How to crimp a high pressure hose with your own hands

High pressure hoses are used in pneumatic and hydraulic structures.

In the automotive industry, they are widely used in steering systems. Thanks to the built-in hydraulic booster, the driver does not have to apply significant load on the steering wheel when turning. However, under certain operating conditions, various deformations of tubes or hoses are possible. Subsequently, this leads to unstable operation of the unit, which can be corrected by repairing the power steering high-pressure hoses with your own hands or with the help of service station specialists.

Hydraulic operation

Hoses, which are often called high-pressure hoses, are flexible pipelines whose main task is pumping working fluids. The transported material is specially prepared motor oils or working fluids based on mineral oils, aqueous solutions of emulsols, glycol, and greases.

Without high-quality flexible hoses that can withstand the required pressure and an extensive pipeline system, it is difficult to imagine the operation of a hydraulic booster. In addition to the direct duty related to pumping working fluid, such hoses act as dampers (compensators), increasing the operational period of connecting elements, fittings, fittings and the system as a whole.

Vibration absorption by flexible elements contributes to obtaining such results. The negative side of the phenomenon is that periodic replacement or repair of power steering hoses in worn areas is required. After all, all abrasions or kinks soon lead to the tube leaking .

Structural features of power steering hoses

In addition to working under high pressure, the power steering hose must have reduced susceptibility to the working fluids used. Thanks to this, its inner surface is made on the basis of oil- and gasoline-resistant synthetic rubber.

The outer surface is protected by layers of wear-resistant rubber. Under certain circumstances, this layer plays the role of thermal protection. It may have the following surfaces:

- corrugated;

- polymer;

- metal.

The outer and inner layers are separated by a metal braid. This gives the entire structure the required operational strength and acceptable rigidity. Wire layers alternate with rubberized elements.

It is customary to distinguish the following types of hoses:

- Winding . During the manufacture of this product, turns of wire are braided evenly around the entire perimeter.

- Braided . Each turn covers the sleeve at a certain angle to the common axis in such a way that it intersects with the turns of the previous layers. This technology increases the strength of the structure and can operate at higher pressures than the previous type.

The frame for the sleeve in some models is textile. The geometric and physico-chemical parameters of wire and rubber are standardized for various applications.

Suspected damage

During operation, motorists may encounter different types of hydraulic damage, after which repair of the power steering hoses is necessary. The following points can be noted:

- Manufacturer defect . This feature is typical for insufficiently known hydraulic equipment manufacturing companies. Failure is characterized by poor-quality crimping of the joint of a sleeve or fitting. This happens when the equipment is undebugged or incorrectly configured.

- Operational output . Damage occurs due to wear and tear during operation of the mechanism. The main problems are cord breaks, cuts and frayed areas. This often occurs due to hose sagging due to incorrectly selected length.

- Structural inconsistencies . Failure occurs due to the installation of equipment that does not meet the specifications specified by the automaker. In such situations, a wire rupture or fittings may break due to a discrepancy between the pressure in the system and the permissible value for the hose.

- Disagreement in temperature or chemical characteristics . Damage to the structure can occur during operation at an ambient temperature for which such rubber was not designed, as well as during the use of aggressive chemicals in the structure of the working fluid.

Damage to power steering hoses

The manufacturer indicates all characteristics and permissible operating parameters for each hose in the instructions for use.

Hydraulic malfunctions with which further operation of the vehicle is not recommended:

- fittings are significantly damaged by corrosion processes;

- significant fracture of the sleeve;

- significant abrasion of the outer part of the hose;

- the presence of complete or partial blockage inside the sleeves;

- lack of sealing of connections;

- failure of the fitting from the landing diameter;

- liquid leakage at joints;

- deformation or damage to the inner surface from high pressure or excess temperature.

Features of high pressure hose repair

High-pressure hoses, more often called high-pressure hoses (HHP), are designed to create or absorb working force, which is transmitted under high pressure by liquids or gases pumped into them.

High pressure hose

The main area of application of RVDs is hydraulic and pneumatic systems of various devices and mechanisms. Outside of industrial production, vehicle owners most often deal with high pressure hoses, these are power steering hoses, and those who use high-pressure pumps, for example, our most common brand, Karcher.

Return

RVD structure

The design of the RVD is determined by the need to withstand internal pressure, which can reach several hundred atmospheres.

In addition, the inner surface of the high-pressure hose must be impervious to the effects of the transported medium. Therefore, its bottom layer is made of oil- and petrol-resistant rubber or synthetic rubber.

To make the upper, thicker layer of the high-pressure hose, wear-resistant rubber is used, which, if necessary, is supplemented with thermal protection in the form of a corrugated coating, metal or polymer.

Between the upper and lower layers of rubber, metal wire is wound in several layers, thanks to which the hose receives the necessary rigidity and strength. Layers of wire are interspersed with thin rubber films.

Depending on the method of winding the wire, there are two types of high-pressure hoses:

- Winding. When producing this type of hose, turns of wire are wound in even rows.

- Braided. In this case, the turns are wound at an angle to the axis of the hose so that the turns of the previous layer intersect with the turns of the next layer of wire. Braided hoses have greater strength and can withstand greater pressure than coiled hoses.

High pressure hose

In addition to wire, textiles can act as an internal rigid frame.

The number of layers of wire and the thickness of rubber layers are set by standards that determine the scope of application of a particular type of hose.

Return

Fittings for high pressure hoses

To secure the hoses in place, fittings (tips) are mounted at their ends, which are of the following types:

- Screw;

- Union;

- Nipple;

- Quick connect connections.

Fittings are attached to the ends of the hose using crimp couplings, which are crimped on special machines.

Depending on the type of shank, fittings are classified into series:

- Universal. This series can be used in all hoses of high pressure hoses with the exception of coiled type hoses.

- Interlock. The series is used for coiled hoses.

- CS. Fittings of this series also crimp coiled hoses, but there is no need to remove the rubber of the upper and lower layers.

When installing fittings of this type, it is necessary to remove both layers of rubber, internal and external.

Fittings for high pressure hoses

The operation of removing layers of rubber is called hose debarking.

Failure of fittings is the most common cause of damage to high pressure hoses. This is explained by the magnitude and intensity of the loads they experience.

Return

Damage to high pressure hoses

The causes of damage can be divided into the following types:

- Manufacturing defects. Most often, this is a poor-quality crimping of the joint between the fitting and the hose, due to the use of handicraft or unregulated equipment.

- Damage sustained during operation of the main mechanism. They manifest themselves in the form of cuts and ruptures in the hose. Their most common cause is sagging of the hose due to incorrectly selected length.

- Damage resulting from non-compliance of hose parameters with operating conditions. This could be a rupture of the hose or a failure of the fitting, because of this the pressure turned out to be higher than that for which the hose was designed.

- In the same row, damage to the outer layer of the hose should be mentioned when it is used in a temperature range other than that for which it is designed.

Important! In order to protect yourself as much as possible from possible damage to hose hoses, when choosing them, it is necessary to carefully check the compliance of their characteristics and parameters with operating conditions.

High pressure hoses with fittings

We are talking, first of all, about the calculated value of the maximum permissible value of pressure, temperature and the minimum bending radius of the hose. The most common damage to high pressure hoses are:

- Corrosion of fittings.

- Sleeve break.

- Abrasion and wear of the top layer of the hose.

- Sleeve blockage.

- Fitting connection leakage.

- The fitting comes off the hose.

- Fitting connection leaking.

- Thermal damage to the inner layer of rubber.

Crimping high-pressure hoses with your own hands - Metalworker's Guide

High pressure hoses are used in pneumatic and hydraulic structures. In the automotive industry, they are widely used in steering systems. Thanks to the built-in hydraulic booster, the driver does not have to apply significant load on the steering wheel when turning.

However, under certain operating conditions, various deformations of tubes or hoses are possible. Subsequently, this leads to unstable operation of the unit, which can be corrected by repairing the power steering high-pressure hoses with your own hands or with the help of service station specialists.

Carrying out repairs

Based on the nature of possible damage, it can be assumed that the most common repair of power steering hoses involves putting the fittings in order or replacing individual parts of the hose. To carry out the replacement, crimping with couplings will be necessary.

Tools for DIY repairs

The work algorithm may be as follows:

- The damaged hose must be disconnected from the system.

- The new hose will need to be the same length so as not to create unnecessary sagging. The measurement is carried out from nipple to nipple. At the same time, we select a hose that satisfies all geometric data and pressure parameters. The markings indicated on the outside by the manufacturer will help with this. The internal diameter will also be indicated there.

- When repairing a high-pressure hose, the ends are stripped both outside and inside to the metal braid. The procedure is carried out faster using debarking machines.

- Fittings are selected according to geometric parameters and technological thread data. Measurements are easy to take using a caliper and thread gauge. Domestic and foreign fittings may differ from each other according to several criteria, so it is better to take measurements yourself.

- We crimp the fittings using crimping equipment, using suitable removable jaws in each case.

- Using a control probe, we determine the quality of the work performed. At specialized factories, this operation is carried out using special industrial stands.

Equipment for crimping high pressure hoses

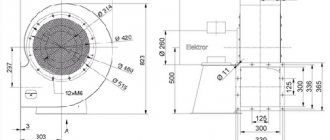

For the manufacture of high-pressure hoses, a special type of equipment is used - crimping machines. With their help, a reliable connection of the components of the hose design is formed.

Operating principle of crimping machines

The general operating principle of the machine is based on pressing fittings of various configurations onto the end parts of the hose. Performing this work requires accurate calculation of the optimal degree of pressure while maintaining the integrity of the high-pressure hose.

Main types of products

A hose clamp is a connecting mechanism that has many variable designs and sizes. Specialized stores offer a huge range: from cheap Chinese options to reliable German products. Commercially available clamps for fastening hoses are divided into several types:

- Spiral. Mechanisms are used to connect the sleeves to the outer helix.

- Worm-shaped. The device contains a special screw that tightens the perforated or stamped tape around the pipe.

- Power. Reliable fasteners designed for harsh environments with high clamping force.

- Reinforced. The tape and clamp of such reinforcement are a single structure that can withstand significant loads and pressure.

Fastening mechanisms are not completely universal. Each type of product has its own specifics - it is used for one or another type of sleeve. For this reason, it is important to know for what purpose the device is selected.

How to connect a high pressure hose with your own hands?

High pressure hoses are used in pneumatic and hydraulic structures. In the automotive industry, they are widely used in steering systems. Thanks to the built-in hydraulic booster, the driver does not have to apply significant load on the steering wheel when turning.

However, under certain operating conditions, various deformations of tubes or hoses are possible. Subsequently, this leads to unstable operation of the unit, which can be corrected by repairing the power steering high-pressure hoses with your own hands or with the help of service station specialists.

We tell you where and how to repair a Karcher hose!

The Korbit tourist club has an equipment base. There is a well and a Karcher pressure washer. For three years this entire system worked without failure. And so, the Karcher hose broke... Many questions immediately arose. Where can I buy a new hose? Where to go if you need Karcher urgently?

We found out everything and are sharing our experience! Firstly, the Karcher hose is a high pressure hose and can be repaired. Secondly, you can repair Karcher high-pressure hoses yourself, or you can do it in a specialized organization.

DIY Karcher hose repair

The technology for repairing a Karcher hose with your own hands is very simple. First, cut the hose along the edges of the tear. Then we make even cuts - either with special scissors, or a machine, or a cutting tool.

After that, we go to a special store to get a fitting (a connecting tube along the inner diameter of the hose) and special power clamps. Ideally, place a pair of clamps on each side. Attention, simple clamps will not work!

This DIY hose repair has its drawbacks. If the hose is used in the washing area, the repair unit (clamps) will constantly cling to something, which is inconvenient.

Another minus. If you don’t have a fitting and a power clamp in your garage (in your warehouse), you still have to waste time searching for and purchasing a fitting of the required diameter and clamps.

But there are also advantages. Such repairs of Karcher high-pressure hoses will not be expensive. Especially if you need to extend the hose or make several repair connections.

Repair of Karcher hose in a specialized organization

If you have little free time, you should turn to professionals. Pros. The Karcher hose will be repaired on site in 10 minutes. They are repaired carefully, the repair unit will not interfere with work with the sink. Repaired using professional equipment and reliably.

Minuses. The cost of repair is 500-800 rubles for each unit. That is, with the market price of a non-original, but acceptable quality Karcher hose at 2000-2500 rubles (autumn 2018), it makes sense to make repairs if you have a relatively new hose and no more than 2 damages. In other cases, it is worth thinking about a new hose.

Subscribe to our news! Don't miss cool events and important information!

- click here -

We have compiled a list of organizations in large cities of the Central Federal District where you can repair a Karcher hose:

- Belgorod, st. Dzgoeva, 6, tel.

- Bryansk

- Vladimir

- Voronezh, st. Dorozhnaya 50, tel. 8 (473)2582296

- Ivanovo

- Kaluga

- Kostroma

- Kursk

- Lipetsk, Voronezhskoe highway, building 35, tel. 8 (4742) 711-411

- Eagle

- Ryazan

- Smolensk

- Tambov, st. Urozhaynaya, 1A, tel. 8 (4752) 569320

- Tver

- Tula

- Yaroslavl

If your city is not listed, try clicking here.

Reasons for repairing Karcher high pressure hoses

At least in a nutshell, we need to talk about the reasons for the repair. In our case, the reason is this: the sink itself “shudders” when started. The hose coming from the sink gradually rubbed against a sharp corner.

But there may be other reasons - poor-quality hose material, the working pressure of the hose does not correspond to the washing pressure, the hose is outdated, and others. Of course, all these reasons need to be eliminated.

That's all! Keep your tools in working order and continue to enjoy working with your hands! Have a good day!

Fittings for hoses for various purposes: what they are and how to choose

Stationary irrigation lines for summer cottages made of metal are extended with pipes of a common diameter by welding. To increase the length of flexible irrigation systems, hose fittings are needed to prevent squeezing and depressurization.

Leaks occur when connecting two sections using a primitive method - a metal tube and clamps.

And high-quality connecting fittings will ensure reliable connection of the hose sections with the pump, but it is important to understand the classification and purpose of each connecting element.

Connecting elements for hoses vary in purpose, material of manufacture and technical characteristics

Types of hose connectors

Integral elements of a flexible “external” water conduit are made from different materials:

- metal;

- polymer;

- composite.

In a dry summer, one of the daily concerns of a summer resident may include “sprinkling” remote corners of the garden. This work will be facilitated by a well-organized irrigation system, which uses not only fittings for connecting hoses, but also other elements of high-quality irrigation:

- flanges;

- fittings;

- adapters;

- adapters;

- turn signals (knee);

- universal connectors;

- connectors with different diameters on both sides;

- tees and crosses;

- couplings and clamps (as auxiliary equipment).

In addition to them, the following are in great demand as options for adjusting the watering jet:

- taps;

- filters;

- plugs;

- valves;

- sprinklers;

- sprinklers;

- “pistols” (other attachments).

You can regulate the pressure and flow of water when using a watering hose using special spray nozzles

Some of the nozzles inside have a rotating module - for better watering. Among the connecting devices, not only options for irrigation are offered, but also elements of other functionality:

- fittings for joining gas hoses;

- nipples for washing machines;

- connectors for hoses and high-pressure hoses (HPR);

- hydraulic fittings.

It is advisable to use connectors not only to extend the hose, but also when its integrity is compromised - the appearance of “fountains” or “unscheduled drip irrigation”.

Fittings with options that allow you to temporarily shut off the water without turning it off at the main valve are very convenient.

The most popular are relatively inexpensive and high-quality Gardena and Hozelock connectors.

Hydraulic fittings for high pressure hoses

High-quality elements for connecting high-pressure hoses and hoses are produced by domestic and foreign companies. Their range is regularly updated, but the main list of items remains virtually unchanged, but there are minor differences:

- in terms of reliability and quality of articulation;

- in combination of diameters of adapters;

- in additional options.

When working with high-pressure hoses, you should choose high-reliability fittings

Repair of power steering hoses

The presence of pressure, vibration, and high temperature of the medium indicates that you will have to use power clamps.

Based on these recommendations, you can easily select hose clamps - you can buy the intended connecting mechanism on our website.

Do-it-yourself hose crimping machine - Metals, equipment, instructions

To manufacture hose hoses, TsPK LLC placed Finn-Power equipment in its warehouse in Moscow, and we also use Parker components.

The high pressure hose is an indispensable and one of the most important parts of the production process. It transports gases and liquids. But installation of high pressure hoses requires special equipment for reliable fastening of hoses and their strong connection.

Lines for the production of high-pressure hoses today need to be equipped with special crimping equipment. Machines and presses for crimping high-pressure hoses are available in various types and sizes and can be used both in industrial conditions and for urgent repairs anywhere (mobile presses).

Types of hose crimps

Pressure testing of high-pressure hoses is carried out using specialized equipment. The technological process is quite labor-intensive and requires care and precision. Today, mainly two methods are used for crimping:

- 1. European (longitudinal). This method is also applicable when crimping braided hose hoses. The essence of the method is as follows: the internal coupling is equipped with ring teeth, which are inserted into the sleeve braid, ensuring a reliable connection. When crimping two types of hoses - 1SN and 2SN - the outer thin layer of rubber is not removed. This allows you to make the connection even tighter.

- 2. Cross crimp. This method is considered classic and is used most often. Used in crimping high-pressure braided hoses. This process uses a tubular coupling. The process is as follows: the top layer of rubber is removed along the entire length, which holds the sleeve from the inside with transverse protrusions. The coupling is pressed tightly against the sleeve and provides fastening.

Traditional crimping is transverse. Longitudinal is most often used for crimping hose hoses with metal braiding of domestic production, produced in accordance with GOST 6286-73. Such hoses are the most economical and reliable in operation.

In hydraulic systems with high pressure, longitudinal crimping methods are mainly used. The sharp teeth on the coupling cut firmly into the metal braid, allowing you to avoid scraping off the top rubber layer.

The connection is sealed due to high pressure compressing the sleeve on the nipple.

Crimping equipment can be divided into types depending on the scope of application:

- The service press is most often used in workshops and small-scale or even single-piece production;

- a mobile press is in demand for urgent repairs, mines and replacement of high pressure hoses directly on site;

- an industrial press is used in large-scale production.

Features of the machine for the manufacture of hose hoses

The hose crimping press is part of the production line. Today on the market there are both small mobile machines and stationary ones for industry. When choosing a machine, it is necessary to take into account the initial parameters of working with the equipment: the type and diameter of the hose, the maximum size of fittings, the type and performance of the machine.

The scope of use of crimping machines is quite large:

- · production of hydraulic hoses;

- · production of auto parts;

- · production of construction equipment;

- · production of sea and railway transport;

- · production of wire, hoses, pipes and pipelines, cables.

The crimping machine has the following features:

- · works from several sources: battery, compressed air or manually;

- · crimping accuracy is always at its best;

- · the design of the machine is convenient and ergonomic, it is easy to operate;

- · quick pressure testing of hose hoses is possible due to the system for quick replacement of cams;

You can use the machine in production conditions and on site.

Selecting a crimping machine

The reliability of fastening of sleeves and hoses depends on the quality and performance characteristics of the equipment. When choosing, pay attention to the details and characteristics of machines and presses:

- 1. Crimping speed. This parameter is especially important in production. Machines with high crimping speeds are used in multi-batch production and various conveyors. In standard press models, the speed ranges from 300–2500 crimps per hour.

- 2. Mobility. In industrial conditions, mainly stationary powerful machines are installed. In the field, for urgent installation and repair, mobile portable presses will be required.

- 3. Crimping force. Varies between 3500-12000 kN.

- 4. Working diameter. The maximum permissible opening of the crimping jaws in millimeters shows the permissible size of the hose that can be crimped.

High-pressure hoses are used today both in large enterprises and in small workshops. Crimping of the hose may be required at any time. A high-quality crimping machine is a guarantee of connection reliability, long service life and strength of the connection point.

We manufacture hose hoses of any complexity and sizes up to 2.5 inches. with fittings made of galvanized and stainless steel, as well as polymer protection (plastic spiral).

Contact us by phone +7 (495) 247-87-27. We are located at: 115230, Moscow, Elektrolitny proezd, 3, 5 minutes from the Nagornaya metro station.

Manufacturing and repairs are possible in front of you and in the shortest possible time!

Business in the production of high-pressure hoses (HHP) (November 2018) - how to open from scratch, examples and a ready-made plan with calculations for beginners

Train your brain with pleasure

Start developing

High pressure hoses are a pipeline through which any gas or liquid can be distilled. They are used both in everyday life and for industrial purposes. Of course, the characteristics of these products, depending on the purpose, are different. These products also exist on the market from manufacturers from Europe and the CIS countries. Today we will look at how to set up the production of high-quality high-pressure hoses.

- What equipment to choose for the manufacture of high pressure hoses?

- RVD production technology

- Franchise business

- Step-by-step plan for starting a business

- How much can you earn

- How much money do you need to start a business?

- Which OKVED code must be specified for the production of high-pressure hoses?

- What documents are needed to open

- Which taxation system to choose for the production of high-pressure hoses

- Do I need permission to open?

This product requires certain knowledge of the technological process. It is also impossible to organize a production workshop without special equipment. It comes in different capacities and differs in other characteristics. You need to study them before purchasing. It would also be a good idea to find out reviews from industrialists who are already working on it.

What equipment to choose for the manufacture of high pressure hoses?

You can buy equipment for the production of hose hoses in the form of a finished line or each machine separately. The standard kit looks something like this:

| Machine name | Price, thousand rubles |

| Crimping press or crimping device | 200,00 |

| Cutting machine | 80,00 |

| Apparatus for stripping rubber inside and on the surface of hoses | 60,00 |

| Marking machine | 50,00 |

Additional equipment (rolls, frames) will cost another 150 thousand rubles. The prices in the table are the minimum prices. This price segment of equipment will provide an opportunity to open a small production facility.

This is enough to start a business, since it is very important to determine the channels for future sales of products.

After establishing strong partnerships with customers, you can think about increasing production capacity.

To make a high-pressure hose you will need the following equipment:

| 1 | Crimping machine or crimping press. |

| 2 | A device for removing the upper and inner layers of rubber from high-pressure hoses. |

| 3 | Equipment for marking. |

| 4 | Roll for unwinding coils. |

| 5 | Racks for presses. |

| 6 | Storage for a set of jaws. |

The technological process can be divided into several stages:

- preparatory work with material and equipment setup;

- crimping operation;

- quality control and testing of finished products.

High-pressure hoses are distinguished by the type of metal coating. They can be made by braiding or winding. I also use different materials for this process.

Crimp the high pressure hose with your own hands

Subtopic two. Updating power steering system parts

.

Who missed it, be sure to read

While removing the power steering pump, the power steering high pressure hose cracked at the junction with the pump. A bolt stuck to it and decided to unscrew along with the tube (hose) and crack.

Unfortunately, I didn’t take any photos of my pipe in the broken version.

Looking ahead, I will write that the hose from Chery Amulet is exactly the same, I will use its photographs as an example (photos of a clean hose from golf 3 in normal resolution are difficult to find).

I took the next photo from HERE, I think the gentleman will not be offended

General diagram of power steering system hoses. I have highlighted the hoses in different colors to make it easier for you to understand. Green hose damaged

Access to it by removing the battery with a tray

And through the bottom of the car from the rear side of the subframe

This is what a removed hose looks like (this one is from an amulet).

Having suggested in the garage how it could be repaired and having consulted with the guys, I left the car and began to receive information. This is a high pressure hose. The pump pumps pressure up to 90-105 bar, a mediocre attitude towards the hose can lead to consequences.

If it breaks, there are several options:

1.

buy used

original hose (price about 1000 rubles). There are practically no problems with them (leaks), I think you won’t get caught with a snotty one. The only thing is that all aged hoses sweat where the rubber is pressed onto the metal. 2.

buy a new hose from Chery Amulet.

Identical hose, installed as original. Price 1200-1800 rub. I won’t write anything about quality, I wasn’t interested. 3.

buy a new golf 3 hose. The pleasure is expensive. With the old dollar rate - 6500, with the new one 11000. Analogue Febi (disgusting) - 7000, old price 4000.

If there are still analogues like HDE, I didn’t even consider the price. 4.

repair the original hose in specialized offices. The asking price is no more expensive than used. original. In almost every CITY there are companies that manufacture high-pressure hoses, air conditioning pipes, and power steering hoses.

I found a bunch of companies in Ulyanovsk and chose two - on Khvatkova and on Moskovsky.

The first one promised to make a new hose or simply repair it. The owner of the office talked on the phone for a very long time about their capabilities and that they were the best in the city. Arriving there, I discovered the absence of the owner, there were only workers.

They said that they would not make a tube (metal), they would simply clamp a new high-pressure hose and replace the tube with it, and at the end the sleeve. Of course, they had the opportunity to make a complete analogue, but the workers clearly did not want to. I agreed.

They took my hose for examination, while I was paying, they brought it already crimped - it all took a couple of minutes. Price - 500 rub.

But one part of the hose was not updated, it was all rusty

Sandpaper in hand, patience. Then I painted it the color of aluminum.

I also cleaned the bolt, new washers, and the hose is completely ready.

The hose holds 330 bar - not bad!

Everything was done on the fly, I didn’t even read the sample notes about repairing Gur hoses. The evening before installation, I googled and found important information. A throttle is clamped in the middle of the hose - a pressure rectifier. Available in most hoses. Absorbs minor vibrations. Here are some clippings from forums of different brands:

«there the guys had the idea that the fault was due to an incorrectly designed high-pressure hose on the power steering, they say our native hose is too rigid, is not able to dampen vibrations, etc. there is no throttle in it - the flow is not evened out in any way, and yet from the pump it does not come out in a steady stream, but in jerks, like a human pulse.

«

I won't copy too much. just read some different situations:

For people at such services, they take out the old throttles and clamp them into new hoses. They didn’t do this to me. I called the owner of the company and said that they had left it, saying that it was needed so that the (old) hose in the middle did not inflate, but with their hose, which is strong, this is not required. In response to my message that it was needed to equalize pressure, he simply laughed: “We have been in this field for many years.

No one was given this choke, no one came back. Who told you such nonsense about the throttle? We agreed that I would take this throttle from them (this is a piece of plastic tube on the inside of the hose, crimped on the outside). Again, laughter and ridicule - “I’ll save it for you. You see, this is garbage, and you want to take it away.” Well, just great service.

in which they consider themselves smarter than everyone else.

Read also: How much is 6 4 inch thread?

We called the second chosen company - they immediately understood which choke I was talking about, they explained that this choke is important, as is the design of the hose itself.

Some machines had problems with noise after replacement (they did), they removed them 3-4 times, changed the characteristics to achieve the result.

This company can make an analogue of the hose; it is possible to replace both the metal tube and the hose, and make a throttle; they can solder a broken tube. The cost of manufacturing a rubber-metal tube with a throttle is approximately 1500.

Some have no changes from such a hose, there are hundreds of examples.

I didn’t have any problems with the steering wheel, except for the hum of the pump, but the noise does not come from it, from the steering column. There was such a noise before the replacement, but I can’t understand whether it became louder. Here an ambiguous situation arises - whether the source of noise is the absence of a throttle. You can buy your own or from an amulet and try to install it.

Or make the most similar hose in the second service. It is known for sure that the Audi A4 produces noise when installing a non-original hose (there are several examples). But a search on the forums also says that the noise of the rack may not depend on the pump; again, there were examples of replacing the pump to eliminate the noise with a similar one, but it did not help. The situation is ambiguous.

Still, I'll do something.

Let's go back to the diagram, I updated all the hoses and tubes. Almost all connections were snotty, especially at the tank

The yellow tube (in the diagram) is the return line, the pressure in it is not so high.

The hose joints were missed; there is no point in clamping them. I won’t even write the price of new ones, it’s expensive. One hose will fit from the amulet A11-3406171AC

I bought a truck fuel line hose. At the bends I placed a spring inside, on the advice of Pawel-K

The tank is also like new

Everything is new in place

If you make a hose this way, calculate the internal volume. Since the inner diameter of the hose is slightly larger than the metal tube, the volume of my entire system increased by 100 ml. It doesn’t seem like a lot, but one liter of gur oil (one bottle) was not enough to reach the dipstick mark.

That's not all! I'm preparing the third part. There will also be observations, practice and conclusions