Due to its properties, aluminum channel is used in various fields. Compared to rolled steel, aluminum is the most versatile and has its own advantages. It is used to create structures with complex shapes that are strong, lightweight and durable.

The Moscow branch of the Samara Aluminum Company offers aluminum channel profiles, manufactured in accordance with GOST, varied in alloy, height, width and heat treatment. It is possible to produce a U-shaped profile of any size, according to customer drawings. If any alloys are not in stock, they will be made to order.

What GOST requires from an aluminum channel

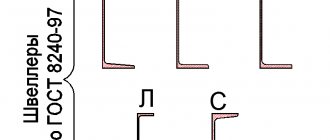

The production of both steel and aluminum bent channels is subject to standards.

- GOST 8617-81 prescribes which pressing methods to use.

- GOST 13623-90 regulates the sizes and assortment of finished aluminum channels of about 300 types with a flange height from 3 to 275 mm.

- GOST 22233-2001 establishes production regulations using the hot pressing method in the manufacture of material for translucent structures.

The shape, size, and cross-sectional area are determined. The drawings indicate the contours of the finished part and the dimensions of the maximum deviations of the shelves in terms of thickness and other dimensions.

The standards do not place restrictions on the use of the profile. Decisions based on calculations are made by those who design and manufacture products.

GOST requirements for aluminum channel

The aluminum channel, like its steel counterpart, has a U-shaped section and belongs to the class of standardized bent profiles. For the manufacture of such channels, the pressing method is used, the requirements for which are specified in GOST 8617-81. The material for the manufacture of such a profile, according to the requirements of GOST 4784-97, is aluminum or its alloys with magnesium. The requirements for finished aluminum channels, their sizes and assortment are regulated by a separate State Standard - 13623-90. According to this document, such products can only be of the equal-shelf type. The marking of U-shaped aluminum profiles, which can be produced up to 6 meters in length, indicates a number corresponding to the width of its upper part - the base.

Aluminum channel 55 cm wide

Aluminum channel, produced in accordance with the requirements of the relevant standards, is classified according to several parameters. One of these parameters is the condition of the material from which it is made. Depending on this characteristic, aluminum U-shaped profiles are as follows:

- manufactured by hot pressing and not subjected to further heat treatment (the designation of such products indicates only the grade of material from which they are made: aluminum or its alloys);

- subjected to hardening after manufacturing and subsequent natural aging (such aluminum profiles are designated by the letter “T”);

- aged after hardening by artificial means (designation T1);

- subjected to incomplete hardening and then aged artificially (T5 marking);

- annealed (such profiles are characterized by increased softness and are designated by the letter “M”).

Application of aluminum channel in the manufacture of double-glazed windows

The strength that any aluminum channel has is formed primarily due to the chemical composition of the metal alloy from which it is made. Meanwhile, this indicator can be significantly improved if the finished product is subjected to subsequent hardening and tempering. However, it should be borne in mind that the aluminum U-shaped profile after such a technological procedure will become less ductile. According to the level of strength, channels made of aluminum and its alloys are divided into the following categories:

- products with a normal level of strength;

- channels with increased strength, which are designated by the letters “PP”.

Aluminum U-shaped profiles also differ in their main purpose. So, they can be products:

- general purpose;

- intended for use in the electrical field.

Aluminum U-shaped channel with anti-corrosion coating

Despite the fact that aluminum and its alloys are very corrosion-resistant materials, the surface of products made from them is still protected with various compounds. The most commonly used protective coatings are:

- liquid paints and varnishes, which are designated by the letters “Zhl”;

- liquid compositions applied using electrophoresis technology - “Zhe”;

- oxide films obtained by electrolytic anodization - “An”;

- powder polymer compositions - “P”;

- two-layer compositions of complex type - “K”.

Aluminum channel, standard sizes

An aluminum channel coated with a protective coating not only becomes much more durable, but also has a more attractive appearance.

Separation by type of aluminum channel

It is a solid profile without internal cavities, produced using the pressing method. Length no more than 6 m.

To classify the profile, some parameters are taken. The variety in the condition of the material lies in the characteristics:

- Hot pressing without subsequent heat treatment (indicated by material grade)

- After pressing, it is subjected to hardening followed by natural aging (designated with the letter T).

- Hardening and artificial aging method (T1).

- Incomplete hardening and aging artificially (T5).

- Subject to annealing (the letter M indicates that the profile is soft).

The strength of the channel can be higher and designated PP. Subsequent hardening and tempering give it more durable properties, but at the same time the ductility standards are reduced.

Profiles vary in application: they have general purpose and electrical.

When aluminum is coated with a protective coating, it looks better and lasts longer. This can be a liquid paint coating, a liquid alloy applied using electrophoresis, oxide films, powder polymers, two-layer complex compositions.

Anodized material, covered with an anodic oxide film, in different colors. Due to this property it is used for decoration.

Weight and technical characteristics affect the cost of rental.

Application

The scope of application of aluminum channels can be divided into several areas:

- bearing structures;

- decorative finishing.

Aluminum U-shaped channel is also used in the construction of translucent, window and advertising structures and for the construction of various types of fences.

The use of an aluminum U-shaped profile makes it possible not only to make the structure lighter, but also to obtain a greater economic effect by reducing the overall cost of the structure due to its low volumetric weight and high load-bearing capacity.

U-shaped profile and its main characteristics

Channels are varied in operational properties and geometric parameters. The strength of an aluminum profile is less than that of a steel profile. If you want to build lightweight structures that will not be subject to loads, preference is given to aluminum. The rigidity and strength of the U-shaped profile are at the proper level, despite the low specific gravity. Complex structures are assembled due to the plasticity of the material. Corrosion is not a problem, especially if there is a protective coating. Weight is reduced due to low density. Alloying with various compounds increases strength, but does not make it heavier. Humidity or direct contact with water does not compromise integrity. But if there is no coating that resists corrosion, rust may appear on the surface over time. The structural elements are connected to each other by fastening material. But if welding is required, aluminum alloys can easily be welded. When heated, the profile can withstand high temperatures, because During manufacturing, alloying elements are added and the melting point increases. The structures last a long time, the performance properties do not change over time, because the alloys are resistant to chemical and other influences.

Our offer

SC MetOptTrading LLC sells high-quality aluminum channels of standard sizes. The company is an official dealer of large manufacturing plants and offers certified products on favorable terms. If necessary, managers will provide professional advice on the selection of U-shaped profiles, help calculate the required dimensions of the aluminum channel and tell in detail about the properties and application of the products. When purchasing our products, you can use the delivery service and receive your order within the next few days after submitting your application. For detailed information, call the numbers provided, request a call back, or send a request to the contact e-mail.

U-shaped aluminum profile has advantages

- It is easy to process, can be mounted using different methods of fastening metals, and is convenient to use.

- Characterized by increased thermal conductivity.

- The surface is smooth, does not allow dirt to linger, and ensures easy maintenance of the profile.

- Not subject to deformation due to air temperature changes from -80⁰ to +100⁰.

- It is affordable and profitable to purchase.

- Meets fire safety requirements.

- Environmentally friendly and harmless.

- At the end of its service life it is suitable for recycling.

- Static electricity does not accumulate.

- When building from a profile, welding may not be used, so temporary structures can be disassembled and easily transported to another location.

Areas where aluminum channels are used

Frequent areas of application: construction, interior decoration. They are taken for the construction of frame elements of an industrial or residential building. Suitable for making furniture, installing doors and windows. The channel is taken for load-bearing blocks of structures and offered for decoration. Assuming increased loads, rolled steel is used as the basis. Suspended systems for ceilings are constructed from thin-walled profiles, like all types of enclosing decorative elements. Drywall and other various panels are attached to them: plastic, lining, siding, porcelain stoneware. Depending on how strong the loads will have to be endured, the channel is selected according to its dimensions, according to the conditions of the cladding manufacturers. The use of aluminum profiles is not limited to pavilions, greenhouses, glazed facades, advertising boards, and office partitions.

In shipbuilding, mechanical engineering, aviation, space industry, applicable in medical equipment. Aluminum channel is a promising and in demand material. The scope of its application is expanding every year.

Aluminum channel: advantages, application

Aluminum channel belongs to the category of standardized building materials. Using such a product, it is possible to form durable, lightweight structures characterized by complex shapes. Finished structures will retain their original characteristics at high humidity.

| № | Dimensions, mm. | Weight 1 l.m., kg | |||

| IN | H | S1 | S2 | ||

| 1 | 10 | 10 | 1,2 | 1,2 | 0,097 |

| 2 | 10 | 10 | 1,5 | 1,5 | 0,122 |

| 3 | 10 | 15 | 1,2 | 1,2 | 0,130 |

| 4 | 15 | 12 | 2 | 2 | 0,211 |

| 5 | 15 | 15 | 1,5 | 1,5 | 0,182 |

| 6 | 15 | 15 | 2 | 2 | 0,243 |

| 7 | 15 | 20 | 2 | 2 | 0,297 |

| 8 | 18 | 38 | 6 | 6 | 1,523 |

| 9 | 20 | 15 | 2 | 2 | 0,270 |

| 10 | 20 | 15 | 1,5 | 1,5 | 0,203 |

| 11 | 20 | 20 | 1,5 | 1,5 | 0,243 |

| 12 | 20 | 20 | 2 | 2 | 0,324 |

| 13 | 20 | 25 | 2 | 2 | 0,378 |

| 14 | 20 | 36 | 2 | 2 | 0,497 |

| 15 | 20 | 40 | 2 | 2 | 0,540 |

| 16 | 25 | 25 | 2 | 2 | 0,405 |

| 17 | 25 | 28 | 2 | 2 | 0,437 |

| 18 | 25 | 30 | 2 | 2 | 0,459 |

| 19 | 25 | 40 | 1,5 | 1,5 | 0,425 |

| 20 | 25 | 50 | 2 | 2 | 0,675 |

| 21 | 30 | 30 | 1,5 | 1,5 | 0,365 |

| 22 | 30 | 50 | 4 | 4 | 1,404 |

| 23 | 31 | 88 | 2,5 | 5 | 1,607 |

| 24 | 31,5 | 28 | 2 | 2 | 0,473 |

| 25 | 40 | 40 | 2 | 2 | 0,648 |

| 26 | 40 | 11,5 | 2 | 1,5 | 0,286 |

| 27 | 50 | 30 | 4 | 4 | 1,188 |

| 28 | 80 | 50 | 5 | 5 | 2,430 |

| 29 | 83,8 | 25 | 8,8 | 5 | 2,319 |

| 30 | 100 | 40 | 4 | 4 | 1,944 |

| 31 | 100 | 50 | 5 | 5 | 2,700 |

| 32 | 122 | 63 | 6 | 6 | 4,018 |

| 33 | 130 | 60 | 5 | 5 | 3,375 |