The car frame is the main supporting structure to which other components are attached.

The frame body structure was used on almost all cars in the world until the early 1960s. The first frames were made of wood (most often ash). In the 1930s, wooden frames were replaced by steel frames. Over time, almost all passenger cars changed their design to a “unibody” (see article “Design of a monocoque car body”). These days, frame bodies are mainly used for SUVs, trucks and buses. The longitudinal beams of the frame bear the main loads. Cross members provide resistance to lateral loads and increase torsional rigidity.

Content:

- Types of car frames

- Frame diagnostics

- How to straighten the frame?

- How to cut a frame correctly?

- If the frame is cracked

- Car frame welding

- Welding of high-strength steel frame

- Frame reinforcement

A frame with one layer of metal is used on most small and medium-sized vehicles. Some frames consist of two layers of metal and have an additional beam inside the main beam. This design provides increased strength without loss of flexibility. This design can be used on large trucks. Often double metal is used only on certain sections of the frame. Different manufacturers have their own design and development concepts to achieve the desired frame performance.

The main functions of the frame on a vehicle:

- Support mechanical components and body.

- Take on static and dynamic loads.

- The frame must not only provide good support for the body and its components, but, at the same time, provide flexibility. This flexibility is necessary because a rigid frame is more likely to crack than a flexible frame that can bend and spring back when the load is removed. The torsionally flexible frame also reduces the load on the suspension when driving over uneven roads.

Types of car frames

Types of frames depending on design:

- Ladder frame (so named because of its resemblance to a ladder)

- Frame that matches the perimeter of the car body (classic, similar to a ladder-type frame)

- X-shaped (used in American cars 1950–1960)

- Space frame, a three-dimensional structure made of pipes.

Typical materials used to create a car frame are carbon steel or aluminum alloys (to achieve a lighter weight structure).

In the case of a single frame, it is made of structural members called beams. These are simple structures made of steel profiles of different sections.

- Frame sections can be made from C-section (the most common type of beam).

- Box profile (square pipe)

- tubular sections (round pipe).

Frames may have rounded arches. Thus, instead of rising above the axle shafts, the frame with arches is located lower, approximately level with the axle shafts and goes around them.

Welding turning works

| Welding work (per hour of work) | 700rub |

| Welding work on non-ferrous metal (argon) (for one hour of work or 5-7 cm of seam) | 1800rub |

| Turning work (per hour of work) | 1100r |

| Restoring the beam of a semi-trailer (threaded connection, per side) | 12500rub |

| Restoration of the semi-trailer beam (removal of the deformed part of the axle beam in the area of the stepladders, beyond the side) | 19000-35000r |

| Restoration of the semi-trailer beam (replacement or repair of the brake pad mounting caliper, drum system) | 12000-20000r |

| Restoring the expansion shaft | 1200-3500r |

| Elimination of pin creases (per piece) | 900rub |

| Repair of tractor frame, production of patches, repair of cracked | 8000-15000rub |

| ICE flywheel boring | 2000rub |

| Brake pad boring price per pair | 1118r |

| Brake drum boring price for 1 piece | 1118r |

Frame diagnostics

- If there is a suspicion of frame distortion, then you need to take diagonal measurements between control points (see “Measuring body geometry”) to determine exactly where the displacement occurred.

- For long frame vehicles, there are several methods of measuring the frame to determine distortion. All methods use a straight line as a reference coordinate and compare the frame to that line to determine the straightness of the frame. Methods for determining a straight baseline include using a laser beam, pulling a cord.

- Using a laser is a precise method. The laser is aligned to one end of the frame, approximately 5 cm from the edge of the frame, and directed along the frame to the other end, the same distance from the edge of the frame. A piece of flat material, such as cardboard, is held against the frame. This is done at several points along the frame. The measurements are recorded and, ideally, should be consistent at all points. Deviation will mean the frame is bent. You can also check the height. If it deviates up or down, this means there is a bend in the frame.

- The cord method is a similar method to the laser, except that the laser is replaced by a cord.

- The plumb line test does not require special equipment and is suitable if there are too many obstacles along the frame that interfere with the measurement and are difficult to dismantle. The method uses a plumb bob to mark points on the workshop floor and a string to connect these points. Symmetrical points are selected on the bottom of the frame beams. A plumb line is lowered from the outside of the symmetrical points to make chalk marks on the floor. The dots are connected. All diagonals should intersect the center line if the frame is level. The tolerance for each test depends on the frame size, but 6mm is generally considered the maximum.

Repair cost

In all auto repair shops, prices for frame restoration are calculated individually.

When determining the final price, the following parameters are usually taken into account:

- Nature of damage;

- The need to dismantle existing superstructures;

- Material cost;

- Difficulty performing the work.

However, by paying for the services of professionals, the car owner receives a guarantee of quality. Before performing work, the frame must undergo diagnostics, which allows us to identify any hidden defects and damage that the car owner is not even aware of.

How to straighten the frame?

Most of the energy during a crash is absorbed by the frame.

Depending on the nature of the accidents, the following types of defects may occur:

- Displacement in horizontal and/or vertical plane

- Twisting the frame

- Frame curvature

- Curvature of crossbars

Often, during an accident, several types of damage occur simultaneously. Part of the frame can move both to the side and down at the same time.

If the damage is minor, the frame can be straightened. If the damage is too serious to be repaired, then the damaged metal is cut out and a new one is welded, taking into account the size of the distances between the control points. Welding joints are reinforced with special pads. We will look at how to properly cut, weld and strengthen the frame in this article below.

A damaged frame can cause the body to tilt to one side and cause increased wear on suspension components and tires. The two most common frame injuries are torsion and downward bending (sometimes sideways at the same time). The difference between these two damages is subtle, but important from a repair point of view. Unfortunately, repairing a bend as a twist, or vice versa, can cause additional damage that may be difficult or impossible to repair.

Frame twisting can occur if the car gets into a trench while accelerating. One of the main symptoms of a rolled frame is when the car leans down on one side. In the photo below you can see the severe frame twist seen from the rear of the car. One side of the frame moves down and the other moves up. If this damage occurs, the vehicle may become unstable, especially when cornering and at high speeds. Frame twisting usually occurs only in its central section. In this case, damage can appear throughout the body. After the repair, the edges of the frame will snap back into place as the twisted center section was keeping them in the wrong position. If you do not correctly diagnose the twisting of the frame and correct its incorrectly located individual parts, then you can only aggravate the damage.

The pickup has a noticeable tilt in one part of the body due to changes in the frame geometry.

Another type of deformation is when one of the longitudinal beams is displaced, this also affects the central section. The frame takes the shape of a parallelogram. Such damage can affect the suspension and, when driving, the car will ride at an angle (the front axle may not be in line with the rear).

Frame misalignment can change the position of the suspension.

Measuring the “geometry” of the frame should reveal the extent of its damage. Once the direction and degree of movement of the frame elements is understood, the frame is secured and special stretching equipment is used to return it to its original shape. Hydraulics and chains are used. It is necessary to avoid concentrated impact at one point, placing wooden blocks to distribute the force over a larger area.

The frame has a so-called memory. The metal tends to return to its original position. It is important to correctly “help” it take its original shape and position using pulling devices. Incorrect repair actions cause additional deformation of the frame and complicate the repair.

The main rule when pulling in body repair, which also applies to the frame, is to pull in the opposite direction and sequence to the impact. The deformation must be pulled out gradually, with intermediate measurements of the distances between control points. The sequence is as follows: pull, hold taut and continue pulling again. Do the tightening a little further than the original parameters, since the metal returns a little after the pulling force is weakened.

If the frame has not been heat treated at the factory, it is possible to heat the damaged element to facilitate the straightening process. When using heat, the metal must cool naturally.

Arc welding with electric rivets

Lada 2101 Logbook Repair of master and slave cylinders of clutch VAZ 21011

When welding with electric rivets, in most cases an arc process is used without moving the arc and without feeding the electrode wire into the arc zone. Welding with electric rivets is carried out using portable or stationary electric rivets. As a rule, electric rivets are used to overlap the welded parts. The essence of the process is as follows.

An electrode wire or a rod of electrode wire with a diameter of 3...6 mm is fixed in a special holder-electric riveter with a contact tip and short-circuited on the product at the place where the rivet is placed. Then the entire area around the electrode is covered with welding flux or protected by carbon dioxide supplied to the contact zone. Voltage from a DC or AC power source is supplied to the part being welded and to the electrode through the current-carrying tip of the riveter. An arc is excited, which melts the end of the electrode and melts the surface of the product. The arc burns, melting the electrode, and thus lengthens until it naturally breaks. The resulting molten electrode metal together with the metal of the product forms a rivet during crystallization. The connection with electric rivets is quite strong and looks neater in appearance than fastening with self-tapping screws or bolts.

How to cut a frame correctly?

Do not make cuts or weld across the load.

- Do not make cuts across the beams. So, after welding, no zones with stress concentration are created. The cut can be made at an angle of 45 or 30 degrees, or in a “Z” shape. This will give more area for welding. This way the load will be distributed over a larger seam.

- You must first mark the cut lines of the frame. Use wide masking tape to mark all cuts. You can stick it on and it will be easier to draw on it.

- Avoid cutting the frame on uneven sections such as curves, arches, and valleys.

- Weld, clean the seam to the surface level and then weld the reinforcing plate.

Features of MAZ frame repair

A serviceable MAZ frame is a guarantee of the safety of the driver and passengers of a heavy-duty vehicle.

However, bad roads and increased loads lead to part failures.

Over time, the frame of your truck can crack or burst. Then there is the question of how to straighten the truck frame.

AvtoResurs Group of Companies LLC will help solve problems with truck frame repair.

We will tell you about the structure of the “skeleton” of a heavy-duty vehicle, the most common breakdowns and how to fix them.

MAZ FRAME DESIGN FEATURES

The frame of truck tractors has several differences from similar designs of passenger cars.

Firstly, all the power elements (cross members, spring brackets, etc.) are transferred to the vertical walls of the longitudinal beams.

Secondly, durable low-alloy steel is used in the manufacture of MAZ frames.

Thirdly, the elements do not have rivet connections on the flanges of the longitudinal beams. All this made it possible to more effectively distribute increased loads while the vehicle is moving. Thus, even greater strength and durability of MAZ frames is achieved.

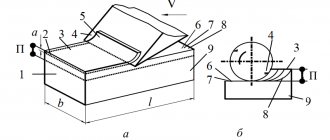

You can study the structure of the truck frame in this figure.

Let's talk in more detail about the design of element 555142-2800010, 555142-2801002-002, 555142-28000010-010.

Basically, most frames for MAZ trucks have the following device:

- 1 and 2 MAZ spars (right and left);

- MAZ frame brackets (3,4, 5, 7, 11,12,13, 14, 15, 16, 17, 18, 20, 27);

- Right support (6), MAZ hydraulic cylinder support (24);

- Crossbar (8, 22, 25, 26);

- Towing fork pin (9) and fork with spring (10, 21);

- Amplifier (28) and bolts (33-37, 41, 46);

- Nuts (38, 39, 43), screws (40), washers (42,44).

REASONS FOR MAZ FRAME FAILURE

Despite the fairly robust design, the element periodically fails.

The most common frame failures are:

- The appearance of cracks in inserts or linings welded to the longitudinal beams of the truck;

- The appearance of small cracks along the holes for most rivets;

- Loosening of rivet connections;

- Concavity of beams (longitudinal).

Naturally, straightening a truck frame on your own is difficult. Therefore, do not allow negligence in the components of your car.

Mostly, malfunctions appear due to increased loads on the truck frame structure. However, if you notice even small chips or cracks on the element, proceed with repairs.

A faulty MAZ frame can cause more serious problems.

MAZ frame repair

Have cracks formed between the spar and the cross members or beams? We recommend welding them using electric arc welding.

However, before this you need to disassemble the frame. To do this, remove the rivets in the cross members that connect the elements to the longitudinal beams.

When repairing a truck frame, use a pneumatic chisel or hydraulic pliers.

If you notice damaged linings on the longitudinal beams that you welded earlier, we recommend restoring the elements as follows.

Cut off a small portion of the frame beam that has welded parts.

Next, attach the additional part, fitting it end-to-end to the MAZ frame beam. Then tack the element by welding at 3-4 points.

Do not forget to place a copper gasket under the joint of the MAZ spare parts.

Then carefully secure it. Next, weld the parts using conventional welding using electrodes with a diameter of 4 mm (before repairing the MAZ frame, study this table).

After finishing the work, remove the slag and protect the seam. Remember that the elevation of the seam above the surface of the truck frame should be no more than two millimeters.

In addition, before welding, dry the electrodes for at least 1 hour at 140-160 degrees Celsius.

For cracks near the brackets or wear of holes, also use an electrode reference.

At the same time, when welding the holes, do not forget to adjust the copper gasket.

We recommend sealing the areas of welded seams with work hardening. At the same time, do not forget that the striker prints should not be solid, since each print must have distinct contours.

After repairing the MAZ frame, the part must meet these requirements:

- The curvature of the top shelf does not exceed 2 millimeters (length no more than 1,000 mm), and over the entire length - no more than five mm.

- The curvature of the vertical wall is no more than two mm (length 1000 mm), and over the entire length of the MAZ frame is no more than 10 mm.

The repair of the MAZ frame is completed.

To do this, inspect the condition of the catch, wash the elements, and tint. Carefully monitor the connections of the crossbars, side members and, of course, the MAZ frame beams.

We will provide you with the best parts. Also, if you don’t know where the MAZ frame number is, call the company’s office.

Thanks to a free consultation, the selection of units will be carried out in the shortest possible time.

Frame cracked

Always try to understand and determine the cause of the crack.

Drill a hole at the end of the crack and bore the crack into a “V” 2/3 of the way into the metal.

After boiling and cleaning, you need to weld a reinforcing pad on top. A common cause of cracks in frames, especially trucks, is metal fatigue. This happens due to cyclical loading and unloading. Cracks often occur at the bottom of beams, as this is often under the greatest stress.

Fatigue is a behavior of a material when a material subjected to cyclic loads may crack. Fatigue is when you bend something several times until the material breaks. Every material has an elastic limit.

Cracks can be repaired by welding, sanding flat and then welding on a reinforcement plate (see below).

Do not weld a patch directly onto a crack without welding it properly.

Order restoration of a truck frame at ILARAVTO

Our service center specialists regularly undergo training at vehicle manufacturing plants in Europe and Russia, as well as from manufacturers of special restoration equipment designed for repairing heavy-duty vehicles. We provide a full range of services for the repair of trailer equipment from Schmitz, Krone, Kogel, CHEREAU, Grunwald, Wielton, MANAC-AUTO and others.

If you still have questions about restoring truck frames, you can contact our specialists by phone: +74957852000.

- Formation of vertical, diagonal, lateral or torsional deformations

- The appearance of kinks, cracks and deflections of the frame

- Displacement of frame side members, etc.

Josam slipway - high-quality straightening of frames of any deformation

The most reliable and modern equipment for straightening trailer frames is rightfully the Josam slipway (manufactured in Sweden). Repairing trailers using this slipway is a modern approach to restoring large vehicle frames. Using the Josam slipway makes it possible to restore almost any post-accident trailer frame. The service station for semi-trailers "Serpri-Auto" has a Josam slipway in its technical equipment, thanks to which the technology for restoring post-accident trailer frames is fully complied with, without changing the metal structure.

Repair of emergency trailers on the slipway

There are several methods for restoring trailers after an accident, among which the technology of straightening trailers using a slipway is considered the most effective and fastest. Thanks to this equipment, it is possible to correct almost any defects and deformations of the trailer, which can be the result of both mechanical damage and direct damage (collisions). Using a slipway, complex repairs of broken trailers can be performed without the introduction of high-temperature methods.

Control and measurement accounting is carried out with a laser tool, which acts as an integral element of the slipway. Using the slipway, the most complex restoration work is performed:

trailers after an accident with varying degrees of damage and deformation parameters of the frame, suspension, transverse ribs of the body part geometry with the possibility of removing dents.

The slipway securely and quickly secures the trailer using wedges, which allows you to start repair work without additional hooks and clamps. Repairing trailers on a modern slipway greatly simplifies restoration work due to pneumatics and powerful braces. All stages of straightening take place taking into account the regulated standards in the Russian Federation for the tempering of metal and its tension after repair of trailer components. Correction and repair of semi-trailer frames.

As a rule, the need to repair semi-trailers arises as a result of prolonged use or after an accident. In the latter case, it is no longer enough to simply align the racks, repair the electrical network and the pneumatic system. If the semi-trailer was also loaded at the time of the accident, the deformation of the frame may be significant. After all, from an impact or as a result of a rollover, the most heavily loaded part of the semi-trailer - the frame - is most damaged. Before the advent of special slipways, severely deformed semi-trailers were written off. Now they can be restored.

Types of frame deformations.

There are transverse, longitudinal, multi-plane deformations of the semi-trailer frame, as well as torsional deformations. Refurbishment of semi-trailers is carried out by qualified Serpri-Auto specialists using specialized equipment - Josam hydraulic stocks, equipped with software and laser meters to control the frame geometry.

As a result, after repair, the semi-trailer can continue to be used, thereby its owner does not have to spend money on a new one.

Semi-trailer frame repair.

The Josam slipway provides reliable fastening of the frame to the slipway, which simplifies its restoration. The movable base platforms built into the frame ensure the installation of even a heavily deformed frame. Its straightening is carried out using hydraulics. Josam power towers are equipped with extended beams that allow straightening of frames of various lengths. The Josam cabaligner measuring system allows you to ensure that the frame dimensions match the factory ones with an accuracy of up to a millimeter. The speed of frame straightening depends on the degree of its damage:

Severely deformed areas need to be kept under load longer. After the repair is completed, the semi-trailer is coated with an anti-corrosion coating and painted.

Car frame welding

- The car contains many electronic modules and control units. They are sensitive to electrical interference that may come from the welding machine. Before welding, remove the negative terminal from the battery. Fuel tanks and pipes near the welding area must be removed. Tubes and electrical cables must be protected from splashes and high temperatures during welding. Paint must first be removed from the welding area. The frame may have a factory wax coating to protect against corrosion. Before starting welding, it is necessary to remove wax from the repair area. Attach the welding compound to the frame, as close to the welding point as possible.

- Do not use oxygen acetylene (autogenous) welding when repairing the frame.

- One of the main rules when welding a frame is to never weld across the load. Vertical welds concentrate the load in only one section of the weld. When the frame bends, the weld can create a stress point that can lead to a crack. Vertical seams will always fail because the load is pulled across the width of the seam instead of being distributed along the length.

- For better penetration, the frame parts to be welded should be prepared in a double "V" shape on both sides. On a double layer frame, the weld penetration should be a single "V" for each layer. It is better not to cut, but to carve a V-shaped groove. Depending on access, when welding, a cooling substrate (made of copper) can be applied to the reverse side. The V-shaped groove on the side opposite the repair must be deep enough to reach the metal that was formed from welding on the other side.

- Once welding is complete, all excess weld metal should be ground flat.

- If a new section is welded to the frame, you need to check the distance between the control points.

- When welding a two-layer frame, when connecting the frame beams, both layers (inner and outer) must be welded in different places, with a minimum seam distance of 30 cm.

- The reinforcing pad is welded when repairing a crack or when joining two parts of the frame, in addition to the main weld (see “frame reinforcement” below).

Seam treatment after welding

All seams must be properly processed after completion of welding work. Metal must be protected from the negative effects of the environment. The connection area must be washed, then sandblasted, degreased, primed and painted.

In conclusion, it is worth noting that welding a truck frame is a process that requires concentration and care. In order for the weld to be as strong and high-quality as possible, the welder must have some experience. Because the frame is an important part on which the safety of driving a car depends. Do not forget about safety and when welding, be sure to wear special protective clothing. If you follow all the rules and requirements, then in the end you will get the highest quality connection.

Welding of high-strength steel frame

- Modern cars may have a frame made of high tensile steel.

- High-strength steel has increased strength, which is achieved during heat hardening.

- Most of these frames require some preheating before welding as they tend to be more susceptible to cracking than mild steel. The metal must be heated evenly throughout its entire thickness by 8–10 cm on both sides of the repair to 100 degrees Celsius. This is important because welding a piece of high-strength steel cold will cause it to heat up too quickly and cool down too quickly. This rapid cooling is the main cause of cracks. Preheating also helps reduce hydrogen levels and minimizes hydrogen embrittlement. The correct preheat temperature is determined by the specific grade of steel and its thickness. Also, the welder must maintain the correct temperature between welding intervals. The temperature can be monitored using a special thermal pencil or contact pyrometer, ideally on the back of the joint, 10 cm from the repair area.

- Cook high-strength steel without lateral vibration of the burner. This will limit the heating of the metal and will not weaken it. Do not weld in a draft or at low temperatures, otherwise the molten metal will cool too quickly, causing cracks to appear immediately after welding or after a few days.

- As with any welding process, controlling travel speed and following recommended welding machine settings will minimize heat stress when welding high-strength steel.

Cold riveting repair

This is the best option for restoring frame structures of trucks. Unlike hot-riveted and bolted joints, this method provides maximum strength by reducing the friction force at the joints. As a result, cold rivets are more resistant to shearing.

The technology for such repairs is quite simple. At the fastening areas, mounting holes are cut into which the rivets are actually pressed. There is no thermal expansion here, which ensures maximum joint density.

Vehicle frame structure

Frame car design

If you carefully consider the design of a frame car, you will understand that the frame plays a huge role in it. It is on it that important components and assemblies of the vehicle are mounted, and how these units will work depends on its reliability and technical characteristics. The frame, in fact, is the supporting system of the car - a kind of “skeleton” to which the transmission, engine and suspension, as well as the body itself, are attached

The frame body makes the car more durable, so it is extremely important to properly care for the frame, protecting it from corrosion and external damage. Frame SUVs include: UAZ Hunter, UAZ Patriot, Great Wall Hover H3, Great Wall SUV, Great Wall Deer, SsangYong Kyron, SsangYong Rexton, Nissan Patrol, Suzuki Jimmy, Chevrolet Tahoe, Mercedes G-Klasse, Toyota Land Cruiser Prado , Land Rover Defender, Mitsubishi L200, Mitsubishi Pajero Sport

This is not a complete list of frame cars, but these models are the most popular among car owners.

What to do if a GAZelle frame bursts?

Professional advice is not to try to fix the defect yourself. The fact is that in makeshift conditions it is impossible to restore the frame to the factory level, therefore, after such repairs, the operation of the vehicle will be unsafe.

If the defect is invisible to the naked eye, it is recommended to diagnose the frame. This will help identify linear deviations and detect internal damage. In situations where damage is obvious, a decision is made to repair or replace. Let's consider several typical situations.

Frame reinforcement for Gazelle 3302 No. 4 for rear shock absorber. a lion. (4mm) L-730mm AZG-Detail

information about delivery

The Gazelist 52 online store ships auto parts from Nizhny Novgorod in the following ways:

Transport companies.

Free delivery is carried out to the transport company terminal in Nizhny Novgorod.

Please check the delivery company’s website for delivery times and costs to your city. The estimated delivery cost is indicated when placing an order.

We strongly recommend that you choose additional packaging for fragile goods; also, at the transport company’s terminal, carefully check the integrity of the packaging and cargo (even if additional packaging of the cargo was not selected); if the packaging is broken or the cargo is damaged, it is necessary to indicate damage to the packaging (even minor damage: a jam, crease, crack, rupture...), demand reimbursement of the cost of the damaged goods, referring to the forwarding receipt, where there are no marks about violation of the packaging of the Goods

(cargo with damaged packaging will not be accepted for delivery), and also

demand insurance compensation according to the declared value (if the cargo is insured)

. Rules for the delivery of goods through transport companies.

Pickup

You can pick up your order in our store at the address: Nizhny Novgorod, Julius Fuchik Street, building 100

.

The order is transferred to the client strictly after receiving an invitation to issue products.

Mon-Fri from 8:00 to 19:00

Sat from 9:00 to 15:00 Sun closed