Production is unthinkable without pressing operations, and modern production even more so: the processing of metals and materials in general by cutting produces waste, which ultimately has a significant impact on the environment and economy. In a home workshop, in a garage, it is also difficult for an individual entrepreneur working in metal to do without stamping, forging, straightening, bending, molding (flattening), pressing and pressing out blanks and parts, but the choice of presses for individual use is not wide, but the prices are scary. A press is no less necessary just on the farm - for squeezing juice, oil, baling hay. Virgin juice/oil can only be obtained from a special press (see below); You need to press the grapes into the wine especially carefully and with skill. And with the choice of ready-made presses and their prices, the situation is similar to the previous one. Finally, rising energy prices are forcing many homeowners to think about switching their autonomous heating to waste (alternative) fuel, or at least how to make fuel pellets or briquettes from existing household waste (straw, husks, husks, sawdust, shavings); This also requires a special press. This publication is devoted to how to make a press with your own hands for these and some other purposes (also see below).

Homemade presses for various purposes

When to buy

Tabletop manual mechanical mini press

But when you under no circumstances need to make a press yourself, it is when you are engaged in precision mechanics, optics, or jewelry work. All homemade presses are not particularly accurate: you can’t make them better at home and/or homemade conditions. And an inaccurate mini-press can break or irreparably damage a tiny irreplaceable part, crack a lens, a gemstone, etc. In these cases, it is still better to purchase a desktop mini-press; Of these, manual mechanical rack and pinion (see figure on the right) are widely available and their prices are reasonable.

Hit or crush?

Pressing operations are carried out mainly by pressure and impact. Impact pressing is very economical: the impact creates a wave of elasticity in the metal of the workpiece, which makes the metal flow better and resist deformation less. In the practice of amateurs and individual craftsmen, impact pressing is widely used for cold forging of metals, especially artistic ones. Impact presses are most often performed using impact-inertial ones: energy is accumulated in a mechanical storage device (flywheel, falling weight). Then the drive is brought into engagement with the press punch, which hits the workpiece. Impact-inertial presses are very compact: such a press weighs 1 ton and has dimensions of approx. 1x1 m is capable of creating an instantaneous force of more than 1000 tf. But impact pressing is one of the most accident-prone and traumatic operations, so only one option for an impact press will be considered below, suitable for use in a home workshop.

What is a compact tabletop press used for?

Tabletop presses, which are offered today by many mechanical equipment manufacturers, are divided into manual and electrically powered. The high popularity of such equipment is primarily due to its compact size, due to which it does not require a large area to place this device and operate it. The working elements of modern models of tabletop presses are made mainly of high-strength steel, which ensures a long service life of this equipment.

Mechanical manual rack press for home workshop

Tabletop mechanical presses, which are driven by applying physical force, are very popular among owners of small workshops and home craftsmen. This popularity is explained by the simplicity of the design of mechanical hand presses, their unpretentiousness in operation and maintenance, which even a novice home craftsman can cope with. In addition, these desktop devices do not require any consumables to operate.

The most common technological operations that are successfully performed using a manual tabletop press are:

- pressing out and pressing of various bushings and elements of bearing units;

- cutting small parts;

- stamping;

- creating connections using the riveting method.

A manual screw-type press for work related to crimping bindings, books or covers, can also be used in carpentry when gluing workpieces

Tabletop mechanical presses are quite versatile devices that can be used to process products made from various materials, such as:

- metals and their alloys;

- polymers and plastics;

- leather;

- wood;

- cardboard;

- rubber.

Another important advantage that desktop mechanical presses have is that such equipment can operate effectively even at sub-zero temperatures.

Hand press for punching holes in leather

Which one should I do?

Pressure pressing allows you to perform almost all pressing operations necessary in everyday life. Homemade presses are most often made energy-autonomous, i.e. without a separate drive, working fluid reservoirs, pumping stations, etc. The choice of one or another design of the press is ultimately determined by its purpose and working force.

It is easiest to use a car jack as a power unit built into the press - it develops a force of up to 100 tf, and jacks for 10 tf are commonly used. The only operation that a jack press cannot handle is molding (flattening) the ends of rods during artistic cold forging.

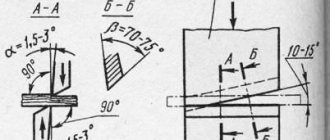

The most commonly used jack is a hydraulic bottle jack (but see also below). In this case, a hydraulic press can be made according to one of the traces. frame design diagrams (see figure):

Basic design diagrams of homemade presses

- Pos. A – the jack is turned upside down, tightly fixed to the fixed upper cross-beam, and a punch is attached to the head of the working rod of the jack. This is the simplest and at the same time reliable and vibration-resistant design (see below for the role of vibrations in the operation of the press). Disadvantages - if the jack is needed for its intended purpose, dismantling it is quite difficult and time consuming, and swinging the lever of a jack hanging upside down is not very handy.

- Pos. B – diagram with a movable table. Structurally more difficult, because a movable traverse is added - a table. They pump the jack as always, it’s easy to remove it, because... it may not be secured at all. Disadvantages – worst vibration resistance; in addition, the technology of most pressing operations is designed for the punch to press on the workpiece or part from above, but if it’s the other way around, it’s difficult and may not work out at all. But for repair and/or mechanical assembly work, this is the best option: if you need to squeeze out a tightly rusted shaft from a pulley or bearing or, conversely, press them onto the shaft, then its (the shaft’s) length is limited only by the height of the ceiling in the workshop. In general, a hydraulic press with a moving table made from a jack is the best option for a garage or service station.

- Pos. B – with a power unit on a movable cross-beam. Structurally the most complex, but vibration-resistant, strong and durable, because the load on the weakest link - the movable traverse - is not point-based, but actually dispersed. The jack may also not be secured, but if it turns out and crashes, the consequences will be worse than if it falls off the base plate. The disadvantage is that pumping a jack that slowly creeps down is not very convenient.

Note: the base plate is a heavy, bulky, material-intensive thing. Placing a press on a slab in a workshop or garage is not always possible. Therefore, the frame of homemade presses is most often placed not on a slab, but on a lower fixed cross-beam, structurally similar to the upper one (see below). This reduces the vibration resistance of the press by approx. twice, but for amateur conditions this is acceptable.

A manually driven screw press (pos. D) allows you to create a force of up to a maximum of 1.5-2.5 tf. In working with metal it is used when this is sufficient, in the following. cases (see also video):

When pressing force less than the specified values is sufficient:

Video: manual screw press for the workshop

Large stroke required:

Video: screw press 2/2

As a small or mini press for small, not very important jobs:

Video: small screw press

How to remove:

Video: homemade press for removing bearings and pulleys

Note: a structurally simple frameless lever hand press, pos. D in Fig. But it finds greater use in everyday life and households (see below), because with its help you can develop a force of no more than 300-400 kgf.

Is it just hydraulics?

A homemade jack press can be not only hydraulic. Many passenger cars are equipped with a diamond-shaped screw jack when sold. It produces a force of no more than 2-2.5 tf, but is cheap (“a new, good one” can be purchased for 1,300 rubles). A small amount of effort is not only a drawback: the frame of a press with a screw jack can be made of a wooden beam from 150x150, and it is also possible to adapt an electric drill to it as a drive, see fig.:

Homemade mechanical press with electric drive from a screw diamond jack

If the maximum you need is to bend rods up to 8-10 mm, such a press will be enough for that. And an interesting fact: about 10 years ago, the author of the article happened to accidentally meet a figure who, working 3-4 hours on the first 2-3 days of the week, earned 20-25 thousand rubles. per month At that time the amount was considerable. How? I bought empty metal cans for half the purchase price of scrap metal, flattened them and sold them at a normal price. Most of the cans they brought were beer ones, they are aluminum, and they are expensive. He complained, however, that the work was dirty - the bulk of the raw materials were brought in by homeless people.

Pressing and vibration

Vibrations of metal stretching during pressing are the scourge of large industry, and giant presses, like the one that NKMZ supplied to the French Forzhal from the USSR, are therefore extremely complex units. But individual entrepreneurs and amateurs should also pay the most serious attention to the vibration resistance of the press. A scuff on a hardened shaft or journal of an axle shaft is an irreparable defect.

Design features and principle of operation

The main parameter, depending on which tabletop mechanical presses are divided into different types, is the type of rod. So, according to this parameter there are:

- rack devices;

- mechanical screw presses.

The most widespread for a number of reasons are mechanical rack-and-pinion presses, the design of which includes the following elements:

- rack rod;

- working shaft;

- a column-shaped frame, in the lower part of which there is a stand for the workpiece being processed or a rotary table;

- a gear train that can be driven by a lever element or a special screw.

Device of a manual mechanical press of static (non-impact) action

A press with a manual drive of the design described above operates as follows: when physically acting on a lever or screw, a gear drive is activated, the rotation from which is transmitted to an eccentric connected to the press punch; making reciprocating movements imparted to it by an eccentric, the punch acts on the workpiece placed on the working surface of the matrix. It is the design of the matrix, which is a replaceable element, that determines what technological operation the mechanical press will perform.

The pressure developed by a hand press depends on the length of the lever

On modern models of manual lever presses or screw-type equipment, several schemes for installing replaceable dies are used. Thus, lever or screw manual presses can be equipped with replaceable dies of the following types:

- point;

- hexagonal;

- spinning.

The main characteristic of manual mechanical presses, which determines the technical capabilities of such equipment, is the value of the maximum force created by the rod.

Tabletop mechanical presses, depending on the model, can create a force whose value is in the range of 450–5000 kg. To perform the entire range of work in a car repair shop, a manual metal press is quite suitable, which is capable of creating a force of 2000 kg, and for use for domestic purposes, a device that creates a force of 500 kg will be sufficient.

The transmission of force in both presses is carried out using a gear, but the model on the right is equipped with a ratchet mechanism for precise and reliable pressing

Important parameters that characterize a tabletop mechanical press are also the dimensions of its working platform and the length of the rod overhang, which, in particular, determines the height of the workpiece that can be processed on such a device. The more powerful a table press is, the larger and heavier it is. So, if the force created by the press increases by only a ton, then the weight of such a device doubles.

The cross-sectional area of the rod, which is installed on a mechanical press, is also of great importance. The higher the value of this parameter, the larger and more massive parts can be processed with such a mechanical press.

Jack press: critical links

Vibrations during press operation often reveal themselves as creaking and groaning metal. Mechanical stresses in the elements of its design are inaudible and invisible, but can quickly negate the efforts and costs of its creator, and a broken crossarm can cause injury and damage. Therefore, the choice of construction materials for the press and its technical design as a whole must be taken no less seriously.

An erroneous solution would be a welded frame made of corrugated pipe (item 1 in the figure below): it practically does not dampen vibration, and welded seams are susceptible to cracking due to the forces generated during pressing. The corrugated pipe is quite massive, very elastic and therefore is a good energy accumulator. That is, if a crack creeps along one of the seams, the heavy traverse with sharp corners can instantly break off and fly to the side.

Examples of erroneous and correct technical execution of a homemade press frame

The frame of a homemade press must be made from channels, single or paired. The I-beam fits worse: at the slightest asymmetry of the pressing force relative to the vertical axis of the frame, significant transverse stresses arise in the I-beam flange, which is contraindicated for this type of profile. In addition, the I-beam is not designed to accept concentrated loads.

A frame welded from a single channel with reinforcing jibs (item 2 in the figure) will be quite reliable and stable under a load of approx. up to 5 tf; A 10 ton jack is too strong for this press. Press crossbars for a pressing force of up to 12-15 tf should be made from paired channels with the shelves facing outwards, pos. 3. This is again the best option for a garage or service station: there is no need to make holes in the traverses for the passage of shafts, which would unacceptably weaken the frame. If the press is designed to work at maximum effort (stamping, forming, bending), then the best option is a powerful single channel (see below) and a bolted frame, pos. 4; Tack welding in this case is technological, facilitating frame assembly. Bolts, firstly, will prevent sudden destruction of the frame. Secondly, they will be good vibration absorbers.

Which channel should I take?

The standard dimensions of the channel for the hydraulic press frame are selected from the jack as follows. in the following way (it is assumed that the profile is made of ordinary structural steel St44 or similar, and the traverses are solid):

- For force up to 2 tf – single from 80x40x4 mm; paired from 60x30x4 mm.

- For a force of 2-5 tf - single from 100x50x6 mm; paired from 80x40x4 mm.

- For a force of 5-10 tf - single from 160x80x8 mm; paired from 120x60x6 mm.

- For a force of 10-15 tf - single from 220x110x12 mm; paired from 150x75x8 mm.

- For force up to 25 tf – single from 280x140x15 mm; paired from 180x90x9 mm.

What are the columns made of?

Homemade hydraulic press with twin round columns

The columns of the press frame do not work for bending, like traverses, but for tension, which the metal resists much better. However, the design of the columns mainly determines the vibration resistance of the press. The channel is not ideal in this regard; it does not dampen vibrations well. To test, tap with a hammer on the sections of channel and square corrugated pipe - they ring almost the same. The sound from a solid steel rod will be much muffled. In addition, round press columns take lateral loads well, especially if the columns are paired. In this case, the press turns out to be as compact and light as possible (see figure on the right), which significantly or completely compensates for its increased labor intensity.

Note : if the press is designed for small forces (mechanical assembly and repair work), then the round columns of its frame can be made from pipes, see video:

Video: jack press

Design examples

Vibration and mechanical stability of the press are very important when repairing and maintaining cars; especially cars. Scuffing and misalignment of the fit of mating parts is not everything; the appearance of the machine is also important. That is, the press used for straightening and/or tuning a car must have the smoothest possible motion and be as accurate as possible. This is achieved by the increased material and labor intensity of the design: the columns are made of turned steel, and the table and traverses are made of solid metal plates.

Drawings of a hydraulic press from a jack with increased accuracy and stability are shown in Fig.:

Drawings of a hydraulic press (from a jack) of increased accuracy and stability

Without compromising the performance of the press, in the geometric center of its upper fixed traverse (part 1), you can drill a hole with a diameter of up to 40 mm for the passage of the shaft/axis when pressing mating parts onto it or, conversely, pressing it out of them. Maximum short-term (10 min/1.5 hour break) working force – approx. 10 ts.

On the trail. rice. Drawings of a press of a similar design and technical design, but for production and technological purposes, are given.

Drawings of a production and technological hydraulic press from a jack with a force of 12 tf

The maximum force is already regular long-term: up to 50% of the working time, therefore the design of this product is much more complicated. The special feature of this press is its double combination frame. Its chassis is on round turned columns, and its support is welded from channels. This frame dampens vibrations very well in almost any fashion. The fact is that the mechanical quality factor of a square pipe welded end-to-end from channels is very low: the elastic waves that enter it, figuratively speaking, become entangled in metal of uneven thickness and are additionally damped in the welds. For more information on the experience of amateur manufacturing of hydraulic presses from jacks, see the video:

Video: press with an inverted jack and a frame made of corrugated pipes

Video: hydraulic press with movable table

Video: press with a movable traverse

Note: just in case - in Fig. drawings of a hydraulic press frame from a jack for a force of up to 100 tf.

Press hammer

To put an end to repair and technological presses, let’s remember what we promised: how can impact pressing be used in a home workshop or at an individual entrepreneur? In the form of a pedal press hammer; It can be used as forging, riveting and stamping.

Presses of this type are also called lever hammers. Their ancestor is a forging hammer driven by a water wheel. The impact force of the press hammer is far from record-breaking, only a few thousand tons. But due to the characteristics of the behavior of metal under impact described above, lever hammers are quite effective, especially since the force and speed of the impact can be adjusted accordingly. character by pressing the pedal.

Arrangement of lever hammers for impact pressing

The kinematic diagram of the lever hammer is shown in pos. a) Fig., and in pos. b) – a device of its traditional type. At pos. c) – a device for an improved lever hammer: a parallelogram suspension of the upper striker (as the punch is called in this case) on a pair of earrings (swinging arms) provides a direct blow, and by moving the rod clamp (carriage) along the lower earring, as shown by arrows, the impact force is precisely adjusted . A pair of springs (the lower one is adjustable) makes it possible to achieve mechanical indifference of the striker: within the working stroke, it remains in any position where it is placed by hand; this makes it possible, without changing the weight of the striker, to precisely regulate the kinetic energy stored in it. Even jewelers and yachtsmen use such lever hammers to install powerful grommets in sails and assemble useful things tightly.

Note: according to maritime terminology, useful things are items of supply that are immovable relative to the ship’s hull, manufactured on shore in production conditions - bollards, cleats, rollers, etc.

Screw household presses

The first economic task for which a press is needed is squeezing juice and oil from juicy fruits. The latter, however, is irrelevant in the Russian Federation: olives do not grow here, and oil cannot be squeezed out of seeds by pressure; it is beaten out by impact pressing on oil churns. Juicer presses are often made on the model of production and technological ones from jacks in a wooden frame, because The pressing force required is no more than 1-1.5 tf, see, for example. video:

Video: press for apples, berries and fruits

But the correct press juicer must be a manual screw press with a wooden basket, see fig.:

Manual screw press juicer and its device

The screw gives your hands the ability to sensitively regulate the pressure, and only the press with a wooden basket produces the highest quality virgin juice/oil. If we are talking about grape juice for elite wine, but all parts of the press in contact with it are also made of wood; The best species for this are oak and mulberry aged for at least 3 years.

About winemaking and wine presses

The grape variety and the conditions for its cultivation are not all that is needed to obtain good wine. For example, many excellent grape varieties grow in the Northern Azov region: the climate is suitable, shell limestone soils are abundant. But during the perestroika struggle for sobriety, an article appeared in Science and Life about the content of fusel oils in homemade alcohol. It was the northern Azov homemade wines that came out on top: 3700 mg/l (!!!). The second place was taken by Sumy potato moonshine, 1900 mg/l; the rest of the “self-propelled guns” were ahead by a wide margin. The holidaymakers who at that time dared to try the local “varyokha” from one glass, excuse me, “got further than they saw.”

Winemaking in general is a delicate matter, and squeezing juice into wine is its most important stage. The juice for wine from elite grape varieties is pressed as follows: for Pinot wines, berries of a certain degree of ripeness are manually selected directly from the bunches on the vines. Selected berries are pressed lightly in 3-5 stages so that only pure juice is released without any admixture of slimy pulp, and the seeds and skin do not have time to release tannins. The remainder of the harvest is added to the Pinot pressings and pressed in the usual way; In this way, juice is obtained for wine of the same variety in the Mosto category. Real Mosto is also a very good wine, but Pinot... you understand - hand-picked one berry at a time by experienced highly paid workers and completely manually pressed “with bated breath.” Therefore, the prefix “Pino” to the names of cheap draft wines (by the way, very often very decent ones) is nothing more than a shameless scam. Unfortunately, it is now legalized in most countries with developed winemaking.

Drawings of a manual screw press for squeezing fruit juices of the highest quality are shown in the figure:

Drawings of a screw hand press for extracting premium quality juices

In addition to the above, it has two more significant features. The first is a relatively small diameter steering wheel instead of a gate. It is difficult to turn the gate perfectly evenly; it transfers pressure into the hand weakly and it is easy to crush the load of raw materials. The second is the rectangular thread of the screw-nut running pair. Better, but technologically more difficult - trapezoidal; threads of the same profile are used wherever smooth, precise clamping is required, e.g. in a mechanic's vice.

It is difficult to turn even a rectangular thread, and it is expensive to order, so if you are making such a press, look in scrap metal for unusable water supply or gas main shut-off valves (valves, gate valves). Their running pairs have rectangular threads, which, if the rust is removed, are most often in order - the valves are the first to become unusable.

Note: for more information about making a juicer with a wooden basket, see the video:

Video: juice press

Lever presses

Manual tabletop lever press for installing metal fittings in garments

Lever presses are also quite common in everyday life and households. For example, in sewing for installing eyelets, buttons, fasteners, dress rivets, denim buttons. The structure of a “tailor’s” desktop hand press is shown in Fig. on right. For precise centering of the clamp, its rod slides in the holder, as in a lever press with a sliding stop, see Fig. above. with types of presses. But the kinematic diagram is different: in this case, a pair of pressure levers and shackles is used. In such a press, the clamping force increases quite smoothly along the course of the rod, which is exactly what is needed for high-quality flaring of the sides of metal sewing accessories. At the lower end of the rod there is a blind threaded hole (socket) into which shaped punches for various types of fittings are screwed.

The next pressing operation, which is often required by owners of private farms and small farmers keeping livestock, is hay baling. Moderately compacted hay not only requires less storage space and is less likely to crumble in the process, but is also much less susceptible to pest damage.

For baling hay for storage, mechanized balers are produced and sold, but these are expensive and rather complex units. They justify themselves only in a sufficiently large, profitable economy. The owner of a private plot or a small individual farmer, at least at first, is better off using a scythe, a rake and a manual lever hay baler, the device of which is shown in the following. rice.:

Lever Hand Baler

This is a basket with an opening gate, a simple one, without any kinematic tricks, a lever with a shoulder ratio of 1:6 - 1:10, and a punch (punch) made of a board panel. Hay is loaded into a basket with a closed gate - pressed, loaded - pressed until a bale of the desired size is formed; they take it out by opening the gate.

Manual lever press for forming fuel briquettes

Finally, let’s remember about independent procurement of alternative solid fuel. Fuel pellets, which produce the lowest ash content when burned, are formed in screw thermoforming installations of a rather complex design, see Fig. on right. Their disadvantage from the point of view of the owner is also significant energy consumption, which can negate savings on the purchase of standard fuel for a furnace or boiler.

It is much easier to build a wall-mounted manual lever press for manually pressing fuel briquettes from dry combustible agricultural waste, see next. rice.:

Diagram of a thermoforming installation for producing fuel pellets

For more information about its production, see the video in 2 parts:

Main varieties

A tabletop mechanical press is not the only type of manual pressing equipment. To perform various technological operations, specialists have created many different models of pressing equipment and manual devices, the most common of which are:

- manual hydraulic presses;

- hole-punching press devices;

- manual presses designed for connecting electrical cables mechanically;

- press pliers used for crimping electrical cables and plumbing pipes;

- tablet press

Manual hydraulic press for punching holes in metal sheets

Manual pressing equipment with hydraulic cylinders containing hydraulic fluid can generate forces that a screw or lever press cannot provide. The magnitude of such efforts in the case of using hydraulic equipment can reach tens of tons, while the user of such a device requires a minimal amount of labor. Hydraulic pressing equipment is used to solve the same problems as a conventional manual screw press or lever-type device, but only in cases where significant pressure must be applied to the workpiece.

Manual punching equipment is a device specifically designed for punching holes in sheet-type workpieces. You can also work with such devices on metal, if the thickness of the sheet does not exceed 4 mm. The diameter of the holes produced by this manual equipment can be in the range of 10–40 mm.

The DS-8 punching press cuts round holes with a diameter of 8 mm in metal up to 3 mm thick

Mechanical presses, designed for crimping electrical cable lugs and making their connections using special tubular sleeves, allow you to create connections that are not only characterized by high mechanical strength, but also excellent electrical conductivity. Such a manual pressing device, made in the form of a lever mechanism, is equipped with a ratchet, which prevents the compressing working elements from releasing until the cable crimping is completely completed. A press of this type can be used to work with electrical cables and wires of any type, the cross-sectional area of which does not exceed 240 mm2.

To crimp the sleeves of electrical wire lugs, manual press pliers with a ratcheting mechanism are used.

Press pliers are also used for crimping elements of electrical contacts, but such a manual mechanical press can be used for crimping electrical cables whose cross-sectional area does not exceed 35 mm2. The weight of tools of this type, to make them convenient to use manually, does not exceed 3 kg.

Hand press pliers for crimping small wire lugs

A manual tablet press is a device that is used to produce tablet medications in a laboratory setting. Devices of this type, with which it is possible to produce tablets with a diameter of 0.4–1 cm and a thickness of no more than 0.5 cm, can be manually, electrically or hydraulically driven. Depending on the model, the productivity of such equipment can be in the range of 200–1000 tablets per hour (and industrial models - up to 6000 tablets per hour and even higher). The maximum force that tablet presses are capable of creating, as a rule, does not exceed 700 kg.

Manual tablet press is used where granular powder needs to be compressed into tablets