Welder's personal mark - how it is assigned, where it is placed

The profession of a welder is not as simple as it seems at first glance. Otherwise, there would be no special certification and qualification tests of knowledge to extend or increase the rank. All this indicates the increased responsibility of the welder before performing labor-intensive and important welds and connections. A mandatory element in this case is the welder’s personal mark.

Why is it necessary?

When welding critical metal structures, next to the welded seam, each certified welder makes an impression with a stamp. This procedure confirms the execution of a specific connection by the person whose stamp numbers are applied to the product.

A kind of handwriting or signature on a metal part, confirming quality work done. Each mark has a strictly individual number, therefore it is called personal and it is simply impossible to confuse welders by it.

If any welding defects or defects are detected, the person who performed the work with violations is determined by the print number.

On October 8, 2104, the FNP “Welding at hazardous production facilities” came into force, regulating strict safety requirements for welding at hazardous production facilities. Thanks to these amendments to the legislation, a unified database has emerged for providing information about welders, which reflects:

- employee position;

- certification date;

- brand code;

- discharge;

- Kind of activity;

- scope of certification.

What does it represent

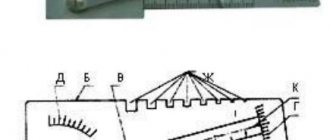

The shape and geometric dimensions of the welder’s mark in accordance with GOST

The stamp is made in accordance with GOST 25726-83 and is a hand tool in the form of a metal rod made of tool steel with a strength of 50-60 HRC. On one side there is a mirrored alphabetic and numerical designation, the other is intended for striking. As a result of the impact, a direct relief image remains on the product.

How to get

The mark is issued to welders who have passed certification at the National Agency for Welding Control (NAKS) along with an attestation certificate. We recommend! TOP 6 household models of inverter semi-automatic machines

Codes are created automatically using the welder’s full name and date of birth. The final image can consist of both alphabetic and digital symbols. The number is assigned to the welder and does not change when the certification is renewed, as well as when certified for another type of activity.

A brand issued before the entry into force of the Federal norms and rules for welding at hazardous production facilities will be valid until the next certification, and then, if it is successfully passed, a new one will be issued that meets the requirements of the Federal Tax Code.

An order to assign a mark to a welder is written in any form, which may indicate the types of structures being welded and additional powers of the performer. order on assigning terminals to welders

Sample order for assigning a personal brand to a welder

Where and when is it placed?

After completing welding work at hazardous production facilities, the welder’s responsibilities include affixing marks next to the welded areas. This is documented by filling out a welding work log, as well as a test report of welded joints. All necessary and legally required executive documentation is prepared.

According to clause 21 of the FNP FNP “Welding at hazardous production facilities”, all welded joints with a wall thickness of more than 6 mm are subject to mandatory marking with a personal number.

The mark is affixed to critical structures, such as welding metal beams and channels, connecting ceiling supports - all those areas where there are increased requirements for reliability and safety.

It is worth noting that when welding metal less than 6 mm thick or fastening reinforcement, knocking out the mark is not necessary - you need to comply with the requirements of technical documentation in production.

Stamp imprint next to the pipeline weld seam

Attention! When stamping metal products, it is not allowed to form riveting, hardening or reduce the thickness of the metal; the imprint itself must be readable and neat throughout the life of the structure. In accordance with

4.10.5 GOST 23118-2012 and clause 1.3.21. RD 34.15

In accordance with clause 4.10.5 of GOST 23118-2012 and clause 1.3.21. RD 34.15.

132-96, the identification code is affixed at a distance of at least 40 mm from the boundary of the welded area, unless other instructions for their location are available in the technological documentation.

When a weld is made by one welder, the marking is made at only one point, next to the starting point marking. If the work was performed by several welders, each one puts his own mark at the beginning and end of the seam.

Order on assigning personal marks to welders

The required system of numbers and letters is laid out on a flexible substrate (for example, on small pieces of radiographic film with the emulsion layer removed, etc.) and sealed with transparent adhesive tape. 2.6.

The required number of sets can be prepared directly in the laboratory, determined by the number of joints planned for inspection per work shift, which include: Joint numbers are dialed directly at the site of inspection work by placing the corresponding lead numbers in pencil cases or between two layers of plaster or adhesive tape. First, numbers indicating the number of the corresponding film must be inserted into the canisters; the joint numbers are added to them at the inspection site. When repeating one or more numbers in the numbers of joints controlled for changing, these numbers are also placed in advance in pencil cases or between layers of adhesive tape or adhesive tape. 2.8.

What is a welding mark, how is it assigned and where is it applied?

It is worth noting that this circumstance must first be discussed with management! Why do you need a brand? When welding critical metal structures, certified welders make an impression with their brand next to the welded seam.

This procedure is a sign of confirmation that a certain connection has been completed by the welder whose stamp numbers are applied to this product. That is, the assignment of a welder’s mark can be called the assignment of a kind of signature that confirms the high-quality performance of welding work.

It is impossible to confuse welders - each mark is called personal because it bears an individual number. If some kind of defect or defect was suddenly discovered, the mark could be used to identify the performer who performed poor-quality work.

Pto

So we can say that the work of a welder is responsible and complex, because it is he who performs labor-intensive and important welded joints and seams. A mandatory element required by highly qualified specialists is the welder’s mark.

Attention We’ll talk about it today. What is a stamp? A stamp is usually called a hand tool made in the form of a metal rod. It is made of tool steel, the strength of which is 50-60 HRC.

The welder's mark is made in accordance with GOST 25726-83. A mirror designation must be stamped on one side of the instrument: alphabetic and digital.

Welder's mark: assignment rules, requirements and features

A brand issued before the entry into force of the Federal norms and rules for welding at hazardous production facilities will be valid until the next certification, and then, if it is successfully passed, a new one will be issued that meets the requirements of the Federal Tax Code. According to clause 8 of the FNP “Welding at hazardous production facilities”, after assigning stamp codes for certification, they are assigned to welders by order of the organization performing welding work.

How to put a welder's mark on the technical and technical documentation?

The requirements are the same.

Federal norms and rules in the field of industrial safety “Safety Rules in the Oil and Gas Industry”. Clause 95. Certification of welders involved in repair work at hazardous production facilities in oil and gas fields, as well as in the construction and repair of field oil, gas and condensate pipelines, must be carried out in accordance with the Rules for the Certification of Welders and Welding Specialists, approved by Resolution of the Gosgortekhnadzor of Russia dated October 30, 1998 N 63 (registered by the Ministry of Justice of Russia on March 4, 1999, registration N 1721), as amended by order of Rostechnadzor dated October 17, 2012 N 588 (registered by the Ministry of Justice of Russia on October 23, 2012, registration N 25903); Technological regulations for the certification of welders and welding production specialists, approved by Decree of the Gosgortekhnadzor of Russia dated June 25, 2002 N 36 (registered by the Ministry of Justice of Russia on July 17, 2002, registration N 3587), as amended by order of Rostechnadzor dated October 17, 2012 N 588 (registered by the Ministry of Justice Russia dated November 23, 2012, registration N 25903). Link…

FNP “Industrial safety rules for hazardous production facilities that use equipment operating under excess pressure.” clause 97. Welders and welding production specialists involved in repair, installation, reconstruction (modernization) of pressure equipment must undergo certification in accordance with the established procedure in accordance with the Rules for the Certification of Welders and Welding Production Specialists, approved by the resolution of the Federal Mining and Industrial Supervision of Russia dated October 30, 1998 N 63 (registered by the Ministry of Justice of the Russian Federation on March 4, 1999, registration N 1721; Bulletin of regulatory acts of federal executive authorities, 1999, N 11-12), as amended by order of the Federal Service for Environmental, Technological and Nuclear Supervision dated October 17, 2012 N 588 (registered by the Ministry of Justice of the Russian Federation on November 23, 2012, registration N 25903; Rossiyskaya Gazeta, 2012, N 283); Technological regulations for the certification of welders and welding production specialists, approved by Resolution of the Federal Mining and Industrial Supervision of Russia dated June 25, 2002 N 36 (registered by the Ministry of Justice of the Russian Federation on July 17, 2002, registration N 3578; Bulletin of regulatory acts of federal executive authorities, 2002, N 32), as amended by order of the Federal Service for Environmental, Technological and Nuclear Supervision dated October 17, 2012 N 588 (registered by the Ministry of Justice of the Russian Federation on November 23, 2012, registration N 25903; Rossiyskaya Gazeta, 2012, N 283). Link…

Welding methods (square 4)

The standardization requirements also describe welding methods. The most common of them are:

- A – automatic. It is carried out using flux, but without gaskets and pillows;

- AF is also automatic. But in this case, on the pillow;

- IN – performed in an inert environment using a tungsten electrode without additives;

- INp is the same method as the previous one with the only difference being that additives are used;

- IP – metal connection is carried out in an inert environment using a consumable electrode;

- UP is the same as IP, only carbon dioxide is used instead of an inert medium.

In this case, the fourth square contains the UP symbols. This means that welding was performed in a carbon dioxide environment with consumable electrodes.

The fourth method is mechanical processing

Mechanical engraving is another important marking method in the industry. Industrial (or mechanical) engraving, this method is the main one for making impact metal stamps. Relief engraving is done mechanically using high-precision modern machines. Allows you to reproduce almost any pattern and any depth of relief. The relief of the pattern is very sharp. This means less effort is required to mark parts.

Like laser engraving, the mechanical engraving method has both strengths and weaknesses. Mechanical engraving is carried out with a sharply sharpened rotating cutter by cutting the material. Mechanical diamond engraving is a type of mechanical engraving that is based on the use of the same equipment, but uses a diamond tip and a non-rotating cutter to apply letters and the required design. Sometimes mechanical engraving can take longer than laser engraving depending on the job being done.

Impact stamps

| +7 Andrey Manager of the metalworking shop. |

It is made in the form of a metal rod (bar) made of steel U8A GOST 1435-99 with a hardness for the working part of 55...60 HRC and 33...38 HRC for the impact part (the one that is hit with a hammer).

Brands can be made by several methods such as laser engraving, electroerosion and industrial (mechanical) engraving. The main and optimal method for producing impact stamps is mechanical engraving.

Application of impact stamps

- for marking gas cylinders

- for individualization of metal parts of machines and mechanisms

- during welding work as a personal welder’s mark

- branding of jewelry with name marks and hallmarks

- calibration and verification marks are used by metrologists when certifying measuring instruments

Product examples:

Information for ordering impact stamps

When ordering, it is necessary to take into account that in order to obtain a good impression, the ridge of the stamp must be “sharp”, so the sketch of the stamp is drawn with thin lines without shading. Also, it is advisable to make the size of the design as small as possible, since the smaller the area of the stamp, the weaker the blow required.

Complex small designs are made by laser engraving, the height of the relief is usually 0.2...0.5 mm. When branding, the part must be securely fastened or be quite massive. The place where the brand breaks through must be level.

Otherwise, you will not be able to get a high-quality print.

Cost of making impact stamps

| Diameter up to 10 mm | Industrial engraving | 0,9-1,3 | 2550rub | 2200rub | 2000rub | Call |

| Diameter 11 - 15 mm | Industrial engraving | 0,9-1,3 | 2750rub | 2450rub | 2250rub | Call |

| Diameter 16 mm | Industrial engraving | 0,9-1,3 | 2950rub | 2500rub | 2400rub | Call |

| Diameter 17 mm | Industrial engraving | 0,9-1,3 | 3250rub | 2850rub | 2690rub | Call |

| Diameter 18 mm | Industrial engraving | 0,9-1,3 | 3350rub | 2900rub | 2790rub | Call |

| Diameter 19 mm | Industrial engraving | 0,9-1,3 | 3515r | 3040r | 2945rub | Call |

| Diameter 20 mm | Industrial engraving | 0,9-1,3 | 3700rub | 3200rub | 3150rub | Call |

| Diameter from 21 to 30 mm | Industrial engraving | 0,9-1,3 | Call | Call | Call | Call |

- We deliver throughout Russia “to the door” or to the terminal of the transport company

- We will pay for delivery in St. Petersburg to the terminal of the TC “Business Lines” or AutoTrading

- Delivery from the terminal in St. Petersburg to your city is paid upon receipt according to TK tariffs.

Methods for making impact stamps

| Industrial (Mechanical) engraving. This method is the main one for making impact stamps for metal. Allows you to make stamps quite quickly, from 3 working days. After engraving, the stamp is subjected to hardening and tempering, as a result of which the hardness of the working part is 56-58 units. according to Rockwell. This method allows you to make the relief of the design as sharp as a knife blade. Thanks to this, it is necessary to use less effort to mark parts, and also allows you to increase the life of the impact stamp | Production of impact stamps using laser engraving. Calibration and verification stamps for metrology, name tags for jewelers, stamps with complex small patterns are usually made using laser engraving. In this case, it is possible to obtain a letter size of about 1 mm, so the area of the print can be only a few square millimeters. You can see such a print using a 4-8X magnifying glass in good lighting. |

| Making impact stamps using the electroerosion method This method is used in cases where a sharp ridge on the stamp is not necessary. These can be marks for working with non-ferrous or hot metal, as well as in the case when products are marked using a press. Electroerosion is advantageous for large-sized stamps. | Stamping using “Low Stress” technology The image consists of individual dots, which reduces surface damage during the marking process |

| Grounding and CE logo marks The stamps are made from high-quality tool steel. Hand stamps with special symbols in accordance with technical and international standards:

| Ready-made sets of impact stamps. The typeface on the stamps corresponds to DIN 1451 (GOST 26.020-80) Each stamp is marked: 1. Brand symbol2. Brand symbol size3. "MADE IN GERMANY"4. International symbol “eye protection”Hardness of the stamp material: 58-60 HRC Sets of stamps of all sizes, including 15 mm. supplied in unbreakable blue plastic boxes |

The second method is the electroerosion method

Electroerosive marking provides high quality, does not cause metal deformation and does not create a zone of internal stress concentration that occurs when marking with impact stamps. The depth of marking can vary from 0.1 to 1 mm. One of the most common methods of making stamps, it is most often used in the manufacture of impact stamps for working with hot or non-ferrous metal, as well as in the case when products are marked using a press. This method is used in cases where a sharp ridge on the calibration mark is not necessary. This is due to the fact that during erosion processing it is almost impossible to obtain sharp cutting edges. Instead, they turn out to be rounded, and the impression area increases, which is undesirable when working with steel, since more force is required to obtain a good impression. Electrical erosion is usually used for large stamps. The electrical erosion imprint on the metal is left due to the action of a tungsten electrode. This marking method is optimal for fragile surfaces that cannot be marked using conventional impact methods.

Brand

The stamps are placed on the center line of the sheet along the rolling.

The mark is applied at a distance of 20 - 50 mm from the edge of the welded seam from the outside. If a seam is welded on the outer and inner sides by different welders, marks are placed only on the outer side through a fraction: in the numerator the mark of the welder on the outer side of the seam, in the denominator - on the inner side. If the welded joints of the vessel are performed by one welder, then the welder’s mark may be placed near the plate or in another open area. If welded joints were performed by several welders, then the marks of all welders involved in its execution must be placed on it.

The brand is welded at a distance of 40 - 60 mm from the welded joint.

The mark is applied at a distance of 20 - 50 mm from the edge of the weld on the seam from the outside. If the seam is welded on the outer and inner sides by different welders, marks are placed only on the outer side of the seam. If the welded joints of the vessel are performed by one welder, then the welder’s mark may be placed near the plate or in another open area.

The mark is applied at a distance of 20 - 50 mm from the edge of the weld on the outside. If a seam is welded on the outer and inner sides by different welders, marks are placed only on the outer side through a fraction: in the numerator the welder’s mark is on the outer side of the seam, in the denominator - on the inner side.

The mark is applied at a distance of 20 - 50 mm from the edge of the weld on the outside. If a seam is welded from the outside and inside by different welders, marks are placed only on the outside through a fraction: in the numerator the mark of the welder who made the seam on the outside, in the denominator - on the inside. If the welded joints of the vessel are performed by one welder, then the welder’s mark may be placed near the plate or in another open area.

Stamps are placed on the outside.

The mark is applied at a distance of 20 - 50 mm from the edge of the weld on the outside. The place of branding is enclosed in a clearly visible frame, made with indelible paint or an electrograph, and is indicated in the vessel passport.

A stamp (12 mm in diameter with the image of the letters PM), certifying the verification of the porous mass.

| Different requirements. |

The mark must be from the manufacturer or electrical laboratory.

| Semi-automatic model MF75. |

Stamps are made by mechanics using gravers, punches (returns), files and needle files. The only difference is that on the punch the letters and numbers do not have a raised image, but a recessed and mirror image. At one end of the punch blank, bevels are filed at an angle of 30, leaving an allowance for processing, and then the contour of the protrusions inside the numbers and letters is processed using needle files. Raw punch blanks are checked on an aluminum plate.

The stamp is placed on the non-working part of the record. The use of unstamped or homemade records, as well as the installation of two or more records instead of one, is prohibited.

The mark is applied at a distance of 20 - 50 mm from the edge of the weld on the outside. If a seam is welded from the outside and inside by different welders, marks are placed only on the outside through a fraction: in the numerator the welder’s mark is on the outside of the seam, in the denominator - on the inside. If the welded joints of the vessel are performed by one welder, then the welder’s mark may be placed near the plate or in another open area.

How to get a welder's mark

To obtain a mark, it is necessary to undergo certification at the National Welding Control Agency (NAKS), which has branches in most cities of Russia. To work at hazardous production facilities, employees at four levels must pass certification:

- Welders are able to perform all types of seams in any spatial position.

- Master welders, who are subject to higher demands. Their competence includes not only welding, but also the responsibility to supervise the work of other welders.

- Technologists control the production processes of the entire enterprise.

- Engineers are responsible for the rules and supporting documents for welding work.

Certification can be primary, repeated and extraordinary. The employee undergoes the initial check at his own request or upon direction from the enterprise. It must also be completed by welders who have not worked in their profession for more than 6 months. Re-certification is carried out every 4 years. After passing it, an order is issued to assign a mark to the welder, indicating a new validity period. The personal code does not change. Employees whose level of professionalism raises doubts among management are sent for extraordinary certification.

To obtain a NAKS certificate, you must prepare the following documents:

- medical certificate with a positive conclusion;

- document on professional education;

- certificate of work experience;

- certificate of assigned rank;

- 2 photos 3x4 cm.

To increase your rank, you must complete advanced training courses before taking the exams and submit a certificate of completion. When preparing documents, it should be taken into account that the minimum length of experience and the level of rank are different for each level.

You need to clarify this data in advance at the branch where the certification will be carried out.

It should also be taken into account that welders are certified for only one type of welding. Therefore, when switching to another technology, you will have to go through the procedure again to get a new stamp code.

The application with documents is submitted to the branch closest to the enterprise. After its consideration, a certification date will be set, which consists of 3 exams: general, special, practical. You can prepare yourself or by first taking a preparatory course at the NAKS training center. If you fail one of the exams, you can retake it within one to 6 months.

Having a personal mark is not only prestigious, but also profitable, since certified welders have significantly higher salaries. However, depending on the conditions of a particular branch and the level of certification, you will have to pay from 25 to 150 thousand rubles for the certificate. Therefore, it is better to obtain referrals from a company that will pay all expenses.

Important points in making stamps:

- When developing an impression of an impact stamp, it is necessary to take into account that the resulting impression will always be less clear than the shape of the working part of the stamp itself. Small elements and complex geometric shapes should be avoided whenever possible.

- Since in most cases impact stamps are used for branding products made from materials with a hardness of up to 43 HRCe, the hardness of the working part of the stamp should be 54..62 HRCe. In this case, the hardness of the handle that is struck must be 34..46 HRCe, otherwise the stamp may be destroyed during operation.

- The profile of the line on the working part of the stamp should have the shape of a trapezoid. This is necessary in order to reduce the area of contact between the stamp and the material, and, accordingly, the force required to obtain a clear impression. The expansion in the lower part of the trapezoid ensures the durability of the mark and reduces the likelihood of chipping on the working surface.

- The working part of the stamp should not have sharp edges or burrs. The roughness parameter Ra should not exceed 3.2 µm.

- Depending on the working conditions, it may be necessary to apply special protective and decorative coatings (chemical oxide, hard chrome, etc.) to the stamp.

Thus, the production of an impact stamp is a rather complex technological process, which is recommended to be trusted only by specialists.

Technology

The main technologies for producing an impact verification mark are as follows.

- Manual. Now this method is almost never used. You can make a workpiece manually using special tools: a serviche, a spitztikhel, etc. First, markings are made on the metal, and then an image is cut out along it.

- Electrical discharge machining. This is one of the most common methods for making impact stamps. Most often, the product made using this method is used for branding parts made of non-ferrous metals. Erosion processing allows you to obtain a pattern with rounded edges. During branding, the impression is larger in size than the original. This effect is undesirable when working with steels.

- Laser processing. Microstamps are made using this method. The finished print has high precision, which cannot be achieved by mechanical processing of metal. A sign made with a laser is expensive.

- Mechanical method. One of the most effective and inexpensive technologies for manufacturing goods for this purpose. The workpiece is processed on CNC machines, which makes it possible to reproduce any image at different depths.

Tool steel U8A

The above GOSTs list the steel grades that must be used in the manufacture of impact stamps, welder's stamps, cylinder marking stamps and other types of manual impact stamps. There are five of them in total: 8XF according to GOST 5950-73, U7A or U8A according to GOST 1435-99, VK8 or VK15 according to GOST 3882-74. As can be seen from the list, U8A steel corresponding to GOST 1435-99 is present in it, unlike 9ХС, ХГВ and the like, which are used by other brands manufacturers. The stamps made in our workshop are made exclusively from U8A steel grade.

Nameplate requirements

4.1. On each boiler, autonomous steam superheater and economizer, the manufacturer must attach a nameplate in accordance with GOST 12971 with marking of passport data, applied by impact or other equivalent means.

(Changed edition, Amendment No. 2).

4.1.1. Markings on steam boilers must contain the following information:

name, trademark and, if necessary, location (city) of the manufacturer;

designation of a steam boiler in accordance with GOST 3619, a steam energy-technological boiler in accordance with GOST 22530;

boiler number according to the manufacturer’s numbering system;

nominal steam output in t/h;

working pressure in MPa (kgf/cm2);

nominal steam temperature in °C.

(Changed edition, Amendment No. 1, 2).

4.1.2. Markings on hot water boilers must contain the following information:

name, trademark and, if necessary, location (city) of the manufacturer;

boiler designation according to GOST 21563;

boiler number according to the manufacturer’s numbering system;

nominal heating capacity in MW (Gcal/h);

working pressure at the outlet in MPa (kgf/cm2);

nominal outlet water temperature in °C.

4.1.3. The marking on the autonomous superheater must contain the following information:

name, trademark and, if necessary, location (city) of the manufacturer;

superheater number according to the manufacturer’s numbering system;

nominal steam output in t/h;

working pressure at the outlet in MPa (kgf/cm2);

outlet steam temperature in °C.

4.1.4. The marking on the autonomous economizer must contain the following information:

name, trademark and, if necessary, location (city) of the manufacturer;

economizer number according to the manufacturer’s numbering system;

nominal water flow in t/h;

working pressure at the outlet in MPa (kgf/cm2);

water temperature in °C.

4.2. The following data must be stamped on the bottoms of the drums or on the bodies of the boilers, as well as on the collectors:

name and trademark of the manufacturer;

serial number of the product;

design pressure in MPa (kgf/cm2);

design wall temperature in °C and steel grade (only on superheater headers). The location of the specified data is chosen by the manufacturer and indicated in the installation and operating instructions.

4.1.2-4.2. (Changed edition, Amendment No. 2).

4.3. The manufacturer's plate must be riveted or welded and a support plate must be securely attached to the body or metalwork of the boiler, superheater or economizer.

4.4. The manufacturer's plate must be made of metals that are resistant to environmental influences. The sign must be clearly visible.

4.5. The manufacturer's plate must bear the quality control mark.

How to get a welder's mark

An order to assign a mark to a welder is the final stage of obtaining a personal mark. It is preceded by NAKS certification. To successfully pass all tests, you need to have the experience required by the rules, have good knowledge of the theory of welding production and cope with the practical part of the exam. The stamp will be issued along with the certificate.

What the NAKS certification is and how to pass it can be found here.

An order to assign a mark to a welder is drawn up by the institution that carries out welding work. The document can be formulated in any form. Most often, it specifies the types of structures that must be branded, as well as a list of additional functions of the owner of the brand.

Why do you need a welder's mark?

Welding is a profession that requires great attention and responsibility. When a welder performs important work, management must be sure that all welded joints are correctly completed

However, how can an inspection reveal who carried out certain welding works? A welder's mark quickly helps resolve this issue. This requirement was approved by law.

Read also: What are the names of alloys of copper with other elements

Metal structures are used everywhere in the construction of most industrial buildings and structures. The elements are connected to each other using welding. It is impossible to unambiguously determine whether the seam will be strong and durable - this is done by the inspection commission.

A timely identified defect allows you to avoid huge expenses associated with deformation and collapse of metal structures. Therefore, when performing work related to surfacing, welding at hazardous production facilities, each welder is required to put his own code next to the work performed - a mark that allows you to quickly determine who owns the work with the identified violation.

Welder's mark obtained as a result of certification by the National Welding Control Agency

Any certified welder who performs work on various metal products is required to identify all welds that he performs. This action is provided in order to fully identify all welds and joints produced by a specific welder. Since 2014, a special metal tool called a welder’s mark should be considered as such a mandatory identifying element.

The concept of a welder's mark and how to obtain it

Welder's mark is an identifier of all welders certified in accordance with the requirements of the National Welding Control Agency, which is assigned after such a welder has passed the entire range of certification activities.

The mark itself is a metal rod, attributed to a hand tool, on which an alphanumeric designation of the welder’s data is applied in a mirror order, based on the results of his certification at the National Welding Control Agency. The shape of the stamp is designed in such a way that on one side the alphanumeric code itself is placed, and with the help of the other side a blow is made, which allows you to make a relief designation of the stamp on the welded products for subsequent identification of a joint or seam.

All certified welders who perform work at hazardous production facilities must apply this mark. This mark is issued along with a certificate based on the results of certification.

hallmarks

The mark is assigned to the welder, as mentioned above, in case of successful completion of the entire complex of certification activities. The data of the code assigned to the mark is entered into orders for assigning a mark in the organization where the welder works, in order to eliminate possible confusion when identifying the seams made.

The mark cipher can be formed in two ways:

- based on the first letters of the last name and first name using an additional digital designation generated automatically. In this case, the mark will have an alphanumeric designation;

- a digital combination that is generated automatically using a special program. Such a brand will be completely generated and unique, since data about it will be saved in the program, and its repetition will be impossible.

When drawing up an order to assign a brand, the following information must be included:

- information about the welder who has been assigned a specific mark;

- date of the certification (indicating information about what type of activity the welder is admitted to, as well as the scope of the certification);

- category and level in accordance with the qualification requirements of the National Welding Inspection Agency;

- code of the mark assigned to the welder and its validity period.

This code can be changed only if certification occurs for working with completely different metals or for other welding technologies. If we are talking about periodic certification, then the brand code remains unchanged.

The issued order on the assignment of a brand indicates only the new validity period if there has been an extension of the NAKS certificate.

Where and when is it placed?

In accordance with the rules applied to regulate the procedure for carrying out welding work at hazardous production facilities, a mark must be placed by the welder on each product that he produces (for example, next to the weld or joint on the wall of the pipeline). To maintain the legality of using a stamp imprint, you must follow some rules:

- the resulting print must be easily readable throughout the entire period of operation of the product in the manufacture of which a specific welder was directly involved;

- the affixing of the mark must be reflected in a special welding work log, and after testing the welded object - in a special test report;

- a mark is placed on any product where the thickness of the welded parts is more than 6 mm;

- the code is placed at a distance of at least 40 mm from the boundaries of the parts being welded in order to exclude the possibility of its incorrect interpretation;

- if we are talking about a circular seam, the mark is placed every two meters, if we are talking about a longitudinal seam - at the beginning and end of the seam;

- if the seam is double-sided (there are internal and external passages), then two stamps are placed in the form of a fraction - the numerator indicates the information about the welder who performed the outer part of the seam, and the denominator indicates the internal part;

- When placing a mark, thinning of the metal or deterioration of its quality at the place where it was placed is not allowed.

The third method is laser engraving

Used for microstamps. This method cannot be replaced for the production of calibration and verification marks with an extremely small imprint area, because the diameter of the laser beam is much smaller than the thinnest engraving tool. In this case, it is possible to obtain a letter size of about 1 mm, so the print area can be only a few square millimeters. Laser engraving is a technology that is performed using a special algorithm for the gradual removal of the thinnest layers of material with a focused laser beam, which is positioned at the desired location of the product with micron precision. The engraving method is rapidly gaining popularity due to its wide range of applications, precise image quality, high productivity and process flexibility. In many cases, laser engraving on calibration marks is the best solution, both for reasons of manufacturability (non-contact and speed of the engraving process, reliability and durability of the image), and due to the external attractiveness of the finished products. This method allows you to make calibration marks quite quickly, from 3 working days.

The method has competitive advantages over others, namely: 1. The stamps have sharp edges and a large depth of relief, which increases penetration ability. 2. Impact stamps will last for quite a long time. 3. The strength of the impact stamp allows you to put impressions on all types of metals and alloys. 4. Laser engraving allows you to make chalk fonts and design elements into the stamp imprint. 5. Leaves a clear and easy to read relief print. 6. The stamps are convenient for active work and are not subject to jagging and mechanical deformation from hammer blows.