Greetings to dear readers! In this material I tried to collect all the data about PIC solder. This Tin-Lead Solder is the most popular solder for mounting radio components and is used more often than others in radio engineering. I will try to explain why this is so and tell you about the types and technical characteristics of POS series solders. I’ll also tell you a terrible secret about POS-60 and POS-62 solders. Go!

Types of POS solders

First, let's remember what types of solders are made from alloys of the tin-lead group. The most popular are antimony-free solders POS-10, POS-40, POS-61 and POS-90. POS solder containing antimony is called POSSU. Antimony in the solder adds several percent to its strength.

When we talk about melting a mixture of tin and lead, we need to remember the definitions of solidus and liquidus . When any mixture of two or more metals is heated, the melting (transformation from solid to liquid phase) of the lightest particles occurs first. This temperature mark is called the solidus of the alloy.

With a further increase in temperature, more refractory components begin to melt. As soon as they melt, the liquidus . The PIC solder is now completely melted. This process is explained in more detail by a picture taken from a presentation on the topic of alloys.

Between these two points is a state of increased ductility of the solder . In this state, the solder can be pulled and deformed without losing integrity.

There are eutectic alloys - solders, in which the solidus and liquidus points coincide. This is very convenient when soldering and indicates the high quality of the solder.

Warming up

Depending on the melting point of the filler material used, different heating methods are used during soldering. In the case of soft materials containing tin, zinc, and lead, the main tool for soldering can be a regular soldering iron.

An example is the assembly and repair of electronic circuits containing components that are critical to overheating. In this situation, lead-tin materials with a low melting point and low-power electric soldering irons are usually used.

The mechanical strength of the connections plays a secondary role here; the main thing is to ensure reliable electrical contact.

When it comes to soldering with high-temperature materials, the soldering iron is powerless. In these cases, heating is carried out using gas burners and special installations using high-frequency currents.

This applies to industrial soldering in production workshops and the use of hard solders.

In some cases, when the parts to be soldered are very massive, and using conventional heating means it is not possible to achieve melting, special furnaces are used, where the workpieces are placed entirely. This is the only way to ensure reliable soldering.

About the composition of solder

The name of the solder of the tin-lead group indicates the tin content in it. For example, POS-40 contains 40% tin, and POS-61 contains almost 61% tin. The rest consists of lead and additional impurities. By appearance, you can estimate the composition . If the PIC solder is more matte and dark, then it contains more lead. If it is lighter and shiny, then there is more tin. This is best understood by comparison. Look at the photo to see what a sheet of tin and a sheet of lead look like.

The strength of solder depends not only on the alloy alloy, but also on the metal being soldered. For example, to solder copper or zinc, several percent of copper or zinc are added to the POS solder, respectively. This reduces chemical erosion of the metal and increases the surface strength of the joint.

Solder alloying

To improve performance characteristics, alloying of solder with the following substances is used:

- adhesion is improved by the addition of copper, cadmium, antimony, aluminum, silver and zinc;

- ductility and resistance to thermal cycling are improved by the addition of indium, silver, manganese, bismuth, and lithium;

- Nickel, cobalt, zinc, silicon, boron, iron add strength

- The corrosion resistance of solder is increased by nickel and copper;

- Heat resistance is increased by silicon, zirconium, tungsten, vanadium, cobalt, niobium, hafnium.

Solder paste

Mainly used for soldering surface-mounted components (SMDs), as well as leadless chips in BGA packages.

It looks like a gray paste, consists of tiny balls of Sn62Pb36Ag2 alloy (silver 2%, lead 36%, tin 62%), and also contains no-clean flux. The fact that the flux is no-clean is indicated by two letters on the packaging: NC (No Clean). The flux containing solder balls dries in air, so the paste is stored in a closed container.

This product is used for complex cell phone repairs and for soldering microcircuits in BGA housings. Its use involves the use of additional equipment for repairing mobile phones, for example, special stencils. The paste is quite expensive because it contains silver.

Lead-free solders are now widely used in electronics production.

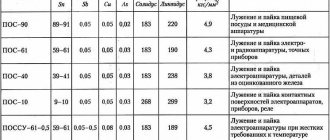

Technical characteristics of POS and POSSu solders

In order not to describe all the technical characteristics of solders of the tin-lead group, I will simply provide a table of parameters. It can be used to determine the melting point, density, electrical resistivity, thermal conductivity, tensile strength, elongation, impact strength and Brinell hardness of solders.

An analysis of the table shows that the most fusible among the list is cadmium with a melting point characteristic of 145 degrees Celsius. The strongest solder is POSSu 4-6 solder with a tensile strength of 6.5 kgf/sq.m. mm.

Technical characteristics of POS-10 solder

POS 10 solder has a distinctive chemical composition. It contains 9-10% tin, about 89% lead, 0.2% bismuth, 0.1% antimony and other impurities in small quantities. POS-10 solder is used for soldering and tinning contact surfaces of electronics. For example, they solder relays and fill control plugs in radio electronics housings.

The POS-10 soldering temperature is 299 degrees Celsius. The solidus point is 268 degrees.

Advantages of POS-10 solder:

- high melting point is useful when soldering equipment cases.

Disadvantages of POS-10 solder:

- low strength and tensile strength of about 3.2 kgf/sq.mm.;

- high resistivity - 0.2 Ohm x sq.mm./m;

- high content of lead, which is hazardous to health.

Composition and characteristics

Chemical components

It was previously mentioned that PIC solder consists of an alloy of tin and lead. Tin has a lower melting point than lead, so by varying the percentage of these two components, you can select certain temperature characteristics. POS 60 has the following chemical compounds in its composition:

- Tin. The share is 59–60.5% of the total mass.

- Lead. The percentage content ranges from 39 to 40.5% by weight of POS.

- Impurities. They are represented by various elements such as copper, iron, antimony, nickel, zinc and others. Their mass fraction is no more than 0.3% of the total mass of the alloy.

Chemical composition of POS61 solder

Other metals also influence the technical properties of the solder alloy.

Physical properties

The large amount of tin contained in this brand of solder directly affects its temperature characteristics and physical properties. Thus, POS 60 has the following properties:

- Melting point 183-190 degrees Celsius.

- Density 8.5 grams per cubic centimeter.

- The resistivity is 0.137 ohms per meter, which is 9–15% of the conductivity of copper.

- The tensile strength corresponds to the limit for soft solders and is equal to 50–70 MPa.

- The Brinell hardness is 14.9 PV.

- Thermal conductivity is 0.117 W/(m×k). Tensile strength is 4.3 kg/mm.

Physical properties of POS 60 and other solders

It is worth noting that tin and lead are identical in both softness and viscosity. Both of these metals have a characteristic of 1.5 on the Moss scale, so their percentage does not affect the physical properties of the solder.

Technical characteristics of POS-30 solder

Solder for soldering of the POS 30 brand is an intermediate link between POS 10 and POS 40. The composition of POS 30 solder is as follows: 30% tin and 69.5% lead. The rest is impurities and doping. Solder POS 30 can be easily replaced with POS 40, which is described below. The melting point (liquidus) is 238 degrees, and the plasticity temperature (solidus) is 183 degrees Celsius. According to the technical characteristics, POS 30 solder is most often used for soldering and tinning of zinc sheets and radiators.

Advantages of POS-30 solder:

- good adhesion;

- high strength.

Disadvantages of POS 30 brand solder:

- high lead content;

- often produced in rods.

Technical characteristics of POS-40 solder

The chemical composition consists of 39-41% tin, 59% lead. The remaining impurities are in the same ratio as in POS-10. Soldering solder POS-40 is often used for soldering and tinning radio equipment casings made of galvanized iron with galvanized seams.

The soldering temperature of the solder is 238 degrees Celsius, and the solidus is 183 degrees.

Advantages of POS-40 solder:

- good ratio of ductility and melting point;

- because of this, it tolerates thermal cycling better than POS-61.

Disadvantages of POS-40 solder:

- high lead content, which is harmful to health;

- elevated liquidus temperature.

The terrible secret of POS-60 solder

Now the time has come for the terrible secret of POS 60 solder . According to GOST 21930-76 entitled “Tin-lead solders in ingots. Technical specifications" and GOST 21930-76 "Tin-lead solders in products. Technical specifications", solder such as POS-60 simply does not exist. GOST 21930-76 itself can. Here is the complete table from this GOST.

So “ POS-60 ” is jargon or a popular designation for “the solder that everyone solders with.” It seems to me that this is due to confusion in the designation of POS-61. Because when the tin content in the solder according to GOST is from 59 to 61%, it is more logical to call it POS-60 rather than POS-61.

Among the solders produced according to international standards there is Sn60Pb40 solder . This is a solder solder containing 60% tin and 40% lead. It could be called POS-60, if at least specifications for it were developed. According to international data describing the characteristics, the melting point of 60/40 solder is 191 degrees Celsius.

The same story with POS-62 type solder . Such lead solder according to GOST has not yet been invented. So, if they ask me “what is the melting temperature of POS-62 solder,” I know that the answer with the figure 184 degrees Celsius must be looked for in the imported solder catalog. For example, you can use the Kester solder catalog.

Technical characteristics of POS-61 solder

The designation of solder, as we found out, is quite controversial, but you can’t argue against GOST. POS-61 is used for soldering and tinning of electronic components and printed circuit boards of precision instruments with highly hermetic seams, for which overheating is not allowed.

Composition of POS-61 solder

The chemical composition of POS-61 solder is as follows:

- Tin 59 - 61%;

- Antimony - no more than 0.1%;

- Copper - no more than 0.05%;

- Bismuth - no more than 0.02%;

- Arsenic - no more than 0.02%;

- Iron - no more than 0.02%;

- Nickel - no more than 0.02%;

- Sulfur - no more than 0.02%;

- Zinc - no more than 0.002%;

- Aluminum - no more than 0.002%;

- Lead - everything else - about 38.7 - 40.7%.

The soldering temperature of POS-61 solder is 220 degrees Celsius. Solidus is 183 degrees. I even shot a slow motion video of this solder melting on my Olympus Tough TG-860 at 240fps.

Solder POS 61 GOST 21931-76 has the following technical characteristics:

- Density determines weight and is equal to 8.5 g/cu. cm.;

- The electrical resistivity is 0.139 Ohm x mm2/m;

- Thermal conductivity is 0.12 kcal/cm x s x deg;

- Temporary tensile strength is 4.3 kgf/sq.mm.;

- The relative elongation is 46%.

Advantages of POS-61 brand solder:

- the best ratio of melting temperature and strength;

- good adhesion to metal surfaces;

- universal solder for soldering and most radio installation work;

- accessibility and prevalence;

- low cost;

- often produced in the form of wire, for example POS 61 T2A solder.

Disadvantages of POS-61 type solder:

- versatility reduces performance in special cases, for example when soldering zinc;

- melting temperature is not suitable for all devices;

- solder fumes (lead in it) are harmful to health.

Characteristics

It is worth noting that solder is undemanding to soldering equipment. This can be either a home option or industrial devices. Hence the prevalence of POS 40 both in everyday life and in enterprises.

Excellent for soldering on printed circuit boards with appropriate properties, as well as for creating a tight, reliable seam.

The density of this substance is 9300 kilograms per cubic meter. The diameter of the solder may vary. It varies from 0.5 millimeters to 3 millimeters. The mechanical tensile strength of this solder is 3.8 megapascals. Solder is produced in accordance with GOST.

Today on the market there are both tubes that already contain pine rosin, and wires that do not contain rosin. It is impossible to say which option is better - it all depends on the specific area in which solder is used. In some places the option with rosin will be preferable, and in others without.

Technical characteristics of POS-63 solder

Solder POS 63 is described in GOST and in the industry standard OCT 4G 0.033.200. POS-63 solder is understood as an alloy that consists of 63% tin and 37% lead. This is a kind of modernization of POS-61 solder, adjusted to the international standard J-STD 006B. Most are also labeled Sn63Pb37 . These are eutectic alloys with a melting point of 183 degrees Celsius.

POS-63 is used for soldering and tinning the leads of microcircuits and packaged radio components, printed circuit boards, wires and cables. In general, of modern solders, this is the most common. The technical characteristics of POS 63 solder are approximately the same as those of POS-61. But I haven’t found the exact values yet.

Advantages of POS-63 solder:

- the most common POS series solder;

- relatively low melting point;

- coincidence of solidus and liquidus points;

- low cost;

- supplied in the form of wire filled with flux.

Disadvantages of POS-63 solder:

- often counterfeited, especially by the Chinese;

- contains lead, which increases the cost of recycling electronic equipment in accordance with modern safety standards.

Technical characteristics of solder POSSu-61-0.5

Solder marking POSSu-61-0.5 indicates a type of antimony solder containing 61% tin, up to 0.5% antimony and about 38% lead. This solder is used for soldering and tinning of printed circuit boards and galvanized radio components under increased operating temperature requirements. But its melting point is 189 degrees.

Advantages of POSSu-61-0.5 solder:

- increased adhesion to the metal surface due to the antimony content;

- technical characteristics are almost the same as POS-61.

Disadvantages of POSSu-61-0.5 solder:

- difficult to find on sale;

- increased cost.

Group of special alloys

When antimony is added to metal compositions in small quantities, the strength of seam joints significantly increases.

The material is marked “POSSU” and has a melting point from 189 ℃ (for a composition with a trace antimony content) to 270 ℃ (for a solder with an antimony content reaching 4%, in some even 6%).

Materials of the first subgroup with an additive concentration measured in hundredths of a percent are low-antimony grades.

Such solders are used in the aircraft and automotive industries, in the production of refrigeration equipment, and food utensils that are subject to subsequent tinning.

Table 1. Low antimony solders:

| Brand | Content, % | Application area | ||

| Sn | Sb | Pb | ||

| POSSu 61-0.5 | 59-61 | 0,05-0,5 | Rest | Soldering parts sensitive to overheating |

| POSSu 50-0.5 | 49-51 | 0,05-0,5 | Rest | Aviation radiators |

| POSSu 40-0.5 | 39-41 | 0,05-0,5 | Rest | Galvanized parts of refrigerators, radiator tubes, windings of electrical machines |

| POSSu 35-0.5 | 34-36 | 0,05-0,5 | Rest | Cable sheaths for electrical products, thin-sheet packaging |

| POSSU 30-0.5 | 29-31 | 0,05-0,5 | Rest | Radiators |

| POSSu 25-0.5 | 24-26 | 0,05-0,5 | Rest | Radiators |

| POSSu 18-0.5 | 17-18 | 0,05-0,5 | Rest | Heat exchanger tubes, electric lamps |

Metal tin-lead compositions with an antimony concentration from 1.5% to 6% are called antimony. They are recommended for use in electric lamps, tubular radiators, and tinplate.

The addition of antimony makes the tin-lead material cheaper, but soldering is more difficult. A slight change in the tin-lead composite significantly reduces the wetting properties of the melt. Only professionals can work with this consumable.

Table 2. Antimony solders

| Brand | Content, % | Application area | ||

| Sn | Sb | Pb | ||

| POSSu 95-5 | Rest | 4.0-5.0 | No more | Pipelines operating at elevated temperatures, electrical products |

| POSSu 40-2 | 39-41 | 1.5-2.0 | Rest | Refrigeration devices, thin sheet packaging |

| POSSu 30-2 | 29-31 | 1.5-2.0 | Rest | Refrigerators, light bulb production, abrasive packaging |

| POSSu 25-2 | 24-26 | 1.5-2.0 | Rest | Automotive products |

| POSSu 18-2 | 17-18 | 1.5-2.0 | Rest | |

| POSSu 15-2 | 14-15 | 1.5-2.0 | Rest | |

| POSSu 10-2 | 9-10 | 1.5-2.0 | Rest | |

| POSSu 8-3 | 7-8 | 2-3 | Rest | Electric lamp production |

| POSSu 5-1 | 4-5 | 0.5-1.0 | Rest | Tubular radiators, parts operating at elevated temperatures |

| POSSU 4-6 | 3-4 | 5-6 | Rest | Car body putty, tinplate soldering |

| POSSU 4-4 | 3-4 | 3-4 | Rest | Automotive products |

Technical characteristics of POS-90 solder

POS-90 brand solder consists of 90% tin and 10% lead. It also contains about 0.1% antimony and 0.05% copper. It is mainly used for soldering and tinning internal seams of food utensils and medical equipment. Yes, 10% lead can already be put into food products - surprisingly, everything is in accordance with GOST 1976. According to the technical characteristics, the melting temperature of solder type POS 90 is 220 degrees.

Advantages of POS-90 solder:

- low lead content;

- rarely counterfeited;

- low resistance;

- high strength.

Disadvantages of POS-90 brand solder:

- high cost (higher than pos-61);

- low plasticity.

Solder Material Selection

One of the main criteria for choosing an alloy for creating a solder joint of metal parts is its melting point.

That is, the filler material must melt earlier than the base material. But this is not the only condition for choice.

The liquid melt should well wet the surface of the base metal. In addition, certain strength requirements are imposed on the soldered joint.

It is for this reason that when soldering any metal product, they try to use an additive based on the same metal as the metal of the product.

At the same time, the lower melting temperature of the solder is ensured by the additional components included in its composition.

However, it should be noted that it is never possible to equalize these characteristics when soldering. That is, during mechanical fracture tests, fracture will always occur at the joint.

In some specific types of soldering, the strength of the connection does not play a major role. For example, when soldering jewelry, the main thing is the aesthetic part of the work. Therefore, products made of gold, silver and platinum are soldered only with solders based on the same metals, and of the same standard.