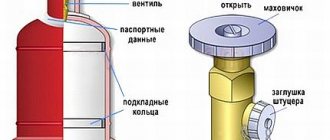

To reliably hold gases under pressure up to 180 atm, cylinders with thick walls up to 6 mm are used. To dose the gas supply, cylinder valves are used, to which reducers are connected. In order not to produce many different reducers according to the connection method, cylinder valves are produced in certain sizes and standards, and are designed for installation on gas cylinders with a volume of 10 to 40 liters. We will consider further what their structure and types are, as well as the rules of operation. This will help you choose the right equipment and use it correctly.

Cylinders for technical gases.

Cylinders for technical gases.

Cylinders for technical gases.

Oxygen cylinders

designed for oxygen refilling and its further storage and transportation. Manufactured according to GOST 949-73.

Oxygen balloon

filled with gas to a pressure of 150 atm.

The working and test pressure of the cylinder is stamped by the manufacturer at the bottom of the passport, which is stamped in the upper part of the cylinder under the neck. (P150 atm P225 atm) or (P200 atm P300 atm). Once every five years, cylinders undergo mandatory technical certification, undergoing a hydraulic pressure test of 225 or 300 atm. Oxygen cylinders come in different sizes from 1 to 50 liters (small or medium volume) and are painted blue or blue with the inscription oxygen in black. Oxygen cylinders from 5 to 50 liters are equipped with valves VK-94-01

, VK-99

.

Small volume cylinders from 1 to 10 liters can be equipped with a VK-94-01 valve, used.

07. Oxygen cylinders for medical gas are equipped with a

VKM-95

made of stainless steel. Medical oxygen is used for medical purposes for breathing apparatus, oxygen cocktails, etc.

Cylinders for technical gases manufactured in accordance with GOST 949-73 can be designed for different types of gases. ( Argon

, carbon dioxide , nitrogen , welding mixture

, etc.).

They also differ in volume. The cylinder must not have mechanical damage, traces of loose rust, or welding. All elements of the cylinder (shoe, neck) are attached to the shell using hot crimping. The cylinder passport must be easy to read. The service life of a cylinder produced since the beginning of 2015, according to the order of Rostechnadzor dated March 25, 2014, is 20 years

.

Gas content in the cylinder;

Oxygen, argon, nitrogen, helium, welding mixtures: a 40-liter cylinder at 150 atm contains - 6 cubic meters. m/8kg. Acetylene: 40-liter cylinder at 19 kgf/cm2 - 4.5 cubic meters. m / 5.5 kg of dissolved acetylene. Carbon dioxide: 40-liter cylinder - 12 cubic meters. m / 24 kg of liquid gas Propane: 50-liter cylinder -10 cubic meters. m / 42 liters of liquid gas / 21 kg of gas.

Empty cylinder weight 40 liters

: Oxygen, argon, nitrogen, helium, carbon dioxide, welding mixtures, amounts to 65-70 kg without taking into account the weight of the protective cap.

Weight of acetylene cylinder 40 liters

:

- 90 kg Weight of propane cylinder 50 liters

:

- 22 kg

Threads for valves in the necks of cylinders according to GOST 9909-81.

W19.2 - from 1 to 10 liters. W27.8 - 40 liters of oxygen, carbon dioxide, argon, helium, as well as 5, 12, 27 and 50 liters of propane. W30.3 - 40 liters of acetylene.

Thread on the valve for connecting the gearbox:

G1/2″ - found on cylinders from 1 to 10 liters; a special

adapter

. G3/4″ – standard thread on 40-liter cylinders. oxygen, carbon dioxide, argon, helium, welding mixture. SP 21.8×1/14″ - left-hand thread for propane.

Safety regulations

Valves are the most vulnerable in gas cylinders, so you need to treat them correctly to prolong their service life. New valves must be stored or transported with plastic plugs. They prevent damage to the threads. If the coils are jammed, it will be difficult or impossible to install the valve in the cylinder. Likewise with the thread for the gearbox.

When a cylinder with a valve is transported, a plastic or steel cap is placed on top. It protects the valve from shock if the gas tank is dropped. Otherwise, the valve may break off and the balloon will become a rocket driven by internal outgoing pressure.

When carrying oxygen, carbon dioxide and acetylene cylinders, two people are allowed to hold the valve with their hands, but this is inconvenient. The faceted square part or the handwheel may press on your hand and cause the valve to slip out, causing it to hit the ground or floor. It is better to use special carts when transporting cylinders around the workshop, enterprise territory, or warehouse. For long-distance transportation of cylinders, special racks are used, where the vessels are secured with belts or chains to prevent them from falling.

Handling oxygen cylinders requires clean hands. Do not unscrew or tighten the valve with gloves in oil, otherwise an explosion will occur. Do not accidentally drop drops of oil or oily things onto the valve or the cylinder itself.

Cylinder valves

Oxygen valve VK-94 (Compressed air, nitrogen and other non-aggressive gases)

| Options | VK-94-01 | ||

| isp.07 | |||

| Du, mm, no less | 4,0 | ||

| Working pressure, MPa (kgf/cm2) | 20 (200) | ||

| Dimensions, mm | 60x62x120 | ||

| Weight, kg | 0,55 | ||

| Connection dimensions | |||

| at the inlet - external thread | W27.8 | W19.2 | |

| at the outlet - external thread | G3/4 -B | ||

Diaphragm valve VBM-1 (for inert gases: helium, nitrogen, argon and other non-aggressive gases)

| Options | VBM-1 | ||

| Du, mm, no less | 4,0 | ||

| Working pressure, MPa (kgf/cm2) | 20 (200) | ||

| Dimensions, mm | Ø62x130 (without filter) | ||

| Weight, kg | 0.65 | ||

| Connection dimensions | |||

| at the inlet - external thread | W27.8 | W19.2 | |

| at the outlet - external thread | G3/4 -B | ||

Membrane valve KVB-53 (oxygen, helium, carbon dioxide, compressed air, nitrogen)

| Options | KVB-53 | |

| Du, mm | 4 | |

| Working pressure, MPa (kgf/cm2) | 20 (200) | |

| Dimensions, mm | 63x63x110 | |

| Weight, kg | 0,56 | |

| Connection dimensions | ||

| at the inlet - external thread | W27.8 | |

| at the outlet - external thread | G3/4-B | |

Hydrogen valve BB-88

| Options | BB-88 | ||

| isp.03 | |||

| Du, mm, no less | 4,0 | ||

| Working pressure, MPa (kgf/cm2) | 20 (200) | ||

| Dimensions, mm | 66x62x120 | ||

| Weight, kg | 0,60 | ||

| Connection dimensions | |||

| at the inlet - external thread | W27.8 | W19.2 | |

| at the outlet - external thread | SP 21.8-14 threads per 1″ left | ||

Ammonia valve (Angle pin valve for chlorine cylinders)

| Options | 15ls93bk | |

| Du, mm, no less | 5 | |

| Nominal pressure, MPa (kgf/cm2) | 1,6 (16) | |

| Weight, kg | 0,52 | |

| Connection dimensions | ||

| at the inlet - external thread | W27.8 | |

| at the outlet - external thread | G1/2 |

Acetylene valve VAB-97

| Options | VAB-97 | |

| Du, mm, no less | 3,5 | |

| Working pressure, MPa (kgf/cm2) | 3,5 | |

| Dimensions, mm | 123x41x39 | |

| Weight, kg | 0,6 | |

| Connecting thread | W27.8 |

Acetylene valve VBA-1

| Options | VBA-1 | ||

| isp.03 | |||

| Du, mm, no less | 4 | ||

| Working pressure, MPa (kgf/cm2) | 3,5 (35) | ||

| Dimensions, mm | 110x45x45 | ||

| Weight, kg | 0,65 | ||

| Connection dimensions | |||

| at the inlet - external thread | W30.3 | W19.2 | |

| at the outlet - boring for a fitting with a clamp | Ø10xØ20x5.5 | ||

Balloon valve Cavagna group (Italy)

How many M3 propane is in 1 5, 12, 27, 50 liter cylinder?

We have made special calculations that conditionally transform propane-butane into a gaseous state. Under standard conditions (100 kPa, 288 K), 0.526 m³ of propane or 0.392 m³ of butane is formed from 1 kg of liquefied gas. Taking into account the percentage of the mixture (60% prop.), the volume of combustible gas is calculated using the formula M*(0.526*0.6+0.392*0.4). How many cubic meters are in a propane tank can be seen in the table below. The last line shows the number of liters of propane-butane mixture (in the liquid phase).

Oxygen regulator and its thread?

#1 Message Igor Kiselev » 03/23/2006 10:59 —> Added: 03/23/2006 10:59 Message title: Oxygen regulator and its thread?

#2 Message Anton » 03/23/2006 13:30 —> Added: 03/23/2006 13:30 Message title: Re: Oxygen regulator and its thread?

#3 Message Valery Mukhin » 03/23/2006 13:51 —> Added: 03/23/2006 13:51 Message title: Re: Oxygen regulator and its thread?

#4 Message Artem » 03/23/2006 15:48 —> Added: 03/23/2006 15:48 Message title:

Yes-ah-ah, Anton the Man asked the right question. The new DIN valve standard for Natrox and O2 is already out and working. There is information on any website. I took the first one I came across: https://sub.com.ua/shop/index.php?productID=624 “. Mistral comes with all standard YOKE 232 bar, DIN 300 bar or Nitrox/O2 M26x2 connections. » That is a regular regulator will not screw into a new Nitrox O2 cylinder. And vice versa, a new nitrox regulator into the air tank. It looks like Igor Kiselev is right: someone really “. He doesn’t know shit about technology.”

There are currently three types of valves:

A-clamp (or English Yoke - clamp) - ensures the tightness of the connection by pressing the regulator to the cylinder valve using a clamp. This type of connection is simple, cheap and very widely used throughout the world. It is rated for a maximum pressure of 232 bar and the weakest part of the connection, the O-ring, is not very well protected against overpressure. 232 bar DIN (5 turns, metric thread M 25×2) - the regulator is screwed into the valve, which ensures reliable fixation of the O-ring. They are more reliable than A-clamps because the O-ring is well protected, but in many countries DIN equipment is not universally used on compressors, so the diver will need to take an adapter when traveling.

Valve standard 232 bar DIN300 bar DIN: (7 turns, metric thread M 25×2) - similar to the previous type of valve (232 bar), but designed for operating pressures up to 300 bar. It is possible to use regulators rated for 300 bar in cylinders rated for 232 bar, but not vice versa. The new European standard EN 144-3:2003 describes a new type of connection that is similar in appearance to DIN 232 or 300, but uses a metric thread M 26x2. This type of compound is intended for use with mixtures in which the oxygen content is higher than in the atmosphere, that is, with nitrox. From August 2008, all equipment used for diving with nitrox or pure oxygen will have to comply with the new standard

Which co2 cylinder to choose? Comparison, characteristics and conclusions

In this article we will consider the issue of choosing a carbon dioxide cylinder for Co2 aquarium systems.

Any cylinder system for supplying carbon dioxide to an aquarium consists of three components: - a carbon dioxide cylinder; — gearbox with its body kit (solenoid valve, fine-tuning regulator, fittings); — components for supplying carbon dioxide to the aquarium (polyurethane tube, bubble counter, check valve, diffuser or flow reactor for supplying gas). Today, the aquarist has a choice of purchasing ready-made CO2 systems from well-known manufacturers of aquarium equipment or alternative systems for supplying carbon dioxide to the aquarium. The price of branded cylinders and systems in general will undoubtedly be high. Let's take a closer look at what cylinders from such manufacturers are. In branded systems there are two types of cylinders: disposable and reusable cylinders.

Disposable branded cylinders

If we consider disposable branded cylinders, they have a definite advantage. This is the ease of maintenance of such cylinders and their connection to Co2 supply systems in the aquarium. But that's where all the positives end. The big disadvantage of such cylinders is their cost, or rather the total cost spent on their acquisition during the operation of co2 systems with disposable cylinders. After all, when buying a disposable cylinder, you need to take into account that after they run out of carbon dioxide, you simply have to throw them away. Moreover, if you add up the money spent on such cylinders, you get a good amount.

It is important to remember that disposable cylinders are usually not interchangeable. When using branded cylinders from a specific manufacturer, they cannot be replaced with cylinders from another manufacturer, since the connection unit (connection) is original and is suitable only for systems of a specific manufacturer. Does it make sense to purchase systems with such cylinders? This will have to be decided by the aquarist himself, of course.

Main characteristics and conclusions:

- Qualitatively

- Beautiful

- Very expensive

- Small volume of gas

- Short service life

Reusable (refillable) branded cylinders

Such cylinders have an aesthetic appearance, very often have a special handle for easy transportation, are made of steel and are designed for long-term use. Such a cylinder cannot be refilled at all carbon dioxide cylinder refilling stations; for refilling you may have to purchase a special adapter.

Main characteristics and conclusions:

- Beautiful (when using a full gas supply kit)

- Expensive

- Comfortable

- Possible difficulties when refueling in certain localities

- Possible problems during recertification

Carbon dioxide cylinders made in Russia

Carbon dioxide cylinders produced in Russia fully comply with GOST requirements. The thread on the valve of such cylinders is standard G3/4 and you can easily fill them at any gas station.

Of course, such cylinders are inferior aesthetically to branded cylinders, but this does not affect the reliability of their operation. The main advantage is the wide range of volumes from 2 to 40 liters.

For more detailed general information about Russian-made carbon dioxide cylinders, you can read the article Important information about cylinders.

Main characteristics and conclusions:

- Long service life

- Acceptable cost

- Qualitatively

- No hassles when refilling

- No problems with recertification

How to check a gas cylinder?

You can check whether there is a leak from a gas cylinder yourself: moisten the cylinder with a sponge and soapy water - bubbles will form at the site of the gas leak. If the gas comes out in a strong stream, you can hear it - as if a balloon is being released.

Interesting materials:

How much does a baggage ticket cost? How much does a plane ticket to Moscow Anapa cost? How much does a ticket from Kyrgyzstan to America cost? How much does a ticket from St. Petersburg to Finland cost? How much does an Emirates first class ticket cost? How much does a ticket to Dubai cost? How much does a ticket to the Zapashny Brothers Circus cost? How much does the BMW M3 E46 cost? How much does a plantain keychain cost? How much does it cost to get to Sakhalin?

Helium pressure in a fully filled cylinder depending on temperature

When using it, you also need to have a good understanding of how helium pressure depends and how it relates to temperature. To understand this, see the table below.

| Pressure | Temperature |

| 160 kgf/cm2 | +40 °C |

| 150 kgf/cm2 (nominal) | +20 °C |

| 140 kgf/cm2 | 0 °C |

| 130 kgf/cm2 | -20 °C |

| 120 kgf/cm2 | -40 °C |

Acetylene pressure in a fully filled cylinder depending on temperature

We present a table with similar values, but this time for acetylene.

| Pressure | Temperature |

| 30.0 kgf/cm2 | +40 °C |

| 23.5 kgf/cm2 | +30 °C |

| 19.0 kgf/cm2 (nominal) | +20 °C |

| 14.0 kgf/cm2 | 0 °C |

| 13.4 kgf/cm2 | -5 °C |

How much do the cylinders weigh?

The weight of a fully filled cylinder is often an important parameter when transporting it. Weight distribution is shown in the table below.

| Gas type | Volume | Empty weight |

| Argon, welding mixture, oxygen, carbon dioxide, helium, nitrogen | 40 l | 70 kg |

| Acetylene | 40 l | 90 kg |

| Propane | 50 l | 22 kg |

What is the thread on the carbon dioxide cylinder?

Any CO2 balloon system has the same structure. Many modules are optional, some can be combined, but in the end the structure is still the same: The cylinder is a source of gas. Often a metal container containing gas under (high!) pressure. They are divided into refillable or disposable. Disposable cylinders - often available in branded systems with an interesting price. The downside is that the cylinders themselves are thrown away after the gas is used up. To work further, you need to buy the same cylinder (without the system) - which is cheaper than a ready-made system, but often still expensive. Or you can look for options for converting the remaining system for replacement cylinders. Evaluate the feasibility of the purchase by calculating the cost of maintaining this system. My personal opinion is that compact systems with disposable cylinders have a right to life, for example in micro aquariums. Refillable cylinders are the most interesting option in terms of long-term operation. Allows you to reuse them. Divided into . As it turns out, the difference is quite significant for our country. They often don’t want to refill branded cylinders because they are “non-standard”, they don’t have certification, etc. Before purchasing a system with a branded cylinder, make sure you find where to refill it. “Our” cylinders are made according to the standards of our country. Can be certified and tested (gas under pressure... the life of relatives is always more expensive than even the most beautiful aquarium). They are checked and refueled at special stations. There are “carbon dioxide”, “oxygen”, converted fire extinguishers, oxygen from medical systems, etc. In essence, they are the same. They differ in size, shape, weight. Oxygen - have greater wall thickness, since oxygen is under greater pressure and have a greater margin of safety. As a rule, CO2 cylinders are made with a margin of safety and, if properly filled and used, are no worse than oxygen cylinders, and at the same time significantly lighter. A further difference between all cylinders is the valve. In fact, it is a tap with a thread that serves to connect to the “REDUCER” cylinder. The size of the valve thread is important when choosing a reducer, it is not directly related to the volume of the cylinder, but, as a rule, the following sizes are used: 1. Thread 12″ or 21.8mm (W21.8×1/14) – used in carbon dioxide cylinders 0.5-5 liters Most imported cylinders use the same thread (in my opinion, the most promising cylinders). 2. Thread (12 mm - not sure) - used in oxygen cylinders. 3. Thread 34″ or 27.8 mm - standard for “large” cylinders (7 liters or more). 4. Some imported systems may have their own thread size in order to bind the buyer to their equipment. In principle, you can look for adapters between systems.

A thread of one size can easily be converted to another using a special adapter. Advice - if possible, do not use adapters. If “this has already happened”, do not use homemade or tap water ones, but buy a special one for high pressure.

The gearbox, as a rule, is the most expensive element of the system. Purpose – reducing gas pressure to “acceptable” values. Roughly speaking, gearboxes are divided into aquarium and industrial (for beer, welding, etc.). Industrial ones have the ability to very roughly control the gas flow and require additional equipment, such as a “fine-tuning valve”. Among the positive features of industrial gearboxes are their maintainability and “brutality” - they are often not so fragile. Industrial gearboxes come with all three thread types. Aquarium gearboxes are designed for more precise adjustment and a small volume of gas that passes through them. Suitable for connection to CO2 equipment without additional devices. As a rule, aquarium gearboxes are much more compact, but more expensive compared to industrial ones. When buying “our” gearbox, decide what you need from it and immediately try to order it with a hose, a fine-tuning tap and, if necessary, a solenoid valve - so that the seller can connect it all at once

Leak test

To check the tightness of shut-off valves, gas is pumped into the vessel under pressure using a compressor or two cylinders are connected with a hose - the one being tested (empty) and the other filled with gas. The test vessel is filled with gas up to 2 atm, control is carried out using a pressure gauge. Apply soap foam to the threaded connection and open the valve slightly. If soap bubbles do not appear, then there are no leaks, otherwise you need to re-tighten the valve and tighten the nuts.

The test is performed several times in a row, in the open and closed positions, using new foam. It is strictly prohibited to check the tightness with a match or lighter - due to the risk of fire and explosion of the gas-air mixture. It is important to know about the dangerous mistake that users make with left-handed gearbox threads; if, out of habit, they are tightened incorrectly, then leaks will become larger.

Carbon dioxide cylinders 5 l, 10 l, 40 l, according to GOST 949-73

CO2 containers (cylinders) with a working volume of 5, 10 and 40 liters are designed for storage, transportation and technological distribution of carbon dioxide to consumers. New carbon dioxide cylinders must be equipped with:

- Oxygen valve VK, weighing 0.5 kg;

- Rubber transport ring – 2 pcs.;

- Support shoe, weighing 5.2 kg;

- A steel or re-certified cap, weighing 1.8 kg, or a fiberglass cap (safety), weighing 0.5 kg;

- Neck ring, weighing 0.3 kg.

The cylinders are made from the material “Structural high-quality carbon steel” grade 45D or “Structural alloy steel” grade 40KhGSA (cylinders with a capacity of 40 liters).

The body of the cylinder is painted black with the inscription “CARBON ACID” printed in yellow enamel. The weight of the cylinder is regulated without taking into account the weight of the valve, rubber rings, support shoe, safety cap and neck ring.

At the top of the cylinder there should be a “Carbon Dioxide Cylinder Passport”. Passport information is applied using the percussion method. In this case, the surface of the passport must be cleaned to a metallic shine and have an outer border in the form of a strip with an approximate width of 20-25 mm, applied with yellow enamel. The cylinder passport must contain the following information (from left to right along the perimeter of the intended circle):

- Date of manufacture of the cylinder, and the year of the next inspection;

- Working pressure “P”, MPa (kgf/cm2) and process hydraulic pressure “P” in MPa (kg/cm2);

- Capacity in liters;

- Empty cylinder weight in kilograms:

- The serial number of the cylinder and the product brand of the manufacturer;

- Brand of the company that carried out the Technical Examination of the cylinder;

- The mark of the Technical Control department of the cylinder manufacturer.

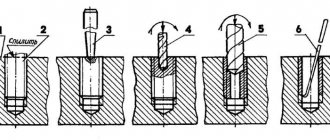

The thread in the neck of the cylinder is cut according to GOST 9909-81, and must meet the following requirements:

- Type – conical;

- The outer diameter in the plane of the neck end is 19.2 mm;

- The number of threads with a full thread profile is 7;

- There should be a thread left on the valve screwed into the neck - 2-5 and 1-2 turns of the visible threaded connection of the valve gland nut;

- The valve is installed on a sealing material, for example, a fluoroplastic sealant - FUM tape;

Gas cylinder device

Before moving on to considering the size and volume of a gas cylinder, it is necessary to say a few words about its design. They all have a similar design - a steel cylindrical vessel, which has a convex bottom, onto which a shoe is pressed or welded, and ends at the top with a neck. There is a conical hole in the neck into which a shut-off valve corresponding to a specific gas is screwed in. To protect the valve from damage, a safety cap is screwed onto the neck.

The body of the propane cylinder is made welded and consists of an upper and lower bottom, which are welded together or welded to the shell.

The welded connection is made on a backing ring, but it is allowed to crimp one of the parts internally.

Propane cylinders with a capacity of up to 50 liters can be manufactured by welding the upper and lower bottoms together, without using a shell. The advantages of this design are the reduction in the number of welds and the labor intensity of manufacturing.

At the same time, there are modifications with a welded collar on the upper bottom, which protects the valve from damage and additionally ensures ease of carrying.