Welding machines are used in many industries. You cannot do without them when installing pipes, constructing buildings, or dismantling any metal products. To perform quality welding, you need to purchase good electrodes. Today, LB-52U electrodes made in Japan have begun to gain popularity. They have properties that have earned them the trust of experts and amateurs.

Purpose

lb electrodes have become very widespread in arc welding of pipes or tanks of various designs used in sea water. The main purpose is as follows:

- Reinforcement of a previously obtained seam on the reverse side.

- Increasing the strength of the root layer of the weld at surface joints of steel pipes.

- Filling joints on fixed knocks of various designs.

Marking of electrodes LB-52U

They are suitable for welding metal structures made of various alloys. LB-52U electrodes of the brand in question are characterized by high quality and versatility in use.

Characteristics

For welding critical products, it is recommended to use lb electrodes. Their technical characteristics are as follows:

- In the manufacture of such consumables, low-carbon rod is used. This chemical composition ensures high quality of the resulting weld when welding.

- Grade LB-52U is used for arc welding of critical parts. This is due to the fact that the resulting connection is characterized by good strength.

- The resulting seam is smooth and without defects.

- The resulting product is characterized by increased resistance to impact loads.

- LB-52U electrodes provide a stable arc, which ensures the quality of the resulting seam.

Packaged electrodes LB-52U

There are also several disadvantages that should be taken into account when using the LB-52U brand. An example is the difficulty of arson.

During prolonged use, slag may form at the end, which must be removed from time to time.

The average price of consumables is quite high, so it is used only when receiving critical parts.

Areas of application

When using LB-52U electrodes, a reliable seam is created when thick metal elements are connected. Most often, LB models are used in the oil and gas industry, because there are many requirements that must be met, otherwise there will be a high probability of leakage. Japanese electrodes are suitable for this, as they not only provide high quality connections, but can also be used in any conditions.

LB-52U electrodes are used in various manufacturing plants. Particularly in those areas where certain requirements for seam tightness and joint strength must also be met.

Metal elements of ships, water and sewer pipes are often connected using LB models.

These electrodes rightfully belong to modern devices . Despite the fact that they provide good welding quality, their price is low and can be used in almost any conditions. However, before purchasing them, you need to carefully study the characteristics to make sure that these are real, authentic electrodes from the Land of the Rising Sun. If the fake is not detected in time, then many difficulties may arise during use.

GOST compliance

When manufacturing consumable materials that are used when working with welding fixtures, GOST must be taken into account. It defines the following points:

- Rod sizes.

- Stability of the resulting arc.

- Concentration of harmful chemicals in the composition.

LB-52U electrodes have been tested repeatedly to certify their quality. The studies carried out indicate that the consumables are of high quality. The products in question comply with GOST 9466-75 and GOST 9467-75.

Download GOST 9466-75

Download GOST 9467-75

Characteristics, advantages and disadvantages

Despite the fact that there are clear differences between all of the above varieties, they have a lot in common . In particular, they all have the same brand, namely “lLB-52U” ; total package weight - 5 kg; maximum strength - 588 MPa; the highest fluidity is 530 MPa.

These electrodes can operate using direct or alternating current . At the end of the work, the electrode typically contains less than 1% manganese, less than 0.5% silicon, less than 0.05% carbon and less than 0.005% sulfur.

Thanks to its positive properties, the characteristics of LB-52U electrodes are confirmed by many advantages:

- They are economical.

- Provides excellent seam connection.

- They contain little hydrogen.

- They have excellent resistance to mechanical stress.

- Only a small amount of metal particles splashes during operation.

- The slag crust comes off very easily.

- With their help, metal can be melted to great depths.

- The finished connection has good ductility.

- The seams formed during welding have a pleasant appearance.

- They provide good impact strength.

Certification

Kobelko LB-52U electrodes have undergone various tests to determine quality and basic performance characteristics. Certification is used to determine the quality of a consumable material.

It is worth considering that when carrying out welding work, it is prohibited to use low-quality electrodes.

When purchasing an LB-52U, you need to pay attention to the availability of certificates. This is due to the fact that there are simply a huge number of different fakes on sale. Their performance characteristics are much lower than those of the original versions.

The LB-52U brand has been certified by NAKS, due to which it can be used in the construction and repair of main pipelines. Electrodes LB-52U are recommended by VNIIST for the manufacture of critical parts.

Chemical composition of LB-52U electrodes

Branded Kobelco LB-52U electrodes are characterized by certain performance characteristics that are associated with the chemical composition. The LB-52U brand includes the following elements:

- Low-carbon metal is used as a base, which ensures high stability of the resulting arc.

- Particular attention was paid to the composition of the deposited metal. The chemical composition is represented by a combination of carbon, silicon, nickel, molybdenum, chromium and some other substances.

Electrode composition

All elements are included in the composition in a certain concentration, due to which special performance characteristics are ensured.

Sizes and range

The range of electrodes under consideration is quite large. When choosing the most suitable design option, you need to pay attention to the following points:

- Rods are available for sale with diameters of 2.6, 3.2 and 4.0 mm. The choice is made depending on how large the resulting seam will be.

- The length with a diameter of 2.6 mm is 350 mm. The 3.2 mm version can have a length of 350-400 mm, with 4.0 mm it is 400 mm.

As the diameter of the consumable changes, the current changes. Large LB-52U electrodes can be used to supply 130-180 A current.

Features of surfacing

When creating surfacing, an alloy with a certain chemical composition is used. Its features include the following points:

- As previously noted, LB-52U electrodes have a low-carbon steel base. It allows you to significantly improve the quality of the resulting seam.

- The outer shell ensures the stability of the forming arc.

- The alloy penetrates deep into the seam, thereby ensuring a reliable connection.

Seam welded using LB-52U electrodes

The manufacturer controls the chemical composition of the outer shell with high precision, which is confirmed by certification.

Electrode manufacturers

Monopoly is a guarantee of high quality. The manufacturer of LB-52U electrodes today is the only company that produces welding electrodes that are part of the Familiarc group and have no analogues. It is called Kobe Steel, and operates under the brand name Kobelko. This is one of the largest suppliers of construction equipment to our country. Their products are sold in different regions.

Many professional and novice welders from different countries speak positively about working with Japanese welding electrodes. Most often they talk about welding the first layer of fixed pipes. Recently, in our country, these welding components have been successfully used for laying pipelines.

As for the cost of the LB-52U, it cannot be called high, at least taking into account the quality of welding that they provide.

Application area

The chemical composition of the shell of LB-52U welding electrodes determines that the resulting products have high impact strength. That is why such consumables are used in the following cases:

- When creating high capacity tanks.

- When welding steel pipelines.

- In the manufacture of various marine structures and structures.

When carrying out welding work, it is recommended to follow several basic recommendations:

- Options with a diameter of 2.6 mm can be used for lining and filling the root layers of the weld. A certain chemical composition provides protection to the seam from environmental influences and certain chemicals.

- Electrodes LB-52U with a diameter of 3.2 and 4.0 mm can also be used in the cases described above, as well as when obtaining a “back weld”.

Pipe welded with LB-52U electrodes

In general, we can say that the scope of application of LB-52U electrodes is very extensive. However, they are rarely used in the production of load-bearing structures that are subject to high constant loads.

Storage conditions

Storage conditions are indicated in the operating instructions on the back of the package. The most important characteristics are:

- Humidity. Humidity has a negative effect on the consumable material. If you store LB-52U electrodes without taking this information into account, they cannot become damp and lose their performance characteristics.

- High or low temperature. The storage recommendations also indicate that LB-52U electrodes should be stored at room temperature.

- At a temperature of 5-15 degrees Celsius, the maximum humidity should be 60%, at 15-25 degrees Celsius, the humidity should not exceed 50%.

Storing LB-52U Electrodes

In addition, the LB 52u electrodes should not be exposed to ultraviolet radiation. If you follow the operating instructions, consumables can be stored for the time specified by the manufacturer. If you do not follow the operating instructions, cracks and pores may appear in the finished seam.

Recommendations for use and storage

The list of advantages of kobelco LB-52U electrodes is quite large, but despite this, there are some recommendations for their use. If you listen to them, you can increase the quality of the seam and achieve a stronger connection:

- Experts recommend drying the welding component before using it. The drying process should take about 40 minutes.

- To prevent the product from being damaged, you should start welding at a low amperage, and then gradually you can move to higher values.

- Electrodes with the smallest diameter: that is, those with a thickness of 2.6 mm, are recommended for use as cladding or filling layers. Thicker models are best used in cases where it is necessary to create an additional seam, which welders themselves often call “gift”.

- In order to get a strong and beautiful seam as a result of the work, you need to choose the right current strength and a suitable gap.

- Usually used in cases where it is necessary to expand the back side of the seam. This can be achieved by deeply melting the metal element.

- You cannot do without Japanese welding components when you need to weld a seam from the reverse side.

After purchasing LB-52U packages, you need to take care of their proper storage . If this is not done, then there is a high probability that they will soon become unusable. Like many others, LB-52U are capable of absorbing moisture, and if there is a lot of liquid in their structure, then various defects, such as pores and cracks, may appear on the finished seams.

To avoid such problems, storage conditions must be observed. It is imperative to know the temperature and humidity in the room where you plan to store the electrodes.

The higher the air temperature, the less water vapor it should contain, otherwise the products will soon deteriorate. For example:

- if the temperature does not exceed 15 degrees Celsius, then the maximum permissible air humidity is 60%;

- at a temperature of about 20 degrees, air humidity should not exceed 50%;

- if the electrodes are stored in a very hot place where the temperature exceeds 25 degrees, then the humidity should be less than 40%.

Advantages and disadvantages

Kobelco LB-52U electrodes are characterized by quite a lot of advantages, but there are also several disadvantages. The advantages include the following:

- Good weldability in all positions. This simplifies the work being done, as well as the preparation of workpieces and their fixation.

- Increased arc stability at low and high current. The quality of the resulting seam largely depends on the parameters of the resulting arc.

- Minimum degree of metal spattering during welding work. If molten metal comes into contact with exposed areas of the body, it can cause burns. Therefore, attention is paid to such quality as the degree of spatter during welding work.

- You can get a high-quality roller from the reverse side. At the same time, the seam is characterized by excellent mechanical characteristics, as well as high impact strength at low temperatures.

- High resistance to cracking when used in a wide variety of conditions.

There are several disadvantages. An example is difficult arson. This is why the LB-52U electrodes in question cannot be used for spot welding or tack welding.

Welding electrodes Kobelco LB-52U

Low-hydrogen welding electrode LB-52U (LB-52U) is designed to strengthen the reverse side of the weld. The use of this electrode allows you to obtain excellent deposited weld metal and a neat scaly root bead without defects when welding on one side of the joint. LB-52U provides much better arc stabilization and penetration than other low-hydrogen electrodes. LB-52U (LB 52U) electrodes are designed for welding pipes made of steel strength classes up to and including K54 and from K55 to K60 inclusive. LB 52U electrodes are certified by NAKS (National Association for Welding Control) and recommended by VNIIST for use in the construction and repair of main pipelines. The price for this electrode in our company is minimal, since the sale is carried out directly and without intermediaries. Effect and advantages of welding electrodes LB-52U (LB-52U):

- Excellent performance and weldability in any position!

- Stable arc and minimal spatter. Provides a stable arc in both low and high current modes and minimal spatter. In particular, when welding the first layer of a fixed pipe, stable welding is ensured in all positions.

- Beautiful appearance of the weld bead. Due to the optimal elasticity of the slag in all positions, a beautiful bead and a wide angle for cutting the edge are provided.

- The welding electrode is thus “essentially” ideal for site welding.

- High resistance to cracking and excellent mechanical properties. Low hydrogen diffusion and high resistance to weld cracking. High impact strength at low temperatures also appears.

- The Charpy impact strength at -40°C is about 100 J/cm². Successful application results on a global scale.

- In most countries of the world, the highest rating for the weldability of the first layer of pipes has been obtained. In countries around the world, incl. In Russia, Asia and Oceania, LB-52U electrodes are used in pipeline laying. Therefore, without exaggeration, we can say that the LB-52U is a welding electrode of global importance!

Recommendations for use

| Electrode diameter LB-52U, mm | For welding pipes of class up to K54 (up to 530 N/mm2) inclusive | For welding pipes of class K55 to K60 (up to 580 N/mm²) inclusive |

| 2.6 | root, filling and facing layers of the weld | root layer of the weld |

| 3.2 | root, back-weld, filling and facing layers of the weld | root and underwelding layers of the weld seam |

| 4.0 | underwelding, filling and facing layers of the weld | weld underlayer |

The use of LB-52U electrodes (LB 52U) allows you to obtain excellent weld metal and a neat scaly root bead without defects when welding on one side of the joint. LB-52U provides high toughness and is often used for welding pipes, marine structures and tank-type structures that only need to be welded on one side. LB-52U provides much better arc stabilization and penetration than other similar electrodes.

Calcination is carried out at 300–350°C for 0.5-1 hour.

Chemical composition (%)

| Ø, mm | C | Si | Mn | P | S | Ni* | Cr* | Mo* | V* |

| 2.6 | 0.06 | 0.52 | 1.00 | 0.011 | 0.005 | 0.01 | 0.03 | 0.01 | footprints |

| 3.2 | 0.06 | 0.51 | 1.02 | 0.011 | 0.006 | 0.01 | 0.02 | 0.01 | footprints |

| 4.0 | 0.06 | 0.49 | 1.01 | 0.013 | 0.004 | 0.01 | 0.03 | 0.01 | footprints |

Mechanical properties of welding electrode LB-52U

| Content of diffusion hydrogen, ml/100 g | Impact strength, J/cm² |

| 1.6 | 130 |

| Diameter, mm | Yield strength, N/mm² | Tensile strength, N/mm² | Elongation, % |

| 2.6 | 441 | 546 | 31 |

| 3.2 | 446 | 540 | 34 |

| 4.0 | 455 | 530 | 35 |

Standards and approvals for LB-52-U

| JIS | AWS | LRS | ABS | DNV | NKK | B.V. |

| Z3211 D4316 | A5.1 E7016 | 3.3Y(H15) | 3H10. 3Y | 3YH10 | KMW53H10 | 3.3YHH |

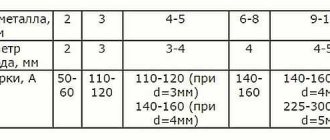

Electrode sizes and welding current

| Diameter, ∅ mm | 2.6 | 3.2 | 4.0 | 5.0 |

| Length, mm | 350 | 350/400 | 400 | 400 |

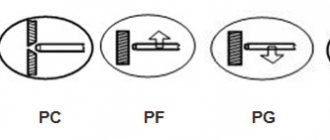

| Current, A | F | 60~90 | 90~130 | 130~180 |

| V&OH | 50~80 | 80~120 | 110~170 | 150~200 |

| O.S.W. | 30~80 | 60~110 | 90~140 | 130~180 |