Application for product/service

Tin solder is rods, wire, powder, foil, granules made from tin. All these products can be used for soldering. Soldering is a method of joining parts using solder. In this case, the melting temperature of the parts is higher than the melting temperature of the substance used as solder.

We sell tin solder in the form of: tin rod with a diameter of 8 to 10 mm; cylinders with a diameter from 80 to 250 mm, wire and ingots in an assortment.

Soldering Solders and Melting Points

- POS-30 solder is an alloy in which 30% tin and the remainder is lead

- POS-40 solder is an alloy containing 40% tin, the rest is lead

- POS-61 solder is an alloy with 60% tin and 40% lead

And so on. There are several dozen types of POS solders produced in accordance with GOST 21931-76 and GOST 21930-76.

#S[2047]#

Of course you shouldn't eat it

, lead is an unsafe metal. But the use of PIC solders is quite widespread. This includes electrical installation work, automotive production, railway construction, and the production of various electrical devices and products. For example transformers or fuses.

For each application, there are recommendations for choosing a solder brand. TD "Skala" has been a manufacturer of solders for over ten years and can offer you a large number of brands of POS solders.

What is solder?

Solder is a mixture of low-melting metals that are capable of providing good contact between two surfaces, resulting from soldering. When heated, solder changes from a solid to a liquid state, which ensures spreading around the perimeter of the soldered part or at the point of their contact. In this case, fixation occurs at the molecular level due to a high degree of adhesion.

In terms of composition, solders can include a variety of components that provide them with the necessary performance properties. However, the vast majority consists of a mixture of lead and tin, the first of which provides hardness and refractoriness, and the second lightness and lowers the melting point. The composition may also contain other components: silver, nickel, zinc, copper, kobold, bismuth, antimony and others.

Due to the multi-component composition, the melting process also goes through several stages: first, the most fusible components are rarefied, while the refractory ones remain in the form of crystals at this moment. Then they melt, the mixture becomes homogeneous and ensures maximum filling and contact. However, fluxes are used in conjunction with solder to provide better filling and oxidation protection.

Diameter of holes

Solder Solder T 2.0 POS 61 is POS solder in the form of a tube with flux with a diameter of 2 mm. Supplied in a coil or reel

Other markings are possible. For example, Solder POS-61-T1 And this is also solder POS-61, but in the form of a tube with a diameter of 1 mm

If you come across the marking Solder POS-61 (wire d-3 mm), then this is POS-61 solder produced in the form of wire with a diameter of 3 mm, without rosin, supplied in the form of a coil.

Marking Solder POS-30 or Solder POS-30 ⌀8 means the same thing. This is POS-30 solder, supplied in the form of a rod with a diameter of 8 mm.

Solder “A”, what is it for?

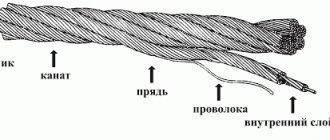

Solder “A” is a tin-zinc alloy, with the obligatory alloying additives of copper and aluminum. Used for tinning the aluminum cable sheath before applying PIC solder. Pre-treatment of the cable surface with solder “A” dramatically increases the electrical and mechanical strength of the soldered contact. However, applying solder "A" requires a lot of attention and skill. Solder “A” is a fairly refractory solder and there is a risk of overheating the cable sheath if unsuccessful attempts are made to rub it with solder “A”. It is very important to use a high-quality gas burner with adjustable flame sharpness for this.

Classification

All criteria for classifying solders represent a rather broad area, which, perhaps, can only be done by highly specialized specialists. Therefore, to simplify the selection, specific brands are made for specific purposes - soldering aluminum, jewelry, copper wire, radio components, etc. The main thing you should pay attention to is the temperature parameter. Since, for example, soldering a microcircuit cannot be done with the same brand of PIC as the connection of cable cores, since the sensitive component may burn out and fail.

Solders for soldering are classified according to the following criteria:

- according to the method of supplying flux - flux-free and self-fluxing, for the former the flux is supplied separately, for the latter they contain it in their composition;

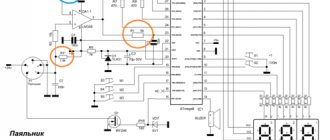

Rice. 1. Self-fluxing and with flux feed

- according to the main soldering element - tin solders, nickel, cobalt, manganese, titanium, silver, zirconium, vanadium, mixed, etc.

- according to the method of production - they are ready-made or formed directly during soldering;

- according to the solubility of components - there are completely melted and partially melted;

- by release form - tin wire, rod, ingots, sheet, granules, paste;

Solder release form

- by melting point - there are those that turn into a liquid state at low and high temperatures.

When choosing tin-lead solder, the most important criterion is the last one, so we will dwell on it in more detail.

Low-melting (soft).

Low-melting solders include those compositions that turn into a liquid state at temperatures from 145 to 400°C. But, at the same time, they provide relatively low strength; for low-melting alloys, the tensile strength is no more than 7 kg/mm2. The most common are tin-lead. Most often, soft solders are used in electronics for printed circuit boards or parts.

Refractory (hard).

Hard solders have significantly greater mechanical strength, but their melting point is more than 400°C, which is unacceptable for most radio components, since they can be damaged even if touched by a heated soldering iron tip. The two largest groups in this category are copper and silver compounds. Copper alloys are generally combined with zinc, but are too brittle and are therefore suitable for carbide alloys that only experience static loading. Silver solders are universal and can be used for soldering any connection points, however, the cost of these brands is also quite high.

Solder pastes.

Solder pastes are also a component for soldering radio components, but they are used for small elements made of low-melting metal. The paste composition contains crushed pieces of solder in a solution of liquid flux. They are used in those boards or devices where exposure to high temperatures can harm the equipment. Pastes are typically soldered with a hairdryer without an electric soldering iron, or can simply be applied as a conductive adhesive.

The soldering mixture is applied to the point where the leads are attached in batches and can be done using a special stencil, syringe or drop-jet cartridge.

Fig 3. Applying solder paste with a printer, syringe, stencil

However, the use of soldering paste imposes a number of requirements that must be met:

- before opening the container, be sure to keep it at room temperature for at least 2 hours; using means of forced solder heating for this is prohibited;

- after opening, the mixture must be mixed until a homogeneous substance is obtained, since during storage the flux can separate from the solder;

Rice. 4. Stir until a homogeneous mixture

- before application, the surface must be cleaned of possible impurities and contaminants; during long-term soldering, the procedure is repeated every 45 minutes;

- installation of electronic components in the applied paste must be carried out within 60 minutes, otherwise it will begin to lose its properties;

- after soldering, the remains and excess paste are washed off, there are those that can be washed off with plain water, others require a solvent, some may not be washed off.

The functional characteristics of such solder are extremely negatively affected by placement in an environment with high or low temperatures, as well as exposure to moisture.

Lead-free solders.

Initially, the reason for creating lead-free solder was the need to eliminate harmful effects on the environment and the human body. Such solders are widely used for soldering aluminum or steel in the food industry, for drinking water supply pipes, laboratory equipment and tools.

In total, there are three most common groups of lead-free solders:

- tin with copper - used for high-temperature soldering, refers to refractory solders, well suited for working on copper products;

- tin and silver - suitable for low-temperature soldering, provide better contact than lead solders, but they are expensive.

- tin with both copper and silver is also a soft option, which has a lower cost than the previous one and is practically in no way inferior to it in the quality of connections.

- tin with bismuth and silver - can be used for soldering copper at low temperatures;

- tin with zinc and bismuth is a cheaper version of the previous one, but has a number of difficulties in use.

Application of pos-30 solder in cable joints

POS-30 solder is an important component of cable joints. Together with Solder “A” it ensures reliable electrical contact of the grounding conductor with the cable sheath. And of course, for high-quality soldered joints in cable couplings, solder fat is used. Due to the special area of responsibility, there are requirements for high quality POS-30 and “A” Solder. At the consumer’s request, we supply POS and “A” solder, standardized by weight. Weight range from 40 g to 200 g in one product.

TD "Skala" has been supplying solder for the production of cable joints for more than a decade and can offer products of high quality and European level.

feature article

Composition and characteristics

Chemical components

It was previously mentioned that PIC solder consists of an alloy of tin and lead. Tin has a lower melting point than lead, so by varying the percentage of these two components, you can select certain temperature characteristics. POS 60 has the following chemical compounds in its composition:

- Tin. The share is 59–60.5% of the total mass.

- Lead. The percentage content ranges from 39 to 40.5% by weight of POS.

- Impurities. They are represented by various elements such as copper, iron, antimony, nickel, zinc and others. Their mass fraction is no more than 0.3% of the total mass of the alloy.

Chemical composition of POS61 solder

The addition of copper or germanium significantly increases the wettability, as well as the strength of the solder joint; such an alloy is labeled POS-60M.

Other metals also influence the technical properties of the solder alloy.

Physical properties

The large amount of tin contained in this brand of solder directly affects its temperature characteristics and physical properties. Thus, POS 60 has the following properties:

- Melting point 183-190 degrees Celsius.

- Density 8.5 grams per cubic centimeter.

- The resistivity is 0.137 ohms per meter, which is 9–15% of the conductivity of copper.

- The tensile strength corresponds to the limit for soft solders and is equal to 50–70 MPa.

- The Brinell hardness is 14.9 PV.

- Thermal conductivity is 0.117 W/(m×k). Tensile strength is 4.3 kg/mm.

Physical properties of POS 60 and other solders

It is worth noting that tin and lead are identical in both softness and viscosity. Both of these metals have a characteristic of 1.5 on the Moss scale, so their percentage does not affect the physical properties of the solder.