A dowel for concrete is a type of fastening element. Used for insertion into vertical or horizontal cement-based structures. The concrete mass is characterized by high strength, so the fastening must withstand high loads. They are considering special fasteners that look like a self-tapping screw, but have improved characteristics.

Device

A dowel (another name is a screw) is a metal rod on which a thread is applied. On one side, the fastening element is pointed, which allows it to be inserted into a dense concrete mass. On the other side there is a head with a notch.

Hardware must withstand significant loads of torsion, compression and tension. Such properties are due to the characteristics of the metal from which concrete screws (pins) are made.

Possible options:

- carbon metal;

- stainless steel;

- brass (an alloy of copper and zinc).

The first option is characterized by strength and ductility. However, only high-alloy steels have these characteristics. They are designed for the production of structural and fastening elements that will be subject to significant loads.

Stainless steel differs from its analogues in its ability to withstand moisture. Products made from this material do not rust. They are more affordable in price when compared with some types of fasteners. Hardware is made from stainless steel containing alloying elements.

A concrete screw (nail) made of brass is characterized by high strength, but mediocre anti-corrosion properties. When environmental conditions change, the products do not become brittle, which is important for fasteners.

Despite a number of positive properties of other materials, self-tapping screws for concrete are often made from carbon steel.

Types of hardware

Fasteners differ in color:

- black: with a protective film, the concrete screw (dowel) does not withstand direct exposure to moisture, therefore it is used only indoors with a normal level of humidity;

- yellow: yellow zinc is used in production, such screws are not intended for use outside the premises;

- silver: zinc is applied to products by galvanic means, which makes the fasteners universal.

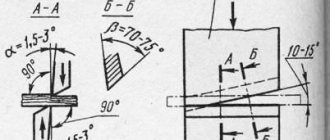

Concrete screws (dowels) are divided into groups taking into account the differences in head shapes:

- secret;

- with a protruding head.

In the first case, it becomes possible to hide the fasteners. In this case, the self-tapping screw is completely buried in the concrete mass. The cap does not rise above the surface. Products with a protruding head remain visible when installed in concrete. Possible types of fasteners, which differ in the shape of the cap:

- hexagonal;

- conical in shape with a slot of different configurations (cross-shaped, in the form of a multifaceted asterisk).

A hairpin or self-tapping screw without a head is considered separately. A nut is loosely screwed onto such an element.

When choosing concrete screws, their dimensions are studied first:

- universal, they are characterized by a length of no more than 20 cm, cross-sectional size of no more than 6 mm;

- with inclined thread, such self-tapping screws are used only in conjunction with dowels; holes are pre-drilled for installation in a concrete mass;

- with intermittent threads, cross-sectional size - up to 7.5 mm, length varies from 7 to 20 cm, this type of product is designed to simplify the process of introducing a fastening element into concrete, but preliminary drilling of the structure is required.

Using a screw anchor

Self-tapping screws come with an intermediate length relative to the 2 main ones - 9-18 cm and from different materials. They are selected by length for each specific purpose for installing fasteners. If you are installing a lightweight and not bulky structure, for example, a bookshelf, choose a 7 cm dowel. When fixing frames for windows or doors, take screws that can withstand the load, respectively, use a longer self-tapping screw. It is better to make a landing opening in heavy concrete using a drill with a diameter 2-3 mm less than the d screw.

If the weight of the fastening element exceeds 100 kilograms, it is necessary to use self-tapping screws from 15 cm, since the speed of screwing into the wall depends on the length of the screw. Pins are used for all types of repair and finishing work for fastening metal and plastic elements, hanging products on light and heavy concrete, and bricks with voids.

Builders note the main advantage of the dowel over other anchors - the load immediately after installation.

Characteristics

Main parameters of hardware:

- outer section does not exceed 7.65 mm;

- thread pitch varies from 2.5 to 2.75 mm;

- internal cross-section reaches 5.45 mm;

- head height does not exceed 3.2 mm;

- cap diameter - up to 11.82 mm;

- if there is a head, a slot is always provided;

- the length of the fastening element varies over a wide range, the upper limit of which is 184 mm;

- the hole for the screw is always smaller than the external cross-section of the fastener;

- the depth of the holes in the concrete mass is 1.5 cm greater than the length of the hardware;

- The minimum permissible distance between adjacent screws is also regulated; when installing fasteners in the most durable material (concrete), it is allowed to leave at least 3 cm between the holes.

Rules for using concrete screws

The correct sequence of actions during installation:

- Determine the required installation parameters when applying the product.

- Transfer the resulting installation dimensions onto the plane.

- Drill a hole with a margin of a couple of mm, taking into account the concrete dust that collects when screwing.

- Remove any residue from the hole.

- Install the element in place of fixation.

- Use a screwdriver or screwdriver to insert the self-tapping screw into the plane.

Due to the cross-shaped notch, you can use a screwdriver for installation. Screws with dowels and the hardware itself with herringbone threads are inserted if large loads are expected. A dowel with a variable thread does not require the use of a dowel. You can install parts or products after tightening them by placing them on the head of a cylindrical screw.

«>

How to choose the right dowel

When you plan to purchase concrete screws, the application (intended purpose) of such fasteners is one of the criteria. This is due to the fact that the parameters are determined by the material and the type of thread of the hardware.

Criterias of choice:

- the type of structure, the material from which it is made, while considering different screws that differ in properties, type of coating, for example, to fix heavy structures of more than 100 kg, products with a length of 150 cm are used;

- choose products according to the type of head: protruding, hidden;

- The type of slot also plays a role, and you need to choose the right tool;

- a type of thread, which determines the method of installing hardware (with dowels, in a finished hole, etc.);

- operating conditions, some types of fasteners are negatively affected by moisture.

Briefly about the main thing

Self-tapping screws for concrete are universal. With their help, you can attach interior items, household appliances, communications, finishing materials to the concrete surface both outside and inside. Externally, they have the shape of a screw and differ in a number of parameters:

- Material.

- Type of protective coating.

- The shape of the head part.

- Type of thread.

When choosing for specific application conditions, it is necessary to correctly calculate the load, take into account corrosion factors, as well as how the fasteners will be combined with the finishing design and what its final cost will be. During installation, a number of rules must be observed, including safety regulations.

Wall mount

For concrete, the screw selected is short enough, since the recommended depth for inserting hardware into such structures is 45 mm. For comparison, the holes in a brick wall are deeper - up to 55 mm. For cellular concrete, a depth of up to 75 mm is recommended. The less durable the material, the larger the fastener should be. Screws are placed using the same principle. If the structure of the material is loose, then holes are made in the wall into the structure as far apart as possible.

When studying the question of how to use such fasteners, it is necessary to assess the condition of the structures. Strength is ensured if the wall does not collapse. Concrete should not crumble; if there are cracks, the reliability of the structure is reduced. In this case, the use of the largest dowel will not provide the required result.

When work begins, determine the area for installing the first screw. For example, it is necessary to deviate from the corner by at least 60 mm. If you break this rule, the strength of the fastening will decrease. Under the influence of significant load, the structure will begin to collapse. This will lead to the collapse of the element, which was fixed with a screw in the concrete.

Recommendations for using the dowel:

- work is carried out according to a pre-drawn up project;

- markings are made on the structure;

- prepare the holes, and it is necessary to ensure that the cement does not crumble, and there should be no chips;

- if the material is porous, it is impossible to put pressure on the tool when inserting a screw into the concrete mass, since there is a risk of damaging the structure, as a result the screws will not hold, the structure will deform over time or immediately as soon as increased pressure is applied to the fastener .

During the work process, there are many nuances that should be taken into account.

Installation begins with preparing the tool. You will need a screwdriver, drill or screwdriver, concrete screws, hammer drill, and a container filled with water.

Instructions for performing the work:

- To prevent chipping, you need to clean the surface. If the structure has defects, you can level it using cement compounds and plaster.

- The load on the fastener is determined. Based on this, drills of the required length are selected.

- Work begins after marking the site.

- Concrete is a dense, durable material. The tool will get hot when drilling. To cool it, water is used. An alternative option is oil.

- If it is not possible to drill the concrete to the required depth, use a hammer. You need to hit the head with the screw several times. However, this method is used when the fasteners will not be subject to significant load.

Safety precautions at work

Equipment for drilling holes is characterized by complex operation and significant weight. You need to work with it carefully. In addition, as holes are made in the concrete for the dowel, solid particles fly in different directions.

To protect yourself, you need to follow the rules:

- You should not work with power tools while wearing gloves, as the material may get caught on the drill, which will lead to injury;

- use safety glasses, clothing should be closed, which will avoid injury from concrete splinters;

- the drill is periodically cooled - immersed in water;

- There should be no children or animals near the area where the work is being carried out.

If dust or solids get into the eyes or mucous membranes, rinse with running water and consult a doctor.