Among the abundant variety of welding machines on the modern market, the manual welding extruder occupies a special place.

A manual extruder for welding is a device for joining products made of polyethylene, polypropylene, propylene, other types of plastics, plastic sheets, films, containers (barrels, swimming pools, etc.), wells, children's slides, and so on. Rarely used for joining PVC products. It is not suitable for use in welding pipelines, since the strength of such joints is no more than 80%, they will not be airtight. The operating principle of this device is as follows: hot air is supplied from the extruder nozzle and heats the space (welding groove or joint) between the planes of the parts, bringing them to the state of plastic. At the same time, the rod is fed into the working area of the equipment, heated and mixed with the screw (or disk), and then forms a homogeneous mass of plastic. The polymer in a molten state is extruded through a die or welding shoe, then after complete cooling, a finished seam is obtained. Squeezing the polymer can be thought of as squeezing toothpaste out of a tube.

The requirement for perfect cleanliness in this type of welding is the most stringent. Surfaces must be thoroughly cleaned immediately before welding.

The surfaces to be joined must be identical. This concept in this vein refers to the same chemical composition, density and fluidity of the material. According to these indicators, the rod must be identical to the parts being welded.

Types of Manual Welding Extruder

- Screw (filler material is melted in the screw (extrusion) compartment of the apparatus and squeezed out using a screw). The filler material is a rod or special granules that are placed in the screw compartment and there, under the influence of high temperature, when interacting with the screw, they become a homogeneous mass, ready for use.

- Screwless or plunger type. The rod in such extruders is first heated using electric heaters around the heating area, and the rear solid part of the filler material acts as a piston for the front, already viscous mass.

- Combined (the two above types are combined).

Screwless welding extruders have lower productivity compared to screw extruders. But there are also advantages: lightness and compactness, which allows you to use it in hard-to-reach places.

The peculiarity and priority of use is determined by the following factors.

- The manual welding extruder can weld products with thick walls.

- Fast welding speed.

- Minimizing the human factor. There is no need to monitor the condition of the weld pool, as when welding metal, to control the correct removal of welding slag, to remove “herringbones” and “zigzags”. This equipment will be easiest for a beginner to use.

Types of welds

GOST 16310-80 establishes more than 10 types of welding seams that can be used to connect polymer parts. The name of the seam depends on the appearance of its cut. Let's look at the main ones.

V seam

Using a carpentry tool (hacksaw, chisel or plane), the ends of the materials to be joined are processed. A bevel is created, which at the point of contact should make an angle of 45-90° degrees. At the lower edge of the bevel there should be a straight end no more than 1 mm thick.

If parts of different thicknesses are joined, then the side with the larger thickness is cut at a large angle, and the smaller one at a smaller angle. Thus, equal thickness of the parts at the joint is achieved.

The gap between the parts should not exceed 2 mm to ensure penetration of the additive into the inside of the seam and ensure a high quality connection.

X seam

Unlike a V-shaped seam, in an X seam it is impossible to control the quality of welding. But the double seam is designed to compensate for this shortcoming. For this type of seam, our own manufacturing technology is provided:

Bevels with an opening angle of 30-60° degrees are formed at the connected ends,

The root layer is joined without a gap; preliminary fixation is carried out using a hot air gun. The seam is welded first from the front part, then from the back.

K seam

When using such a seam, the ends are processed with a rounded scraper, then the sheets are pre-fixed using a hot air gun. Additionally, welding can be performed on the second side of the connection.

HV seam

The execution of such a seam is similar to the V-seam, however, the opening angle should not exceed 60° degrees. The parts do not fit together tightly; there is a gap of 2 mm between them. This gap allows the additive to enter the joint and exit from the outside, sealing the joint.

Double HV seam

Manual welding extruder: operation diagram

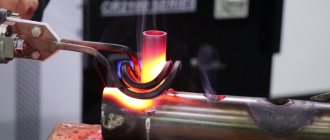

When making a connection, both parts must be heated. For the purpose of heating surfaces before extruding filler material, a manual welding extruder may contain in its design a special air flow heater or, in other words, a hot air gun. Also, the heated air flow can come from external equipment: a compressor or an organization’s pneumatic network. The filler material is heated using special electric heaters around the screw (extrusion) chamber. But in older extruders, the chamber is heated using hot air, which is used to heat the welding zone. Before heating the welding area, air flows around the screw compartment and melts the filler material. The filler material in molten form flows out into the welding zone through the welding shoe.

Extruder welding is most often used for low-density polyethylene, polypropylene and other types of thermoplastics of the first group. For this type of thermoplastic, the temperature difference between the molten state and the state of thermal destruction is about 50 degrees. This suggests that even large overheating of the material (by about 30-40 degrees) is not capable of severely damaging it.

Thermoplastics of the second group include PVDF and PVC. Their temperature difference between thermal destruction and the fluid state of the material is insignificant, so when welding there are strict requirements for the operation of the heating department. When working with thermoplastics of the second group, there are special requirements for the screw; it must be of a special shape in order to mix the mass more thoroughly, preventing overheating.

Also, when working with PVC and PVDF, the extruder should not be turned off and/or remain in standby mode for a long time.

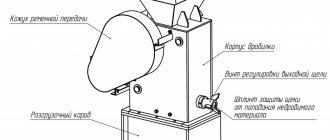

Design

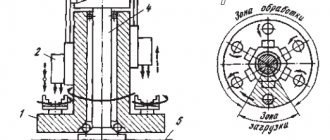

The appearance of the device resembles a pistol with a handle. The drive motor is located inside the handle. This design is compact. The extruder device can be divided into two parts. The first of them is a high-power heater, the function of which is to melt the plastic being joined. Convenience during operation is ensured by the presence of a temperature relay.

The other part is the extrusion device. It is equipped with a screw mechanism, with the help of which the melt is supplied through a nozzle attachment to the welding site.

The design includes the following elements:

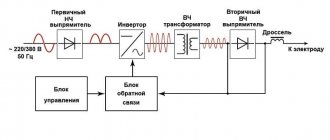

- Electric drive . It uses a high power transformer.

- Heater with fan. When connected to the electrical network, hot air is generated, the flow of which leads to softening of the parts being connected.

- Material feed chamber . It has the shape of a hollow pipe inside. There is a screw screw located in the center, the function of which is to grind the plastic fed inside and move it to the exit.

- Extrusion chamber . A place where crushed and molten material accumulates, which, under pressure, emerges from an opening located at the end of the chamber.

- heating element . This element is designed to create a kind of heating jacket around both chambers, which ensures that the plastic is heated and melted.

- Welding shoe . It is a nozzle placed on the nozzle of the extrusion chamber, due to which the molten mass takes on a certain shape.

- Adjustment block . The block contains controls that can be used to change the parameters of the welding mode, including the speed at which the auger rotates.

The device is powered from the mains.

Extruder welding

If the device is not used for the first time, then it is necessary to remove the filler material used previously. Even if it is of the same composition. Repeated heating of the filler material reduces its strength.

Before directly starting welding, it is necessary to remove the cold start locks, heat the machine and welding shoe to the temperature required for work, and adjust the performance.

During the welding process, it is necessary to maintain the desired angle of inclination of the welding machine, depending on the type of seam being made. If you need to take a break, the extruder must be placed on a special stand. If you are planning a long break, reduce the temperature by about 40-50 degrees. Such a decrease in temperature will allow the heating of the filler material to be stopped and operation to be resumed quickly.

Thus, welding with a manual welding extruder is one of the easiest to use among other types of welding and with the use of other devices. You don't need to be a professional at all. You just need to follow the operating instructions for the extruder and follow the above rules when working with the device and the materials being welded.

For what materials is it applicable?

The device is designed to work with polymer thermoplastics , which under the influence of high temperature acquire high elasticity or become fluid.

Attempting to heat thermoset plastic results in an irreversible chemical reaction. Polymers have different melting points. Low pressure polymers (LDP) change their state of aggregation at 120 Cº, polyvinyl chloride - at 220 Cº. The melting point range of other industrial compositions varies between 160-220 Cº.

High-quality units are equipped with a mechanism for adjusting the temperature of the mixture, which allows you to work with any polymer.

Equipment

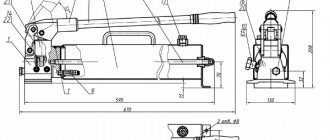

For extrusion welding of plastic, profile devices called extruders are used. They are designed for manual seam formation and are intended for outdoor and indoor use.

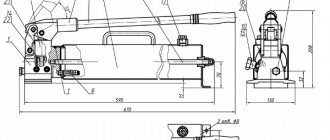

The extrusion unit for pipe welding includes the following components:

- A heating element. Welding machine module that heats the additive and the air supply unit.

- Screw. A rotating element that forces the molten additive through a nozzle. Instead of a screw, a plunger can be used.

- Controls. Keys to control the extrusion welding process.

- Air supply block. The part of the extruder that supplies hot air to the weld area. This ensures heat treatment of the surface, guaranteeing integration of the extruded material.

- Storage device. Unit for storing extrusion wire or granules. In the first case, a spool holder is used, in the second, a small hopper is used.

- Shoe. An auxiliary element that simplifies extruder welding. The shoe is located at the end of the device. It presses down the supplied additive, preventing it from leaving the welding zone. The element is made of refractory polymer and is resistant to temperature and abrasion.

The shoe is a removable part of the extruder, repeats the geometry of the weld, and is selected taking into account the work being carried out. Some nozzles are used for welding pipes, others for making tanks, and others for making casings.

Proper selection of the shoe simplifies extruder welding and allows you to obtain a tight and durable connection.

Manufacturers offer equipment for extrusion welding with left and right nozzle placement. This simplifies preparation for the process and carrying out work.

The price of an extrusion module for pipe welding starts from 30,000 rubles (MSK). Outside Moscow, the cost of equipment for extrusion welding can increase significantly.

When choosing an extruder, it is important to remember the compatibility of additives. Domestic devices work with Russian and Western products, foreign ones - only with wire and granules approved by the manufacturer. Trying to use local materials in an imported extruder increases the likelihood of expensive equipment failure.

Technical equipment of the device

The technical equipment of the extruder is very important. For example, simple models of extruders are equipped with only a pair of mechanical switches - handles with divisions. Using them, you can adjust the temperature of the supplied plastic mass and its feeding speed.

Professional instruments are equipped with electronic systems. Here the electronic unit is responsible for the adjustment, and the information is displayed on the liquid crystal display. Moreover, the digital thermoblock can be located not only on the extruder, but also on the hot air gun.

Luxury extruders are equipped with ambient temperature sensors to minimize the possibility of differences in the output of the plastic mass.

You can always contact our specialists by calling 8-495-505-63-15 and they will help you choose the equipment that best suits your needs.