Gas burners for sauna stoves

The use of such economical and high-energy fuel as gas as a heat source for heating homes at one time made a real revolution in people's lives.

There is no longer a need for labor-intensive preparation of firewood for the winter, and even for the bulky brick stoves themselves, which many got rid of by installing modern gas boilers instead. At the same time, until recently, bathhouses continued to be built and heated in the old fashioned way - with wood, burning them in brick or metal stoves. In areas where there are no large forests, purchasing firewood for bathing procedures is a big problem, which also entails additional financial costs.

Manufacturers of stove accessories relatively recently offered consumers a worthy alternative to wood-burning and electric stoves and they were right - gas heater stoves and special gas burners for existing wood-burning stoves began to be in high demand among the population.

The most efficient devices of 2018

The most efficient certified boilers and gas burners this year:

- Bosch Greenstar series. The boiler is small, very quiet, environmentally friendly and uses economical condensing technology providing an AFUE rating of 95%. Greenstar is available in two models - combi for spatial and point-less water heating or space heating, which can be used with domestic hot water tanks. It is equipped with a heat exchanger with a 5-year warranty.

- Bradford White Brute Elite Series. The boiler with 95% efficiency has a condensing multi-pass stainless steel heat exchanger with an advanced modulation system. Innovative design features make Brute Elite easy to install in both new and existing heating systems.

- Bradford White Brute Elite 125 Series. Customizable combi based heating only models are 95% efficient with a combi unit providing heating and hot water from one unit. Requires only one gas connection, one ventilation system and built-in expansion tank and boiler pump, and is easily accessible for repairs.

- Buderus GB142 series. Condensing gas boiler. Using state-of-the-art condensing technology with 95% AFUE, the Boer Buderus GB142 wall-mounted condenser maximizes the heating value of every m3 of natural gas or liquefied propane.

- Boiler Alpine Series. This is a natural or liquefied gas condensing hot water boiler with a stainless steel heat exchanger. Equipped with Sage2 boiler control system. 1 TM, which supports multiple firing speeds, is also equipped with an external reset and a touch interface.

- Carrier BMW Performance Series. 95% AFUE. Stainless steel. The modulating condensing boiler is equipped with a unique vertically oriented stainless steel heat exchanger, 5 to 1 ratio, compact design with light weight, compact wall mounting, primary and secondary piping, with a 15-year warranty.

Having familiarized yourself with the design and operating principle of gas burners and popular models, you can easily choose exactly what suits your needs.

Advantages of using gas burners for a sauna

Gas burners for factory-made sauna stoves have become a real godsend for people living in steppe and forest-steppe regions. Despite the apparent complexity of converting wood-burning stoves to gas, it is very simple to do; you just need to comply with some safety conditions, which will be discussed a little later.

- it is more convenient to heat with gas than with wood - just open the valve, light the burner and after 60-80 minutes you can use the steam room;

- heating a sauna with gas is 20-30% more economical than using wood, and 100-120% more economical than using electricity;

- gas is an easier fuel to use than firewood - there is no ash after it, no additional space is needed for storing firewood;

- from a fire safety point of view, gas is preferable - the temperature of the exhaust gases is much lower than when heating with wood, so there is no need to additionally insulate the places where the chimney passes through the ceiling and roof.

Gas burners for sauna stoves can be divided into two large groups , which are fundamentally different from each other. Each type of burner has its own advantages and disadvantages, as well as design features that determine their scope of application.

Atmospheric burners

These are the cheapest, easiest to manufacture and use burners, with which you can quickly and cost-effectively convert your wood-burning stove to gas (see photo below).

Atmospheric burners do not depend on the availability of electricity; their operation does not stop when the gas pressure in the main line changes. The mixing and combustion of the gas mixture in the firebox occurs due to the pressure difference, i.e. in a natural way, hence the main drawback - the bathhouse will need to be additionally equipped with a high-quality air flow, as well as monitor the condition of the chimney. Otherwise, gas will be consumed inefficiently, and there may also be problems with high-quality, uniform heating of the fuel chamber and, accordingly, the entire steam room.

Installing atmospheric burners in existing wood stoves usually requires additional modifications and improvements, both to the fuel chamber itself and to the dimensions of the burner. The fact is that the fireboxes of a conventional sauna stove have more or less standard sizes; By placing a burner there, we get a situation where the flame from it, when burning, touches the bottom of the heater, or the metal parts of the stove, i.e. the burner is too high. This is unacceptable, since for proper heating of the fuel chamber and the entire furnace, it is necessary that the flame heats the air, and the source must be as close as possible to the bottom and exactly in the center. According to reviews from people who have already converted their wood-burning sauna stoves to gas, this is quite possible, although it requires some effort.

Types and characteristics of elements for gas combustion

The gas burner for the boiler is selected according to the following characteristics:

- Life time. The period cannot be less than the operating life of the heater.

- Low noise level. If the injectors make a lot of noise, this indicates a malfunction - all parts are checked at the factory and must comply with sanitary and hygienic standards.

- Type of fuel. Manufacturers offer universal nozzles that operate on main gas, bottled gas, diesel fuel, etc. When changing the energy carrier, a simple reconfiguration of the equipment is required - such burners are especially convenient for owners of country houses.

- Easy to install and dismantle.

The main purpose of the device is to mix gas and air to form a flammable medium. The efficiency of the burners is high; the type of mixing differs between atmospheric and fan. It is worth considering their features in more detail.

Atmospheric burners

To form a combustible substance, the burners take air from the room where the heater is installed. Atmospheric gas burners for heating boilers operate on the ejector principle - nozzles for supplying gas are located inside the channel structure. Air is delivered to the nozzles, then a combustible mixture is formed, exiting through the perforation of the nozzle.

As the mixture exits, a low air vacuum is created, which allows oxygen to be drawn in and a new portion of the mixture to be formed. The gas combustion chamber is equipped with several parallel channels with nozzles, so the process of forming the gas-air mixture is carried out in a continuous cycle.

After combustion, the heated gas moves to the upper part of the heat exchange structure, giving off heat to the heat exchanger, and then the combustion products are drawn into the chimney. The warm gas reacts with the cold outside air, resulting in the formation of draft, which provides the supply of fresh air to form a gas-air mixture.

Advantages of atmospheric gas devices:

Simplicity and relative cheapness; there will be no problems with replacing equipment. Energy independence. No electricity is required to start the boiler

It is important to maintain an optimal level of fuel supply pressure and build a high-quality chimney. Low noise level, compact device.

The disadvantages include the necessity of constructing a chimney so that combustion products are completely removed.

As for the efficiency of the equipment, it is quite high, since manufacturers are increasing the number of inlet holes with a small diameter. This “perforation” ensures uniform distribution of the gas-air mixture throughout the combustion chamber, increasing the performance and energy efficiency of the system.

Fan burners

These are more complex gas burners for heating stoves, allowing control of the fuel combustion process. The fan is installed to force air into the combustion chamber and ensures the formation of a gas-air mixture in a sealed compartment for fuel combustion.

Fan-type nozzles are used in combined heaters equipped with a sealed combustion chamber.

Device Features:

- high efficiency;

- forced air injection;

- the optimal combination of portions of gas and oxygen to form a combustible mixture.

In addition to pumping air into the chamber, the fan is responsible for removing combustion products to the outside and allows you to change the pressure in the network by changing the speed of rotation of the blades.

The main difference between fan nozzles and atmospheric ones is the formation of a combustible mixture. In atmospheric boilers, a gas-air portion is formed at the entrance to the burner, in fan boilers - at the entrance to the combustion chamber.

A fan gas nozzle for heating a private home has a wide list of advantages:

- Monitoring the operation of the network, the ability to influence the process of forming the gas-air mixture, and change the boiler power.

- Saving fuel consumption.

- High efficiency.

- Can be installed in apartments and small buildings. This is achieved by eliminating the need to connect to a standard chimney. The coaxial pipe is run through the nearest exterior wall.

Domestic gas fan heaters are expensive energy-dependent devices, which is a disadvantage of the units. If the device breaks down, only a specialist can replace it, and the burner turns off if there is a failure in the supply of fuel or electricity.

Pressurized burners

Pressurized or blown burners are a higher quality, fully automatic analogue of atmospheric burners, which are sold complete with a fan that forces air into the fuel chamber. When installing a forced-air burner in a wood-burning stove, it is not necessary to place it exactly in the center of the firebox - the fan creates forced circulation of hot air in it, which promotes uniform heating of the chamber.

Such burners, as a rule, have many settings - depending on the average gas pressure, the size of the steam room, the mode of use of the oven, etc. Multi-stage safety systems and high-quality automation make the use of stoves with forced-air burners quite convenient and comfortable, while they can be adjusted to almost any power in a wide range.

Perhaps the only drawback of such burners is their dependence on power supply, so in places where the power supply is unstable, it makes sense to provide alternative power sources. Also, when purchasing a forced-air burner, it is necessary to correlate its length with the depth of the fuel chamber - the flame should not touch its rear wall.

General rules for installing a chimney for a stove

Another condition for the normal operation of a gas stove is the installation of a chimney. For gas-fired stoves, smoke channels must be vertical, without ledges. The design of the chimney of a wood-burning stove is often not suitable for the removal of gas combustion products.

The slope of the chimney is allowed, but not more than 30°, and provided that the cross-section of pipes on inclined sections is not less than the cross-section of pipes installed vertically

You can refurbish an old chimney by lining it. Upgrade options:

- Installation of a stainless steel pipe in the chimney duct. In this case, the diameter and height of the pipe should be selected according to the characteristics of the chimney duct. The gap between the walls of the chimney and the pipe is filled with non-flammable heat-insulating material such as expanded clay or foam glass.

- Application of FuranFlex technology. The method involves placing an elastic polymer tube inside the channel, which, under pressure, takes its shape and hardens. The protective layer serves to insulate, seal and internally protect the chimney.

If none of the chimney modification options work, you will have to install a new one. Depending on the location of the stove, two options for installing a chimney are possible: an external attached one or an internal one.

The influence of the characteristics of the chimney on the safety of heating is such that it will necessarily be checked by the Fire Inspection authorities with the subsequent issuance of a written certificate, without which the equipment will not be connected to gas networks.

Which one is better to choose?

Any buyer thinking about converting their wood stove to gas fuel must carefully weigh the many parameters and factors that will ultimately influence the choice of a specific solution. Atmospheric burners are cheaper - they can be purchased for as little as $100 and do not rely on electricity - but you will likely need some modifications to the fuel chamber. Blast (pressurized) burners are more advanced, easy to use, but expensive - their average price is about 250-300 dollars. The operation of such burners will require a minimum of attention and personal participation from the bathhouse owner.

However, in any case - if you are just planning to build your own bathhouse and are thinking about purchasing a heater stove - it is better to buy a ready-made gas stove with a built-in burner. The design of such a stove and the configuration of its fuel chamber will be adapted to the type of burner you have chosen, and it will be equipped with all the necessary automation and safety systems. And believe me, after you try a gas oven, you will not regret your choice.

How to choose a good device?

The main characteristics of such products are:

- Thermal power.

- Characteristics of the gas that will be used in the product.

- The relative length of the flame leaving the burner.

- Design gas pressure in the furnace.

- Operating adjustment: ratio of theoretical thermal power to minimum.

- Limit adjustment: the ratio of the highest thermal power to the lowest.

- Chemical composition of the fuel.

- The noise level produced by the product.

When choosing a device, you need to keep the following factors in mind:

- Simplicity of design. In this case, the cross-sections of the paths for the passage of gas must be the same and create minimal resistance to the gas.

- Room size. For small rooms, an atmospheric device will be sufficient, but for larger rooms the power of such devices may not be enough.

- Manufacturer of the product. Domestic and foreign (mostly products made in Germany are on the market) units have approximately the same cost, but some similar devices are designed for installation in specific types of stoves. For example, the domestic product AGG-15 is suitable for use only in stoves with a long channel for the fuel mixture.

Photo 2. Gas nozzle AGG-26, suitable for furnaces with a long channel.

Type of heating device.

Important! You need to know where the fuel will come from to the heating device: from individual cylinders or from the main pipe. This is also taken into account when installing the stove

Types of gas burners for sauna stoves

You can install two types of gas burners in the sauna: atmospheric and forced. Atmospheric ones are cheaper and work autonomously without electricity. They are one or more hollow tubes into which gas is supplied under pressure. The air necessary for productive combustion of gas is taken directly from the room in which the stove is installed. It is mixed with gas, then the gas-air mixture is ignited using electric or piezo lighters.

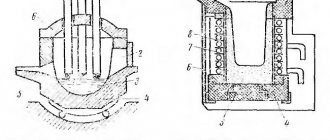

The structure of an atmospheric gas burner

It is in the mechanism of operation that the main drawback of atmospheric models lies - good traction is required, as well as an effective ventilation system that ensures air flow. The dependence of this type of equipment on the state of the atmosphere in the room from which the bathhouse is heated causes a lot of trouble. With each more or less active movement of air, the proportions of the gas-air mixture change, which leads to a change in the amount of heat that is released. In general, such burners do not burn gas completely, and a significant part of it flies into the chimney. A minimum of automation, of course, monitors the presence of air and flame, ensures minimal safety, but it is necessary to monitor the operation of the equipment.

What is also important is that an atmospheric burner cannot be simply placed in a wood-burning sauna stove if this was not provided for during the design. If this is done in stoves with an internal heater, the flame will rest against the stone container. And the gas must burn in the air, without contact with metal. If you put an atmospheric burner in a stove without a heater, the gas burns normally, but only the upper part of the fuel compartment heats up - the flame is directed upward and the lower part remains almost without heating, which reduces the heating rate of the steam room.

One of the gas stoves for a bath - “Taimyr Inox BSE ZK anthracite”

One more point: experts advise installing only gas burners specially designed for them in sauna stoves. They are longer than usual, since they are designed for a remote firebox (when using gas, it is necessary to heat only from the room adjacent to the steam room). One problem: they are several times more expensive than conventional ones used for heating boilers. The price is almost the same as for forced-air burners, and the efficiency is almost two times lower. Therefore, more often they either install devices for heating stoves, or with forced air supply.

The second type of gas burners for sauna stoves is fan or forced-air, blown (these are all different names for the same design). In them, gas is mixed with air using a fan. Its rotation speed is adjusted during installation. Subsequently, the parameters of the atmosphere in the bathhouse have little effect on the intensity of gas combustion. Structurally, it looks like a block with attached sensors and a controller.

Scheme of operation of a burner with a fan

This type of equipment is on average two times more economical than atmospheric type installations. Their disadvantage is their volatility (they only work when there is a power supply) and their high price - 2-3 times higher than atmospheric ones. Nothing can be done about the price, but you can reduce the dependence on the availability of power if you create a backup source (battery or diesel generator).

The advantage of forced-air gas burners is that they can be installed in wood-burning stoves. You just need to select a model so that the flame does not rest against the back wall of the firebox (use short-flame models). Wood-burning sauna stoves are designed for the combustion temperature of wood - this is about 800°C. When gas burns, the temperature at the top of the flame can reach 1600°C. That is why it is so important not to allow the flame to touch parts of the furnace (in the case of an atmospheric installation the situation is the same). But even in this case, the metal will most likely burn out faster - the temperatures are higher.

The positive aspect of burners with fans is the ability to adjust to any power and switch to liquefied gas (and vice versa).

Pressurized gas burner from Termofor

Ignition type

All burners can be divided according to the type of ignition:

- Electronic type . They do not have a constantly working igniter. Requires electricity to operate. Electric ignition is one of the most convenient inventions for modern heating units. Thanks to him, the operation of the stoves has become as comfortable as possible. Electric ignition makes it possible to light the burner flame safely, without using available wicks or lighters.

- Burners with piezo ignition . No electricity needed.

Sometimes special working conditions are required, for example, burners are placed in a sauna stove, which must distribute the flame well. These are dividers or ordinary distribution tubes. This is how kitchen gas ovens work.

The fuel consumption passing through the burner can vary widely and depend on its design.

Gas burners for your furnace should be safe and energy efficient. This can be achieved if all technical requirements are met. Self-indulgence in this matter can only do harm. Therefore, the installation of gas burners must be carried out by specialists.

Permits and requirements for installing gas equipment in a bathhouse

Like any gas equipment, installing burners on a sauna stove requires permission from the gas supply organization. If we talk about the use of atmospheric models, they are very reluctant to issue them. When issuing, the following requirements apply:

- good ventilation system;

- excellent adjustable traction;

- a room with a volume of at least 12 m3;

- ensuring fire safety measures when installing the stove;

- insulation of the chimney as it passes through the ceiling and roof;

- the presence of a spark arrestor at the top of the pipe.

If these requirements are met and you have a Certificate of Compliance and a Rostechnadzor permit, you may be given a permit.

When installing pressurized gas burners, permission is also required, but some requirements for the premises are not imposed (ventilation, draft and volume are unimportant, all others remain in force). When following the installation rules, it is enough to have certificates of conformity and an operating permit from Rostechnidzor (included upon purchase).

Atmospheric gas burner for a bath: appearance

But this is only when using main gas. Liquefied gas must be stored somewhere. According to the requirements of the pozhnadkhor - in a separate room. And this is not a dressing room, canopy, etc. This must be a separate room. In principle, a free-standing metal cabinet or gas holder is suitable for storing liquefied gas cylinders - an underground container measuring 3 cubic meters or more (should be located no closer than 5 meters to the building).

A pipeline is laid from the gas storage site to the furnace. It must be made of non-flammable materials - copper or steel pipes. It must be completely sealed (be sure to check all connections).

In what cases is it necessary to adjust the burner flame?

An atmospheric gas burner for heating equipment often fails. It is equipped with models of both wall-mounted and floor-standing boilers. The injection burner of floor-standing equipment reduces its efficiency for various reasons:

- Burner power is too high. This happens when a high-power burner is purchased for small heating equipment. At the same time, there is not enough space for combustion, the air flow for such power is weak, which leads to the transition of the flame from blue to yellow, sooting of the combustion chamber and chimney.

- If the chimney is poorly cleaned, the boiler draft deteriorates. At the same time, waste combustion products are poorly removed, and the air flow is small. This worsens combustion and the flame turns yellow.

- A defect in the burner itself does not make it possible to correctly adjust the complete combustion of the fuel.

- Due to pressure changes in the gas supply system, well-regulated equipment can release large amounts of unexhausted gas into the chimney. Partially it settles with soot and soot. A large layer of soot reduces traction and increases fuel consumption.

- Starting heating equipment after repair.

- The presence of extraneous noise during operation of the boiler or gas burner.

- Changing the type of fuel.

Popular gas burners for saunas

Most often, atmospheric burners of the UGOP type are installed in sauna stoves. They are available in different modifications - from 8 kW to 30 kW. There are models equipped with draft presence sensors, a gas shut-off valve, and flame control. All these options increase the safety of using gas equipment, but at the same time they raise the price and also make repairs more difficult (and expensive). There is also a temperature control function, but it is rarely found. The most popular gas burners are UGOP-16 and 12 - they are suitable for most steam rooms. Their technical characteristics are shown in the table below.

Technical characteristics of UGOP 12, 16, 30

Please note that there are dozens of manufacturers of this equipment, and some parameters may vary. Be sure to read the description and technical specifications of the specific equipment model. The description must indicate that the device can be used in sauna stoves. Before purchasing, be sure to find out the physical parameters of the burner (at least the length of the tubes) and decide whether this modification is suitable.

Burner UGOP-P 16 with micro-flare burners

Other differences

Let's consider the division of gas burners by type of ignition. The simplest option is with a burning igniter (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to heat the coolant. There are two disadvantages here - increased gas consumption and low safety (the igniter may go out). Primary ignition is carried out with matches or using a piezoelectric element that produces a spark.

Natural gas from the mains provides even combustion without forming excessive soot on the walls of the chimney pipe.

Electronic ignition of the burner requires the presence of a high-voltage converter in the gas boiler. Energy is taken from batteries or the electrical network. The first option is used in non-volatile boilers that do not have electronic automation. The second option is relevant for complex units with electronics on board. Along with such ignition, modules for ionization control of the presence of flame are often installed.

There is also a division according to the type of fuel used. Natural gas supplied from the pipeline is cleaner, it is supplied at optimal pressure (we do not consider cases of pressure surges in both directions). The flame in the boiler is clean, without soot. The equipment is connected to the network without modifications. There are burners that can operate on propane - this requires setting up the system and installing a jet. The flame from propane combustion gives off a yellow color, and there is increased soot deposits on the chimney.

Jets allow you to normalize the propane pressure to an acceptable value - they are supplied as a set or purchased separately.

Making gas burners yourself: to do or not

Doing something with your own hands is a pleasure, and often brings significant savings. But in the case of gas burners, it’s better not to take risks: you can’t be sure that you did everything right, and the cost of a mistake is too high. At the same time, the cost of an atmospheric burner is only about $20. It's not worth it. The only thing you can do is change the parameters of the distribution pipes. This part can be redone without much risk.

One more thing: you will never get permission to use a homemade burner. You can, of course, install equipment without permission, but the fines are too high.

Making a gas boiler with your own hands

Doing something yourself is always nice. This, in turn, can also provide significant cost savings. However, making gas burners for a sauna stove with your own hands is too risky.

Without the proper skills and experience, you can make mistakes, the cost of which in this case can be extremely high. Atmospheric sauna burners don't cost that much. So it’s better to use ready-made options.

The situation is different with a solid fuel boiler for indoor use. It can, if desired, be converted to gas. An ordinary person can install an atmospheric gas burner with his own hands.

In addition, the boiler can be automated by placing all the necessary equipment outside. At the same time, the device will be inferior to a conventional gas boiler in compactness

If the dimensions of the heating system are an important criterion, then it is better to pay attention to ready-made products

The camping burner can also be upgraded. Unlike heating boilers, in many cases improvements are simply necessary.

During the cooking process, it is very important that the heat supplied to the heated container is not carried away by the wind. It is also important to protect the fire from being blown out.

Wind protection is used for these purposes.

The options offered in stores are quite expensive. A profitable solution is to manufacture this element yourself.

In order to manufacture wind protection, first of all, it is necessary to decide on the material. Aluminum sheets are a suitable option. The main thing is that they are thin. This will ensure ease of working with them.

In addition, the thinner the material, the less it will weigh, and during long hikes, weight is of particular importance.

It is necessary to construct a hollow cylinder from the sheets. Its height should be sufficient to cover the burner and the container in which food will be cooked. The process of making a windbreak will not take too much time.

Anyone can cope with this task. So why pay an extra price to the store for purchasing this design if you can do everything yourself?

An alternative to expensive electric fireboxes is a gas stove for a bath: device features

Arranging your own bathhouse on a country site has long become a tradition - without a pleasant evening in a steam room, a vacation at the dacha can no longer be considered complete. the choice of stove type is especially important .

The speed of heating the room, the quality of the heat produced, and the amount of steam depend on the type of heating element and its design. Although it is traditionally believed that there is no better option for a bathhouse than a wood-burning stove, its arrangement and further maintenance are often associated with a number of difficulties , as well as significant costs.

Therefore, the installation of gas devices in the bathhouse is becoming increasingly popular - this is a much more economical fuel consumption, as well as easy-to-use heating device.

Design and principle of operation of a sauna stove

The gas oven provides everything necessary for a steam function, including convenient adjustment of the heating level, while being compact and aesthetically pleasing. One of the main advantages of this option is the availability of fuel such as gas, its low cost, and environmental friendliness (unlike firewood, gas burns completely, without an unpleasant odor, and leaves no waste).

Photo 1. A gas sauna stove made of metal takes up little space in the room due to its compact size.

Gas appliances are built from both brick and metal. The first option has the advantages of greater heat capacity and long-term heat transfer, but will require prolonged heating to the optimal temperature.

Metal gas devices are more common due to their compactness and high efficiency, but in order to make staying in the steam room more comfortable and increase heat accumulation, it is recommended to build a brick screen around the stove.

All types of devices have a similar design:

- housing made of sheet steel 3 mm ;

- combustion chamber where gas combustion occurs - the walls of this compartment are usually made of especially strong steel 5 mm thick to avoid burnout;

- fuel channel - located so that it is convenient to lead it outside or into an adjacent room, where the channel is connected to a cylinder or line;

- gas panel with burner - attached to the fuel channel, the burners are located in the combustion chamber;

- thermostat – allows you to adjust the flame size, in some models it automatically turns off the burner when the firebox overheats;

- compartment for stones - usually installed immediately above the firebox, it can be either open or closed;

- pipe - like a chimney, it brings heated air out; often a tank for heating water is installed in its lower part.

The principle of operation of the gas model is very simple - fuel is supplied through a channel into the combustion chamber, where, when burned, it heats the walls of the device, as well as the stones in the compartment located at the top, and the chimney pipes.

The stove body is always made larger than the combustion chamber; special holes in the bottom and top allow for air circulation - cold air enters from below, heats up near the walls of the firebox, rises and exits into the steam room atmosphere.

Gas-burner

The fundamental part of the design of the device is the gas burner; fuel consumption , and therefore the efficiency of the device and its cost-effectiveness, partially depends on it.

Gas combustion requires a constant supply of air, which is why burners are divided into two main types:

- Atmospheric - the most common, due to its simplicity, accessibility, and independence from electricity. The design consists of an outlet through which gas is supplied to the chamber under pressure, and a piezo lighter. For proper operation of the burner, it is necessary to create high-quality draft (it is better to take air from the adjacent room using a ventilation pipe). The simplicity of the design results in its low efficiency - often it is not possible to create the required level of draft, the gas burns poorly, most of it goes into the chimney pipe, also creating the danger of leakage.

Photo 2. Appearance of an atmospheric gas burner for a furnace and diagram of the device’s operation.

- Assisted burners - a ventilation system and mini-fan are used to ensure uninterrupted air supply. Such a burner requires connecting to an electrical outlet or installing a battery , which affects the overall cost of the device. Fan burners significantly improve the quality of gas combustion, reduce its consumption, and improve the efficiency of the heating element. Thanks to the connection to electricity, sensors and thermostats are installed on them, which allow you to automatically regulate the intensity of the burner.

When installing a burner of any type, it is better to choose a long, elongated outlet shape - this will increase the flame area and allow the furnace walls to heat up faster.

Equipment setup

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional configuration.

Scheme of actions for setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a pressure gauge, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers and phases are connected correctly.

- Place a gas analyzer in the chimney pipe.

- Start the device.

- Using a pressure gauge, take pressure readings at the outlet of the burner block. Pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow using the air damper.

- The gas analyzer readings must also comply with all gas equipment installation standards.

Setting up gas equipment should be carried out by specialists. The simplest open-type boilers can be configured independently if you have certain skills and knowledge of the design of the burner unit. The efficiency of the boiler, its level of efficiency, and fuel consumption depend on the quality of the burner. It is possible to superficially determine that the equipment is malfunctioning by the changed burner flame.

A heating system where the main element is a gas stove is a common type of heating for private households and cottages. There are many things in favor of natural gas as a heat source: high efficiency, environmental friendliness, and the ability to make the heating process fully automated. The fuel itself is also the most inexpensive at present, unless, of course, you take into account wind energy and solar radiation. But these methods have not yet found wide demand due to the unaffordable price of the equipment.

The quality of gas heating depends on how efficiently the gas burner for the stove works.

Criteria for choosing a sauna stove

To correctly select the most suitable gas device model, take into account the following factors:

- The area of the steam room - the power of the device directly depends on the size of the room ( one kilowatt of power per cubic meter of air ).

The quality of the thermal insulation of the steam room and the presence of windows that cause heat loss and, accordingly, require an increase in the power of the heating apparatus are taken into account.

- The heat capacity of the stove is an important factor that allows you to better heat the room, as well as effectively dry the steam room using residual heat. Brick models have the greatest heat capacity; in the case of making the device from metal, the presence of a screen, the location and length of the pipe, and the type of heater are of great importance.

- Fuel consumption - depends mainly on the power of the stove, average figures for a small steam room and a 10 kW device: 1.5–4 cubic meters / hour . When tasked with heating a fairly large room for several people, more powerful stoves with two and three burners are usually used, and gas consumption increases significantly. Increasing the heat capacity of the furnace helps reduce losses.

To increase safety and save space in the steam room, it is recommended to choose a model with an external fuel channel , which allows you to place part of the equipment behind the wall. This will also provide more convenient control of fuel supply and the necessary maintenance of the device.

Wood and gas stoves

Very often a combined version of the stove is installed, usually equipped with two fireboxes .

This makes it possible to use both the traditional heating method - by burning wood, pieces of peat and other solid fuels - and heating using a gas burner.

Often such a universal model is obtained by converting an existing sauna stove, usually brick - its design almost does not have to be changed, only a gas channel is supplied for additional heating and a burner is installed.

Reference! The combustion of wood, especially when using a brick stove, produces a softer heat , which is beneficial for health and creates a special comfortable atmosphere in the steam room. Therefore, when building a bathhouse, many do not want to give up this heating method, although using gas is much more profitable.

Installing a combined stove is very convenient when there is no gas main and heating is provided by imported liquefied gas from cylinders. Then the ability to heat the bathhouse with wood will protect you in case of interruptions in the supply of fuel.

The design of a metal gas-wood stove is almost no different from a conventional monofuel stove. The difference lies in the ability to remove the block with the gas panel, which turns the gas firebox into a regular wood fireplace. An even easier-to-use option with the installation of an additional fuel receiver is common.

Choosing a combined design

As in the case of a monopropellant device, the following conditions are taken into account when choosing:

- Steam room area - depending on the size of the room, the power of the stove is calculated for each type of fuel.

If the wooden or tiled walls of the steam room do not have surface thermal insulation, the oven power is selected to be one and a half times greater in order to warm them up efficiently and create the correct microclimate.

- Heat capacity - combination stoves are often built of brick, which increases their ability to retain heat, and therefore save on fuel. When choosing a metal model with two fireboxes, it is recommended to lay out the brick lining.

- Fuel consumption - on average, wood stoves require about 4 kg of firewood per hour, if the steam room area does not exceed 20 sq.m. To reduce fuel consumption, increase the heat capacity of the furnace - this will increase the heating time, but will reduce heat loss.

Due to their versatility and multifunctionality, combination stoves do not lose popularity in bathhouses in suburban areas. When choosing this option, it is recommended to calculate in advance where the fuel for the stove will be stored (you will need space for both gas equipment and firewood).

Purpose and advantages of nozzles

Gas burners (or nozzles) are designed to operate the stove on gas. Like other similar devices, the nozzle mixes fuel - natural or liquefied gas with air. As a result, the temperature in the oven increases.

Most often, such gas products are installed in baths, where high temperatures are required for a long time. However, nothing prevents you from installing a nozzle in your home in order to save yourself from the usual methods of kindling. In addition, such products have a number of significant advantages:

- Safety. Since such products work with explosive material, they are subject to strict requirements regarding reliability. You can verify this by reading the quality certificate.

- Availability of automation. Most gas products are equipped with automatic temperature control, which provides not only economical fuel consumption, but also protection from overheating or explosion of the furnace.

- Economical. As you know, gas is much cheaper than the cost of firewood, coal or electricity.

- Variety of fuels used. Many devices can operate on natural or liquefied gas.

- Ease of operation. The operation of gas devices for furnaces does not require any specific skills. In addition, some models can be operated from a special remote control.

- Ergonomics. Storing coal, firewood or other flammable materials requires a lot of space. The supply of fuel to the injector comes from the gas column.

Installation in a bathhouse

If you want to install a gas-powered device in a steam room, you will first have to obtain permission from a specialized gas supply company.

Its employees will check the correct location of the device in the room and compliance with all safety measures.

When choosing a location for a sauna stove, you must follow the following rules:

- the walls around the stove are carefully covered with fire-resistant material ; a non-combustible base must be installed on the floor;

- the height of the fire-resistant base is 10 cm higher than the floor level ;

- the device itself is installed at least half a meter from the walls ;

- the presence of adjustable draft in the combustion chamber;

- the best option would be to position the stove so that its entire front side is in the dressing room, and not in the steam room - this will protect the stove from exposure to a humid atmosphere, facilitate control and increase safety;

- high-quality ventilation must be established in the dressing room ;

- all pipeline joints are checked for perfect tightness to avoid the risk of gas leakage ;

- The pipes connecting the stove to the chimney are insulated especially carefully - when passing through the ceilings and roof.

Important! Compliance with all requirements will allow you to install a gas stove with a ventilated burner without much difficulty. When using an atmospheric burner, the risk of a hazardous situation is significantly higher , and the inspection of the premises will be more thorough and strict.