Posted by admin on 07/08/2020. Published Blog

The specificity of industrial winemaking is the multitasking that the owner faces. It is important for an enterprise not only to offer a high-quality product with excellent product characteristics, but also to increase profitability, and this is possible by reducing or optimizing consumed resources. To achieve this, certain winemaking processes are being improved and modern installations are used. Only under such conditions is it possible to increase production volumes using the same amount of raw materials. In particular, it is possible to increase the production of wine materials in primary winemaking using a must press. INPROMINOX engineers spoke about the design, operating principle and advantages of using pressing equipment. The Bulgarian company specializes in the supply of Italian equipment for the food industry, which fully meets production requirements.

Introduction

You can, of course, squish grapes in a bowl with your hands and feet the old fashioned way, or even use a recycled washing machine. But such methods have a number of disadvantages:

- tiring

- less effective

- not always aesthetically pleasing

“You need health for this! Or good helpers!” (c) Nikolay Kurdyumov

It is better to use specially designed devices. What is more suitable - crushers or presses? The table below will give you a little idea about this.

| Crusher (crusher) | Press |

| Relatively easy to do yourself | Self-production is more difficult, but the efficiency is slightly higher |

| More budget options | The price is on average more expensive, but this is a price to pay for quality |

| Manual work is often expected | More automation |

| More compact | Less compact (on average) |

| Relatively easy to maintain, assemble and disassemble | It’s more difficult to care for, but it’s still not the most complicated mechanism for this. |

Based on the information above, you can make a preliminary conclusion about what is most suitable for you, and then we will move on to considering the advantages of specific varieties.

Design features

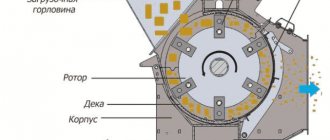

The type of device affects the volume of juice and ease of use. Main types of grape press designs:

- lever: the simplest devices. Operated by a lever. Such devices are not highly productive and require physical strength. A type of lever press is a jack press. They are easier to work with because they do not require much tension;

- screw: activated by rotating the handle. Presses are more productive than lever presses and produce more juice;

- screw: they work on the principle of a meat grinder. The berries are ground, the pulp is advanced to the filter by a screw element.

Pressers and crushers

A grape press or crusher is a relatively simple device that helps extract juice and pulp from berries.

Speaking about specific models, it is worth recommending a DB-3 mechanical crusher for purchase. She managed to earn a lot of good reviews.

In particular, it is praised for its ease of use and maintenance and good performance - meaning it would be an excellent choice for private use or maybe even a small business.

The only disadvantage is the small number of control and adjustment options.

Materials

The most popular material options here are:

- steel-stainless steel;

- plastic;

- varnished wood.

Without considering in more detail the pros and cons of other options, as it is unnecessary, we will immediately highlight that in most cases, stainless steel is the best. In this case, the components are easier to wash and disassemble. Longer service life, less odors.

If more than five hundred to seven hundred kilos of berries are processed, then it is definitely recommended to use a crusher with a motor.

destemmer

The second is the presence of a comb separator. Raw materials must be cleaned of ridges. Because the ridges ripen much earlier than the berries and they contain much more tannins, which results in excess bitterness.

Therefore, the use of a comb separator is often justified - a device made of helical blades and a shaft. The raw material first hits the shaft, then onto the pressing elements.

Expert opinion

Kislyar Yuri Borisovich

61 years old, Voronezh, has been growing grapes for 15 years

For some red varieties, such as Cabernet Sauvignon and Merlot, the destemmer is not used because the quality of the raw material deteriorates.

Control

The advantages of mechanical/manual ones are compactness and cost-effectiveness. If you crush some grapes at home or on your personal farm, then these are the ones worth recommending. A simple attache includes something like the following:

- square bin;

- 2 smooth rollers;

- lower wooden frame;

- gear system;

- handle on the side.

Thanks to its light weight, it can easily be placed even on a table. But electric crushers make it possible to almost completely automate the process. As a rule, they even have an additional destemmer.

Here, as specific models, it is worth recommending crushers from Grifo; they have exactly the same destemmer and their quality is confirmed by many positive reviews.

Full automation of the process makes it possible to greatly reduce the time and effort spent on work. Various models of electric crushers have the following performance:

- 1200-1500 kilos of grapes per hour;

- 1500-2000 kilos of grapes per hour;

- 2000-2300 or more kilos of grapes per hour.

Pros and cons of using

- large volumes are processed quickly;

- all resources are used as wisely as possible;

- the resulting pulp is of excellent quality;

- The cake is automatically cleaned;

- it is easy to control the process.

- some variants of Atregata are not suitable for Muscat varieties;

- the price may seem expensive to some (although the quality more than justifies it).

It should be noted that with minimal skills, it is quite possible not to buy a crusher ready-made in a store, but to make it yourself (but this, of course, is already associated with certain risks and is a topic for a separate article. By default, we recommend purchasing the product).

Option for the lazy

To quickly process grapes, you can use a conventional drill or screwdriver with a mixer attachment. This method is good because it does not require any special devices.

The negative side is that many small ridges get into the pulp along with the berries. And not all the berries can be broken. Instead of a standard construction mixer, you can use a homemade stainless steel knife made in the shape of a propeller. This allows you to mix the berries more evenly. Still, this method is recommended for use on destemmed berries.

Read why they are needed and how to grow wild grapes.

Presses

There are the following types of presses for squeezing grapes:

- mechanical (screw);

- hydraulic;

- combined.

Screw

They act like a vice, squeezing food and squeezing out juice.

There are two sub-variants of this variety. The cheapest among manual presses in general are those with a screw mechanism at the base. Their main drawback is that due to the nature of the mechanism, lubricant can get into the wine and ruin it (not completely, but significantly).

You cannot lubricate such a device - then it will deteriorate on its own.

Another significant disadvantage of this device is that the paint on the steel bottom often quickly begins to peel off and, accordingly, rust is revealed. That is, the quality, as almost everywhere else, matches the price tag.

The option is already better - with a screw and a housing frame. Here the press screw is already at the top and the piston has a protective rubber lining, that is, the lubricant will not damage the wine.

Another advantage of such presses is their small size, which makes them easy to place in any kitchen. It is worth recommending them.

Hydraulic

Now let's move on to hydraulic presses in more detail. There are such options.

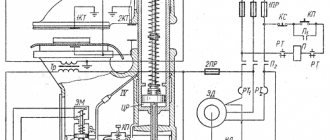

Made from cylindrical pistons and large rectangular bodies. The jack is located in the center and is either fixed at the top, pushing the piston and lowering it, or at the bottom, lifting the tank with it up.

This device has a major advantage: even girls and minors can use it, because the jacking mechanism requires minimal force.

A press with a hydraulic cylinder is already suitable for use not at home, but either in the country, or even in industrial activities.

The housing includes a hydraulic cylinder and a pump that passes hydraulic oil into the piston. Such presses come in volumes of 50, 100 and 200 liters.

Hydraulic cylinder versions of hydraulic presses are manual and semi-automatic. In the second case, it will be enough to manually collect the finished products and load them, and the processing process itself will be automatic after pressing a button.

Expert opinion

Vladimir Alexandrovich Rembe

experienced winegrower from Novokubansk

It may seem to some that these presses are expensive, but the price for such quality is more than justified, including the complexity of the design, but its operational efficiency.

Combined

According to the name, combining the advantages of other presses. Processing takes place in two stages. First, the juice is squeezed out using a screw, and then the remainder is squeezed out of the raw material using a jack. With the help of combination presses, juice is prepared much faster.

Other tips for choosing abs

Choose a barrel based on working volumes. Often they take a machine with a tank of ten to twenty liters, but if you only have a few buckets of grapes, then a five-liter press with a VP-5 screw may be enough.

When choosing between a screw press and a hydraulic press, a lot depends on how you plan to work. The screw press will have to be secured with screws, but the hydraulics can simply be placed on the surface.

Wooden basket

The separator basket is a kind of sieve that retains the pulp but allows the juice to pass through. Traditionally it is made of stainless steel. But you can make it yourself from wooden blocks (it is advisable to use oak or other hard wood) and metal tape.

At home, the easiest way is to make a non-separable separator. To do this, the bars are attached to the tape at regular intervals using stainless steel screws, leaving a small gap between them. This kind of mat is then wrapped around the piston to fix the desired diameter. After this, tighten the last pair of screws. A wooden barrel like this with slots will quite successfully replace stainless steel.

For greater convenience, the separator can be made collapsible. To do this, you can assemble it from two halves, connecting them with pins. This design will be much easier to clean.

Important! When using a wooden separator, be sure to rinse and dry it after spinning to avoid infection with mold fungi!