Fencing made from corrugated sheets is distinguished by durability, speed of assembly, and aesthetics. Because of these advantages, it has gained popularity when arranging dachas, country houses, and private sector estates. But to install a high-quality structure, you need to be able to properly attach the corrugated sheet to the fence. This assembly stage has important points, which we will discuss in this article.

Features of fastening corrugated sheets depending on the material of the pillars

Before purchasing corrugated sheets, you should select the raw materials, type of coating, and color in advance. In addition, you need to calculate the number of sheets and fasteners for them. You will find detailed recommendations for choosing sectional material here:

- What kind of corrugated sheeting is used for fences

- Fence made of metal siding under timber

After this, you can begin construction. Having determined the location and completed the markings, they form supports for the future fence. The method of attaching the corrugated sheet depends on what material they are made of.

Brick

Creating brick pillars is a labor-intensive, long and expensive process due to the high cost of the material. But ready-made supports do not require additional finishing, and if masonry technology is followed, they will last for decades.

Article: laying pillars for a brick fence

They screw the corrugated sheet onto the fence with such posts not onto the brick, but to special metal lintels.

Tree

Inexpensive option for supports. The frame is assembled quickly, so you can easily handle it alone.

But builders do not recommend using wood as posts for a permanent fence made of corrugated sheets. Even with careful care, the fence is unlikely to last more than 5–8 years. It is better to install such racks under temporary fences.

We recommend reading the article: “Installation of wooden fence posts.”

To properly attach corrugated sheets to wooden posts, you must first fix the metal corners and then use self-tapping screws. An alternative is to immediately mount the sheets to the joists with self-tapping screws, but this option is inferior in strength to the first.

Metal

The most reliable type of supports for corrugated sheets.

The only caveat is the need to coat the poles with an anti-corrosion solution to protect the metal. For aesthetics, it is recommended to paint the support. An article about the procedure for installing metal poles.

There are two ways to attach logs to racks:

- Welding. The crossbars are welded strictly horizontally between the posts or in front of them on the street side of the fence. The frame is more rigid and stable in the first case.

- Cross-shaped brackets. They are plates with curved edges that are attached to the joists with self-tapping screws. This option does not require welding.

If you have no experience in welding, then it is better to use the second type of installation.

How to choose the right material

All corrugated sheets are conventionally divided into several classes, which are designated as follows:

- N - used only for permanent coverings, floors and formwork, it is considered the most suitable option;

- C – intended for walls, it is often used when installing fences;

- NS – combined, it can be used for fencing or flooring.

It is very important to choose the most suitable brand. It is clear that N is considered the most reliable and durable among all, its thickness is not too large, there are several additional stiffening ribs, and the corrugation itself is quite high

NS is also sometimes used for laying roofing, but this type is more suitable for roofs that are not subject to heavy loads. The cost of brand N is slightly higher than C or NS, but all costs are quickly justified by the durability of use.

Profiled sheeting N can withstand enormous loads, so it is possible to increase the step between the sheathing strips. It turns out that you can use less fasteners and it will cost much less.

When talking about deck thickness, there are a few things to consider. If the roof has a fairly high pitch angle, then it can be covered with NS sheets, because they are a little thinner and cost much less. However, if the roof is quite flat, then it is better not to save money or take risks. With a flat surface, the load on it increases significantly, so the larger the waves and the thicker the profile, the safer the entire structure will be.

Sheet fastening schemes

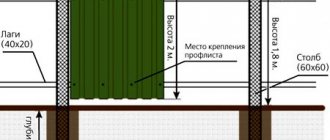

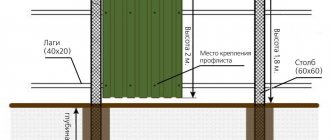

Below are diagrams of the correct installation of corrugated sheeting to metal and brick pillars, an example of installation of sheets when creating gates, wickets, photos of fastening the material when the fence is on a slope.

Self-tapping screws (self-tapping) for metal with a metal washer and rubber seal

A self-tapping screw (commonly a self-tapping screw) is made in the form of a rod with a tip resembling a drill, a triangular thread and a head for a wrench or a screwdriver. In addition to screws with a drill tip, screws with a sharp tip are produced. To fasten the corrugated sheet, complete with a screw, use a press washer and a rubber sealing gasket.

- for attaching corrugated sheets to metal surfaces;

- with steel thickness up to 12.5 mm;

- without pre-drilling holes;

- for installation of corrugated sheets on roofs, for cladding facades, pediments, making gates, wickets, etc.

- for fastening sheets to tool and high-carbon steels;

- for binding metal profiled sheets together;

- for fastening to wooden structures;

- for fastening to metal less than 1 mm thick.

We select reliable fasteners

There are several ways to fix sectional material to the fence frame:

- self-tapping screws;

- bolts and nuts;

- rivets;

- welding

Let's look at the features of each of them and determine the most reliable one.

Self-tapping screws

To secure fence sheets, roofing screws (hardware) are often used. They are made from steel type C1022, which is highly durable and has a protective anti-corrosion zinc coating 15 microns thick.

Photo: color scheme of roofing screws

They consist of 3 parts:

- Drill. Using it, the element is screwed into the corrugated sheet.

- Rubber gasket under the press washer. Located under the cap itself. Ensures the tightness of the fastener and prevents moisture from penetrating the sheets at the points of fixation.

- Heads (hats). It is covered with a durable layer of polymers, due to which the self-tapping screw becomes resistant to environmental influences. The colors are different and matched to the sectional material. This way the hats become almost invisible against the general background of the fence. Shapes – round, hexagonal, cylindrical, semicircular.

Hardware is produced with a diameter of 4–6.5 mm and a length from 19 to 250 mm.

It is most convenient to screw in the screws with a screwdriver.

Photo: the process of attaching corrugated sheets to joists using a screwdriver

To calculate the required number of elements, you need to divide the total area of the sheathed fence (including overlaps) by the area of one sheet. Builders recommend doubling the number of hardware near the ends for greater fastening strength.

The average consumption of self-tapping screws is considered to be 8–9 pieces per 1 square meter. m.

When screwed in, the fastening element must be strictly perpendicular to the sheet without distortion.

To assemble fence sections, it is allowed to use hardware for metal tiles.

Bolts

This fastening method is as strong as self-tapping screws.

Photo: securing sheets to the profile using bolts. You should first drill holes for the diameter of the bolt.

In addition, if the hardware can be easily unscrewed with a screwdriver and penetrated into the fenced estate, then the bolts can only be removed from the inside of the yard. But their price is several times higher than self-tapping screws, and the color range is limited to black and silver, which significantly sets them apart from the general sectional covering.

It will not be possible to do the fastening work using this method alone, since the sheet will have to be attached to the frame in advance, mark the hole for the bolt, drill it, and only then fix the corrugated sheet to the joists.

The average norm for 1 sheet is 4 pieces.

Rivets

Provide a strong connection between the corrugated sheet and the fence frame. Consist of two parts made of different metals:

- hats made of aluminum;

- legs made of steel.

Hats are:

- colored;

- unpainted.

Diameter – from 3.2 to 6.5 mm. Fastening is carried out using a rivet gun.

Photo: metal rivet for a manual rivet gun

The average consumption of elements is from 6 to 8 pieces per 1 sq. m.

With this method of fixation, you do not need to drill through the profile to get a strong connection; it is enough to make a hole in only one side of the joist.

When choosing rivets, it is important to consider the weight of the sectional material. The larger the diameter of the rivet, the stronger the fastener.

You also need to pay attention to the length of the purchased elements. It should be selected so that the tip of the rod is visible above the fixation site by at least 10 mm. It will not be possible to achieve this with a lower rigidity index.

What to do before installation

Before you begin installing a metal profile roof, you need to do some more work, namely:

Fastening the roofing sheeting with self-tapping screws.

Calculate the material. To determine the number of sheets, it is necessary to measure the roof slope, its sheathing, and diagonals. When performing all calculations according to the drawings, it is necessary to duplicate all measurements to take into account the error if the roof has a non-rectangular shape. It works best if the length of the corrugated sheet corresponds to the slope, then you will not have to provide additional sealing, and the fastening of the metal profile itself will be less labor-intensive. During measurements, it must be taken into account that all profiled sheets located in the first row must protrude 4 centimeters beyond the cornice. Provide waterproofing and ventilation. Before fixing the corrugated sheeting, it is necessary to ensure proper waterproofing by installing it along the entire sheathing. Laying a waterproofing layer is necessary to avoid the formation of condensation or leaks. Ventilation is installed to prevent moisture from accumulating. There can be no exceptions here; ventilation with waterproofing must be arranged regardless of the steepness or flatness of the slopes. Leave 2 centimeters between the waterproofing layer and the corrugated sheet. To do this, several slats are laid on top of the waterproofing.

It is important to place them so that this layer of air can be ventilated freely from the eaves itself. Choose a sheathing. Before starting work, you need to consider a very important point

If various additional elements are located in the roof itself: chimneys, ventilation shafts or fire hatches, the sheathing around it must be reinforced with additional bars. There are no standards regarding sheathing thickness, so it is possible to use many different combinations, which are affected by the length of the screws or corrugated sheeting. The main thing is that the cross-section of the bars is no less than 32x100 millimeters. The board that goes along the very eaves must be much thicker than the upper bars.

Why you shouldn't use welding

Craftsmen do not recommend installing sheets by welding due to high temperatures. Accidental thermal exposure will destroy the protective layer of corrugated sheeting and lead to further corrosion of the material, and in the absence of experience, you can completely deform the section or make a hole in it.

If the fence is needed as a temporary structure and quickly, then all welded metal elements are cleaned, treated with an anti-corrosion solution and painted.

Characteristics of metal profiles

Key positive factors when using metal profile roofing:

- low specific gravity;

- increased safety due to fire resistance;

- corrosion resistance due to polymer and oxide coating;

- wide range of colors;

- mechanical strength;

- range of sizes;

- affordable price.

Metal profiles are produced with a thickness of 0.4 to 1.0 mm from galvanized steel with or without polymer coating.

Three labeling options are used depending on its purpose:

- C – wall profile. Used for fences, partitions and walls, as well as for light roofing. Wave height 8-44 mm;

- N – profile for load-bearing structures. Used for permanent roofing and interfloor slabs. Wave height 57-114 mm;

- NS is a universal profile for roofs and walls. Wave height 35 and 44 mm.

If the length of the roof slope requires the installation of sheets in several rows, then before attaching the metal profile to the roof, it is necessary to determine the overlap of the sheets.

The horizontal overlap is made on the sheathing and depends on the angle of inclination of the roof slope:

- with a roof slope angle of 12-15°, the minimum required overlap is 200 mm;

- with a tilt of 15-30°, the overlap limits are 150-200 mm;

- in the case where the slope of the roof slope is more than 30°, the overlap can be 100-150 mm;

- If the roof slope angle is less than 12°, the vertical and horizontal overlaps should be sealed using silicone or thiokol sealant.

The vertical overlap is made in half a wave for steeper roofs, one wave and two waves for flatter roofs (the recommended overlap must be checked with the manufacturer).

Connection methods and installation procedure for corrugated sheets

Performed in two ways:

- Butt. Each sheet is individually attached to the fence joists. Most often, the fastening elements are self-tapping screws in the amount of 5–6 pieces per 1 sheet. Additional screws are screwed at the bottom to increase strength. Mounting holes are pre-drilled. They should be slightly larger in size than the diameter of the screw. In places where the sheets join, flashings are fixed.

- Overlapping. The most durable installation method. The amount of overlap of the corrugated sheet is one wave (profile bending). The hardware is tightened until it fits tightly to the material. As in the first case, holes for self-tapping screws are drilled in advance, after which it is recommended to treat them with an anti-corrosion compound.

It is important to note that, regardless of the chosen method, holes for hardware are drilled strictly level, adhering to a straight line. This ensures smooth fastening of the sheets to the fence frame.

In addition, it is worth considering the following points:

- To speed up the assembly process, make marks with a marker or chalk at the points where the screws will enter the sheet.

- First you need to secure the edges of the corrugated board, check the verticality and then proceed to fixing the intermediate screws.

- If the logs are wooden and the hardware rotates during installation, then it is permissible to stuff a small sliver of wood into the fastening area.

- To cut sheets, use metal scissors or a jigsaw. It is not recommended to use a grinder. Sparks during operation of the tool damage the protective coating of the material, causing the sheets to begin to corrode.

Upon completion of installation, corner joints and ends of the material can be processed. It is better to cover them with a metal strip of the same color as the fence, placing them on hardware in increments of up to 30 cm.

Advantages of metal profiles

The advantages of products made from metal profiles, in comparison with wood, plastic, ceramic and other analogues, have allowed them to become the main building material in their segment. The following positive properties of the material are distinguished:

- Reliability, durability and strength. These qualities of the metal were inherited by products made from it. In addition, frame materials are distinguished by the presence of stiffeners, and sheet panels have a metal thickness sufficient to withstand significant loads.

- Resistant to corrosion, sunlight and other external influences. Almost all products that are intended for outdoor use have a protective coating made of zinc or polymers. If it is not damaged during transportation or installation, the metal profile will last for decades without losing its original appearance.

- Convenience and ease of installation of metal profiles. Fastening metal products does not require special knowledge. Any craftsman who knows how to use universal tools can handle this work: a screwdriver, a grinder, a hacksaw.

- Price/quality is the best indicator among analogues. Low cost with all the variety of choice distinguishes metal profile products from alternative options.

Installing the top decorative strip

The finishing touch to the construction of a fence made of corrugated sheets. A special strip is attached to the upper part of the structure with self-tapping screws. The color should match the fence.

Photo: corrugated sheet fencing with a welded strip

Its main purpose is to strengthen the strength of the frame and give the fence a finished look.

Compliance with the technology for installing corrugated sheets allows you to create a reliable fence with your own hands in a short time, saving money on ordering the services of specialists.

How a video can help when installing a galvanized profile under drywall

More recently, the installation of gypsum boards was carried out on not entirely reliable wooden blocks. Making connections in such a design was a very difficult process. Today's metal frames are much more reliable, they are easier to assemble due to the wide selection of hardware components available for them.

At first glance, a novice developer may have many questions, including how to connect several drywall profiles or how to assemble a two-level frame with your own hands. Not only books on construction, but also video materials prepared by experienced craftsmen will help you solve your problems.

Having studied such tips in detail, every more or less capable person will be able to do both simple room renovations and complete complex home improvement projects. In addition to creative pleasure and experience, you will receive tangible financial savings.

Is it possible to attach corrugated sheeting to shell rock (limestone, brick)?

We mount the sheets directly to the wall made of stone or brick using dowels and anchors. To install, pre-drill holes in the metal. We select fastener heads with a monolithic wide washer. The shape of a plastic insert with a shimmer that serves as a seal. We make the hole in the corrugated sheet 0.5 mm larger than the diameter of the insert.

- For quick installation, use dowels with impact screws. They differ from traditional screws and screws in the shape of the thread. Disadvantage: if struck, the surface of the sheet can be damaged.

- Do not attach sheets to surfaces with protrusions or uneven surfaces.

Briefly about the main thing

Special self-tapping screws for fastening profiled sheets are used not only during the construction of fences, but also when covering roofs, finishing facades, and constructing partitions. Such hardware is made mainly with a hexagonal head. Their design also includes a sharp drill tip and a washer with a high-quality rubber gasket.

Fastening elements are durable self-tapping screws made of alloy steel. They simplify the installation process; they can be tightened with a power tool or a wrench. The fasteners are made with galvanic coating. Only experienced craftsmen can screw it in quickly and correctly.

To secure 1 m² of corrugated sheeting, approximately 4 to 8 hardware are required. It is recommended to use only fasteners with markings and an EPDM gasket no thinner than 2 mm.

How to cover the bottom of the fence?

During construction, it is undesirable to leave a gap between the fence and the ground, since the profile is susceptible to corrosion, and the fence itself becomes less stable. To cover the bottom of the profile sheets, you can:

- Fill the cracks with soil or crushed stone. To prevent animals from undermining the fence, it is recommended to first dig a ditch 10 cm deep and fill it with a compacted layer of crushed stone;

- Another simple way is to close the space using a chain-link mesh, slate scraps or corrugated sheets;

- The most labor-intensive option is brickwork or a monolithic concrete base, for which you will need to make a foundation of concrete and a metal frame.