Edged boards are an environmentally friendly and easy-to-process material, but the cost of 1 cubic meter of high-quality wood will be quite expensive. In cases where you need to purchase a large amount of building materials, many home craftsmen think about making their own lumber.

To independently produce high-quality boards or timber, you cannot do without the use of special woodworking devices. New equipment will cost tens of thousands of rubles. Therefore, if you want to start making such a device yourself, the article will describe a step-by-step guide on how to make a band sawmill with your own hands with minimal financial costs.

How to cut a log with your own hands

It is not necessary to purchase a device for sawing boards with a chainsaw. You can make it yourself. The simplest option is a device made of metal profiles. Such a nozzle will not only be convenient, but also stable, durable, and reliable. Are you planning to make the most functional frame possible? Use mechanical gearboxes.

With them, the device will turn into a kind of machine for longitudinal cutting of logs. Mechanical gearboxes are necessary to simplify the process of moving the chainsaw along the trunk. There is no need to exert force (pressure on the tool manually) to process the material. All you need to do is turn the gear handle. As for adjusting the thickness of the boards, it is convenient to adjust this indicator by using an attachment made of metal profiles, lifting the workpiece itself, and not moving the gasoline saw in relation to it.

At home, you can also make a device that will cut a log not in a horizontal, but in a vertical plane. The only significant nuance is that it is more difficult to work with compared to the previous frame (despite the fact that its design is simpler).

The difficulty lies in the fact that the operator has to put effort into moving the tool along the workpiece. In addition to the chainsaw and attachment, you will have to use an addition made of boards and metal. This kind of support is attached to a log.

An alternative option is a carriage installation. To create such a frame structure, you will need a pair of wheels and a profile pipe. This device differs from others in its mobility (ease of movement along the workpiece). In addition, the wheels will simultaneously serve as stops for the chainsaw, which means that additional devices will not be needed. The only thing that is needed in addition to these parts and a profile pipe is an aluminum ladder (it will play the role of a guide element).

You need to select a ladder taking into account its width, which should coincide with the distance between the wheels of the frame structure, which will be placed directly at its ends. The best option is to attach it to the log being cut using self-tapping screws, clamps or nails. The created device for cutting boards with a chainsaw with your own hands is placed horizontally.

It should lie as flat as possible. You can make sure that it is placed correctly using a building level. It’s easy to level a ladder with a log, using boards (pieces) of different thicknesses. As for the tool itself with the nozzle, it is installed on the ladder, moving the working saw along the workpiece, applying pressure on it with your hands.

Lightweight nozzle and debarker

The use of longitudinal sawing of logs has been sorted out, and you can move on to the lightweight method. It is really very easy to use, since the element is attached on one side. However, this method has lower productivity when compared to the first. In addition, the boards will turn out somewhat uneven, and therefore they are usually used for secondary buildings.

Another attachment is a drum debarker, or debarker. The technology for sawing logs into boards with a chainsaw involves the use of this attachment as one of the most suitable for dissolving the material. It works through a V-belt drive. The attachment is attached to both belts, and the kit includes special pulleys to secure it. As for the rotation speed, and therefore productivity, it directly depends on the size of these same pulleys. Thanks to this, changing the speed of work in the desired direction will not be difficult.

How to properly cut a log into boards with a chainsaw? In relation to working with this nozzle, the question is most relevant, since during its operation it is very important to monitor the progress of work, for which experienced craftsmen can even attract assistants

Snowmobile

Work begins with the snowmobile frames and track block, which are made in the form of 2 welded spars. In the middle parts, 50x36 corners are used; metal plates of 2 mm thickness are installed in the front and back. The latter have the edges bent by 90°, which adds rigidity to the parts.

A hole is made in the front plate for the shaft that drives the caterpillar, in the rear plate - for its second axis, which is a tension one. Near the latter, on both sides of the frame, tensioning devices for the caterpillar and chain drive are mounted.

5 brackets with open grooves are welded to the side members from below. They contain the axles of the track rollers supporting the track. The last 18, 3-4 pieces each. on each axle - front and rear at the edges, middle ones - in a checkerboard pattern. The axles are secured in the grooves using nuts and locknuts.

The rollers come from a unit that is used for sorting potatoes, the axles come from a potato digger. The axles are released, machined, and an M10 thread is cut. Between the rollers, to fix the position, duralumin tubes of the appropriate diameter are placed.

3 racks are welded onto each spar using 30x30 angles. They are connected at the top with the same crossbars:

- a steel sheet 2 mm thick is welded to the front and middle on the right side, on which a gearbox with an intermediate chain drive shaft is mounted;

- Between the other pair there is a box with a lid that serves as a seat.

A transverse beam is welded to the front ends of the side members - the crossbeam of the front axle. At its ends there are bushings for the steering skis, in the middle there is a stand that forms the engine subframe. All parts are made from water pipe with an outer diameter of 32 mm.

The caterpillar for the motorized dog is from Buran. It is shortened by 50 cm and stitched. Drive and tension gears are made like “Buranovsky” ones from strong plastic 1.5 cm thick.

For the caterpillar drive shaft, a pipe with an outer size of 28 mm is used. On the edges:

- The flanges are welded to which the gears are attached through the holes.

- Pin tips are pressed into the shaft holes, the diameter of which is previously ground to fit bearings 80204. One of the tips is made longer and a driven sprocket is placed on it, through which the shaft is driven into rotation. It is secured with an M14 nut, under which the end of the axle is machined and a thread is cut.

Similar to the drive shaft, but with 2 identical tips, a tension shaft is made.

The chainsaw engine is mounted through its frame on a motor subframe - a rack located on the cross beam. The gas tank is located on top. The gearbox is rotated 180° and secured to the site. A speed reducer is also installed on it - an intermediate shaft. Sprockets with a number of teeth of 38 and 10 are attached to it. Chains for transmitting rotation are taken from the Voskhod, Minsk motorcycle.

The steering includes:

- support-steering skis on which levers are installed;

- the bipod of the steering shaft, to which the ski levers are connected by rigid rods;

- motorcycle 2-lever steering wheel with a gas control lever near the right handle.

The walls and bottom of the box are covered with 4-layer plywood or boards. Its lid serves as a seat: for its manufacture, 6-layer plywood is taken, covered with a layer of foam rubber and leatherette.

Do-it-yourself sawmill from a chainsaw: video instructions and drawings

Having the drawings available and having studied the video instructions, it is quite simple to independently make a structure for processing logs, boards and slats. Before starting work, you must select a suitable location. You can install a sawmill using a chainsaw in an old barn, garage, hangar, or even just under a shed. If the room for the unit is closed, then you should take care of the hood.

Chainsaw sawmill - option No. 1

To make the structure, in addition to a chainsaw, you will need:

- two channels 8 meters long and 140-180 millimeters high;

- two rails;

- corners 50x100 mm and 40x40 mm;

- 25 cm sections of water pipe as ties;

- steel plate 4-6 cm thick and 60 cm long;

- movable hoses;

- pipes with a diameter of 35-40 mm.

Making your own sawmill should begin with assembling the base from rails and 50x100 mm corners turned upside down. They must be installed strictly parallel to the floor, so you need to use a building level.

Next, the following work is performed:

- Along the length of the base, according to the drawing, holes are drilled in increments of 1-1.5 meters and with a diameter of 14-16 mm.

- Then, according to the number of holes, ties are taken and connected with bolts.

- Stands are made from metal squares and the base is placed on them. The distance between the outer posts and the base should be about 100 cm.

- To make the structure more rigid, braces between the posts can be welded.

After the base is completed and installed, you need to make a movable cart with your own hands. To do this, a 40x40 mm corner is welded to the bottom of the steel plate and the product is placed on rollers or bearings. Two corners are welded on top of the plate, to which a chainsaw is attached.

At the last stage of the work on making a homemade sawmill, it is necessary to make a structure for fixing the logs. To do this, movable hoses and pipes should be positioned at the required height and secured.

The first version of a homemade sawmill using a chainsaw is ready. There is another way to make a wood processing unit with your own hands. The tools and drawing for it will need the same, however, the design itself is more refined.

Do-it-yourself sawmill from a chainsaw - option No. 2

The structure consists of four main components:

- Driven saws.

- A mechanism for regulating the thickness of the board being produced.

- A mechanism for moving the saw part of the structure.

- Devices for fixing logs.

Since a chainsaw with a working engine and cutting teeth is already available, you will only need to make both mechanisms and a device for fixing logs with your own hands.

Mechanism for adjusting the thickness of the boards.

Logs are sawed by raising or lowering the base, which must be welded to the plate using four nuts with bent edges. At the top of this device, it is necessary to install lock nuts, which must be tightened after the unit is adjusted to the desired thickness of the material being processed.

Mechanism for moving the saw.

The saw in the structure moves along the frame along guide angles, the distance between which should be 50 cm. Two 20 mm rollers or bearings must be welded to the posts. The lower roller should keep the sawmill from lifting, and the upper one should rest on the guide angle.

Device for fixing logs.

On such a unit, logs are fastened using two ridges - a stationary one and one moving by means of a screw. After the material to be processed has been installed, the moving comb is secured with screws in a stationary state. Now you can safely begin to operate a homemade sawmill made from a chainsaw.

Components

A typical chainsaw carriage design consists of the following parts:

- Support frame with guides, which are assembled directly at the site of use using standard sections.

- Systems for automatic control of woodworking parameters, which include a limit switch, cutting depth control sensors, temperature detectors, units for measuring current tool vibrations, etc. The set of such units is different for each carriage manufacturer.

- Measuring scales installed on guides.

- Carriage movement motor.

The equipment does not require additional maintenance.

As an example, let's look at the design and capabilities of the Logosol F2 Farmer portable sawmill with a carriage for a chainsaw. It is intended for longitudinal sawing of logs with a diameter of up to 60 cm and is assembled from standard sections 1 m long, which are made of anodized aluminum.

There are two drive options:

- For chainsaws with manual feed, a design with a 4-meter guide is used, along which vertical and horizontal movement of the carriage is carried out. The most suitable type of chainsaw for such a chain sawmill is the Stihl MS391. Engine power is 3.3 kW and weighs 6.4 kg. If you use a higher-power saw, for example, Stihl MS661, the cutting will go even faster.

- For chainsaws that are equipped with an automatic feed function, Logosol Log Moulder is more suitable. This is a complex that includes a drive carriage that has the ability to change the performance and speed of movement of the saw blade depending on the resistance force of the material being processed. The installation is used primarily for electric saws, but can also be adapted for gasoline ones.

Chainsaw sawmill

This type of design is the easiest to manufacture, but it will also require special skills, tools and experience working with them.

This type involves installing the carriage on guides, but is not mandatory. You can use a flat wooden plank as guides, along which the carriage structure will slide easily. It allows you to remove the first layer evenly. The cutting plane on the log is used as subsequent guides.

Attention! The absence of a frame and carriage adds a number of difficulties. The master may have problems holding the log in one position

You cannot start work without proper fixation, as this can lead to injury.

The step-by-step process for making a carriage for a chainsaw will look like this:

- Let's make the base. To do this, we weld together a pipe measuring 25x25 mm.

- Perpendicular tubes, the size of which is 30x30 mm, are welded to the base on opposite sides. They are necessary for attaching the moving part that holds the saw and sets the thickness of the planks to be cut.

- Nuts are welded into the side parts of the guides. With their help, it will be possible to fix the moving parts at the desired height with bolts.

- We make the moving part. It consists of two pipes with a T-shaped end. The end of the pipes is made in the form of a vice, clamped with bolts and nuts. These clamps will hold the chainsaw blade. Pipe size – 25x25 mm.

- To prevent the saw chain from rubbing against metal parts, two metal plates of the required sizes are welded onto the internal parts of the vice. They completely depend on the thickness and width of the chainsaw blade.

- We assemble the carriage into a single structure, select the desired height and install the saw. The sawmill is ready for use.

The video below fully describes the carriage manufacturing process. In addition, the author of this device notes the main difficulties and some inaccuracies that he made during the assembly of the sawmill. This will allow you to avoid such mistakes and make the device for sawing logs more practical.

Bottom line! This carriage design is suitable for personal use and one-time sawing of wood. It is not suitable for commercial purposes.

Brief operating instructions

In addition to the fact that you need to make a sawmill, you should also work on it correctly, and for this it is important to know the brief instructions.

It is best to install a vice on the base, with which you can clamp the log. Next, markings should be made on the runners and sawmill. The unit starts up smoothly and slowly begins to move towards the log. In this case, the chainsaw bar should be located exactly in the center of the cut marking.

It is very important not to make any jerking movements during operation, as this may lead to the tire stopping.

Design of various attachments for longitudinal sawing of logs

Let's start with something simple, with the design of a gas cutter. Visually, it resembles a bearing assembly, complemented by a pulley and a movable shaft (performs rotational movements). This device is driven by a belt drive. The unit is equipped with a special mechanism designed to fix the disks. The latter must be selected from an assortment designed for cutting metal, wood, and stones. With the help of such discs and attachments, transforming a gasoline saw into a multi-tool is not difficult.

An alternative version of the device for longitudinal cutting is a debarker. This is popular not only because of its ability to increase the efficiency of making boards, but also due to its ability to remove bark from logs. In addition, it can be used to cut grooves in the material being processed. These are just a few examples of the purpose for which a debarker is used. Such nozzles are found in two varieties:

- drums;

- disk.

They differ from each other mainly in functionality.

There are other devices for longitudinal cutting of logs. Most of them are developed by large companies, but you can also see homemade devices on the Internet. They differ from those manufactured at factories of famous brands mainly in their design features.

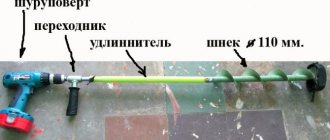

In this regard, homemade nozzles are much simpler. The most common version of these is a manual sawmill. The basis of such a small sawmill is a gasoline chain saw, supplemented not only with guide elements, but also with wheels designed for moving along the log (in order to reduce the resistance indicator). This device has no more than 2 wheels, one on each side of the workpiece.

A manual sawmill is a simple and convenient device. With its help, you can produce a large number of smooth and neat boards without much effort. The only essential condition is the correct installation of the chainsaw. It should be positioned horizontally (unless the operator requires an oblique cut).

Cutting technology

To cut a log into boards, it is not enough to use one attachment frame. An additional support will be required. You can’t do without it, especially in cases where you need to cut down the upper part of the material, the one that is close to the bark. In other words, a stop is needed to turn a log into a beam. The necessary device is usually made from boards in the amount of 2 pieces.

Each board must be at least 40 mm thick, but not more than 50 mm. They are fastened together by first placing both in a perpendicular plane. Afterwards, the boards are fixed to the log using self-tapping screws. Stops need to be placed on the sides, which requires the same devices made from boards.

Much attention is paid to the fastening procedure

It is extremely important that the top end of the vertical board is in relation to the top edge of the log below. The distance between these two points should correspond to the thickness of the piece of material being cut

Upon completion of the preparatory stage, the chainsaw is installed directly. Part (only one) of its frame should rest against a board installed across it. It will then be obvious to the operator why the installed plank fixtures are called supports. The base of the frame literally rests on it, on its vertical part.

After that, just start the tool and start making longitudinal cuts, focusing on the gap between the end of the vertical board and the upper edges of the log. An important point is that you don’t need to put a lot of pressure on the gasoline saw with your hands. There is no need to push the device; the cut will be smooth and precise. Upon completion, it is enough to dismantle the device from the boards. After this, the log is turned over (90 degrees), and the supports are reinstalled in the same way as described above.

If we are talking about cutting logs into regular boards, you can do without a wooden stop. But when cutting slabs, it is necessary to install it. Once the material has been converted into timber, the plank fixture can be set aside. By “timber” we mean lumber with a rectangular cross-section (with 4 smooth outer surfaces, which themselves will serve as a support for a gasoline chain saw with an attachment). The technology for working with such a tool (with frame) is simple:

- The frame is pressed against one rectangular section.

- The operating device is advanced along the workpiece, thereby cutting the timber.

In order to change the thickness of the board being cut, it is enough to use a stop element placed perpendicular to the entire structure (it is simply moved across the cut).

Benefits of sawing logs

How to cut a log into boards with a chainsaw? People who have this question are usually guided by the fact that it should be quite convenient and nothing more. However, in fact, this process has several significant advantages, which is why it is used.

What is very important is the ability to cut logs during wet weather or even rain. The equipment will not deteriorate because of this, and the ability to work in almost any weather significantly expands its functionality.

The ability to cut a log into boards with a chainsaw, as convenient for the owner, is also distinguished by the fact that a fairly powerful device can work all day. The only requirement is more than 7 horsepower.

In addition, if gasoline-powered equipment was purchased, then it becomes quite versatile in terms of its use in any place where it would be convenient to set up a work site, since there is no dependence on electricity.

There is another very valuable property - the presence of a soft start, as well as the ability to regulate the speed of the chainsaw. This quality is perfect for those who are just starting to master working with this unit.

Last on the list, but a very important advantage is cost. Even a good chainsaw costs much less than a small sawmill. In addition, repairs will cost much less and take less time when they are needed.

Band sawmill

This mechanism is one of the complex types. To manufacture it, you will need to purchase expensive materials, including an engine of the required power, prepare a machine movement system and carry out complete debugging and configuration of the equipment. Making it at home can be extremely difficult and expensive.

The principle of operation of a band sawmill lies in its name. The cutting element is a long saw blade rolled into a ring. This ring is installed on the pulleys. To prevent the tape from flying off during heating, car or motorcycle wheels are used as a pulley. They provide the necessary elasticity.

The main structural element that needs to be given priority attention is the frame. It is this that will hold the cutting elements, drive, engine

The frame also provides smooth movement along the guides and adjustment of the cutting thickness. The assembly of the structure should begin with the frame.

The engine plays an important role in the sawing process. An insufficiently powerful system will lead to frequent saw jams and low efficiency, while a system that is too powerful can break the cutting element. As a rule, electric motors with a power of 2 kW are used. The engine is placed on the side of the frame opposite the cutting mechanisms.

The easiest part is installing the guides. It is allowed to use any durable materials - rails, channels, I-beams. The distance between two parallel guides is the diameter of the largest log that will be sawed on this sawmill. The guides are mounted on supports installed every half meter. The parts are fastened together by welding.

Advice! Such designs are often used by small enterprises. At a relatively low cost, you can get an effective tool capable of longitudinal sawing a large number of logs. However, for one-time use the tool cannot be called effective - the costs are too high.

This video describes the process of sawing wood with a band sawmill. This will allow you to evaluate its effectiveness, as well as notice the main positive and negative aspects.

Using the above drawings and descriptions, you can make a carriage for a chainsaw with your own hands. It must be remembered that a chainsaw is an extremely dangerous tool. All parts of the structure, especially those holding the saw bar, must be reliable and strong. Parts should not “walk” when a load is applied. Otherwise, you may suffer serious cuts or traumatic amputations of body parts. If you are not confident in your abilities, it is recommended to entrust the assembly of the mechanism to professionals or purchase a ready-made kit.

Long sawing technique

Longitudinal sawing is used quite often, and therefore it is better to say a few words about the correct working technique. Since this method is used to obtain boards used in the construction of important buildings, they need to be almost perfect. In order to achieve the same dimensions, it is necessary to use a guide during operation. The role of this auxiliary element can be performed by an iron lath or another board, but it is very strong and perfectly flat.

Design features of a snowmobile and snowmobile

A snowmobile made from a chainsaw is considered one of the most complex home-made devices, because its manufacture will require a large number of additional parts, including:

- frame;

- frame;

- tracks and front skis;

- steering wheel;

- control consisting of a handle and a clutch.

There is another difficulty. In order for a snowmobile to move, it needs to be equipped with suspension and transmission, so it will not be easy for a beginner to cope with such work.

Creating a snowmobile from a chainsaw with your own hands begins with a supporting frame, which is a steel profile measuring 20x20 or 20x30 cm. A swing arm is responsible for damping the rear suspension, and a motorcycle-type steering fork is responsible for the front suspension.

To make a snowmobile from a chainsaw, you will need to purchase many additional parts. Note! A more complex design consists of two skis; with the steering wheel it will be possible not only to turn the axis, but also to pull the levers of the steering linkage. Despite the fact that this method is technically more complex, it provides more convenient control.

Additionally, a do-it-yourself snow scooter with a motor is complemented by a centrifugal clutch with a V-belt and chain. To enhance the traction force, a gear is attached to the caterpillar shaft, the diameter of which exceeds the drive part of the chainsaw shaft. For normal operation of a homemade device, you need to take a motor with a power of at least ten horsepower.

A simpler option is the snowmobile, which has a similar method of use, but is a propeller-driven aircraft moving through the snow. Due to the simplified design, the sled does not have a large load capacity, maneuverability and stability. The main advantages are simple design and ease of manufacture. The rotating propeller, installed behind the driver's back, must be covered with a protective casing made of fine mesh. Control is carried out by turning the skis, the gas lever and the brake. The optimal engine power is considered to be 5-6 horsepower.

Main types of sawmills

There are the following types of sawmills:

- Frame. It is a structure with flat saw blades mounted on a frame. Frame sawmills are most often installed in large woodworking shops. This device is distinguished by its high power and robust design. The frame sawmill does not require additional maintenance. Its disadvantage is the large thickness of the cut, which increases the amount of chips produced.

- Tape. Processing of workpieces is carried out using a saw band, regulated by stabilizing rollers. The cutting element makes only translational movements obtained from the rollers. Band sawmills are used in small woodworking shops.

- Disk. It is one of the most common types of manual sawmills. It is equipped with a disc with teeth. Each tooth cuts a small part of the log. To improve productivity, these machines are equipped with several cutting discs.

- Chain. Sawing of logs is carried out using a chain saw mounted on a frame with a metal profile. The chain sawmill is lightweight and small in size. Therefore, this mini-machine is most often used in domestic conditions.

When choosing a sawmill, it is necessary to determine the volume of workpieces processed and the operating conditions of the equipment. You also need to take into account the technical characteristics and materials from which the cutting elements are made. One of the main selection criteria is the strength of the structure. The woodworking machine must be able to support the weight of the logs being processed.

DIY chainsaw carriage. Blueprints

Since the price of professionally produced equipment (similar to that described in the previous section) ranges from 2500 to 3000 US dollars, it is not difficult to come to the conclusion that you can make your own carriage design for longitudinal sawing of timber.

Depending on the size of the chainsaws used, the dimensions of the carriage assembly, as well as its appearance, are shown in the figure.

The manufacture and assembly of a carriage for a chainsaw is carried out in the following sequence. First, the drive motor is prepared for installation. To do this, remove the drive pulley and install the engagement clutch, resulting in a finished cutting head. A support bracket must be made for the motor mounting plate. By changing the diameter of the pulley, you can control the cutting speed of timber - up to 2.5 times faster than allowed by the base engine speed. To reduce the temperature and eliminate the possibility of engine jamming, its output shaft is ground so that the chain drive sprocket, without taking into account the dimensions of the central bearing, fits tightly to the bracket.

The presence of a belt drive on the shaft that drives the chain protects the engine from vibration and shock generated by the chain. All that remains is to adjust the gearing to get the correct chain speed. Then it is necessary to install bearings on the drive shaft for more intense operating conditions, with increased load-bearing capacity.

Most home renovation and construction work requires the availability of the necessary materials. Buying boards or timber of the right size is not a problem, but sometimes you need lumber of a certain size. Planks of one or another type of wood, non-standard thickness or width are often required. Finally, there are simply several logs from which to cut boards. It is possible to solve such problems; you only need a DIY chainsaw carriage.

This simple device allows you to make a carriage, timber or boards of the required thickness from logs of any type. This device is especially valuable because it makes it possible to process non-standard logs - short, uneven or strongly curved. Let's take a closer look at this issue.

Ripping chains

The tooth shape of any cutting blade for longitudinal and transverse cutting of wood is different. The same applies to chainsaw chains. In a hacksaw or two-handed saw for regular cross-cutting, the tooth is located straight, at 90 degrees (along its axis) to the blade.

In rip saw blades, the tooth is inclined forward. Chainsaw chains for rip sawing have a different sharpening angle. You can find such chains on sale. But they are required quite rarely, so there is not a large selection of them on sale. We have to search. In addition, among the variety of chains for different models and brands, choosing a suitable chain is even more difficult.

Sawing along the grain (lengthwise) of chains with both (30 and 5 degrees) sharpening angles will be at approximately the same speed. But at a sharper crosscut angle of 30 degrees, the chain tends to find places in the wood with the least resistance between the fibers and unpredictably pull the cut in that direction. As a result, the tire may bend, make a crooked cut, or jam.

Chainsaw Attachment for Metal Cutting

Attachments for chainsaws (suspended equipment): motor drill, compressor, wood cutter

Modern chainsaws can do more than just cut wood. This is a universal device that can be adapted to perform a wide range of tasks. If desired, an ordinary chainsaw can be used as a pump, motor drill, boat or bicycle motor.

In terms of the breadth of capabilities, no other tool can compete with them now. With additional equipment, the saw can pump water from wells or wells, cut stone, metal, and stretch cars stuck in snow or mud. All this becomes possible thanks to suspended equipment. Chainsaw attachments can significantly expand the functionality of this tool.

A few words about the capabilities of modern devices

These tools use a fairly powerful, but at the same time compact internal combustion engine.

A very sealed fuel system and a diaphragm carburetor work together with the power unit. All this allows the device to perform the widest range of tasks.

You can attach various attachments for chainsaws to the output shaft of the motor, allowing you to do whatever you want. Another advantage of such gasoline tools is increased mobility. Work can be done anywhere.

The chainsaw has a very successful design. And breakdowns of this system are a very rare case.

Types of nozzles

If you have a chainsaw, but you don't understand how to use it, and all the wood has already been cut, then this information will help you use the gasoline tool to its full potential.

Chainsaw attachments allow you to solve virtually any problem. The chainsaw attachment for the removal attachment is also called a metal cutting attachment. Buy a diamond wire saw for cutting stone wholesale from China. Products directly from factory on alibaba.com. There are a lot of species here.

So, there is a device that allows you to cut wood in a horizontal plane. With its help you can cut a log into equal parts. Collets, collet, attachment for engraver, for engraver, Dremel. Tools » power tools. With all this, the frame structure of this device will be able to provide the required hardness.

Another attachment allows you to cut logs in a vertical plane.

Despite its simplicity, cutting accuracy with this accessory is very high.

With the help of a gas cutter it is very comfortable to cut and saw a wide variety of metals and stone - it’s the same grinder, but mobile.

Chainsaw debarkers make it possible to clear logs of bark or various growths. The device is also used for cutting cups, various grooves and hollows. There are two types of this nozzle. So, there are drum and disk debarkers.

Cutting process

After you have learned how to turn on, configure and change some components of the system, you can start cutting.

It is very important to understand how best to position the log and how to fasten it

To do this, consult a specialist and let him give you instructions, where you will see all the nuances step by step. Before starting the saw, be sure to check the tension of the belt, as well as the level of its sharpening.

The quality of the resulting board depends on these parameters. The first few times, make the cut under the supervision of a specialist who will tell you all the nuances, since there are quite a lot of them and it is difficult to remember them the first time.

When cutting, the saw should enter the tree smoothly and without much pressure, as otherwise this may lead to its breakage. Carry out the cut carefully, without sudden movements.

Carriage for Chainsaw for Longitudinal Sawing with Your Hands

Boards are intensively used for various construction and repair activities. There is an option to make such material independently from any suitable log using an ordinary chainsaw.

A chainsaw, often also called a chainsaw, is essentially a chain hand tool equipped with a two-stroke (almost always) gasoline engine. This popular mechanism is indispensable in any homestead. The chainsaw is small-sized and at the same time powerful. It works without breakdowns for a long time in offline mode, so it can be used in any location and in a position that is comfortable for the user. A chainsaw also has the following advantages:

- Equipped with mechanisms for selecting operating speed and soft start. Therefore, the risk of breaking the chain is reduced to zero.

- Used when wet.

- Does not require electronic energy.

- It is characterized by the highest power indicators (tangibly greater than that of a power tool).

- Has a quick-acting inertia brake.

A chainsaw is essentially a chain hand tool

The main advantage of a gasoline saw is the ability to equip it with different attachments. It is they who make it a universal tool, irreplaceable for the home craftsman. Using a chainsaw, you can saw logs, cut stone, metal, brick, tiled building materials, remove bark from wood, cut out mounting grooves and various recesses in bars.

The functionality of the tool can be expanded to a greater extent; the main thing is to choose the right attachment or equip it with a special device.

We will not outline what remains to be done for our client with the ability of a chainsaw. For the purposes of this article, we are only interested in the issue of sawing logs using a chainsaw. More on the specifics of doing such work on your own.

Cutting a log with a gasoline saw can be done after equipping it with various types of devices and special attachments. It is not difficult to obtain relatively even boards from the trunk of an old, withered tree on your own summer cottage if you install a standard attachment for longitudinal cutting of wood on your chainsaw. Fundamental point. You will not get perfect boards using this attachment. But the cut products can be used to build a fence around the site or a simple shed.

Nozzles for work

How to cut a log into boards with a chainsaw? Everything became clear with the advantages of this method, and then it is worth noting that the work is carried out using certain attachments that are suitable for various types of work.

There is an attachment that is used for sawing logs lengthwise, and it is called quite simply - an attachment for longitudinal sawing. Naturally, in this case the entire work process will take place in a horizontal position. The process of working with such a nozzle guarantees the production of boards of the same thickness. The finished materials will have to be dried, after which they can be used for the desired purpose.

The result of making your own sawmill from a chainsaw

If you set a goal to build a mini sawmill for your home, then you need to start first by making a homemade diagram. Based on the diagram, you can begin to implement the idea into reality. Making a mobile machine for sawing boards is not difficult, and every craftsman can handle it. To do this, you need to have on hand the necessary tools in the form of a grinder, a drill and a welding machine, consumables in the form of fasteners, handles and screws, rollers, as well as the main parts - angles, channels, tubes.

Then it's a matter of time and skill. When working at a sawmill, you need to take into account the following: in the design of a chainsaw it is better to use chains made of carbide materials with pobedite or diamond coating on the teeth. This will extend the life of the chains and also eliminate excess stress on the tool when the teeth on conventional chains become dull. It is not recommended to cut logs at low temperatures, since frozen workpieces will dull the teeth of gas-powered tools even faster. Having a chainsaw on your household, you should not limit yourself to its basic functionality, since this tool is capable of performing a lot of useful work, replacing such expensive equipment as a sawmill. What other capabilities does a chainsaw have that can be expanded using special attachments? You can read it in the material.

Maintaining safety while working

To avoid failures and accidents, you must follow safety precautions when working with materials and tools:

- When working, do not allow strangers to enter the work area, especially children.

- While working,

you should use protection from noise and sawdust that is thrown during cutting. - You should have a first aid kit with everything you need to use in case of cuts.

- When using a circular saw, it must be equipped with a protective cover.

- Do not pour gasoline into a hot chainsaw

. - Use the chainsaw only for its intended purpose and do not run it at full power if it is not working.

- Do not press the saw too hard while working.

- The log for sawing should be installed on the right side.

Chainsaw. This is a handy tool that you can use to make your own boards. It is suitable for use on a private farm where it is necessary to renovate or build new outbuildings. In such cases it is not required. Therefore, they can be easily cut from any logs of the required size. Once you get the hang of it, the work gets done quickly and the quality of the boards is excellent.

Post Views: 8

Chainsaw Partner 340 Malfunctions And Their Elimination

Why does the Huter Electric Saw Chain Often Weaken?