Aluminum Company is located at 266 Ligovsky Prospect, not far from the Moskovskie Vorota metro station, next to the freight highway - Vitebsky Prospekt, exits to the WHSD and the Ring Road. Loading documents are issued on site.

Source