Fan device and design

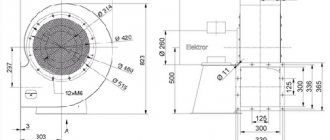

Radial fan operation diagram

Sometimes an impeller and a power unit are not enough to move air. In conditions of limited space, a special type of exhaust equipment design should be used. It has a spiral-shaped body that acts as an air channel. You can make it yourself or purchase a ready-made model.

To form the flow, the design includes a radial impeller. It connects to the power unit. The wheel blades have a curved shape and create a discharged area when moving. Air (or gas) enters it from the inlet pipe. When moving along the spiral body, the speed at the outlet increases.

Depending on the application, the centrifugal fan volute can be general purpose, heat-resistant or corrosion-resistant. It is also necessary to take into account the amount of air flow created:

- low pressure. Area of application: production workshops, household appliances. The air temperature should not exceed +80°C. Mandatory absence of aggressive environments;

- average pressure value. It is part of exhaust equipment for removing or transporting small fraction materials, sawdust, grain;

- high pressure. Forms an air flow into the fuel combustion zone. Installed in many types of boilers.

The direction of movement of the blades is determined by the design, and, in particular, by the location of the outlet pipe. If it is located on the left side, the rotor should rotate clockwise. The number of blades and their curvature are also taken into account.

For powerful models, you need to make a reliable base with your own hands to secure the body. The industrial installation will vibrate strongly, which may lead to its gradual destruction.

Where are volute centrifugal fans used?

The purpose of centrifugal radiators is not to create a pleasant blow, which is what most household axial (axial) fans do, but to ensure air exchange, and the highest pressure models are used to transport granular, bulk raw materials, sprayed compositions, and supply air-gas mixtures through air ducts. Therefore, before choosing a scroll fan, you need to proceed from the tasks for which it is intended: most of these units cope well with some functions and poorly with others. Models with average capabilities are universal, but mediocre.

In this regard, we can give the following recommendations for choosing radial radiators depending on the task and location of application.

Hood

This is a standard task that is assigned to all radial fans. High performance allows them to remove polluted air and waste gas mixtures from process air ducts, industrial, public and domestic premises.

A logical question arises here: which is better: a duct fan or a “snail”? You can answer it as follows.

Duct fans are of the axial type; many of them are very compact, which is beneficial when using duct fans in everyday life. But radial fans can be located at a great distance from the exhaust area, i.e. one centrifugal fan can serve several air intake points at once; moreover, they provide more stable air flow parameters. An axial duct fan must still be mounted near the contamination zone, and this is its disadvantage.

When choosing a radial fan for an exhaust hood, you should follow these recommendations:

- Its engine must be remote so that the flow of exhaust air does not pass through the engine. Dust, fumes, and grease fumes will not harm the remote motor;

- For dusty rooms, models with a dust impeller - its blades are spaced less frequently, so it will be more difficult to clog the impeller with dust or plant fluff;

- Each type of room is characterized by such an indicator as air exchange rate . It also influences the choice, which we will discuss in more detail below.

Inflow

These fans perform the opposite function: instead of removing gases and polluted air, they supply clean air into the room. There are many methods for calculating a radial fan for installation as a supply fan, and these methods operate on different parameters. Europe uses its own calculation systems, but in our country, along with them, Soviet GOST standards and diagrams are used, and they all take into account a completely different set of parameters. These include:

- Internal volumes of premises ;

- The number of staff or residents staying in them at the same time;

- Complexity of air ducts : their resistance, determined by the design documentation of the ventilation system;

- Air exchange rate , indicating how many times in one hour the air in the room should be changed. For example, for an industrial kitchen this figure is maximum and is 20 units (once per hour). In hallways and bedrooms this figure is 2–3 units. It is also characteristic that this parameter is also taken into account when choosing exhaust fans, since they are used together with supply fans.

There is a simpler answer to the question of how to calculate a centrifugal fan for inflow. Depending on the length of the air ducts, we choose a low, medium or high pressure fan - this will at least make it possible to get an idea of how the price of the fan is calculated. Other parameters: air flow speed, performance, acoustic characteristics, protection class will be helped by specialists depending on the specifics of the object and specific operating conditions.

Fans for spray booths

Painting of many products - from furniture and cars to precision equipment - takes place in painting booths, in which optimal temperature, humidity and hygienic conditions must be created. The exhaust fan should remove harmful paint odors and dust. Supply air – provide air filtration, the required temperature and drying. At the same time, powerful fans are used as compressors for the spray gun.

All these conditions indicate that preference should be given to medium and high pressure fans with a remote motor - so that it does not become clogged with paint and dust.

For solid fuel boilers

Industrial furnaces, incinerators and household solid fuel boilers are often equipped with radial fans for quick ignition and maintaining a high combustion temperature. Their performance is not as important as the material from which they are made. Here you can get by with small models with a built-in motor and a metal impeller: the plastic can be deformed and burn due to temperature if the fan is located too close to the boiler.

For smoke removal

Many fire protection and technical systems use radial fans to reduce the level of gas pollution in rooms, incl. removal of smoke and volatile combustion products. How to choose a fan snail is obvious in this case. It must have a remote motor, a heat-resistant housing and an impeller capable of withstanding temperatures up to 100C.

For restaurant or cafe kitchens

We remember that industrial and commercial kitchens, based on the intensity of air exchange, are classified as rooms where the most efficient fan is required. In addition, these units must have a remote motor, a large distance between the impeller blades, and grease filters. Anyone who has ever cleaned a regular household kitchen hood understands the meaning of our recommendations well.

Features of the snail hood

The memorable shape and distinctive operating principle make this type of ventilation stand out from similar ones. The most popular snail will be for rooms with a minimum area and free space. The design of the fan in the form of a spiral serves as an air duct in any warehouse or industrial premises.

There are different configurations available for your choice, but if you wish, it is quite possible to build a cleaning system with your own hands. How to install a snail and why is it better than other cleaning systems? The answers to these questions lie in the structural features of the device.

Peculiarities

A good-quality snail fan can be obtained with your own hands during the assembly process only if you know the design. The installation and impeller create torque for air movement. The need for an exhaust device increases when space is limited, so installation takes place with specialized equipment. The fan casing is made in the form of a spiral and serves to direct air.

Homemade fans of this type have become very popular lately. However, if you lack the skills and the necessary time, purchasing ready-made equipment will be one of the best options.

To create an air flow in the inner part of the snail fan mount, you need to place a radial element - a wheel attached to the installation. The discharged space is created by the curved working blades of the wheel.

The air mass enters through the inlet pipe. The inlet pressure drops and draws in ambient air. As a result of the rapid movement of air in a spiral, the speed in the outlet hole increases significantly and high pressure is created. Air flows rapidly from the outlet pipe. If the pipe is on the left, then the rotor rotates clockwise, if on the right, then in the opposite direction.

When assembling with your own hands, the curvature of the “snail” blades used is taken into account.

Snail design

A standard volute (umbrella) consists of an impeller and a power unit. Your fan, depending on its assigned functions, may have protective properties against corrosion or be characterized by increased heat resistance.

The structure of the snail is selected directly for the room in which an additional cleaning system should be installed. When choosing a device, it is recommended to take into account the strength of the air flow, namely:

- low pressure flows;

- average pressure;

- high pressure flows.

When choosing a “Snail” fan, you should take into account the strength of the air flow

Professionals warn that the more powerful the ventilation unit, the more effort should be put into installing it. A homemade box or base will facilitate quick connection and correct operation of the entire device for a long time.

Homemade snail

Before starting to create a homemade system, craftsmen recommend deciding on the functional purpose of the future device. A centrifugal fan, that is, an umbrella made from simple available materials, is suitable for partial cleaning of premises or complex equipment.

In cases where a do-it-yourself snail fan is intended for boilers, the body of the device must be made of heat-resistant steel sheets. A home-made centrifugal fan is made from old parts of a vacuum cleaner or cleaning system of a residential building. Fans such as a snail or an umbrella will serve well in small workshops, but for large-scale enterprises such devices will be of little use.

The entire process of creation and subsequent connection of the fan takes no more than two days, taking into account fast and high-quality work at all stages. First, calculate all the parameters of the future device, including the outer box and insulation. It would be a good idea to consider the option of additional gaskets that reduce the vibration effect from the operation of the snail device.

Homemade “Snail” fan is made from improvised materials

Next, the centrifugal fan is assembled from scrap materials or parts of an old device. Metal sheets or plastic are suitable for such purposes. Installation of the power unit requires special attention, so at this stage time is devoted to choosing a shaft or drive. The installed cooler will ensure timely cooling of the unit, extending the life of the entire device.

The centrifugal fan is mounted in the outer casing and mounted on a fixed base.

You can use a simple circuit to make and then connect a homemade device called an umbrella, supplement it and equip it with all the necessary elements for working in a given room. The main thing is to comply with all fire safety standards and use the snail for its intended purpose.

Centrifugal fan: equipment design

Ventilation systems equipped with this equipment have high potential even in difficult climatic conditions. A centrifugal fan is a structure consisting of several components:

- spiral body;

- impeller;

- impeller blades;

- electric motor.

All parts of the structure are connected by spot welding, rivets and bolts, which ensures reliability. The centrifugal fan often has a powder-coated stainless steel housing, which minimizes the possibility of corrosion. Indicators such as efficiency and vibration level depend on the direction of blade bending.

ERA D 125 (STELS 125) – modular assembly

Supply and exhaust fan. The direction and purpose are determined during installation - by connecting the inlet or outlet hole to the mating flange. The body is made of steel coated with protective enamel. The terminal box is enclosed in a sealed casing.

The single-phase electric motor and external rotor are mounted on a separate, folding platform. This provides easy access for inspection and routine operations. The centrifugal fan is used for duct installation.

Pros:

- Regular, channel, works, good power.

- Protective coating of the housing.

- The engine and rotor are assembled on a separate opening lid.

Minuses:

- Careful installation is required; distortions and blockages will cause vibration and loud noise later.

Centrifugal fan: operating principle of the design

The popularity of this equipment largely depends on efficiency and economic feasibility. The centrifugal fan is designed in such a way as to maximize these indicators.

The air, falling on the blades, is deflected at an angle of 90 0. Then it passes through the spiral casing of the centrifugal fan and only then enters the room. Thus, the most efficient circulation of air flows in the room is achieved.

You can buy a fan in our online store. Our catalog contains a large selection of different models: axial centrifugal air fan, centrifugal exhaust air fan, etc. Here you can easily choose a suitable centrifugal fan, the characteristics, price and quality of which will meet your requirements. We give our clients the opportunity to buy a centrifugal fan at a profit - the cost of the equipment will pleasantly surprise you.

Where is it used?

Removing small waste from machine tools at any enterprise is an important organizational task. Woodworking is one of the industries with the maximum equipment capacity and corresponding amount of waste. If the process of constant waste disposal is not properly organized, labor productivity drops sharply due to the need to constantly interrupt for cleaning the premises.

A fan for removing sawdust and shavings turned out to be the optimal solution to the problem, operating with virtually no human intervention and completely eliminating the need for enterprise workers to carry stretchers with waste.

The main area of application is carpentry or woodworking enterprises, furniture production and other workshops that process solid wood. In addition, a dust fan for sawdust has also proven useful at other enterprises that work with light, fine-grained bulk materials that need to be transported or removed from the premises. An example of such use would be grain elevators, enterprises producing cereals, etc.

Types of centrifugal radial fans

There is no fundamental difference in design between radial fans. They are divided into several types according to purpose and power.

By power

The working pressure that the volute hood is capable of depends on the engine power of the device, the number and configuration of the impeller blades.

There are 3 types of radial fans according to this parameter:

- Relatively low pressure devices (up to 100 kg/cm²). These are small fans used to create forced ventilation in residential buildings, labeled as BP 80-75. In apartment buildings, such devices are mounted on the roof, in a common ventilation duct.

- Devices that operate in the medium pressure range from 100 to 300 kg/cm². They are used in ventilation systems of production workshops without special safety requirements. The general marking of hoods of this group is BP 300-45.

- Powerful (working pressure in the range from 300 to 1200 kg/cm²) snail hoods are installed in hazardous industries where there is a need for intensive removal of caustic, flammable and explosive gas mixtures. The general marking of this class is VR 12-26.

Which fan should be chosen for a given ventilation system is influenced by many parameters: the length of the channels, their branching, throughput, and the required air exchange rate per unit time. Such calculations are carried out by specialists at the design stage of the ventilation system.

Note! Centrifugal fans are installed not only for exhaust, but also for air supply, for example, in boiler rooms.

By purpose

The second classification system for radial fans divides them according to their purpose:

- General purpose snail hoods. They are operated at temperatures up to +80 degrees in an atmosphere where there are no specific or dangerous contaminants. Installed in residential or industrial sectors.

- Explosion-proof - the body and parts of the mechanism are made of materials that prevent the occurrence of sparks during operation. Used in rooms where there are explosive gas mixtures. The permissible operating temperature range is from -30 to +40 degrees.

- Fire-resistant or heat-resistant hoods are installed in industries that use increased temperature in the technological process. The devices are made of carbon steel and coated with heat-resistant compounds. Operate at temperatures up to +200 Celsius.

- With enhanced anti-corrosion protection. These are fans that are installed in chemical plants with aggressive environments.

- Dust (marked VRP) – fans for removing air masses with suspended particles. The devices have a larger gap between the housing and the impeller and a reduced number of blades so that the device does not become clogged with waste during operation. Design features here lead to a drop in the efficiency of the device. It is necessary to choose a hood with a reserve of operating power.

- For smoke removal (marking VRDU). These fans are installed to remove smoke if a fire occurs. The devices operate in the temperature range of 400-600 degrees.

General information about centrifugal (radial) fans

Coil fans have a dual designation (marking): VR and VC, that is, radial and centrifugal. The first indicates that the blades of the working part of the equipment are located radially relative to their rotor. The second is the designation of the physical principle of operation of the device, that is, the process of intake and movement of air masses occurs due to centrifugal force.

It is centrifugal fans in ventilation systems that have shown themselves on the positive side due to the high efficiency of air removal.

Operating principle

As already mentioned, fans of this modification operate based on the action of centrifugal force.

- The blades attached to the rotor of the device rotate at high speed, creating turbulence inside the housing.

- The inlet pressure drops, which causes the suction of nearby air, which rushes inward.

- Under the action of the blades, it is thrown to the periphery of the space, where high pressure is created.

- Under its action, the air flow rushes to the outlet pipe.

This is how all centrifugal models work, which are installed not only in ventilation systems, but also in smoke removal systems. About the latter, it must be said that their body is made of aluminum alloy or steel, coated with heat-resistant materials, and is equipped with an explosion-proof electric motor.

Design Features

As already mentioned, the main design feature is the snail. It is also necessary to indicate the shape of the blades. Fans of this brand use three types:

- with straight slope,

- with a backward tilt

- in the form of a wing.

The first position is small fans with high power and performance. That is, they can create conditions in which other models require a large body. At the same time, they operate with low noise levels. The second position is an economical option that consumes 20% less electricity than other positions. Such fans can easily withstand loads.

As for the design that relates to the electric motor, there are also three positions:

- the rotor is fixed directly to the motor shaft through a coupling and bearings;

- through a belt drive using pulleys;

- The impeller is mounted on the electric motor shaft.

And one more feature is the connection points between the fan and the air ducts of the ventilation system. The inlet pipe has a rectangular hole shape, the outlet is round.

Design features

A snail hood is a radial fan built into a specially shaped housing, reminiscent of a snail's shell. Air is directed into it under the influence of centrifugal force.

The centrifugal fan consists of the following parts:

- Spiral shaped body.

- The suction pipe is round in shape, the diameter size coincides with the size of the impeller.

- An exhaust duct ending in an outlet pipe.

- The outlet pipe is rectangular in shape and is located with the throat facing up.

- Impeller with blades.

- Electric motor.

The center of the housing is occupied by the fan impeller. Its blades differ from the usual large ones, starting from the axis of rotation. In a radial fan, the impeller blades are rectangular, straight or curved in a certain way, and are located along the rim of the circle of rotation.

The shape of the snail hood blades depending on the purpose:

- straight – for removing volatile suspended matter (dust, small chips);

- with the blade bent backwards - to increase the speed of rotation of the wheel with reduced noise generation;

- with the blade bent forward - to increase the pressure and efficiency of the engine.

The design features of a radial fan lie in the different ways of transmitting torque from the engine to the impeller:

- The impeller is “mounted” directly on the motor shaft. This design is simple and accessible. However, if the fan breaks down, it must be completely disassembled for repair work.

- Torque is transmitted via a belt. A common type of interaction between a motor and rotating parts of a mechanism, which opens up many possibilities for manipulating pulley sizes and speeds. The belt drive makes the device more bulky and expensive.

- The impeller is connected to the motor shaft through a coupling. This fit relieves the load on the engine bearings without increasing the complexity and metal consumption of the design. This type of snail hood can be considered the best in terms of maintainability and price.

We recommend that you read: Hood in the chicken coop

The speed of a snail-type hood is regulated not only by the power of the motor, but also by the number of blades on the impeller. The fan housing is made of steel, alloys or aluminum. To protect against corrosion, steel parts are painted or coated with special protection.

How does a snail hood work?

The device operates from the mains. Sizes range from household (main body diameter 25 cm) to industrial (diameter 150 cm).

The fan “rakes” air with small blades that rotate at high speed. The air flow is directed into the housing, makes a turn and is removed into the outlet hole. Passing through the curls, the flow loses speed and creates pressure.

Note! If the fan inlet is hermetically connected to a closed channel, then the volute hood will work like a vacuum pump.

What are they?

Dust fans belong to the group of radial or centrifugal devices. They are capable of creating sufficient pressure to move mass through the duct system. Centrifugal designs work equally well for both discharge and suction, which increases their capabilities, allowing the direction of flow to be changed if necessary.

This distinguishes them from axial fans, which are capable of high performance, but do not have the ability to provide high pressure. The air flow from axial structures cannot overcome the aerodynamic resistance of the air ducts, while simultaneously moving certain masses of material.

Radial fans vary in the amount of pressure they create. High-pressure dust fans for sawdust or shavings are needed to work on long and branched air duct systems. Medium and low pressure fans are used in appropriate conditions and are selected based on calculated data.

Expert opinion

Online ventilation store "Runicom"

The difference between dust fans and other centrifugal devices is the design of the impeller . Most samples have 16, 24 or more blades, but on dust fans there are much fewer - usually 5, 6 or 7, on larger numbers there may be 9.

Self-production

radial fan for boiler

First of all, you should decide on the functional purpose of the centrifugal fan. If it is necessary for ventilation of a certain part of the room or equipment, the housing can be made from scrap materials. To complete the boiler, you will need to use heat-resistant steel or make it from stainless steel sheets yourself.

First, the power is calculated and the set of components is determined. The best option would be to dismantle the snail from old equipment - a hood or vacuum cleaner. The advantage of this manufacturing method is the exact match between the power of the power unit and the body parameters. A snail fan can be easily made with your own hands only for some applied purposes in a small home workshop. In other cases, it is recommended to purchase a ready-made industrial-type model or take an old one from a car.

Procedure to make a centrifugal fan with your own hands.

- Calculation of overall dimensions. If the device will be installed in a confined space, special damper pads are provided to compensate for vibration.

- Manufacturing of the body. If there is no ready-made structure, you can use plastic sheets, steel or plywood. In the latter case, special attention is paid to sealing the joints.

- Installation diagram of the power unit. It rotates the blades, so you need to choose the type of drive. For small structures, a shaft is used to connect the motor gearbox to the rotor. In powerful installations, a belt type drive is used.

- Fastening elements. If the fan is installed on the outer casing of, for example, a boiler, mounting U-shaped plates are made. With significant power, it will be necessary to make a reliable and massive base.

This is a general scheme according to which you can make an exhaust functional centrifugal unit with your own hands. It may change depending on the availability of components. It is important to comply with the requirements for sealing the housing, as well as to ensure reliable protection of the power unit from possible clogging with dust and debris.

The fan will make a lot of noise during operation. Reducing this will be problematic, since vibration of the housing during the movement of air flows is almost impossible to compensate with your own hands. This is especially true for models made of metal and plastic. Wood can partially reduce background noise, but at the same time it has a short service life.

In the video you can see the process of manufacturing a case from PVC sheets:

Adviсe

First of all, you need to know some of the intricacies of labeling. For example, fan No. 6.3 has an impeller diameter of 63 cm rather than 60 cm.

The most common fan model for small and medium-sized workshops is considered to be VRP 115-45 No. 6.3 or its analogues . At the same time, it should not be used without preliminary calculations, since operating conditions and the length of air ducts (sleeves) can significantly change the requirements for the fan.

Expert opinion

Online ventilation store "Runicom"

Dust installations experience strong vibration . The reason for this lies in the composition of the flow - the presence of a large amount of solid particles creates significant loads on the hoses, causing vibration. This forces you to constantly monitor the condition of the fan housing. Sooner or later, metal fatigue appears and cracks appear. If you don't touch them, the case may simply tear in half. The solution to the problem is welding along the fault line , but this measure is short-lived. The metal at the welding site is stressed, vibration loads quickly form a new crack, so after repair the body must be monitored even more carefully. If the problem cannot be resolved, the fan will need to be replaced.

How to make it yourself

One of the features of such snails is their different price range. The minimum price for a snail hood will be about 3 thousand, but such devices, as a rule, are not very powerful and are very limited in size. The average price of a high-quality unit will exceed 20 thousand rubles.

Therefore, for domestic needs, it is more advisable to make a homemade snail for extractor hood. The standard design of such a housing will consist of two parts: the engine will be located in one zone, and the blowing blades in the other .

The casing for the snail can be purchased at hardware stores. If you are going to make it yourself, purchase the motor and other parts in advance, since the dimensions will have to be adjusted. It is better to make the case from metals (for example, aluminum and steel). Plastic will be less resistant to mechanical damage, and wood will quickly catch fire in the event of a malfunction.

The fan in such a system will operate at high speed. Therefore, incorrect design of the hood can have bad consequences. Check the quality and reliability of not only the base itself and fastening mechanisms, but also the motor, impeller and fan.

The fan dimensions are selected taking into account the area and degree of contamination of the room. Industrial designs are large.

Important! When installing the motor inside the box of such a hood, make sure that the design includes cooling holes. High temperature stress on the system can lead to an explosion.

Pay special attention to the choice of internal materials. Fan operation can be affected not only by temperature, but also by the power of air flow, the amount of debris and dust.

When air with large impurities is sucked in, the blades of the rotating wheel may be damaged. And in order to thoroughly clean the air, the unit must operate at high speed and under high pressure - this creates additional stress on the entire internal structure. Therefore, it is better to choose parts made of durable materials, such as steel or aluminum .

Compliance with the following recommendations will allow you to create a high-quality and safe hood with a long service life:

- choose the right size and power of the motor : take into account the maximum load on the structure, as well as the required operating speed of the hood;

- When mounting such a system vertically, carefully check the reliability of the fan and wheel fastening : with rapid air flows, they can jump off or change their location;

- materials adjacent to such a hood must be fireproof , as are all parts used in its assembly;

- observe the proportions between the individual hood zones : in the standard models offered in stores, the optimal ratio of the length and width of the structure is taken into account;

- If you are not sure that the assembled hood is safe, contact specialists who will check its serviceability .

Please note that hoods are rarely used in living rooms . Firstly, they take up a lot of space, and secondly, in rooms like a kitchen, the flow of polluted air can have different directions, so it is best to install such a hood in a ventilation shaft, where all the air coming from the apartment is concentrated.

The design of such structures will also play an important role in living rooms, but it is not diverse and does not always harmonize with the interior.

Tip: When placing such a hood in an open environment (outdoors), make sure that weather conditions will not affect its functionality.

Ventilation hoods can be used not only for air purification . In domestic conditions, they will do an excellent job of heating the room, and will also affect the humidity in the room .

The cost of equipment intended for domestic and industrial needs will differ significantly, but, in any case, such units have sufficient power for full operation.

For an example of designing a snail hood, see the attached video.

Electric motors used

The industrial snail hood is equipped with explosion-proof electric motors, durable housings and covers. Most often, asynchronous mechanisms with a fixed rotation speed are used as a drive. This unit quickly reaches maximum performance and is reliable and durable. The disadvantages of asynchronous electric motors include the inability to adjust the speed of rotation of the working shaft, which somewhat limits the possibilities of using such equipment.

The presence of dimming in the electric motor and an automatic control unit allows you to regulate the rotation speed, significantly expanding the functionality of the use of volute fans. The disadvantage of using such motors with variable speed control is their high cost, as well as reduced reliability of units in which the electronics that control the operation of the drive often fail.

Sources

- https://StanokGid.ru/osnastka/ventilyator-ulitka-svoimi-rukami.html

- https://vozduhstroy.ru/vytyazhka/ventilyator-ulitka-svoimi-rukami.html

- https://www.RoomKlimat.ru/section/5/64-tsentrobezhnye-ventilyatory/

- https://TopVentilyaciya.ru/ventilyaciya/vytyazhka-ulitka.html

- https://AeroClima.ru/dymoudalenie/ventilyator-ulitka/

- https://ru-remont.com/kvartira/kuhnya/tehnika/krupnaya/vytyazhka/vidy/ulitka.html

- https://spk-kovka.ru/stanki/ventilyacionnye-ulitki.html

[collapse]