Reinforcement is the basis of concrete walls, screeds and columns. This important element experiences all the main loads and bending moments, preventing deformation and destruction of the concrete base. Metal rods of different diameters, which have a circular cross-section, are used as reinforcement. There are two main types of reinforcing metal rods: A1 and A3. To understand the difference between A1 and A3 fittings, as well as their scope of application, it is necessary to familiarize yourself with their main characteristics and consider their advantages and disadvantages.

Explanation of markings

Marking of reinforcing bars is usually done using letter designations. The letters indicate the exact method by which the reinforcement was produced. So, for example, the presence of the letter A in the name indicates that the product was made using the hot or cold rolling method. If we compare both methods, it is worth noting that the steel obtained by cold rolling has increased strength characteristics and has greater hardness. The number usually denotes the degree of fluidity of the steel used in the reinforcement; it determines the main difference between the grades of metal. The yield coefficient depends on the maximum stress, which causes the metal to begin to deform. That is, the higher this indicator, the greater the strength of the rod itself. So, for example, A440 steel has a greater safety margin compared to A240.

When building structures made of reinforced concrete, it is necessary to achieve the best strength of the entire structure, using elements with minimal mass. One solution is to reinforce the structure using a steel frame, for the assembly of which reinforcement of various cross-sectional diameters is used. It can be in the form of skeins or rods.

Visual comparison

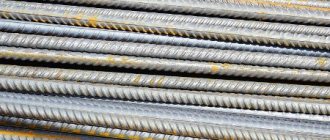

The first class of reinforcement always has a smooth profile of the rod; very rarely it can be the second class, but all other classes have only a corrugated surface. Also, different classes differ in diameter, weight and length.

Reinforcement of the third and fourth classes are similar in characteristics, but the bars of the fourth class are larger, since higher quality steel is used in their creation. Reinforcement of the fifth and sixth classes is easier to recognize; the rods are much larger and longer, and they are also much more expensive.

This knowledge will help when choosing fittings, but you can simply contact a sales consultant.

- < Back

Difference between fittings A1 and A3

The main types used in construction are A3, as well as A1 reinforcement, GOST 30136-94. Sometimes you can find other names. For example, A1 fittings are often found under the name A240, and A3 – A400. The weight of reinforcement A1 and A3 is approximately the same, however, the main difference between these types of reinforcement is that A1 has a smooth surface, and A3 has a corrugated surface. Corrugation provides better contact with concrete. Due to the presence of a corrugated surface on A3, it has better reinforcing qualities compared to smooth reinforcement A1. The disadvantages of A3 include the appearance of additional stresses due to the need for an additional rolling cycle, which is necessary to form a corrugated surface. Another disadvantage is the reduction in the effective cross-section of the reinforcement with a constant weight per linear meter, as well as a higher cost due to the complexity of its production. Strength decreases by 6% with an asymmetrical position of the corrugation pattern compared to round reinforcement.

A3 or A500C

Many online publications publish information that these are the same type of fittings. In fact, these types of rolled metal are made from different metals and have visual differences.

Class A3 fittings are produced in accordance with GOST 5781-82. Material – low-alloy steel grades 35GS, 25G2S or 32G2Rps. It is often labeled as A400 due to its yield strength of 400 N/mm2.

Figure 2. A3 fittings

Class A500S fittings are produced in accordance with STO-ASChM 7-93 and GOST R 52544-2006 from low-carbon steel with the mandatory addition of:

- silicon;

- manganese;

- phosphorus;

- sulfur;

- nitrogen;

- copper

The quantity of these elements is regulated by GOST.

Due to the fact that the reinforcement of these classes is made of different steels, there are significant differences in their application. It is forbidden to weld the A400 fittings; the connection is made only with the help of a binding wire. But the letter C in the A500C marking means that it is allowed to use a welding seam in cross-shaped joints. This was achieved by reducing the amount of alloying additives in steel.

Externally, these two types of fittings are also different. The A400 necessarily has longitudinal ribs, and the transverse protrusions are located along helical lines that have right entries on one side and left entries on the other. The transverse protrusions are connected to the longitudinal ribs.

Longitudinal ribs in the periodic profile A500 are not a mandatory element and are available in hot-rolled and thermo-mechanically hardened versions. Cold-deformed rolled products can be three-sided crescent-shaped or four-sided segmented. In this case, there are no longitudinal ribs. In the case of longitudinal ribs, the transverse protrusions are located less frequently than in A3 and are not connected to them.

Figure 3. A500S fittings

Material of manufacture

There are differences between reinforcement A1 and A3 in terms of the type of steel used. Typically, steel with a low carbon content in its composition is used for the manufacture of materials. For the manufacture of A3 reinforcement, steels with increased ductility and low carbon content are used. A1 reinforcement is made from stiffer and harder steels. Also, according to GOST, variety A1 should not have corrugation.

The cross-sectional diameter of the reinforcement bars, regardless of the profile, usually varies between 8-25 millimeters. When constructing larger structures, such as bridges and high-rise buildings, reinforcement with a diameter of 40 millimeters is used. The composition of the material with a smaller cross-section includes mild steel that is more deeply purified from impurities. For large diameter fittings, any type of steel with a low carbon content can be used.

Class comparison table

| Reinforcement class | Rod type | Rod diameter (mm) | Tensile strength (MPa) | Elongation at break (%) | Grade of steel used |

| A1 or A240 | Smooth | From 6 to 40 | 373 | 25 | St3kp, St3ps, St3sp. |

| A2 or A300 | Fluted | From 10 to 40 From 40 to 80 | 490 | 19 | St5sp, St5ps, 18G2S. |

| A3 or A400 | Fluted | From 6 to 22 | 590 | 14 | 35GS, 25G2S, |

| A3 or A500 | Fluted | From 6 to 40 | 600 | 14 | 32G2Rps. |

| A4 or A600 | Fluted | From 6 to 8 From 10 to 18 From 10 to 32 From 36 to 40 | 883 | 6 | 80С, 20ХГ2Ц. |

| A5 or A800 | Fluted | From 6 to 8 From 10 to 32 From 36 to 40 | 1030 | 7 | 23ХГ2Ц. |

| A6 or A1000 | Fluted | From 10 to 22 | 1030 | 7 | 22Х2Г2АУ. |

Application of fittings

Let's talk about the difference between A1 and A3 fittings in terms of application. A1 is widely used for reinforcing concrete structures in any form, be it a mesh or a complex frame. Smooth reinforcement is also actively used in the construction of any structures that have an auxiliary value (fences, products in the form of gratings, fences, etc.).

A3 reinforcement, which is corrugated, is mainly used for the construction of simple, lightweight and high-strength frame structures made of concrete. This variety is not used in the construction of structures that perform an auxiliary function.

Now about the assortment

The diameter, meaning nominal, of thermally strengthened rolled products is from 6.00 to 40.00 mm. The form of production is coils for rolling with a diameter of 6.00 and 8.00 mm, everything over 10.00 mm is produced in rods (rods). The regulatory document under consideration stated that thermally strengthened reinforcing steel At400S and At500S with a nominal diameter of 10.00 mm can be produced in coils. Coils are usually sold by weight up to 3.00 tons. The rods are sold in lengths from 5.30 to 13.50 meters. It is allowed to produce this type of long products with a length of 26.00 m. Manufacturers produce reinforcing steel according to the length specified by the buyer. Or you can cut it at a metal scrapyard if necessary. Moreover, the length can be measured, measured with unmeasured segments, or unmeasured (from 6.00 to 12.00 m). The marking indicates the class (yield strength) and nominal diameter. Operational parameters are also indicated (weldable, corrosion-resistant or not). As an example, 10At400C. Reinforcing steel with a nominal diameter of 10.00 mm, heat-strengthened, class 400, weldable.

Heat-strengthened products are produced from low-alloy (with the addition of alloying components) and carbon steels. At400S fittings are made from steel grades St3PS, and also St3SP. But the At500S reinforcement with increased yield strength from St5SP and St5PS. These are carbon steel grades. A two-letter index indicates the degree of deoxidation. SP – mild steel, PS – semi-mild steel. 3 or 5 is a steel grade based on the chemical composition, St – steel.

Pay attention. Previously, according to GOST 10884-94, rolling markings had to be used for this type of long rolled metal. If it is not there, then color coding was used. The ends of reinforcing steel rods of class At400 were painted with white paint, and At500C with white and blue. We tell you in detail because products manufactured in accordance with the specified GOST are still sold on the market.

A little history...

With the advent of concrete, construction became much easier. Before this, metal beams were also used, but in combination with clay (the first structures of this type were discovered on the island of Sicily, dating back to approximately 400 century BC). However, the adhesion of clay bricks and iron beams for reinforcement was not strong. Moisture penetrated into the resulting cracks, the metal rusted and the buildings rapidly collapsed. The invention of concrete marked the beginning of the massive use of reinforcement: the adhesion of concrete and metal reinforcement turned out to be very strong. The combination of the opposite properties of cement and metal rods - compression and elongation - was also successful. All this ensured the high popularity of concrete products in construction.

What to look for when purchasing?

In addition to intermediary markups, the cost of products is also affected by:

- Rolled metal class.

- Brand.

- The diameter of the rods and their length.

- Type of packaging and other characteristics.

Therefore, carefully study the information on the product page and compare it with your tasks. If you don’t know how to choose an A3 for specific purposes, contact one of our employees. He will clarify the nature and scope of the work ahead of you, and then recommend a product with optimal characteristics.

Buy a3 fittings: metallbase.com/production/armatura/klass-a3/#ves

Specialized fittings A3 35GS

One of the varieties of A3 rolled metal is A3 35GS. This is a very durable reinforcement with a round cross-section and a corrugated surface. It is made from low-alloy structural steel to create welded structures. The diameter of this product can be in the range of 6-36 mm, and the length of the rods should not exceed 11.7 m. Sometimes the length indicator is changed upward. But this is done exclusively on an individual basis.

As a rule, this type of rolled metal is used in road construction. This involves laying conventional road surfaces and concrete slabs. This scope of application is associated with the high strength of the products, high-quality adhesion to concrete and resistance to frost. The latter characteristic is due to the presence of manganese in the raw material, which tolerates low temperatures well. A3 35GS products can be installed longitudinally or transversely in concrete. If the rods are laid longitudinally, they take on tensile stress. In the case of transverse laying, the compressed section is tied and coupled. But, regardless of the location of the reinforcement, in both cases the risk of the formation of inclined cracks is reduced.

Despite all its advantages, this product also has a disadvantage. It is associated with the inability to use manual arc welding. If you need to use this method of welding metals, use another type of A3 - 25G2S rods. They also contain manganese, so they are immune to severe frosts.

Purpose of reinforcing steel class A3

A3 is used for reinforcing conventional and prestressed structures as working reinforcement (installed according to design calculations of structures for loads and impacts) and as mounting reinforcement (in case of installation due to structural and technological necessity).

Class A3 reinforcement is used in the production of reinforced concrete products, in the construction of foundations, for reinforcing plaster layers, concrete screeds, strengthening walls made of sand-lime brick, aerated concrete structures, etc.

Reinforcement mesh

For large-scale construction, reinforcing mesh is used. The reinforcement bars are welded or knitted immediately before pouring concrete and the finished mesh is rarely transported. Products made of special steel are used for welding. Or use a special welding wire. The disadvantages of welding include increased fragility of the product in the welded area and poor response to bending. The bonded frame is stronger and more flexible. If, of course, the mating conditions are met and high-quality wire is used.

Transportation rules

When transporting A3, you must follow the transportation rules. But first of all, you need to pay attention to the packaging of the products. It is regulated by GOST and must be observed unconditionally.

As mentioned above, transportation of goods in coils is possible only with a rod diameter of no more than 12 mm. Moreover, packaging in coils makes transportation not only convenient, but also profitable for the manufacturer and buyer. After all, too thin rods are easily deformed and become kinked. Due to damage, some products will not be able to be used for their intended purpose.

If you are transporting rolled metal with a thickness of more than 12 mm, it must be packaged in the form of individual rods up to 12 m long. The following are acceptable:

- Packaging of fittings with measured length. In this case, all the rods will have the same length.

- The presence of segments with a length in the range of 6-12 m. They should be no more than 15% of the total weight of the products.

- The presence of segments up to 6 m long. In this case, their weight should not exceed 7% of the total weight.

You also need to know that the rods should not bend during transportation. Possible curvature coefficient is 0.6% of the length.

There are other requirements for packaging A3 fittings before transportation. For example:

- A bundle cannot contain products of different classes or diameters.

- The permissible bundle weight depends on the type of unloading. When using the manual method, the weight should not exceed 80 kg. However, with a mechanized unloading option, heavier packages can be formed.

- Before transportation, the skeins are secured with radial straps, and individual rods are tightly stacked and tied crosswise every 2-3 m.

Additional questions about the characteristics, application and features of transporting rolled metal of class A3 can be asked to our employee and you can receive answers, as well as recommendations on the choice of fittings.