Any experienced craftsman will tell you that 50% of the work is quality components. The strength and durability of the welded joint largely depends on good electrodes. At the same time, high-quality products need proper storage, otherwise all the advantages come to naught.

Of course, wet electrodes can be calcined in an oven, thereby drying them, but if the rods are cracked or the coating begins to crumble, then only purchasing new materials will help. Proper storage of electrodes will avoid additional costs and save your time.

Electrode storage

For frequently performed welding work, you need to stock up on a sufficient amount of electrodes, which are the main consumable raw material in welding. It is profitable to purchase larger quantities of packages than individually at retail prices.

Electrode life

In order for the electrodes to work properly, they must be stored in optimal conditions. High humidity may occur in warehouses and other areas, which will cause water to accumulate in the winding. When storing filler materials, certain conditions must be followed to ensure optimal performance of the electrodes.

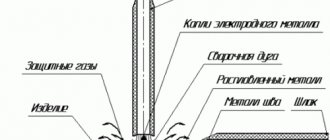

When an electric arc is ignited from the electrode rod, the metal melts due to the high temperature, and moisture in the winding may boil. The winding is designed for stability of arc combustion and protects against the penetration of unnecessary objects. If there is a large amount of moisture, the winding begins to crumble or boiling may occur in the weld pool during work. Because of this, defects appear, which are the main reason for the poor quality of metal seams.

It is not advisable to use low-quality electrodes, which can quickly deteriorate as a result of improper storage. If, when a certain volume of water accumulates, the electrodes can be dried, then if there is damage, when the coating lags behind the rod, welding of critical products with these filler materials is not allowed.

The service life of electrodes can be extended if certain conditions for their storage are created and additional equipment is used to isolate them from the influence of external factors.

Electrode storage conditions

Basically, the shelf life of welding electrodes is influenced by the conditions of their maintenance, therefore, if all recommendations are followed, this period can be long. Welders must comply with the conditions of packaging and storage of consumables in accordance with GOST 9466-75 and GOST 9467-75. This applies to manufacturers storing them in finished product areas prior to shipping, as well as manufacturers storing electrodes prior to actual use. During the period of moving electrodes and other activities, they are exposed to high risks, but their damage can be minimized by drying and hardening. To ensure high quality filler materials, all conditions must be met.

Shelf life of electrodes

If the standards for moving and storing electrodes are observed, their shelf life will be unlimited. All rules are established by clause 3.15 in GOST 9466-75. If any reasons arise due to which the conditions were not met, then before starting the welding process a visual inspection should be carried out and suitability for further use should be determined.

During visual inspection, there may be several options for the state of the electrodes:

- externally normal condition of the electrodes, ready for use without preliminary preparation (if this is not required during welding work);

- the presence of certain shortcomings in consumables, which can be eliminated during preparatory procedures, drying, cleaning, etc.;

- completely damaged electrodes that are not suitable for work. In this case, it is better to send them for recycling or use them for educational purposes.

You can find out all the nuances by checking the strength and water content of the electrode coating. But filler materials can be completely damaged due to improper storage. In other cases, they can be used for many years.

Electrode shelf life

Welded electrodes must be stored in special warehouse conditions where optimal dryness and warmth are maintained. In accordance with the technology, the following storage conditions are determined:

- relative humidity level up to 50%;

- minimum temperature limit up to +14 degrees;

- use of air conditioners to control humidity;

- presence of waterproofing in the room.

Welding electrodes must be stored at constant temperatures without strong fluctuations. The bottom line is that due to natural temperature changes (during the change of night and day), dew appears on the fold, which is quickly absorbed by the coating and worsens the properties of the coating. As a result, without additional measures for insulation and insulation, consumables will be exposed to adverse factors every day.

To increase the shelf life of filler materials, you can use the following recommendations:

- during welding in the open air, the packaging should be removed from foreign objects and moisture;

- It is advisable to place boxes with electrodes on pallets or shelves that prevent direct contact of the container with the surfaces of walls and floors. This will reduce the risk of condensation penetrating into the coating;

- open containers must be tightly closed, because they are highly susceptible to moisture.

If the welder has few consumables, then their shelf life can be extended with the help of special tools and pencil cases. Basically, electrodes are stored in stacks, where the bottom rows are considered the most vulnerable. For such storage, the warehouse is equipped with lifting mechanisms (for quick change of materials).

Storing and working with electric tools at subzero temperatures

In winter, some self-builders send power tools to storage in the household, while others continue to work with them. Both of them are concerned with the following questions:

- Is prolonged exposure to cold harmful to power tools?

- Is it possible to work with power tools in the cold?

- How to operate a power tool if you bring it from a cold place to a warm room.

I'm building a house. I work in temperatures down to -10 degrees Celsius. I use power tools - a miter saw, a thickness planer, a corded drill and a screwdriver. I store them in the cold. I don't use cordless tools. An old screwdriver with a nickel-cadmium battery does not hold a charge well, and the lithium-ion one is said to be afraid of frost. Tell me, who has worked with power tools in the cold, is this harmful to them?

I want to know if it is possible to store an electric tool that runs on mains power in the cold? In winter, the temperature in the garage drops to -10 - -35 degrees Celsius. Can I leave my plane, circular saw and grinder there until summer?

First, let's answer the question that Osya asked.

The laws of physics apply to the instrument. Take, for example, a screwdriver; when heated, it expands. The battery is also expanding. When expanding, it squeezes out excess air from its insides, and the air is hot. When you leave the tool in cold and humid air, as it cools down, the rotor, stator and battery draw in something that is colder than it. Including moisture. Therefore, after bringing a tool from the street into an apartment or simply into a warm room, it is advised not to turn it on for at least 2 hours, but when taking it from a warm room to a cold one, there are no such restrictions.

Don’t forget about the appearance of condensation when bringing a tool from cold to warm.

Article on the topic: What's in your garage

If you stored the tool at sub-zero air temperatures and will be working in a warm environment, then, first of all, you should be wary of condensation. And condensation is a potential risk of short circuit.

You can store an electric tool for a long time even in the cold . Nothing will happen to him until spring. You can also work in winter.

I worked on a woodworking machine right outside in the winter. Ordinary hand-held electric tools too. I sawed, planed, and chamfered for more than one day in a row. Nothing happened to the instrument.

How to store welding electrodes

According to GOST 9467-75 and GOST 9466-75, welding electrodes have an unlimited shelf life. However, if the storage conditions for thematic consumables are not met, the quality of its operation will deteriorate.

How to store welding electrodes?

Welding electrodes are packaged in packs of several kilograms or less in cardboard packs 0.7 mm thick. The latter, despite its outer vinyl layer, tends to accumulate moisture, which subsequently passes to the electrodes and spoils their performance properties. To avoid corresponding negative impacts, you must adhere to the following rules:

• Packs of welding electrodes should be stored inside dry and ventilated warehouses;

• The temperature of the storage area should be kept within 14-15 degrees Celsius;

• The humidity level inside the warehouse should not exceed 60%;

• Packages with thematic consumables must always be kept closed;

• Between packs with electrodes and other surfaces from which moisture and cold temperature emanate, a distance must be maintained;

• Access to packages and selection of the appropriate brand of welding electrodes should be ensured through proper organization of the storage location - packs of one brand should be located separately from another, and the height of the stacks should not exceed 600 mm;

• It is better to store a small number of remaining electrodes in thermal cases, because Inside the half-empty cardboard packaging, the welding rods are quickly exposed to moisture.

It is not always possible to fully comply with the given rules. However, overlooking any point does not make welding electrodes unsuitable for use. The fact is that welding rods can be gradually restored by drying for an hour and a half at a temperature of 100 degrees Celsius and further calcining for an hour and a half at a temperature of 270-300 degrees Celsius. Moreover, the last process may last differently depending on the brand of welding electrodes. The latter allow calcination to be carried out no more than 2 times.

What are the dangers of improper storage?

Improper storage conditions for welding electrodes have different effects on the quality of their further operation. A negative result is also contributed to by non-compliance with basic preparation - draining and calcination. The following problems arise due to waterlogging of the electrodes:

What is regulated

The welding machine rod is regulated by a number of standards:

- GOST 9467-75 “Coated metal electrodes for manual arc welding of structural and heat-resistant steels. Types" reveals different types of consumables and their characteristics.

- GOST 9466-75 (ST SEV 6568-89) “Coated metal electrodes for manual arc welding of steels and surfacing. Classification and General Technical Conditions” divides rods based on suitable steel, types of coating; lists dimensions, symbols.

Storage of welding materials

Warehouses for storing electrodes, solid and flux-cored welding wire and flux must be dry, protected from precipitation, have heating, lighting and ventilation. The air temperature in the room for storing welding materials should not be lower than plus 15 ° C, and the humidity should not be higher than 40%.

Warehouses of workshops and sections must be equipped with ovens for drying and calcining electrodes and flux, and, if necessary, with machines for cleaning and winding welding wire.

Welding materials should be stored on racks by batch, type, grade, diameter and date of manufacture. In order to avoid damage to the coating of the electrodes, they should not be stored in mutually perpendicular directions. The stacking height of packages should not exceed five rows. Coils and coils of wire must be stored in the original packaging.

Fluxes should be stored in paper bags, stacked, or in special closed containers (containers, bunkers, chests). If the packaging is damaged, fluxes should be stored only in containers, bins and chests.

Each cell on the racks must be equipped with a plate with characteristics of welding materials and an indication of the expiration date. Welding consumables with expired shelf life may only be used after re-checking their technological properties.

Cylinders filled with gases used in welding and cutting should be stored in special dry, ventilated areas. Warehouses for storing cylinders filled with gases should be one-story with light-type coverings and not have attics. Walls, partitions and coverings of warehouses for storing gases must be made of fireproof materials of at least II degree of fire resistance; Windows and doors must open outwards. The height of storage areas for cylinders must be at least 3.25 m from the floor to the lower protruding parts of the covering.

The floors of warehouses must be level with a non-slip surface, and warehouses for flammable gas cylinders must have a surface made of materials that prevent sparking when any objects hit them. Filled cylinders with shoes are stored in a vertical position, without shoes - in a horizontal position on wooden racks.

To protect against falling, cylinders are installed in specially equipped nests, cages and protected with a barrier. Cylinders must be stored with caps screwed on; There should be plugs on the valve fittings of cylinders with flammable gases.

To store electrodes at workplaces, use portable cases with a capacity of up to 5 kg.

The issuance of welding materials from the central warehouse is usually carried out according to requests, which are drawn up by line engineers responsible for the production of welding works, after calculating their needs according to approved standards, and checking their compliance (by type and brand) with the requirements of welding projects.

Welding materials are issued from the central warehouse in quantities not exceeding two-week requirements. Welding materials must be provided to the workplace in quantities not exceeding shift requirements.

The amount of materials issued to the workplace must be taken into account in the “Individual card for recording the consumption of welding materials.”

How long do welding electrodes last?

The quality and result of any work depends, among other things, on the quality of consumables and components. The shelf life of welding electrodes, storage conditions, and their state of preservation are important factors that should be taken into account before performing welding work. This is due to the fact that the rods have coatings of various types - and they, in turn, have certain chemical compositions, the quality and condition of which directly depend on storage conditions and packaging features.

Shelf life of welding electrodes

Formally, the shelf life of electrodes for welding according to GOST has no time restrictions. The packaging only indicates the date of their manufacture, but you will not find an expiration date on any box. In accordance with GOST 9466-75 (clause 3.15), products can be stored for as long as desired, but only subject to strict adherence to the rules of storage and transportation, which are formulated in the specified GOST, as well as in GOST 9467-75.

However, the key storage conditions for electrodes—humidity and temperature—may be violated. In this case, the rods must be calcined in special stationary or mobile ovens. Calcination reduces the moisture content in the electrode coating and thus avoids shedding of the coating, poor initial and subsequent ignitions, sticking of the rod - that is, those consequences due to which the electrodes will have to be replaced with new ones.

If electrodes are stored correctly, the likelihood of them becoming damp and causing defects is extremely low, so formally they do not have an expiration date.

Storage rules

In accordance with the requirements for storing electrodes in accordance with GOST 9466-75, products must be stored in heated, dry rooms, with a humidity level that should not exceed certain indicators. Conditions must exclude the possibility of contamination or mechanical damage to boxes with rods. If we are talking about industrial rather than domestic use, it is advisable to install stationary or portable electronic devices that control temperature and humidity indicators. The pencil cases and boxes themselves should be stored in wooden boxes or boxes made of thick cardboard, and not on the ground or concrete floor, but preferably on wooden pallets.

Storage temperature

The temperature in the room where welding electrodes are stored should not fall below 15 degrees Celsius according to state standards. In winter, the room must be heated; sudden temperature changes are very detrimental to coating.

Humidity

The optimal humidity level in a warehouse should not exceed 50%. It is recommended to provide it with high-quality waterproofing, since the coatings absorb moisture well, which can penetrate with precipitation. Additionally, plastic film will protect consumables from moisture. To maintain a constant level of humidity, it is possible to use air conditioners (if appropriate conditions exist).

Package

The rules for packaging electrodes are formulated in paragraph 6 of GOST 9466-75. In accordance with them, products can be packaged:

- in sealed plastic cases;

- in wrapping paper (according to GOST 8273) and then placed in metal cases (boxes);

- in cardboard boxes followed by packaging in plastic film;

- in cardboard boxes without PE shell;

- in packs wrapped in two-layer packaging paper or in moisture-resistant sack paper.

Best before date

The shelf life of electrodes is unlimited, but only if you comply with the storage conditions. There is even a special GOST that establishes rules for storing and transporting rods. If you intentionally did not comply with storage conditions, you can visually determine the expiration date and understand whether the electrode can be used in your work.

Inspect the electrode carefully. If there are no visible defects on it, and the coating does not crumble or crumble, then most likely the electrode can be used. We recommend that you first test it on an unnecessary metal surface. If you find minor defects or contamination, bake the rods in an oven at a temperature lower than the melting point of the electrode, or clean the electrode using a rag and a soft brush. If the defects are significant and the coating crumbles in your hands, then discard the rod or use it as a training rod.

Article on the topic: How to build a garage for a Kamaz

Test the electrode for strength by tapping the end of the rod on the metal surface and make sure that the electrode is dry. Proper storage will ensure many years of use. Never use damaged components in your work.

How to store welding electrodes?

For welding work, electrodes are constantly needed, and in large quantities. That is why they are purchased in packs, depending on the required diameter. In large enterprises, welding consumables are stored in specially designated rooms, but only a few know how to store them.

The question arises about the shelf life of the electrodes. This is important both for large enterprises and for small firms that weld only occasionally. Let's consider the rules for storing the main consumables for welding. How to extend its useful life, because the quality of work will depend on this?

How to store?

The shelf life of electrodes directly depends on how they are stored. For this, not only a room without high humidity is used. It is possible to use special equipment that will protect the surface of the electrodes from the negative influence of the external environment.

Most often, electrodes are stored in warehouses where it is dry and warm.

The rules for storing electrodes are as follows:

- temperature conditions above +14 °C;

- indoor air humidity up to 50%;

- using air conditioners to ventilate air in enclosed spaces;

- waterproofing the warehouse to prevent moisture ingress.

It is important to adhere to the temperature regime and not allow it to fluctuate, since this affects the surface of the consumable for welding and the quality of subsequent work.

To increase shelf life, you can use special cases, boxes or pallets. Do not store electrodes on the floor, as condensation may cause them to get wet. You can keep them in a box, but if you do not use them all at once, you should seal the package tightly.

Shelf life of electrodes

Storage features directly affect the shelf life of consumables, which, if all standards are observed, can be long.

All storage features must be strictly observed in accordance with the regulations of GOST 9466-75 or GOST 9467-75. This applies to both manufacturers of welding consumables and consumers who purchase electrodes in large quantities. Even during transportation, the goods should not be at risk. Although consumables that have been exposed to moisture can be dried or hardened.

The shelf life of consumables can be unlimited if stored correctly. If there are certain defects during external inspection, you can get rid of them by drying, cleaning or other operations. It is better not to use those electrodes that have completely deteriorated, although they can be used for educational purposes. Existing shortcomings are easy to identify visually.

Why do you need to calcinate the electrodes?

To remove traces of high humidity and extend the shelf life of the electrodes, you can use an operation such as calcination. This is necessary so that during operation, somewhat damaged consumables do not stick to the welding seam.

In order to calcinate the electrodes, construction companies use special equipment. Each new pack that is opened must be completely used up. If there are unused electrodes left in it, you should not store them in an open space or basement.

How to choose the type of electrodes for welding work?

Don't know how to choose electrodes for welding? Then we suggest that you familiarize yourself with the criteria for their selection.

Here's what to pay attention to:

- The thickness of the metal product on which the weld will need to be applied (the higher the diameter of the electrodes, the greater the thickness of the metal).

- Type of steel (stainless steel, ferrous metal, heat-resistant, etc.).

- Features of welding, that is, how the welding seam will be applied to the product (horizontally, vertically, top to bottom, etc.).

- We determine the current through the electrode.

Each type of electrode has its own current parameters, and the manufacturer indicates them on the product labeling. Experienced welders use a special formula for this.

Types of electrodes by diameter:

- Electrodes (2 mm) - current 40-80 A. They are considered the most fastidious consumables, since they are designed for thin sheets of metal and require special skills to perform high-quality work.

- Electrodes (3-3.2 mm) - current 70-80 A (at direct current) and 120 A (at alternating current).

- Electrodes (4 mm) – current 110-160 A. Work with thick sheets of metal.

- Electrodes (diameter from 5 mm) are a professional consumable material used for surfacing, not welding.

How do you know if the electrodes are no longer suitable for welding?

Many people are interested not only in the question of how to store electrodes in accordance with GOST 9466-75, but also how to check their expiration date. It is not always possible to accurately determine storage or transportation conditions, since electrodes can be purchased by companies. To do this, perform a visual inspection of the welding material.

If the consumables look free of defects in appearance and the coating does not crumble, then such an electrode is still suitable for welding. If the consumables have even small defects, you can clean or dry them.

You should not use low-quality or used consumables when performing important work or those that require precision. Not only the appearance of the weld, but also its quality depends on this. Be sure to check the electrodes before starting work.

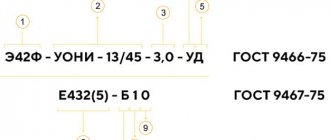

Marking

Contains the following complete information about the "cartridge". For example, E42A-UONI-13/45-3,0-UD E432(5)-B 1 0 means:

- E42A – type, strength 42 MPa;

- UONI-13/45 – brand;

- 3.0 – diameter;

- U – purpose for carbon steels;

- D – coating thickness;

- E432(5) – metal characteristics;

- B – type of coating – basic;

- 1 – spatial position – any;

- 0 – current characteristics – constant, reverse polarity.

How to store welding electrodes?

Welders can follow these simple guidelines for storing, drying and handling SMAW electrodes to reduce exposure to moisture and ensure quality, shelf life and performance.

As important as shielded metal arc welding (SMAW) electrodes are, the process of properly storing them is often overlooked. However, proper storage of SMAW electrodes is integral to the quality of the weld and the successful outcome of the welding project or job.

For SMAW electrodes to work properly, you must keep them dry and in low humidity conditions. If the electrodes have absorbed moisture from the atmosphere, they must be dried to restore their ability to produce quality welds. Electrodes that have absorbed too much moisture can cause weld cracking or porosity.

If you are having unexplained weld cracking problems or if the arc performance is deteriorating, you may need to reconsider your electrode storage methods.

Storing Low Hydrogen Electrodes

Low hydrogen electrodes have more stringent and precise storage requirements than others. Take the 7018 Series Electrodes for example. These welding rods are typically used where welding quality is critical, such as shipyards, pipelines, and the petrochemical industry. They have low hydrogen content blocks and will break down if exposed to the atmosphere for more than eight or nine hours. These electrodes capture hydrogen molecules from the atmosphere, which can lead to poor weld performance such as flux cracking and weld cracking.

Your low hydrogen electrode may be damaged if you begin to notice porosity and spatter in the first few inches of the weld. Porosity may even be internal and not visible from the outside of the weld. As the rod begins to heat up, the weld will improve and become smoother, but by then the weld may already be damaged.

To combat damage or moisture absorption, be sure to store these electrodes in a welding electrode oven at 120 degrees C. Welding electrode ovens, also known as electrode stabilizing ovens and electrode holding ovens, help ensure high-quality welds by preventing moisture absorption electrodes from the atmosphere. These ovens range in size from 20 quarts, which can be easily transported to a job site, to as large as a commercial oven.

Years ago, welders thought they could store electrodes in an old refrigerator with a light on. This is not an option. For electrode integrity, store them at 120 degrees Celsius.

If you have electrodes that may have been exposed to weather and humidity, place them in an oven at 200 to 250 degrees Celsius to dry and recondition them. You can dry the electrodes no more than two times in a row.

Electrodes with low hydrogen content also have storage requirements. All 60 Series and some of the 70 Series (7014 and 7024) should be stored as sealed as possible to avoid contamination from smoke, moisture and other atmospheric contaminants. Keep in mind that some 60 series electrodes actually benefit from a little moisture just before use. For example, the 6910 and 6011 have a cellulose flux that requires little or moderate moisture to keep the flux flexible, otherwise the flux becomes brittle.

For SMAW electrodes to perform properly, they must be properly stored in dry, low-humidity conditions. Electrodes that absorb moisture from the atmosphere must be dried to restore their ability to produce quality welds.

Measures to protect your electrodes from the atmosphere

Here are a few steps you can take to protect SMAW electrodes from atmospheric contamination:

- Let's consider moisture-resistant electrodes. Some manufacturers offer a classification of moisture-resistant electrodes. Although these electrodes are a little more expensive, they are made with an H4R coating that is moisture resistant and contains only 4 ml of hydrogen for every 100 grams of weld (approximately 3½ ounces). The moisture-resistant coating prevents the electrode from absorbing moisture and protects the integrity of the weld, especially in critical projects where a low-hydrogen electrode is required.

- Don't forget about packaging. For added protection, consider purchasing vacuum-sealed electrodes, which protects the electrodes from the elements and provides a longer shelf life. You don't have to worry about electrode degradation or worry about storage until you open the package.

- Another way manufacturers make electrodes easier to use and store is by packaging them in individual small bags. For example, in a box of electrodes of 20 kg. Will contain four 5kg vacuum sealed boxes packed in a container for use as needed.

- Many manufacturers simply package their electrodes in air-sealed cans or cartons, which results in a shorter shelf life than vacuum-sealed packaging.

- Depending on the type of welding wire and storage conditions, some electrodes may fail within six months, while others may last several years. Although stick electrodes do not have an expiration date, they generally should not be stored for more than a year.

- Buy electrodes in small quantities. Buy the smallest number of electrodes you need. You may be tempted to buy a larger quantity to get a small discount, but it's better to buy the smallest quantity that makes sense. Buy an automatic welding machine with a place to store electrodes.

- It may be helpful to store SMAW electrodes in guard rods—plastic round tubes with a rubber seal—which can be purchased at welding supply stores. They are airtight for longer shelf life, and you can open or close them as often as you need.