Types of jobs

Proper organization of the welder's workplace is the key to quality welding and high productivity. There are stationary and non-stationary welding workplaces. At stationary welding places, welding work is usually carried out on small parts that are easily placed on the table.

Permanent places are intended for the production of welders in industrial enterprises: in workshops, workshops. A stationary workplace can be single-station (which implies the presence of a workplace for only one welder), which is powered by a transformer, as well as multi-station, in which there are several cabins in the room, powered by a single current source.

Parts can be supplied by mechanics or other workers, and the welder himself is mainly located in the cabin. The welding transformer in this case should be located in a separate room.

A general or individual panel must include measuring instruments, various protective equipment, signal lamps and switches, clamps, etc. For an individual place, a separate panel with measuring instruments is provided.

Temporary mobile workstations are used to perform work on equipment and installations that are not allowed to be moved to the post. A mobile or non-stationary welding place usually involves welding large-sized products that lie motionless. In this case, the welder has to move around the perimeter. When preparing a mobile location, you need to create conditions in which nothing would interfere with the process.

When using a transformer for a mobile non-stationary location, it can be located inside the building or outside.

When performing welding work outdoors, the workplace must be protected from the atmosphere. For these purposes, tents, portable awnings or awnings, etc. can be used.

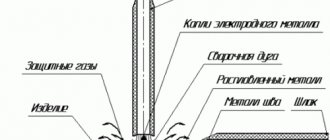

How to move the electrode

There are three ways to move the welding electrode.

These include:

- Progressive view. In this case, the electrode moves uniformly along the trajectory. The main advantage of this method is that a long arc is formed. It helps maintain maximum speed for melting the metal inside the electrode;

- Straightforward look. Here the electrode is smoothly moved along the line of the metal seam. In this way, it is possible to maintain a comfortable speed in the welding process. The seam is of high quality and durable;

- Oscillatory appearance. This technique is recommended for creating wide seams. The electrode moves smoothly along the direction of the deposition line. The main advantage of this type is the uniform heating of the edge, which is located at a large distance.

Organization of a welder's workplace for manual arc welding

The design of the welder's workplace should provide him with unhindered access to workpieces and safe working conditions. In particular, care must be taken to ensure that there are no flammable or explosive substances, and welding cylinders must be sufficiently removed from open flames. The welder's workplace is organized in accordance with GOST 12.3.003-86.

When equipping a workplace with tools, the specifics of the work are taken into account. But we can identify a certain minimum list of tools, without which a welder cannot work fully. The standard workplace is equipped with:

- welding machine;

- wire brush;

- welder table and chair;

- chisel and hammer;

- electric holder;

- screw clamp;

- welding helmet.

At the same time, you should not unnecessarily clutter the workplace with unnecessary things and equipment that can interfere with work and pose a danger.

Welding work at posts is carried out only with operating ventilation. When working, mobile air suction units should be used.

When performing work in mobile places, they are fenced with fire-resistant screens, shields, and must also be equipped with fire extinguishers and fire extinguishing equipment. The type of fire extinguishers is determined depending on the area of impact, productivity and class of the room, etc. In addition to the fire extinguisher, the mobile station site is equipped with a box of sand, a bucket and fire extinguishing equipment.

If necessary, the workplace can be equipped with small-scale mechanization equipment, which facilitates loading and unloading operations.

Correct name and code of profession

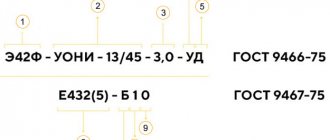

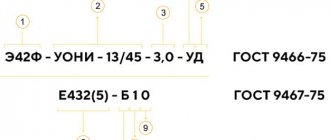

The occupational code according to OKPDTR includes the code itself plus the index of the base group, control numbers indicating the rank, qualifications, type of remuneration, facets of conditions and the degree of mechanization of labor.

The welder profession code includes a code and control numbers.

For example, the profession code for electric and gas welder is 19756 2 02 7212 Х-Х-ХХ-Х-Х, where:

- the first 5 digits are the profession code;

- 2 – check digit;

- 02 – numbering according to ETKS;

- 7212 – OKZ group code;

- X – indicator according to the tariff schedule (from 1 to 8);

- X – qualification (from 1 to 3);

- XX – form of remuneration (from 10 to 22);

- X – normal/difficult/particularly difficult working conditions (1/2/3);

- X – mechanization of work (from 1 to 5).

equipment requirements

When organizing welding work, importance is attached to the correct placement of equipment. Units and installations, which consist of several welding units, are located in a separate room, fenced with partitions with a height of at least 1.7 m.

Welding transducers during operation can create noise, which has a negative effect on the nervous system, leading to decreased attention and performance. Therefore, it is recommended to isolate them and remove them from the production premises.

The passages between welding units and installations must be at least 1.5 m , between the welding unit and the wall - from 0.5 m, between the stationary unit, wall and column - from 0.5 m.

The permanent welding machine must be installed in a well-ventilated room protected from the atmosphere. It is optimal that the floor in such a room is concrete, and the walls do not reflect welding glare, which poses a hazard to vision. The doorway should be covered with a canvas curtain, which is suspended on rings.

Using welding equipment on the installation site can create certain difficulties during its storage. It is best if the welding machine is located indoors, and only welding cables are pulled to the workplace. If this is not possible, then it is optimal to install the welding machine on a mobile cart, which will simplify its transportation.

Workpieces must be previously prepared for welding work.

Personality traits and psychology

Individual character traits play an important role for a welder. Workers in this specialty are predominantly balanced and patient. The advantages are intelligence, determination, and focus on results. Activity, good hand mobility, and physical endurance are encouraged.

To work at height, the master must obtain the approval of a medical commission and obtain the appropriate permit.

Considering the harmfulness of the profession in question and the physical stress, the majority of welders are men, but they cannot do without women in this field.

Welding tables

Welding booths must be isolated from outsiders. They house a welding table and other work accessories, so they are quite spacious. The size of the cabins is 2*2 or 2*3 meters, and the height is up to 2 meters. To improve ventilation, the walls are mounted so that there is a gap of 20 cm from the floor.

Welding tables are used for welding and assembling parts. They are located inside the welding cabin at a height of 50-60 cm if the post involves welding in a sitting position, or at a height of 90 cm if the work is performed while standing.

The table area is at least one square meter. The requirement for the welder's workplace involves the use of special bolts to which the wires from the welding machine are attached. To suck dust from the welding arc, it is not allowed to place an exhaust hood, since otherwise the flow of gases and dust will pass through the welder’s respiratory tract.

There should be sockets for electrodes on the table. If the desk has a drawer, then documents and tools should be stored there. There is one more requirement: there must be a rubber mat under the welder’s feet.

If the table is equipped with local suction, it can be installed both on the table and outside the room. The fan built into the desk creates noise that reduces productivity. The optimal design for a welder's table is one with lower-side suction and installation of a fan outside the room: then dust and gas do not enter the welder's breathing zone.

Additional amenities may be provided in welding tables . For example, many welders practice stripping the end of the electrode by touching it to the surface of the table. As a result, after a certain period of time, metal growths form on the table, which interfere with the movement of products on the table and worsen its aesthetic properties. To prevent this from happening, the table surface is edged with copper plates at the edges. As a result, the table surface is not contaminated by the electrodes, since the metal does not stick to the copper.

Local lighting may be provided in the table . For welding small parts, when seams are applied around the perimeter, it is advisable to use a rotating table, which is adjustable in height with screws. This allows the parts to be raised and lowered to a comfortable position. During such work, the welder gets less tired and is less exposed to harmful emissions.

To eliminate the awkward position, you need to provide the welder with a seat that is height adjustable.

Where to work?

Options:

- Employment after training (some vocational schools and training centers provide it). They usually find employment in enterprises in their own city. If the city is large, then firms often cooperate with training centers and vocational schools. Just when enrolling in courses, be sure to check whether this is possible.

- Shift method. Shifts are recruited either by recruitment agencies (there are more than one in large cities), or by large organizations directly (but they often delegate this task to recruitment agencies), or by foremen. If newbies are hired for a shift immediately after the course, it will be somewhere in an uncomplicated position - you shouldn’t expect that after 3 months of evening training you will go to the North to weld rigs for Gazprom for 100-120 thousand rubles.

- Search through message boards. If there are no such advertisements in your city, it’s worth looking in the nearest large ones, or in Moscow or St. Petersburg.

- Work abroad. You can also search through message boards, only foreign ones. Now for many nearby countries there are separate ones where they are looking for visitors, including Russians. True, after the course it is unlikely that you will be able to immediately go to Germany.

- Employment through the labor exchange. As an option, you can go to the stock exchange immediately after completing the courses. If there are no suitable vacancies there, you can register to receive benefits and continue to look for work.

Electrical holders for manual arc welding

One of the main tools used by welders is the electric holder. Safety and productivity depend on it. The basic requirements for them are lightness and ease of use. The weight of the electric holder should not exceed 0.5 kg so that the welder’s hands do not get too tired. In this case, the holder should not be exposed to heat during operation.

Among all types of clamps, pliers are the most optimal.

Three types of electrical holders are available:

- for current up to 125 A and wire cross-section 25 mm;

- for current up to 315 A and 50 mm wire;

- for current up to 500 A and 70 mm wire.

It is necessary to have insulation and reliable fastening of the electrodes. The holder must withstand 8,000 electrode clamps. The design allows you to replace the electrode in no more than 4 s.

Approximate cost of electrode holders on Yandex.market

Holders for currents of 500 A and higher are equipped with shields to protect hands from the heat of the welding arc and from metal splashes. Electrode holders are also used, which are equipped with devices to turn off the current when changing the electrode. This additionally ensures greater operational safety.

The welding station must be equipped with a tripod (stand), which is welded to the table, for placing the electric holder during breaks in work, in order to avoid the formation of an electric arc when the holder touches the table surface. The surface of the tripod or stand must be made of electrical insulating material.

During welding, splashes of metal stick to the holder, this leads to its weight and overheating. In order to avoid this, it is recommended to lubricate it with an auto scrap once per shift.

Welding methods: lap, butt, tee and corner

The work of a welder involves several methods of welding parts: overlap, butt, T-joint and corner. The seam is made with an inclined electrode, except for butt welding, when the electrode is held almost straight. When doing fillet welding, it is recommended for a beginner to place the parts to be welded “in a boat” rather than in an L shape; in this case, it is easier to achieve a high-quality seam with well-welded edges.

Workwear

Even with full compliance with safety regulations at the welder’s workplace, it is impossible to protect the welder from negative factors without the use of special clothing. The set should include a jacket, mittens, trousers, safety shoes, etc. Most workwear for welders is made from tarpaulin with asbestos in it, which can protect against molten metal. Clothing should cover the entire body so that there are no exposed areas.

Among personal protective equipment, shields and helmets are important. They must comply with GOST 12.4.035-78. The mask cannot be heavier than 0.5 kg.

Approximate cost of a welding helmet on Yandex.market

When choosing a mask, pay attention to its material. Ideally, it is plastic that is resistant to elevated temperatures and humidity. Such a mask does not deteriorate under the influence of metal splashes and prevents electric shock to the worker.

If work is carried out in cramped and enclosed spaces where it is impossible to use an exhaust hood, then you need to use special masks that provide air supply.

A light filter is inserted into the helmet, which is held by a frame with dimensions of 120*60. Protection means include 13 classes of filters with different densities, which are used for different power modes.

The use of colored glasses that are not intended for welding is prohibited, as they do not provide reliable eye protection from ultraviolet rays. This puts the welder at risk of chronic eye disease.

Modern masks are designed like a “chameleon”. They allow you to automatically adjust the darkening of the glass depending on the brightness of the arc.

Among the requirements for the material of the suit are the following:

- The material of the welder's suit is heat-resistant (for example, suede or tarpaulin).

- Pockets - only internal.

- The jacket should not be tucked in.

- Boots are made from non-flammable material , they must be high enough and must not contain nails.

- The headdress should reliably protect the neck.

- Gaiters or mittens are made from non-flammable material ; they must be long enough to prevent material from getting inside during ceiling welding.

Required Professional Skills and Responsibilities

Professional requirements for welders:

- Knowledge of the basics of electrical engineering, physics, chemistry.

- Understanding of the operating principles of welding devices.

- Analysis of the properties of gases, electrodes and related elements used in welding operations.

- Knowledge of the characteristics of metal melting.

- Experience in soldering and fusing metals.

- Welding by all methods in accordance with specialization.

- Ability to calculate deadlines and volumes of work.

- Taking into account the types of defects at seams, the ability to prevent and eliminate them.

- Analyzing the appropriateness of the technology used, suggesting design improvements (if necessary).

- Knowledge of required consumables.

Welders must have an understanding of the operating principles of welding devices.

Welding curtains

Certification of a welder's workplace requires him to have an overlap, especially for multi-station areas. These overlaps are called welding curtains. They are made from fire-resistant fabric, which is the same as that from which workwear is made.

Curtains completely isolate the welder's workplace from strangers in order to eliminate the negative influence of the welding arc and other negative factors.

Welding curtains have the following functionality:

- They protect against ultraviolet radiation.

- Minimize the risk of fire as they provide protection from sparks and splashes.

- Prevents the negative impact of air currents on the welding zone.

- Increases the efficiency of exhaust equipment.

Approximate cost of welding curtains on Yandex.market

They are quite economical and easy to install. Curtains can be solid or striped. Solid curtains are made from a single fabric. They are made of PVC, stitched on all sides and have reinforced holes for hanging rings with a distance of 20 cm. The strip welding curtain is a separate strip with a width of 50 cm. The assembled width of the curtain is 140 cm.

Medical contraindications

It is not recommended to allow people who have problems with hearing, vision, psyche, or the musculoskeletal system to become a welder. Allergic reactions and disruptions in the cardiac and vascular systems are unacceptable. The standard set of occupational diseases of a welder is asthma, visual impairment, and problems with the respiratory system.

We recommend reading: How to weld heating pipes using electric welding

To minimize harm from the profession, safety precautions should be strictly followed. This includes the use of PPE (masks, special shoes, suits, gloves). You need to eat right. At most enterprises, representatives of this specialty are given milk.

It is not recommended to allow people who have hearing or vision problems to become a welder.

Ventilation

When using gas in the welding process, it is necessary to ensure good ventilation of the room.

Ventilation is needed for several reasons:

- To reduce the concentration of toxic substances that may be released from the metals being welded . When carrying out welding work, various harmful impurities can be released into the air: carbon monoxide, nitrogen monoxide and fluoride inclusions.

- In order to remove gas contamination from the room , which can lead to detonation.

- To ensure cooling of working tools and equipment that overheats during operation.

Ventilation can be natural, which is carried out using air flow from the street, as well as artificial. For artificial ventilation, special hoods, fans and other means of air circulation are used.

Exhaust ventilation is designed to remove harmful gases from the room as much as possible, while supply ventilation is designed to compensate for organized exhaust by diluting substances to acceptable working concentrations for health.

The best option for a welder's workbench is one that is equipped with dust extraction directed downward or to the side. The effectiveness of the suction of harmful substances from the inhalation zone is ensured by the close location of the exhaust intakes to the arc site.

Is it possible to work for yourself?

Can.

This can be organized as a part-time job (if you work as a welder in some company and want to earn money after a shift or on weekends). How you can earn extra money:

- make some simple products to order (for example, pipe stoves);

- weld simple structures: fences, gates, tables for cottages or garages, racks, benches, canopies;

- engage in artistic welding: create and sell jewelry, souvenirs, interior or exterior items (example);

- weld reinforcement when arranging the foundation or during monolithic construction;

- find small (or medium-sized) companies that periodically need a welder, but not so often as to keep him on staff (for example, construction and repair teams, companies for the installation and maintenance of utilities, for the production of garden furniture);

- cook and repair products for cars, agricultural machinery, special equipment, and do body repairs.

If you already have experience (you know how, what and with what to cook correctly), you can try working for yourself. But this is relevant mainly for large cities - in small towns, orders may not be enough for a normal income.

Other requirements

Also, do not forget about the following additional tools that make the welder’s work easier. This:

- screw clamps for tight contact with the product;

- wire brushes (manual and electric) - to remove slag and rust;

- narrow and wide steel brush for cleaning edges and seams;

- chisels, stamps and hammers - for cutting out places with defects, eliminating splashes, installing a stamp, etc.;

- a hammer with a pointed end for beating off slag;

- a set of templates for measuring the size of seams;

- canvas bags or glasses - for storing electrodes.

The welder should have easy access to consumables: electrodes, wire, flux, etc., so that he can easily change them during work. It is necessary to follow the labor protection instructions individually and generally.

If the welder works with a non-consumable electrode, then he must have a set of sharpened tungsten electrodes, pliers, wrenches, wire cutters, pliers, etc. The tool should be stored in a special box or bag.

Thus, the overall efficiency and safety of the work depends on how competently the workplace of a welder using the manual arc welding method was organized. The workplace is understood as an area assigned to the welder, which is equipped with equipment, tools and devices for welding. A properly organized place reduces injuries and accidents at work.

Preparing the elements to be welded

Before starting welding, the joints between parts must be cleaned of dirt and rust and moisture removed. If the thickness of the part is more than 3 mm, then it is better to chamfer the edges; this will allow for better welding of the elements, which is important, especially for a beginner. We recommend that you do not skimp on time and prepare the parts to be welded well.

Opinions about the profession

Having studied the opinions of users about the welding profession, we can conclude that the specialty is now in demand, given the number of bridges, houses, shopping centers and other facilities being built throughout the country. A good craftsman will not only weld parts together, but also repair structures that cannot be repaired in any other way. In addition, a specialist always has a part-time job, helping acquaintances, neighbors, and friends. Work puts a lot of strain on the eyes and lungs, so it’s not easy to work for 20-30 years without harm to your health.

Qualification categories

Each welder can receive 6 categories. Each of them is obtained sequentially; you cannot miss a single one. The first category is received by all graduates of the relevant educational institutions, after final exams.

When a welder proves that he can weld in low and vertical positions, he can receive a second rank.

If you have additionally studied pipe sealing, have the skills to use simple drawings, have a complete understanding of safety precautions, and the operating principle of basic welding tools, you can count on the third category.

When a specialist can easily weld in any position (except for the ceiling), can handle special types of pipes, confidently uses drawings and is allowed to work with objects of medium complexity - this will be useful for the fourth category.