The process of processing hard coal cannot be carried out without equipment such as a coal crusher. This equipment is presented on the modern market with a wide range of modifications that allow the production of coarse, medium and fine crushed coal. For the manufacture of the main working units, high-alloy steel was used, which is resistant to wear. Processed coal is subsequently used as a technological and energy raw material in many industries, as well as for the production of plastics, paints and varnishes, synthetics, etc.

Widely Used Coal Crusher

As a well-known crushing equipment manufacturer, SBM offers you high quality coal crushers with low price. Widely used crushers for crushing coal are jaw crusher, impact crusher, cone crusher and roller crusher.

Jaw Crusher for Coal Crushing

Coal jaw crusher, also known as coal jaw crusher, performs the crushing process by moving two jaws. Coal jaw crusher is widely used in many fields, such as mining, metallurgy, building materials, highway, railway, water conservation, chemical and so on. A jaw-type coal crusher allows crushing all types of materials with a compressive strength of no more than 320 MPa. As one of the most common crushing equipment, the jaw crusher appears earlier than other crushing machines. Jaw crushers are commonly used as primary crushers, and are one of the main types of coarse crushers in a mine or concentrator. Our stone crusher is designed based on many years of product development. Our jaw crusher is divided into 11 models, which can meet most productivity requirements in primary and secondary crushing, with low energy consumption and easy maintenance. Every feature of these primary crushers has been carefully designed to ensure superior quality and performance, which is why our jaw crushers have already won first place in the Chinese and overseas markets.

Impact Crusher for Coal Crushing

Impact crusher for coal crushing is a new type of high-efficiency coal crusher, characterized by small size, simple structure, high crushing ratio (up to 40), low energy consumption, high productivity and good particle distribution. All these advantages make the impact crusher your crushing equipment in coal mining technology. The impact crusher is used in processing plants due to the use of highly abrasive materials for the production of spare parts. Besides crushing coal, the impact crusher can process mineral and quarry materials with a length ranging from 100mm to 500mm, with the highest compressive strength can reach 350MPa. When it comes to mineral impact crusher, there are so many manufacturers in the world, so it is difficult to choose a great manufacturer. In China, SBM enjoys good reputation at home and abroad, and our coal impact crusher is very popular among customers for open pit coal mining. We believe SBM will be your good choice.

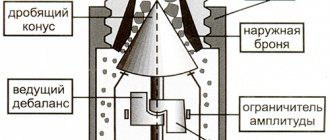

Cone Crusher for Coal Crushing

Coal crushing cone crusher is a widely used crushing plant for processing hard coal, also used for medium crushing and fine crushing of all kinds of rocks and minerals with pressure below 350Mpa into small sizes in coal, mining, cement, sand and other fields . The ideal combination of high-performance crushing chamber and high crushing frequency greatly improves the controllability of the cone crusher. Working principle of cone crusher: When the cone crusher is running, the motor rotates around a fixed point through the belt wheel or clutch, while the transmission shaft and cone part of the cone crusher are adopted by the action of the eccentric bushing, which makes the crushing wall close to the punched mortar wall at regular intervals time. The coals will then be subjected to pressure, pressure and constant bending in the crushing chamber, resulting in the coal being crushed. All spare parts for the cone crusher are made of high-strength materials.

Roller Crusher for Coal Crushing

A roller crusher for crushing coal can be called a compression crusher. In the mining industry, roller crushers are used to crush ores and medium- to low-hard rocks, for the production of cement, chemicals and construction materials. Its effect is higher than that of conventional crushing equipment. The roll crushers used can be divided into 2 types: single roll crusher and double roll crusher. The advantage of a roller crusher for crushing coal is that it produces a final product that has a fine size distribution, and they produce little dust or fine particles during operation. Roller crusher is widely used for crushing low abrasive minerals and small-scale mine production. Roller crushers are mainly used in coal mining. When mining coal, the surface of the rolls will have teeth or convex shapes (when used for mineral and metal ores, the rolls have a smooth surface). SBM can provide you not only with the coal crushing roller crusher and all accessories, but also with introduction to type selection, installation guide, etc.

Design

Despite the variety of design features, most jaw crushers use designs that were developed more than a hundred years ago.

The main regulatory document relevant for this equipment is the interstate standard that is still in force, adopted in 1993 - GOST 27412-93. The standard jaw crusher model includes the following main components:

- Bed . It is a cast base on which all other parts and mechanisms are installed. The frame has a reinforced design and significant weight, since the safety of the crusher depends on its stability and reliability.

- Crushing chamber. It is formed by two crushing plates (cheeks) and has a wedge shape. One of the surfaces is fixedly fixed, the second is placed on the connecting rod and together with it carries out a reciprocating (swinging) movement in the vertical direction. The movable “cheek” is designed so that it is possible to adjust the position of its lower edge in the horizontal plane and set the maximum size of crushed pieces at the exit.

- Eccentric shaft . Transfers energy from the power drive to the movable “cheek” and converts rotational motion into reciprocating motion. The main shaft contains a connecting rod, a pulley and a flywheel.

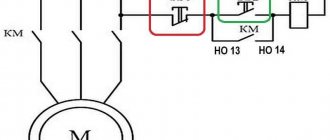

- Drive unit . It includes an electric motor and a drive pulley connected to it through a coupling, which is fixed to the shaft and transmits torque to the driven one.

- Control system . Ensures the execution of all basic commands: step start, emergency shutdown, activation of protective relays (during overload, overheating, etc.), operation of a pre-start alarm, and more.

Crushers with a complex movement of the movable jaw (SMC).

The crusher with complex jaw movement has a specially designed movable jaw. Due to the eccentric fastening of the upper end, the cheek has a complex movement: at the upper support it makes circular movements, and at the bottom, at the unloading end, it makes elliptical movements. As a result, pieces of ore are subjected not only to crushing, but also to abrasive action.

To adjust the width of the exit slot, a device with a vertical adjusting wedge is used, which is raised and lowered by a screw. A casing is provided to prevent the crushed material from flying out. The safety device is usually the spacer plate itself, which breaks when the permissible load is exceeded, preventing failure of more critical and expensive crusher components.

The crushing force of crushers with a complex jaw movement is completely transferred to the eccentric of the crankshaft, so crushers of this type are not manufactured in large sizes and are not used for coarse crushing. Jaw crushers of the ShchDS type are used for crushing relatively small, low-abrasive ores with a high content of clay and moisture. The width of the receiving opening usually does not exceed 600 mm, and the exit slot has a width of 20 to 200 mm.

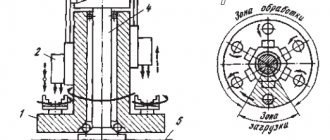

Crushers with a simple movement of the movable jaw (SMJ).

The crusher with a simple movement of the movable jaw is installed on a frame, in the side walls of which the main bearings of the eccentric shaft are fixed. A connecting rod is suspended from the eccentric part of the shaft. At the bottom of the connecting rod there are grooves for installing the support blocks of the spacer plates. When the eccentric shaft rotates, the connecting rod receives a rocking motion, which is transmitted to the movable cheek using spacer plates. The cheek receives a pendulum movement centered on the suspension axis. Fixed and movable crushing plates are fixed on the cheeks.

The width of the exit slot is adjusted by installing additional spacers of varying thickness between the stop and the rear wall of the frame, a system of wedges on screws, or replacing the rear spacer plate with a longer or shorter one.

The advantages of crushers with a simple swing of the jaw are: the ability to crush high-strength rocks and relatively little wear of the crushing plates. The disadvantage is the high metal consumption compared to crushers with complex jaw swing, as well as the greater unevenness of the resulting fraction.