The alloy of tin and lead has special parameters that allow it to be used in various branches of industrial production. The technical characteristics and physical properties of each metal determine their use for long-term storage of products, soldering and surface treatment of parts in order to increase their service life.

An alloy of tin and lead is used to give strength to manufactured parts.

Physical properties of lead

Lead, a waste product from silver processing, turned out to be a very useful metal in production.

Archaeological artifacts indicate that this chemical element was known to man more than 6,000 years ago. Its discovery is associated with the presence of metal in ores containing silver. When they were smelted, the material was thrown into waste, but over time they began to make various products from it: figurines, water pipes. Currently, lead is used:

- for the production of batteries;

- in the cable industry - to create a protective seamless sheath;

- for the manufacture of paints and solders;

- during the construction of protective structures - for sources of radiation pollution (sarcophagi);

- for the production of alloys based on it (babbitt);

- for the production of printing compositions;

- in medicine.

The main consumer of lead is the automotive industry, where babbits are widely used. The production of lead-acid starter batteries is constantly growing, and improvements are being made to developments.

In the chemical industry, the material is used to coat steel products: apparatus, tanks, pipelines. Since iron and lead do not combine with each other, a thin layer of molten tin is first applied to the products. This processing process is called tinning.

In production, not only pure lead is used, but also its compounds. For example, lead oxide is used in glass making. A slight addition of the compound to the material when melting glass makes it possible to give crystal products the transparency of a natural mineral - rock crystal.

LEAD ALLOYS

LEAD ALLOYS , lead-based alloys. Basic alloying elements - Sn, Sb, Cu, Bi, Hg. They are characterized by a low melting point (48-320 °C), low fur. strength and hardness, high ductility, corrosion resistance in dilute. solution, in an environment of H2S, SO2, SO3 or C12 (at temperatures of 100°C); have good casting properties, well wet regular and galvanized Fe, Ni, Fe and Cu alloys. Mn. metals form a eutectic with Pb, certain metals (mainly alkali and alkali-earth) are stable intermetallic. compounds - plumbides (for example, Na2Pb, Mg2Pb, La2Pb), heavy metals - low-melting eutectics (for example, Pb-Bi, Pb-Cd, Pb-Sn); solid solutions with alloying metals are rarely formed.

Lead alloys are obtained by fusing the starting metals or their alloys (with the introduction of refractory alloying elements), as well as by reducing the CaCl2 melt with a Pb-Na alloy. Lead alloys are produced in the form of ingots, plates, rods, tubes, wire and tape. Most lead alloys are well processed by pressure (rolling, forging, pressing) and cutting. They are divided into processed and non-pressurized.

Pressure-processed alloys include low-alloy lead alloys containing one of the elements - Sn (up to 2%), Sb (up to 0.5%), Cd (up to 0.25%) or Cu and Fe (up to 0.06% each). Such lead alloys are used for the manufacture of sheaths of electrical, telephone and other cables; in recent years they have been replaced by cheaper A1 and polyethylene.

Alloys that are not treated with lead pressure are divided according to their intended purpose into antifriction (babbitt), printing, solders and low-melting alloys.

Babbitts are lead alloys alloyed with Sn, Sb, Cu, Ca, Na and other elements (from 15-17% or less). By melting point (240-320 °C), hardness (HB 22-32), coefficient. friction with lubricant (a 0.004-0.007) they are close to tin babbitts (see Tin alloys), inferior to them by ~1.5 times in thermal conductivity and ~1.5-2 times in wear resistance. The structure of babbitts contains hard (compounds SnSb, Cu6Sn5, Pb3Ca, etc.) and soft (hard solution based on Pb) components. The first provides a low coefficient. friction, the second is good running-in in friction areas. Such lead alloys-anti-friction materials are used in mechanical engineering in friction units of low and medium immersion, in urban and railway transport, replacing expensive and scarce tin babbits.

Typographic lead alloys, known for more than 500 years, contain up to 20-23% Sb, 5-7% Sn, 1-4.5 As and 1% Cu. They are distinguished by high fluidity and low shrinkage during crystallization, hardness (HB 17-28), constant composition after repeated remelting; resistant to corrosion in contact with paints and wash-off solutions. They are used for casting hand and machine typefaces, white space, rulers and stereotypes.

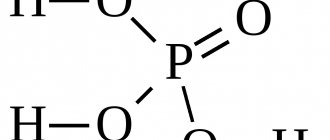

Lead-based solders alloys contain Sn, Cd, Bi, Ag, In and P (from 1.3-1.7 to 49-51%), have low melting points (from 90-142 °C with Sn, Cd , Bi and up to 220-310 °C with Sn, Ag, In and P). Used for low-temperature soldering of Fe, steels, Ni, Cu and its alloys. The joints with Cu and Cu-Zn alloys have low corrosion resistance in a humid atmosphere and, in the presence of condensation, are used only with paint and varnish protective coatings; solder joints with solders containing In and P do not need protection from corrosion. Separate solders containing Ag, Sn, Cu and Ni are used for soldering cryogenic products.

Low-melting lead alloys (mp 48-96 °C) contain Bi, Sn, Cd and Hg; in composition they correspond to ternary and more complex eutectics. For example, Wood's alloy (25% Pb, 12.5% Sn and Cd each, the rest is Bi) with mp. 69 °C is close in composition to the quaternary eutectic (Pb3Bi + Bi + Cd + Sn). Used in electrical engineering, fire alarm systems (fuses) and medicine.

The disadvantages of many lead alloys are the presence of expensive and scarce elements (As, Sb, Sn, etc.) and toxicity of vapors.

Lit.: Turkin V.D., Rumyantsev M.V., Structure and properties of non-ferrous metals, M., 1947; Shpagin A.I., Antifriction alloys, M., 1956; Maltsev M.V., Metallography of industrial non-ferrous metals and alloys, 2nd ed., M., 1970; Handbook on soldering, 2nd ed., M., 1984. AM Zakharov.

Technical Parameters of Tin

Tin - from spoon to radiator

This chemical element has been known for more than 3,500 years and was originally intended for the manufacture of tableware. Modern consumption of tin is associated with the canning industry.

A patent for a method of storing food in tins belongs to a chef from France. Since 1810, humanity has been able to store food for a long time.

Tin is the main component of solders used for soldering and tinning of heat exchangers, radiators of automobile engines, and tinning of medical and food equipment.

The material is used for the production of tin bronze, which has excellent mechanical, casting, and anti-corrosion properties. Such alloys are used in parts intended for use in special conditions and under special loads.

An alloy with a low coefficient of friction is babbitt. It contains 83% tin, antimony and copper. It is used in the production of bearings. Thanks to the stable compound of antimony and copper, the alloy has high hardness.

The bearing operating mechanism and composition components eliminate the occurrence of mechanical damage on the surface of the part.

Tin has specific physical properties:

- Its deformation is accompanied by a sound generated as a result of shear under the influence of force.

- At temperatures of -39 °C and + 161 °C, tin turns into powder.

History knows cases of such transformations. Buttons made from pure material lost their shape in the cold, and the “tin plague” destroyed metal ingots.

History of the discovery of lead

The most ancient artifacts made by man from lead are considered to be ancient Egyptian figurines about 5 thousand years old, although archaeologists have found more ancient simple products from this metal. The first boom in the use of lead occurred during the Roman Empire, when they began to make water pipes from it and even used it for gastronomic purposes. Already in those years there were suspicions that it could be harmful to health. After the fall of Rome, lead consumption dropped significantly, but the use of the toxic material in water supplies lasted until almost the 20th century in many countries.

The malleable metal was actively used as a connecting material in window frames and roof coverings. With the industrial revolution of the Victorian era, the need for lead increased many times over, and every year new opportunities and applications for lead compounds opened up. Quite quickly, this metal became one of the most important elements necessary for technical progress, and remains so to this day.

Main lead producing countries

The lion's share of global lead production comes from the European Union, but it's worth noting that they get 60% of the metal from recycling rather than direct mining - a trend that is gaining popularity in other countries. The next 3 places are shared by the USA, Russia and China, with small gaps from each other. In the post-Soviet space, Ukraine and Kazakhstan traditionally demonstrate high levels of lead production. The latter also has one of the world's largest proven reserves of this metal.

The most important lead compounds and their applications

Lead, being a fusible heavy metal, has been used since ancient times to this day for the manufacture of ammunition, including for civilian purposes. Another feature of lead is its ability to absorb radiation, which has led to its widespread use in nuclear energy and medical technology. But much more extensive possibilities are opened up by various compounds of lead with other substances and metal alloys. Without them it is difficult to imagine any branch of human activity. The chemical industry and agriculture, military science and batteries, mechanical engineering and lithography, geology and much more - all these areas involve lead compounds.

Human exposure to lead

The most common culprit of heavy metal poisoning is lead. For a long time, lead additives were used to lead gasoline, which led to severe air pollution in large cities. Today, the use of lead to increase the octane number of fuel is prohibited almost throughout the world (in the Russian Federation - since 2002). Other possible sources of poisoning:

- industrial emissions;

- agricultural products contaminated with heavy metals;

- household items containing lead;

- work in hazardous industries.

Once in the body, lead has a strong toxic effect. Metal poisoning in childhood is especially dangerous. Lead intoxication in a child leads to delays in physical and mental development, and cognitive impairment can manifest itself throughout subsequent life. In adults, constant contact with lead or regular inhalation of its vapor causes chronic poisoning, impairs brain function and significantly increases the likelihood of serious diseases, including cancer.

Lead oxides

Lead oxide (PbO) is a slightly water-soluble crystal, yellowish or scarlet in color. It is used in the manufacture of glass products, crystal, glossy enamels and varnishes. A common component of lead-acid batteries. Raw materials for other compounds.

Lead dioxide is a toxic brown powder with a characteristic odor. An important catalyst for many chemical reactions and processes, no research laboratory can do without this substance. When added to paints, it speeds up the drying process, which is actively used by manufacturers of paint and varnish products.

Lead tetroxide, also known as lead tetroxide, is an insoluble orange-red powder. Rare, but found in nature. It is widely used as a pigment for anti-corrosion coatings in the construction of buildings, bridges, ships and other large objects. When some parts of an unfinished ship appear “rusty”, this is the effect of red lead in the composition of protective emulsions.

Separately, it is worth mentioning PZT - an oxide of a compound of lead zirconates and lead titanates. A most valuable substance that can induce a charge when subjected to deformation, or produce a reverse reaction - deform under the influence of current. Without it, it would be impossible to create many types of electroacoustic devices and capacitors.

Lead salts

Lead nitrate is prepared by dissolving lead plates in nitric acid. Known for over 400 years, commercial production began only in the 19th century. In a calm state it is a colorless powder, highly soluble in water. Used as a reaction suppressor in nylon polymers and an improver in gold cyanidation. It was used for some time as a pesticide and oxidizing agent in organic chemistry, but due to its severe toxicity, its use has virtually disappeared. Currently it serves as a raw material for the production of more complex compounds of lead and other substances.

Lead azide is a salt of hydronitrous acid and is extremely poisonous. A common explosive used as an initiator (in detonators). Being very sensitive to physical and temperature effects, it requires special precautions when handling.

Lead chloride is obtained by reaction with hydrochloric acid. Occasionally occurs in nature (cottunite) with a relatively small amount of impurities. At the same time, it has moderate radioactivity; this leads some scientists to think about the meteorite origin of the mineral. Widely used in batteries as a cathode.

Lead sulfate is also known as lead sulfate. Poisonous and dangerous to human health. Often found in nature (anglesite). It is synthesized as a by-product during reactions in batteries and is one of the main pollutants. It has found application in industry as a pigmenting material.