A good handyman always has a variety of different tools at home, each used for a specific task. One of the most famous tools is end cutters or any other type. People often talk about the purposes for which this tool is used, and almost everyone already knows its main purpose.

Any wire cutter is used primarily for cutting wire. The basis of the tool's operation is the principle of leverage. With the help of the best cutters, you can reduce the amount of effort required when cutting various materials to a minimum. It turns out that you don’t have to put in almost any serious effort to cut the wire.

It will not be possible to do without this tool if there is a need to make small cuts, for example, on plastic.

Often, without tools, it will not be possible to perform installation/disassembly of any equipment.

If you have, for example, side cutters at home, then without any special physical effort, you can cut any wire yourself without any problems.

In order to quickly cope with such a task as cutting a cable, you only need to keep the main wire as close as possible to the hinges of the tool.

Types of nail clippers

There are three types of cutters based on their functionality:

• for the cuticle (cuticle). They are sometimes called nippers or cuticle nippers; • for fingernails; • for toenails.

Nippers for cuticles and rough skin of the side ridges are a must-have tool for trim manicures, as well as some types of combined manicures.

Fingernail clippers are an alternative to nail scissors. These pliers are larger and stronger than nail clippers and are used for working on hard and rough nails. Thanks to the powerful blades (10 to 15 mm long), they can treat ingrown toenails with minimal pain.

Pedicure nippers are distinguished by more powerful cutting edges (15-25 mm), as well as a reinforced design and greater strength. This allows you to work on rough and ingrown toenails without crumbling or crushing them.

What to choose - wire cutters or scissors?

It depends on situation. For example, you can treat the cuticle with either method; some masters prefer to do this with cuticle scissors. But scissors may not be able to cope with rough, ingrown or aging nails. In this case, wire cutters come to the rescue. The main thing is that they are of high quality.

What it is?

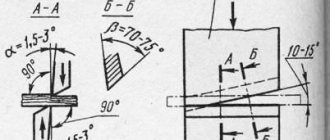

The main difference between side cutters and end cutters is that the jaws of the cutters are perpendicular to the handle, while the jaws of the side cutters are parallel or at a slight angle.

The main characteristic of the tool is the length of its jaws. As a rule, mini side cutters have blades that are 10-15 mm, which is quite enough for stripping wires and similar products. But the best side cutters, which are intended for processing large objects, can have a jaw length of 25-30 mm.

If you need high-quality side cutters, the price of which provides the opportunity to save money, you should use the catalog of the Anchor24 online store to purchase them.

What kind of lighting do you prefer?

Built-in Chandelier

How to choose nail clippers?

What does it say about the quality of the instrument? First of all, this is the material from which it is made.

Nipper material

An excellent option is a stainless steel tool. It will withstand any disinfection and sharpening. And the cobalt coating makes it more resistant to chemical and thermal sterilization. Therefore, popular manufacturers of professional tools often recommend stainless steel cutters with cobalt coating.

One of the signs of the manufacturer’s integrity is the indication of the metal grade on the packaging. If it is, most likely you have a quality tool in front of you. The most common steel grades: 30Х13, 40Х13, 65Х13, 95Х18. By the way, glossiness and matteness do not affect the properties of the metal in any way, so between glossy and matte nippers, choose the ones that you like best.

Tool design

Tweezers differ not only in function and material, but also in the components of the tool. Let's start with its upper part, which is called the “head” of the cutters. Here we are interested in the “heel”.

What is a heel and what should the blades of the nippers be like?

The heel is the protrusion of the cutting part of the tweezers relative to the hinge joint. Its height affects the depth of the cuticle and skin around the nail.

This means that nippers with a heel can capture more of the cuticle and skin than those without a heel. They are best used for treating rough leather. If the client’s skin is thin with closely spaced vessels, it is better to use an instrument with a small heel or without it.

It is also recommended for beginners to use nippers without a heel, since it is more difficult to control the cutting progress, and this increases the likelihood of grabbing too much and damaging the skin. For beginners, it is better to choose a tool with a minimum projection angle.

What else is worth paying attention to? The shape and size of the cutting part and the length of the blades are important. The cutting edges must be sharp, smooth, without chips, dents or nicks. The blades should be identical and close tightly from tip to heel without gaps, have a sharp nose and converge in front to one point. This can be checked by doing a light compression with the spring removed.

The shape of the blades depends on the angle of inclination of the cutting edges. The length of the blades varies: from 4 to 20 mm. If you are looking for nail clippers for yourself and your nails are small and narrow, then clippers with 4-6mm blades will suit you. If you have little experience with wire cutters, also choose a tool with a shorter blade length, this will reduce the risk of injury.

What should the hinge mechanism be like?

In addition to the “head” of the pliers, their “joint” (or lock) is important to us for quality work. This is what the hinge joint is called.

The joint is a part of the pliers, consisting of two halves connected by a rivet. The strength of this part of the tool ensures its long service life. If the lock is defective, no sharp blades will save you, you will have to change the tool.

In the area of the hinge joint, the tightness of the elements is important. To do this, we need to evaluate the wings of the joint from the side. The seam in this place should not have large gaps or irregularities. The parts should be located close to each other, this will ensure the reliability of the tool. If everything is in order with this component of the nippers, they will probably last a long time.

Before purchasing a tool, be sure to move its handles in different directions to make sure that there is no play between the parts of the joint. In this case, the blades should not move, and the springs should be in the non-working position. If during such a check there are no clicks, this indicates good quality of assembly and that the cutters will not fail during operation.

What should the spring mechanism be like?

The spring mechanism of the cutters can be presented in the form of one or two springs or in the form of a spiral. Nail industry professionals advise giving preference to a mechanism with two springs; in second place in terms of practicality is the spiral version, in third place is the single version.

Often manicurists work without springs at all, but it is difficult to remove them yourself at home.

How long should the handles be?

It is very important that the tool fits comfortably in your hand, so the size of the handles should correspond to the size of the brush. For example, for craftsmen with small brushes, pliers with standard or slightly longer handles are suitable. If your fingers are thin, pay attention to handles with attachments, this may be your option.

Important! Choose a tool whose handle does not pop out when closed.

Comfortable handles bring us to the next criterion for choosing a tool.

Smooth ride

When checking the operation of the hinge mechanism, make sure that the handles do not bounce when pressed and pressed, otherwise you may injure yourself or the client. Tweezers should not work jerkily or jam during squeezing and unclenching.

It is important that the handle does not rest against the central part of the hand. It should go slightly beyond the center, come out from the depths of the palm, otherwise in the future it threatens rapid fatigue and discomfort, squeezing blood vessels and nerves.

Important! If the wire cutters are too tight, don't expect to work them out and it will go away. Take those you feel comfortable with right away.

The nippers should have a smooth and soft stroke, but not “loose”. To do this, pay attention to the spring. A double spring is considered smoother, but single springs are less likely to break.

Sharpening quality

Another very important criterion. If the tool is not sharpened well, it will tear and pull the skin. If the nippers are well sharpened, they will cut it smoothly. This tool will serve you for more than three years. For high-quality sharpening, use a diamond disc.

How to check the wire cutters according to this criterion? Ask the store to cut through the plastic film with tongs. If they pass your test, you can safely choose this model.

Tips for quality sharpening

With constant use, the tool may become dull. You can take it to a workshop, or you can try to sharpen it yourself.

Before starting sharpening work, you should make sure that the cutting edges occupy the same position under any load. In other words, so that there is no gap between the hinge hole and the axle (or backlash, as it is also called). If such a problem exists, then it needs to be corrected. In the middle of the end it is necessary to make a hole with a drill measuring two times smaller than the diameter of the axis. Using gentle blows of a hammer, you need to push the metal apart.

If the metal in the axle is strong and the previous method does not bring success, you need to use a sharp center punch to make several shallow depressions at the end of the pliers with a gap of two millimeters and a millimeter of indentation from the edges. A hammer is also used here. You should hit carefully so as not to disrupt the ease of movement of the tool.

A file is used to grind off excess metal from the blades. Sharpening is best done using an abrasive rotating wheel. For a good result, you need to use only a smooth circle of the correct shape, otherwise you won’t be able to do the job well. If the circle is uneven, then you should either grind the existing one or use another one. You need to use both the end of the circle and its cylindrical surface. Then the sharpening will be of high quality. The metal must be removed carefully to ensure precise alignment of the cutting edges.

To increase the service life of the tool, proper operation is necessary. It is not recommended to cut thick wire or other solid iron materials with a tool that is not designed for such loads. Wire cutters are commonly used for cutting aluminum and copper wires. Other metals need to be cut with special reinforced nippers. Conventional ones can quickly fail when cutting steel or other metals.

Which brand of wire cutters is better?

Now you know what points you should pay attention to when choosing cuticle and nail nippers. Their choice is quite wide, how not to get lost in this variety? There are several brands that have already established themselves as manufacturers of high-quality and durable tools; we settled on three.

Among the most popular brands of professional manicure instruments are Yoko and Metzger. These are the nail clippers that nail technicians prefer.

"Stalex"

A popular brand with a wide range of nippers. “Staleks” manicure clippers are made of stainless steel, are distinguished by professional sharpening, stylish design, easy and smooth operation during operation.

Yoko

The tools of this brand are durable and wear-resistant. Yoko manicure clippers are resistant to any type of disinfection and sterilization. Many models are sharpened by hand.

Metzger

Metzger wire cutters are made of high quality steel. They are resistant to thermal and chemical disinfection and can also be processed in a sterilizer.

No matter how luxurious the instrument is, it must be stored and handled correctly.

Pliers

This instrument comes from our childhood. A large encyclopedic dictionary of technical terms defines pliers as a hand-held metalworking and assembly tool equipped with pyramidal jaws of rectangular cross-section, used for gripping and bending small metal parts . From the definition it is clear that with pliers you can:

- hold an object (metal strip, washer, nail, electrical wire);

- bend a metal strip or wire.

That is, their main purpose is capture and manipulation. The tool can only hold and bend. It is not for nothing that among its many relatives - pliers - the tool is now extremely rare in store windows. Domestic pliers must comply with GOST 7336-93, according to which they are:

- With short (25–55 mm) or long (50–63 mm) jaws. By the way, the criterion for belonging to one type or another is not the length of the jaws, but the ratio of their linear dimensions to the dimensions of the clamping handles.

- With plain or insulated handles. The latter are manufactured in accordance with GOST 11563-94, which regulates the requirements for hand tools for performing work under high voltage.

Dimensions of manufactured instruments: 125–220 mm (total length).

Domestic tools are made from tool carbon steel U7A with volumetric hardening up to 45 HRC units. Decorative coating for protection against corrosion is applied in one of 3 ways:

- Chemical oxidation. The color of the coating is dark gray with a black tint.

- Chemical phosphating. The surface of the instrument is matte gray, in various tones (from light to dark gray).

- Chrome plating. This coating is the most durable and corrosion-resistant.

How to care for nail clippers

To ensure that your manicure is always of high quality and safe, and that the tool lasts as long as possible, there are a few simple recommendations.

The working process

- When working, always place the tweezers with the cutting part facing up. Do not throw them with the sharp blade facing down, this will avoid scratches and nicks.

- Before starting work, grab the tool with your palm on top, then turn your hand over. The index finger should be under the running gear and not too close to the blade, and the thumb should be on top of the running gear. The remaining fingers should be located along the line of the left handle (for left-handed people - vice versa).

- Always position the pliers with the blade facing away from you and the client to avoid accidental injury.

Care, sterilization and storage

- Store your cutters in a protective silicone or plastic cap and case. After sterilization, place them in a craft bag. Never store metal tools in damp or damp conditions. The recommended indoor temperature according to SanPiN is from 21°C, and humidity is 40-60%.

- Each instrument has its own individual characteristics. When disinfecting and sterilizing, be sure to follow the manufacturer's recommendations so that the instrument lasts longer. Pay attention to the proportions for preparing the disinfectant solution, the recommended exposure time in it and the temperature during heat treatment.

- After sterilization, it is recommended to lubricate the nippers with oil - 1 drop on the contact surfaces.

Sharpening

- If the tongs become dull or fall with a sharp edge onto a hard surface, they must be immediately sharpened or repaired to restore the geometry of the head, blades, and joints.

- If you work in a salon, it is recommended to sharpen the tongs at least once every six months to a year, depending on the flow of clients. When used at home, a professional tool can last about 3-5 years without the need for sharpening.

- Give the nippers to a specialized service; do not experiment with sharpening at home. This can damage the instrument, sometimes beyond repair.

Follow these rules, and you will be guaranteed long-term comfortable work with pliers.

Now let’s sum it up in a short checklist! Imagine that you come to a store of tools and materials for manicure. These simple questions will help you make the right choice.

Pliers. Everything is captured

If you put pliers and pliers side by side, the difference will become noticeable. Next to its humble relative, the pliers look more solid and are capable of more in their work. If you can only lightly grab the object being held with pliers, then pliers will clamp it much more securely. This works especially well when gripping cylindrical parts (rods, studs, bolts), thanks to the jaws, which are equipped with special recesses with a large notch . Some models have two pairs of grooved grooves of different depths, and sometimes they make an additional semicircular groove located on the side of the handles (can serve as a crimp). The ends of the jaws are flat and equipped with the same notches as those of pliers. Sometimes pliers are equipped with additional corrugated elements made on the inside of the handles, next to the hinge, resulting in a second-class lever.

In the standard version, all pliers have cutting blades (side cutters) located next to the hinge, which can be used to cut thin metal strips and electrical wires. Wire and thin nails can be cut through two cutouts on one side of the tool, which work on the principle of a guillotine. In this case, the cutting force pinches the part in the grooves, making it possible to squeeze the handles with both hands. The force increases even more due to the increased ratio of the lever arms - the cutting grooves are located close to the axis of rotation. Due to their additional working functions, pliers are often called combination pliers. They usually have one (fixed) axis of rotation of the handles. There are designs with an adjustable hinge - two- or multi-position, which expands the clamping range of the tool.

Pliers are made from stronger steel than pliers. Typically chrome-molybdenum or chrome-vanadium steel is used. The gripping jaws are hardened to 53 HRC, and the edges of side cutters are hardened to 60 units. A little about the handles. The amount of force applied depends on their shape and material. For this purpose, ergonomic pads are used to improve grip comfort. The material is rubber or a two-component coating (for example, thermoplastic rubber with santoprene linings). Dielectric handles (made of plastic) must have a confirmation inscription: work under voltage up to 1000 V.

Source: proinstrumentinfo.ru

A short checklist for choosing wire cutters

- What material is the tool made of? It's good if it's made of stainless steel. And if the metal grade is indicated on the packaging - even better!

- What is the “heel” of the tool? If you are a beginner, choose with or without a small heel. If you are already confident in using wire cutters, you can choose one with a more prominent protrusion.

- How long is the blade? We choose either for our own nails (if we do a manicure for ourselves) or for the most common type of nails (if we work with clients). We also take into account our experience: if it is small, then we choose smaller blades.

- Do the blades close tightly? Are they sharp and smooth enough (without dents, nicks or chips)? If the answer is yes, move on!

- Is everything okay with the “joint”? We carry out the test by making movements with the handles of the pliers.

- What does the spring mechanism look like? We give preference to two springs or a spiral, although single springs are less likely to break - they all have their advantages.