For thousands of years, wine has not lost popularity due to its unique taste and aroma. In the recent past, exclusively manual labor was used to make wine. Huge plantations required large human resources. Grape juice was pressed with hands or feet, which took a lot of time and effort. Industrial progress has made this task much easier. Manual labor was replaced by machines, making the process of preparing the drink easier and significantly faster. Grape crushers began to be used to squeeze out juice.

A grape crusher is a device that processes grape bunches to produce pulp. It is used for processing large volumes of wine material. This saves time and makes the wine material better quality, since the grape seeds are not damaged during processing, and the finished wine will not have a specific bitter taste. There are mechanical and electric presses. The choice between them depends on the amount of material being processed. To process raw materials less than 700 kg, a manual model is used, and above this weight, an electric model is used. For small volumes of berries, you can make a grape crusher with your own hands.

A manual crusher is a wooden structure consisting of rollers, a frame and a wort container. The crusher works as a berry crusher by grinding the bunches with special rotating rollers.

Purpose and description of the device

The mechanism for processing grape bunches allows you to automate tedious manual labor, speed up agricultural operations, and improve the quality characteristics of the resulting raw materials.

Using the simplest means of mechanization, you can quickly produce a large volume of natural grape juice or an alcoholic drink based on such berries. The device is suitable for use on a farm or in a personal garden.

A grape crusher (you can make a simple mechanical device with your own hands using a ready-made drawing) is designed for crushing bunches for further processing. The structurally simple device is distinguished by high performance.

A typical homemade grape crusher consists of a loading container with a pair of cylindrical rollers located on the bottom in a parallel plane with a smooth, grooved or perforated surface. The crusher, mounted on a wooden, plastic or metal frame, processes the berries by crushing them. The rotation of the rollers is ensured by a simple gear or bearing mechanism attached to the handle.

An electric unit with a gear rotor, which does not require the application of muscular force, has a more complex design. A self-made device is equipped with a receiving hopper into which the processed grape mass arrives.

Crushing does not damage the small seeds, which give the raw material a bitter taste. It is advisable to use an electrically driven mechanism for processing berries over 700 kg.

What is a comb?

If we consider a bunch of grapes, it consists of the following components:

The grapes are collected in bunches, then processed - separating the berries from the ridges.

This is a labor-intensive process. To avoid this, a comb separator is built into the crushers. He is just sorting the berries and this rubbish. A large number of ridges in the pulp will give the wine a rich herbal taste. And this is critical, especially for white wines. Let's look at several options for making a grape crusher with your own hands.

Source

Types of grape presses

There are several design schemes and design options for such devices. For home or garden use, grape berry choppers are made of compact size and light weight.

The device must:

- easy to disassemble for washing and cleaning;

- be durable;

- have high safety during everyday use;

- differ in operational reliability.

The design diagram for self-implementation is selected based on the required performance of the device, simplicity of technical design, and various individual factors.

Mechanical modifications of grape presses suitable for making at home are shown in the table:

| Construction type | Technical features |

| Roller | The simplest device with cylindrical pressing elements arranged in parallel and rotating in one or opposite directions. |

| Reciprocating | The working design of the piston modification crushes a portion of grape raw materials and sends the resulting mass into a storage container or into a plastic barrel placed nearby. |

| With radial blades | The activator rotates inside the grape mass. The blades break the berries with radial impact, the juice from which flows into a receiving container located below. |

| Hammer | Such designs contain a metal, plastic or wooden shaft with a rotor element. Additional axes are installed on the periphery, to which impact hammers are attached. The crushed berries are pushed into a storage container. |

| Screw | Contain an element of the same name with a variable pitch. The device crushes the berries by crushing them. |

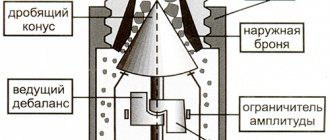

| Eccentric | The design consists of a pair of cylinders, one of which is inserted into the other. During the rotational movement, their surfaces come closer together, crushing the berries between them. |

A do-it-yourself grape crusher can be made with or without a destemmer. The design detail gives the berry raw material chopper a useful option. The comb separator allows you to obtain a mass that does not require further cleaning of branches.

The element can be of a centrifugal, shaking out or blade design. Each option has its own nuances and subtleties of manufacturing for a similar purpose. Below are the design diagrams of grape presses available for your own implementation.

The simplest roller modification

Widely distributed among farmers and gardeners. A roller grape press allows you to obtain high-quality raw materials in small volumes. The basis of a compact agricultural unit is horizontally mounted cylindrical elements or blades with a fixed or adjustable gap. To improve the quality of the finished product, a self-made device of this type is equipped with a built-in comb separator.

The simplest roller modification unit has a top loading. A pair of choppers rotate in different directions, mechanically affecting the berries. The crusher is set in motion by turning the handle located on the body. The electric version is equipped with a rotary gear drive. A distinctive feature of different designs is the shape of the working cylinders.

By configuration they are:

- corrugated;

- smooth;

- perforated;

- lobed.

The easiest to make yourself are the first 2 options. The blade modification contains 4, 6 or 8 berry breaking elements. The speed and productivity of the grape crusher depends on their quantity.

Impact centrifugal design

In this model, a special rotor is installed that crushes the berries with a dynamic load of calculated force of the appropriate direction. Such devices are used to obtain the maximum volume of coloring substances contained in grape berries.

Impact centrifugal crushers are only available with an electric drive and support vertical or horizontal loading, depending on the method of spatial orientation of the central shaft. The standard rotor speed is 190-250 rpm.

With destemmer

The part is a horizontal perforated cylindrical shaft with thread-like blades. The raw material intended for processing first comes into contact with the destemmer. After this, the crushed berries fall under the crushing structure, cleared of branches. The reverse design option is possible. First, the raw materials are crushed, then the ridges are separated.

Working principle of a grape crusher

The mechanism, regardless of the technical modification, separates the juice from the cake by crushing the berries, removes branches and bones, and performs additional cleaning operations. The operating principle of the unit allows it to be used for processing any varieties of grapes. Raw materials are loaded into a receiving bowl called a hopper. Horizontal or vertical moving parts are installed at the bottom of the container.

They perform the function of pressing to produce juice and grounds. The processed raw materials are sent to an integrated storage tank or a separate vat. The design is at the same time affordable for self-production, efficient and reliable. The principle of operation of the simplest manual unit is to grind berry products by the radial movement of a pair of rollers driven by the rotation of a handle attached to the side surface of the body.

Such devices require the application of muscle force and are intended for processing relatively small volumes of raw materials. Modifications with an electric motor allow you to grind a significant amount of grapes without effort. The use of such a device ensures high quality pressing and separation of berry products. The operating principle of crushers with a destemmer is similar to other options, with the exception of the presence of an additional working part.

Peculiarities

For processing red grape varieties, units without a destemmer are used. Such products require pulp. The features of the device are determined by the design and operating principle.

Most home-made devices grind berries using a pair of simple cylindrical rollers with a smooth or grooved surface. At home, it is not difficult to implement a reciprocating design.

Such units operate on the principle of a mortar, in which a metal or wooden piston is placed. It is advisable to equip grinding devices with an electric motor.

A do-it-yourself grape crusher can be made with an electric motor.

Working with a mechanical device of such a technical modification requires significant muscle effort and is characterized by low productivity. The peculiarity of the hammer crusher is the presence of peripheral axes located parallel to the central shaft to which they are attached.

This design ensures the highest quality extraction of berries. The raw material enters a perforated deck, which rotates under the influence of centrifugal force. When making a crusher of this type with your own hands, it requires precise calculations. Otherwise, the device for crushing grapes will not fulfill its intended purpose. The peculiarity of screw units is that they crush berries using the compression method.

Press

This manual grape crusher is simple and low cost. The device will require a stainless steel container with a tap, oak planks, a stainless steel strip (you can use a perforated one), a car jack, and a welded frame. To begin with, the inner container is assembled from oak planks. Holes are drilled at the ends of the bars at the top and bottom, fishing line and stainless wire are threaded through. This creates the frame of the future internal container. Its height must match the height of the stainless steel tank. Next, using a strip, the resulting structure is fastened together. A gap of 2-3 mm should be left between the bars. The next step is to make a wooden support for the press. It is also made from wooden blocks.

Its diameter should be slightly smaller than the diameter of the inner wooden container. A metal container is fixed to the frame, the internal wooden part is installed in it, grapes are poured in, and a support is placed under the press. As a force, you can use a screw system or a car jack. The second option is more affordable and is available to every car owner. The jack is installed on a wooden cover so that in the future the upper part of the frame becomes the second point of support. It is also necessary to prepare several bars and planks. They may be needed when working with a jack. The tap opens and the juice starts squeezing out. Don’t forget to place a container under the stream for juice.

Manufacturing materials

Grape juice is chemically reactive. For the manufacture of crushers, materials are selected that are resistant to long-term exposure to phenolic and other compounds contained in processed berry raw materials.

Suitable:

- chemical inert polymers;

- natural wood;

- durable organic glass;

- metal alloys with anti-corrosion properties or appropriate coating.

Wood is considered the most environmentally friendly material. Its disadvantage is the need for thorough washing and disinfection after each procedure for chopping grapes. This material is distinguished by high mechanical strength. Wood quickly deteriorates when exposed to moisture. The material is susceptible to infection by bacteria and infestation by insect pests.

Wood is resistant to long-term or constant mechanical loads and is relatively easy to process in the manufacture of grape crusher structures. The material has high viscosity and wear resistance. Another suitable option for making a grape crusher is metal alloys.

Use:

- stainless steel;

- duralumin;

- galvanized copper for the body;

- cast iron.

The latter option is the least preferable due to its heavy weight and complexity of machining. Stainless steel is distinguished by endurance, colossal durability, and hygiene. Metal alloys are easy to clean and do not transfer foreign odors and tastes to the berry product. Crushers are often made from composite materials by combining plastic, alloy and organic glass or wood.

The most expensive option is a home grape press with ceramic rollers. This material is distinguished by absolute chemical inertness, high strength, and resistance to long-term mechanical loads.

Instructions and drawings

A do-it-yourself grape crusher can be designed using the simplest roller operating principle. This scheme is considered the easiest to implement independently. This device is perfect for home use.

You can use a ready-made drawing or develop your own unique design. First, a sketch of the device is made indicating the dimensional parameters. In a simple device, the rollers are fixed. In more complex models, they can be made adjustable to increase the efficiency of processing grape raw materials.

Materials for making a roller crusher:

- Oak bars measuring 50x50 cm. They will serve as the body.

- Wooden rod with a cross section of 5x5 mm and a length of 1-1.5 m.

- Chopping rollers. You can use wringer parts from an old washing machine or a rolling pin for rolling out dough, made from linden, birch, and aspen.

- Metal alloy studs, 2 pcs.

- Gears. Their size and number depend on the type of technological scheme being implemented.

- Stainless steel mesh with cells 10x10 or 12x12 mm.

- Axle with blades for the manufacture of an impact-centrifugal structure.

- Handle for operating the device.

- Plastic container for supplying recycled materials.

The wooden parts of the structure are coated with a protective layer of colorless varnish. The simplest crusher is suitable for processing raw materials up to 500 kg. To increase the strength, reliability and durability of the unit, the body is covered with sheet metal.

How to make a crusher with your own hands?

The base of the structure is assembled from pre-prepared oak bars. If such material is not available on the farm, you can use plastic or aluminum channels used in construction and repair work.

Installation steps:

- Assemble the frame. When using oak blocks, nails are suitable as fastening elements. Other materials are fixed with screws or bolts. The dimensions of the frame depend on the number of rollers and the size of the hopper for receiving processed raw materials.

- Use a hacksaw to cut the cylindrical parts that will become the pressing elements.

- Make a bunker from wooden planks for loading berry raw materials. It is advisable to give it the shape of a funnel. You can use a plastic container of the appropriate geometric configuration.

- Install the rollers. They are secured with metal pins.

- Attach 2 metal gears to the pressure cylinders on the outside of the housing.

- Mount the parts of the structure on a support frame made of a wooden rod, metal or plastic rod.

- Attach the rotary handle to the gears with the rollers.

- Coat the wooden parts of the structure with colorless varnish.

A do-it-yourself grape crusher can be made using a different technological scheme or subsequently upgraded by installing an electric drive. The receiving hopper is cut out of plywood. To connect wooden parts, it is advisable to use copper self-tapping screws or nails made of a similar metal. Instead of gears, bearings are suitable.

Electric crusher assembly

Such a device is mounted on a wooden frame made of bars with a cross-section of 4x4 cm or welded from profile pipes with a diameter of 25x25 mm. The unit is equipped with a gear motor with a rotation speed in the range of 190-250 rpm. A target with a star-shaped part from an old bicycle is suitable as a drive for a separate comb separator axis. The assembly of other parts of the mechanism does not differ from the previous version.

In electrical construction, it is better to use metal for the container body in which the rollers and other moving elements rotate. The device is subjected to high mechanical and vibration loads, which will lead to rapid destruction of the wood.

Installation of a unit with a destemmer

The auxiliary element is installed below the pressing rollers. To manufacture the comb separator, a semi-cylindrical part made of stainless steel or an aluminum-based alloy is used. The structure must have a perforated surface with an approximate hole diameter of 10-15 mm. The shaft transmitting rotation can be made of birch or oak cuttings. The handle of a garden shovel will do.

The blades separating the ridges from the berries are made of a copper or steel plate 0.9-1.5 mm thick. To attach them to the shaft, use copper or brass self-tapping screws. The comb separator is installed in such a way that when rotating it moves in a horizontal plane.

A semi-cylindrical structure can be obtained by bending a steel mesh and welding its adjacent edges. The blades are attached in increments of 4-5 mm. The grapes crushed by the rollers fall onto the destemming shaft rotating below, which cleans the raw materials from the branches.

Second creation method: “Typhoon”

The operating principle of this grass cutter is no different from the previous one. It just looks better and the quality of work is higher. In this case, the raw material passes through the upper hole, and the finished substrate exits through the lower one, which is located in the side of the apparatus.

To avoid negative consequences, you should use a protective casing. This homemade crusher does not look ideal, but you will get it for free. Typically, the chopped grass is placed in a bucket, which is placed under the outlet. The body of the old Typhoon vacuum cleaner is perfect for a garden grass shredder. It has a top hole with the right size. Remember, this is a great option, but not the only one! Any cylindrical container is suitable, be it a pan, bucket or a piece of pipe. The engine can be obtained from an old washing machine.

We also recommend reading:

Knives can be made from an old hacksaw blade, and a rectangular profile can be used as stands. The bushing on which the knives are mounted must be turned on a lathe. The engine with the parts removed is mounted on studs from below to the container. To clamp the knives, you need to use plumbing nuts. When creating bushings, first cut threads for these nuts.

Then make a hole for the motor shaft. For better fixation on the shaft, two holes of 7 mm in diameter with threads for locking bolts are made in the bushing. On the other side of the motor shaft, platforms are created to increase the fixation of the bushing with special bolts. The next step is to remove the edges and put on the knives. To make knives correctly, you need to make four pieces of canvas using a grinder. Square holes with a side of 26 mm are created in the center of each workpiece.

The width of any part depends on the source material. Knives should be placed closer to the bottom. The platform must be reliable and stable. To do this, the base should be made larger than the top. The platform holds the chopper and protects the engine. It needs to be attached to the container with 3 bolts m6x45. The edges on the sides are covered with sheets of tin. In the racks it is worth cutting threads for M3 bolts, with which the sheets are secured to the platform.

Operating rules

The first launch of a self-made unit is carried out in test mode in order to check the performance, reliability of the assembly, and the quality of processing of the berry product. If necessary, increase or decrease the gaps. After checking, the results are analyzed. Weigh the separated ridges and finished raw materials. The sum of both masses is compared with the weight of the original product. This allows you to determine the level of losses during processing.

A high-quality homemade mechanism should ensure a reduction in volume by no more than 1-2% of the original volume of raw materials. The number of branch fragments in the useful mass is analyzed. It should be no more than 1% of the total mass.

The operating rules for the crusher provide for periodic disassembly and cleaning of the unit. This possibility is included at the design stage of a device for crushing grapes. You can make your own unit with two-level rollers, which will significantly increase the efficiency of processing the berry product.

Advantages of using the device

Advantages of producing pulp with an automatic crusher:

- fast processing of large volumes of grapes;

- rational use of resources;

- the opportunity to obtain high-quality pulp;

- automatic cleaning of cake, juice from twigs, excess ridges;

- simplicity and convenience of the unit, which can be improved if necessary;

The simplest wooden model can be assembled with your own hands. It will become a handy tool for owners of small vineyards.

Devices made of wood and stainless steel are popular.

They are not subject to oxidation and corrosion. This ensures long-lasting use as the juice is highly acidic.

The only drawback is the inability to use certain types of units for processing nutmeg varieties.