In the design of a ball bearing, one of the main elements are balls. It is thanks to the high quality of these elements, the accuracy of dimensions and processing, that the flawless operation of the ball bearing is ensured. The technological process as a result of which balls for bearings are manufactured is a rather complex production cycle, which is carried out in the following sequence:

Making a blank

The irregularly shaped workpiece is made from steel wire with a diameter slightly larger than the diameter of the future ball. The blanks are formed on a cold-exhibitor machine or a cross-helical rolling mill. Rolling to the original shape is carried out on a machine for processing balls. Here the workpiece is clamped between two disk dies and the rolling process begins until the workpiece receives the correct shape with some tolerance from the exact size.

Processing process

The balls obtained after the first process require processing. Therefore, first of all, rough processing is carried out using an abrasive material. The processing process takes place in special drums. After rough processing, the balls are again rolled on a ball processing machine. On the machine, workpieces are repeatedly rolled between faceplates, which have cast iron disks of a special profile. Next comes the heat treatment procedure in special ovens. As a result of thermal hardening, the balls acquire the required level of hardness.

Grinding process

Grinding the bearing balls is the next step in the entire process. Here the task is to bring the product to the nominal size with a tolerance of no more than ten microns. After the hardening procedure, the balls are sent to a grinding machine, structurally similar to those noted above in the text. The only difference is that a ball grinder has grooves and discs designed for more precise processing. The machine rolls balls along working chutes, and during the rolling process the balls are automatically mixed. Rolling is performed many times and upon completion of the process, ready-to-use balls are obtained.

The final cycle

Here, bearing balls are thoroughly washed with special means, undergo strict quality control, sorted into groups, packed in transport containers and sent to their destination.

| Anatoly 2014-02-09 08:07:25 Do you have balls with a diameter of 24.3-25mm in stock? [Reply] [Reply with quote] [Cancel reply] |

A bearing is a functional unit that performs the function of supporting and guiding a rotating shaft and axle. The device is designed to reduce friction between the moving part of the mechanism, as well as its stationary elements.

Bearings reduce energy loss, eliminate heat and reduce wear of parts.

Leading manufacturers

Among the world's famous brands, experts especially highlight the following manufacturers:

- Swedish industrial group SKF supplies products to 130 countries;

- German manufacturer FAG;

- Slovak concern Kinex

- French company SNR - considered the largest supplier for Europe;

- Japanese companies NSK, NTN and Koyo;

- American concern TIMKEN

To produce high-quality products, strict adherence to technological standards at all stages of production is mandatory. Only well-known global brands usually meet this requirement. The Ukrzakhidpostach company supplies bearings exclusively from leading brands, the quality of which has been tested by time.

Bearing manufacturers in Russia and abroad

Enterprises specializing in the production of bearing components have a developed infrastructure and an established management system. There are many factories operating in our country that produce various modifications and models of bearings. The products of these enterprises are used in industry and in household areas. The most respected among foreign bearing manufacturers is SKF. The company's products are distinguished by high quality and reliability, as well as a wide selection of parts and components of any modification.

the Industrial Automation online store

.

Sales specialists will help you choose the right product and select analogues that will meet the needs of your business. Contact us for advice by phone or email Bonus from the Industrial Automation

: free delivery of goods for orders over 5,000 rubles.

Features and stages of production

The production of bearings requires the use of special grades of steel. For the rings and rolling elements, steel made from iron is selected, while the cage will require alloys of heavy and light metals such as cast iron, bronze, aluminum and brass.

A large number of specialized bearings have now been developed, each of which has its own technological production chain. Regardless of this, all products undergo turning, pressure treatment, heat treatment, grinding, and assembly during the manufacturing process.

Ring production

These elements are manufactured according to the following scheme:

- Blanks are prepared from metal pipes and rods according to the calculated diameter.

- The initial processing is carried out by rolling and pressure.

- Turning work is carried out aimed at cutting individual rings and general surface treatment.

- Heating the rings to 850ºС, then rapid cooling to 40ºС.

- Tempering of parts at a temperature of 170ºС.

- Grinding of end, internal and external surfaces, raceways.

- Final grinding of raceways to the required roughness values.

Manufacturing of rolling elements

The technological chain for the production of these parts is as follows:

- Using a special steel wire of a certain diameter, the initial blanks are cut.

- The parts are compressed with a special press to give them a spherical shape.

- A final pressure treatment is carried out to achieve an allowance of 100 microns.

- Heat treatment using the same method as for rings.

- Sanding and polishing the product.

Separator production

To manufacture the separator, another technological chain will be required:

- Preparation of the workpiece - steel sheet.

- Punching holes in the sheet corresponding to the rolling elements.

- Rough and finishing stamping of a workpiece, aimed at giving it the required shape.

- Drilling holes for rivets.

- Finishing holes.

Assembly

To assemble the bearing, it is necessary to insert the inner ring into the outer ring and place the rolling elements between them. Next, a separator is installed in two places using rivets. Before putting finished products on sale, a mandatory check of functionality, labeling and lubrication of the product is required.

The rotation unit is an important part that provides motion during rolling or linear movement; it serves as a support or stop for the movable structure. More and more bearing manufacturing plants are being built in the Russian Federation. This becomes a profitable business, since such parts are used in all sectors of the national economy (heavy and light industry, ship and automotive industry, agriculture).

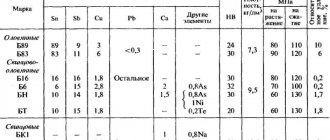

Metal ceramics

The replacement part of the sliding bearing can be made of cermet. This material is made by pressing and sintering copper and iron into powder form. Graphite, lead or tin are added to the composition.

This is a porous material that is pre-saturated with molten oil. This allows the system to operate for a long time without replacing the lubricant. Metal-ceramic liners are used in low-speed machines, in places where it is difficult to supply lubricant.

Production methods and stages

There are two main types: sliding and rolling. We will look at steel products, where the elements that facilitate rotation are balls. This is the most popular type currently. They are divided into radial and thrust. The difference is that the former compensate for loads directed perpendicular to the shaft, while the latter are responsible for axial displacement.

The part consists of an outer and inner frame, metal elements and a device that ensures their correct distribution around the perimeter. For units operating in conditions of increased contamination, a boot washer is installed on one or both sides. It prevents the entry of abrasive particles from the outside and limits the space in which the lubricant is located.

Bearing production technology begins with the preparation of the required steel grade. The plant receives metal of a certain grade in the form of round rods.

First, let's consider the issue of making clips:

- . Round bars are cut by an automatic line to the dimensions required for this type.

- . A hole is made in a cylindrical blank using a press. The result is a rough washer.

- . This is followed by the rolling process. In this case, the part acquires parameters and shape that are roughly similar to the final product.

- . The next stage is turning work. On a numerically controlled machine, the outer and side surfaces and the groove are formed along which the rolling elements will move.

- . Next comes the phase of imparting the necessary physical qualities to the workpiece. In most cases, this is done by hardening. First, heating occurs to 850 degrees, then sharp cooling to a temperature of 40 to 50 ° C and tempering. In a special chamber, the part is heated to 170 and allowed to cool slowly.

- . Bringing to the required dimensions by grinding. On machines in automatic mode, all parameters are refined to an accuracy that complies with GOST.

- . The last stage is polishing all surfaces to a clarity class of 0.06.

Advantages and disadvantages

There are a number of advantages and disadvantages of plain bearings. The positive characteristics of the design include:

- The design is simple, so the cost of this type of parts is relatively low. For lightly loaded and low-speed machines, the bearing is made in the form of a simple bushing.

- Reliability during operation. Sliding bearings are used even in high-speed drives. Moreover, their design is quite reliable, which allows them to operate such a part for a long time.

- Capable of accepting and withstanding large dynamic loads. The design is not afraid of shocks and vibrations. This is due to the large working surface area that takes the load. The lubricant layer has a damping effect. It is located between the liner and the shaft, which also significantly extends the service life of the product.

- The bearings produce low noise levels during operation. At any speed, the system operates almost silently.

- The radial dimensions are relatively small.

- When using detachable structures, they can be installed on shaft journals of complex shapes, for example, a crankshaft. In this case, there is no need to dismantle gears, pulleys and other parts located on other axles.

The design of plain bearings also has certain disadvantages:

- During operation, the system is constantly monitored. This is explained by the need for lubricant in the design. Otherwise, the system may overheat. If lubricant stops flowing to the rubbing elements, it will break.

- The axial dimensions are quite large. This is necessary to increase the working area of the working surface of the structure. She takes the load.

- During the start-up period, significant power losses due to friction are observed. This can happen when using low-quality or unsuitable lubricant.

- Operating costs are relatively high. This is due to the need to use a large amount of lubricant. The units are also stopped to clean and cool the system. This leads to equipment downtime.

- During the start-up period, the system affects the wear of the trunnion surface. This is especially noticeable when using low-quality lubricant.

Materials

An important question for production is what steel are the bearing races made of? The most common material is branded:

- . ШХ15;

- . ShH15SG;

- . ShH20SG;

- . ШХ4.

They differ in the content of technological additives. The composition includes magnesium, silicon, carbon, chromium in amounts up to 2 percent and impurities of sulfur, phosphorus, nickel, copper in very limited quantities. Hardness is acquired by heat treatment.

For products that can withstand heavy loads, it is necessary to have a strong contact surface and a plastic middle. In this case, steel grades are used:

- . 15G1;

- . 18HGT;

- . 20Х2Н4А.

The planes are cemented. In this case, strength is achieved from 59 to 66 HRCe. The core remains softer with a score of around 36. The production process is slightly different from before.

Industry requires units to operate in aggressive environments. For production in this case, steel grades 95Х18Ш and 110Х18МШД are used.

In foundries, in heat treatment units, products made from heat-resistant material are needed. In Russia they use 8Х4В9Ф2Ш and 8Х4М4В2Ф1Ш.

How balls for bearings are made at the factory, video

The production of such material is a high-precision production. It is necessary to achieve certain parameters at which friction will be minimized. This is usually a separate industry that provides rolling elements to assembly shops. It should be taken into account that the material is not only steel of different grades, but also ceramics, Si3N4. This is a completely different industrial cycle. They are used in units with high rotation speeds because they have less mass, are not subject to deformation at high temperatures, and pairs (steel, silicon nitride) have better sliding performance.

Manufacturing technology of balls for bearings:

- . A larger diameter rod is taken and cut into cylinders of the required length.

- . The cold-exhibition machine is shaped into a ball with a characteristic belt. The workpiece has dimensions slightly larger than required. The surface has a fairly rough configuration.

- . The next stage is rolling between two rotating disks. The future rolling element takes on an almost ideal shape with some allowance.

- . Then the parts are processed in a roller cutter. Using abrasive materials, scale and burrs are removed from the surface.

- . Next, rolling occurs between two cast iron faceplates. In this case, dimensions close to the required ones are achieved.

- . While soft elements require hardening. They are subjected to heat treatment or carburization. It depends on what metal it is made from.

- . The final stage of production is grinding. The workpieces are continuously rolled between two discs, automatically mixing. The output is a product with a tolerance of 10 microns. If necessary, the accuracy can be increased even higher.

- . The final phase is washing with special solvents, quality control in an automatic way, during which culling and sorting takes place according to accuracy class.

- . The product is packaged and labeled in accordance with GOST, and sent to consumers. Part of the goods is used for the production of rolling units, and the rest is sold as a finished product.

Deep Flute Ball Bearing Grinding Line

Peculiarities

1. The deep groove ball bearing grinding line widely adopts leading technological methods, such as SBS control system, fast approach, anti-impact system, etc. The entire control system and tools of the machine are products from international well-known manufacturers, so this equipment has the following features - high level of precision , high level of efficiency and durability. 2. The deep groove ball bearing grinding line has the function of selecting technical data based on the selection of cutting control system. This product has a reverse flow and can perform the function of self-regulation. This grinding line has an automatic alarm when the grinding head is not in the correct position. The deep groove ball bearing grinding line has the following features: an automatic stop signal for certain workpiece dimensions and acceptable size and weight values. 3. The deep groove ball bearing grinding line has the following features: high level of efficiency, stable loading, passport, and reduced system with a high level of quality.

Configurations

Automatic grinding machine for inner race of ball bearingAutomatic grinding machine for inner bore of ball bearingAutomatic high level finishing grinding machine for inner race of ball bearingAutomatic grinding machine for outer race of ball bearingAutomatic grinding machine high level of finishing for outer ring of ball bearing.

Application of Grinding Line for Deep Groove Ball Bearings

1. RF30Q ball bearing grinding line is ideal for producing small ball bearing rings (inner ring inner diameter 10-30mm, outer ring outer diameter 26-62mm). 2. RF50Q automatic grinding line is ideal for producing small ball bearing rings(inner ring inner diameter 17-50mm, outer ring outer diameter 40-100mm).3. The RF100Q deep groove ball bearing grinding line is ideal for producing small ball bearing rings (inner ring I.D. 40-100mm, outer ring O.D. 100-200mm). 4 RF160Q automatic grinding line is ideal for producing small ball bearing rings(inner ring inner diameter 80-160mm, outer ring outer diameter 120-250mm).

Technical Specifications

1. Automatic ball bearing inner ring grinding machine Features

1. The grinding spindle uses high-precision bearing mechanism, air insulation device and imported inverter.2. Spindle control is used together with frequency change motor and spindle precision device.3. The feeding and processing system is adopted with an integral ball screw mechanism, which guarantees synchronous feeding and processing compensation.

| Model | Processing area | Processing accuracy | Efficiency (WITH) | Power (kW) | Weight (T) | |||

| Inner diameter (mm) | Width (mm) | Dimensions accuracy | Roundness (μm) | Roundness (μm) | ||||

| 3MZ131 | Φ5-10 | 5-10 | P4/P5 machining precision | 0.8 | 0.32 | 5-10 | 4.5 | 1.25 |

| 3MZ133 | Φ10-30 | 8-20 | 0.8 | 0.32 | 8-20 | 13 | 3.5 | |

| 3MZ135 | Φ17-50 | 10-32 | 1 | 0.32 | 10-30 | 13 | .3.5 | |

| 3MZ1310 | Φ40-100 | 20-60 | 1.5 | 0.4 | 15-45 | 16 | 5 | |

| 3MZ1316 | Φ80-160 | 20-80 | 2 | 0.4 | 20-50 | 20 | 5 | |

2. Automatic Grinding Machine for Inner Channel of Ball Bearing

Features 1. This product adopts imported PLC and touch screen. The grinding feed uses AC servo control. 2. Imported linear guides and ball screw mechanism. 3. Imported self-monitoring system, anti-collision system, and automatic reverse feeding system are optional. 4. The wheel hydraulic motor is used with a high-speed and high-power electric spindle, as well as a spindle speed control system, all of which are controlled by the auxiliary frequency of the inverter. 5. Spindle control is used with programmable indicator motor and imported spindle precision device. 6. The oscillation mechanism is used with a programmable indicator motor or a “cross roller” linear guide.

| Model | Processing area | Processing accuracy | Efficiency (WITH) | Power (kW) | Weight (T) | |||

| Inner diameter (mm) | Width (mm) | Dimensions accuracy | Roundness (μm) | Roundness (μm) | ||||

| 3MZ201 | Φ5-10 | 5-10 | P4/P5 machining precision | 1 | 0.32 | 5-10 | 8 | 1.25 |

| 3MZ203 | Φ10-30 | 8-20 | 1 | 0.32 | 8-20 | 14 | 3 | |

| 3MZ205 | Φ17-50 | 10-32 | 1.2 | 0.32 | 10-30 | 18 | .3 | |

| 3MZ2010 | Φ40-100 | 20-60 | 1.5 | 0.4 | 15-45 | 22 | 4.5 | |

| 3MZ2016 | Φ80-160 | 20-80 | 2 | 0.4 | 20-50 | 25 | 4.5 | |

3. Automatic High Finish Grinding Machine for Ball Bearing Inner Ring

Peculiarities

1.

This product adopts imported PLC and touch screen. The grinding feed uses AC servo control. 2. Imported linear guides and ball screw mechanism. 3. Imported self-monitoring system, anti-collision system, and automatic reverse feeding system are optional. 4. The wheel hydraulic motor is used with a high-speed and high-power electric spindle, as well as a spindle speed control system, all of which are controlled by the auxiliary frequencies of the inverter. 5. Spindle control is used with programmable indicator motor and imported spindle precision device.

| Model | Processing area | Processing accuracy | Efficiency (WITH) | Power (kW) | Weight (T) | |||

| Inner diameter (mm) | Width (mm) | Dimensions accuracy | Roundness (μm) | Roundness (μm) | ||||

| 3MZ143 | Φ8-30 | 5-10 | P4/P5 machining precision | OR 0.3 | 0.32 | 8-10 | 8 | 1.25 |

| 3MZ146 | Φ26-62 | 8-20 | OR 0.3 | 0.32 | 10-20 | 19 | 3 | |

| 3MZ1410 | Φ40-100 | 10-32 | OR 0.3 | 0.32 | 10-30 | 20 | .3 | |

| 3MZ1420 | Φ100-200 | 20-60 | OR 0.5 | 0.4 | 20-45 | 22 | 4.5 | |

| 3MZ1425 | Φ120-250 | 20-80 | OR 0.8 | 0.63 | 30-60 | 27 | 5 | |

4. Automatic grinding machine for ball bearing outer ring

Peculiarities

1. Internal centering and pressing of the final coating. 2. Electric converter is used for the working part and for speed regulation. 3. The pressure of the abrasive stone is adjustable. It uses black finishing and fine finishing. Using the abrasive stone is an automatic process, and the alarm is also automatic when the stone is replaced. 4. The oscillating mechanism is light and fast, which ensures efficient operation of the mechanism. 5. The hoist is used to transfer between two working positions, so the overall structure of the equipment is more reliable and compact. 6. Double position method of two stages (roughing and fine processing) are used.

| Model | Specifications | Process accuracy | Power (kW) | Weight (T) | |||||

| Processing area | Rolling angle of the donkey | Number of whetstone swings per minute | Working speed (rpm) | Roundness | Roundness | ||||

| Inner diameter (mm) | Width | ||||||||

| 3MZ311 | Φ5-10 | 5-10 | ±18° | ~1000 | ~8000 | perfect corner radius≥20 | 0.03~0.08 | 3.5 | 1.25 |

| 3MZ313 | Φ10-30 | 8-20 | ~1000 | ~8000 | 5 | 3 | |||

| 3MZ315 | Φ17-50 | 10-32 | ~700 | ~6000 | 6 | 3 | |||

| 3MZ3110 | Φ40-100 | 20-60 | ~700 | ~3000 | 9 | 4.5 | |||

| 3MZ3116 | Φ80-160 | 20-80 | ~450 | ~3000 | 10 | 4.5 | |||

5. High Finish Automatic Grinding Machine for Ball Bearing Outer Race

Peculiarities

1. Position of the outer diameter at the end of the press. 2. The operating speed of rotation and vibration of the whetstone are all controlled using an electronic inverter. 3. The regulation of the casting pressure and its automation are balanced. The touchstone has an automatic warning system when it is changed. 4. The rolling mechanism of the whetstone together with the adjustable frequency has a high level of process efficiency. 5. Internal work movement has a rational structure. 6. Double stops for uneven surfaces and for a more efficient final process.

| Model | Specifications | Process accuracy | Power (kW) | Weight (T) | |||||

| Processing area | Rolling angle of the donkey | Number of whetstone swings per minute | Working speed (rpm) | Roundness | Roundness | ||||

| Inner diameter (mm) | Width | ||||||||

| 3MZ323 | Φ10-30 | 5-10 | ±18° | ~1000 | ~8000 | circular degree improve≥20 | 0.03~0.08 | 3.5 | 1.25 |

| 3MZ326 | Φ26-62 | 8-20 | ~1000 | ~8000 | 6 | 3 | |||

| 3MZ3210 | Φ40-100 | 10-32 | ~700 | ~6000 | 8 | 3 | |||

| 3MZ3220 | Φ80-200 | 20-60 | ~700 | ~3000 | 9 | 4.5 | |||

| 3MZ3225 | Φ120-250 | 20-80 | ~450 | ~3000 | 10 | 4.5 | |||

RIFA is a leading manufacturer and supplier of deep groove ball bearing grinding lines. Our company offers various products such as CNC stator grinding machine, single column CNC vertical lathe and many other products. Our products are high quality and competitively priced. We offer a full range of products, such as high speed vertical CNC machining centers, horizontal CNC machining centers and more. Our low production costs contribute to the formation of competitive product prices. More detailed information about each type of product is indicated on the description page.

Raw materials and how balls for bearings are made: video

A small part for the entire mechanism is one of the most complex in a technological sense. After all, it is very difficult to achieve smooth, round balls from a metal rod with precise dimensions down to hundredths of a micron, because an extra indicator can negatively affect the operation of the entire mechanism. The factories use special high-quality steel, regulated by GOST 3722-81:

- . Chrome-carbon sheet, type ШХ15. For indicators with higher hardness, ShKh4, ShKh20, 15 G 1, 12Kh18, 95Kh18, 18KhGT, 110Kh18, 8Kh4M4V2F1 are used to order.

- . Molybdenum. It is used for making hunting shotgun pellets and for special-purpose balls. Copper, aluminum, brass, polyamides, polymers and cermets are added to the main component in small quantities.

- . Recently, a new alloy made of synthetic material has been used - silicon nitride. It is used to produce special-purpose products that are capable of self-reinforcement.

We have determined what steel the bearings are made of. Steel balls are used for the production of rolling units. Separately, they are used in various sectors of the national economy. They are also indispensable in the automotive, paint, defense, cement, confectionery, chemical and agricultural industries. In addition, they can act as separate parts for deodorants and pen refills.

These devices are an integral part in the manufacture of wheels and rollers for warehouse equipment (hydraulic trolleys, lifters), for spare parts and furniture fittings. You can find the required part in the catalog of the MPlast online store. To do this, you need to enter the website and find the required product there, as well as decide on the price and form of payment.

In units operating in aggressive environments, balls with a high nickel content are used. Environmentally friendly shot is rolled from soft iron (lead causes more harm to the environment than low-carbon steel) and copper-plated shot, with a diameter of 4.5 for air guns.

The next step in manufacturing was the creation of rolling elements from ceramics. They have found their application in extreme operating conditions (jet engines, spindles in metalworking machines, Formula 1 cars.

Non-metallic liners

Bushings can be made of non-metallic materials. For this purpose, special anti-friction plastics are used. Laminated plastic and rubber can also be used for these purposes. These types of liners are resistant to jamming and do not require lubricants. They work well in the knot. The scope of application of these bearings is specific. Since the system can be lubricated practically with water, this allows the bearing to be used in the food industry and a number of other industries.

Factories

In Russia there are more than two dozen large enterprises that produce such products. We will give some examples:

- . JSC "Moscow Bearing" Specializes in the production of parts for metro construction and railways.

- . OJSC GPZ-2 is the oldest plant, operating since 1916. It produces a huge range of small-sized products from 4 to 6770 grams. Supplies products to 50 countries.

- . Saratov has been operating since 1941. The product for consumers is balls.

- . Samara "ZPON" produces roller mechanisms of various types (4000 items). It has equipment production and its own research base.

- . Tomsk "ROLTOM" GPZ-5. It produces mechanisms with miniature sizes with a diameter of 2 mm to large ones - 22 cm.

- . Yekaterinburg plant No. 6 specializes in the production of spherical double-row products with increased radial load.

- . Baku gas processing plant-7.

- . Kharkovsky No. 8. The production range of products is from 30 g to 45 kg.

- . Samara plant number 9 produces roller units.

- . GPZ-10 in Rostov-on-Don has been operating since 1938 and produces parts for agricultural machinery, processing equipment and metallurgy.

Products come to the Russian market from factories in different countries. The most popular bearings are made:

- . In the People's Republic of China by AAA. It specializes in the manufacture of parts for the automotive industry.

- . And India at the ABC Bearings concern. The company has been operating successfully for more than 50 years and imports its products to many countries around the world.

- . In Slovakia by AKE. This new brand is not inferior in quality to famous brands. Every year the range of manufactured products increases, the cost of which is significantly lower than that of other imported analogues.

How to buy quality bearing products

Purchasing a bearing for equipment or a vehicle is a very important step. Therefore, many people prefer to deal with our company, which has been working in the Russian and neighboring markets for many years. We have everything you might need to repair or manufacture equipment of various types and purposes. But even if you don’t find the desired model of rolling or sliding support in our catalogs, we will offer you excellent alternative options. If you know the sizes of imported bearings or domestic products, then our tables will help you choose the analogue that best suits its characteristics. Your profile is the development of non-standard equipment? We will help you in this case too. Our partners are the most famous companies in the world, whose services include the production of custom supports. It is also worth adding that imported bearings can be purchased on our website at the most attractive prices and with a mandatory official guarantee. We provide prompt delivery of products from a warehouse in Moscow to anywhere in Russia, as well as to Belarus and Kazakhstan.

Kinds

These mechanisms can be divided into groups according to the direction of the load, according to the elements on which the holders rest, according to the presence or absence of a rotating spacer and according to the material of manufacture.

What are they made of and how are they made?

The product can be radial and supporting, with full or partial rotation. Depending on the operating conditions, it is manufactured in the form of: outer and inner races (lower and upper), sliding sleeve (washer), lubrication system (forced, natural, air).

Polished surfaces, due to the lubricant or due to the physical properties of the gaskets, provide long-lasting easy sliding. Raw materials for production: steel, cast iron, bronze, fluoroplastic, babbitt, aluminum, ceramics. Pairs with a minimum friction coefficient are selected. What metal the bearing bushing is made of directly determines in which cage it will rotate.

Rolling

Such units are divided into radial, thrust and complex. This determines the direction of the load. The first are divided into three main classes: ball, roller, needle. These species can be with or without restrictive rings, with one or two anthers, and completely open.

The second type is created on the basis of spherical elements, cylindrical and conical rollers. Completely collapsible varieties are available. The third one combines the qualities of the first and second in terms of perceived effort. There are also open and closed types.

Depending on the materials for the manufacture of rolling bearings, there are several subclasses:

- . standard (most common);

- . designed for increased loads;

- . designed for extreme temperatures;

- . resistant to aggressive environments.

For special conditions (ultra-high rotation speeds, strong heating, the need to operate in the presence of acids and alkalis), products made of ceramics, silicon nitride, and plastics are used. There are models where the sliding layer is a gas or a magnetic field.

Structure lubrication

When considering the design of plain bearings, it is worth noting that one of the important elements is lubrication. As already mentioned, it consists of a body and a bushing. The supporting part of the shaft is called a journal. It (as well as the shape of the working surface of the structure) can be conical, cylindrical or flat. If the journal is at the end of the shaft, it is a tenon. If it is located in the middle, it is the neck.

A mandatory design element is a lubricating device. It supplies oil or other material with appropriate qualities into the gap formed between the shaft and the bushing. Lubrication allows the structure to rotate with little resistance. If this material runs out, the part will fail due to overheating caused by friction. Work surfaces will also be destroyed.

Lubricants can come in different forms. Most often these are consistent materials with high viscosity. As the bearing operates, it heats up and becomes more fluid. This explains the high-quality sliding of moving elements.

To increase the safety of using such structures, industrial bearings began to be provided with a special lubricant. It is a solid porous material. This is a powder lubricant that is durable and of high quality. It ensures long bearing life.

This is a self-lubricating system of the structure. It is made using powder metallurgy technology. During bearing operation, oil is released from this material. The solid fraction is initially impregnated with it. When the system is idle, it cools down. The oil is absorbed back. This way oil losses are kept to a minimum. This is especially important when operating industrial bearings. They are subject to significant loads, so there are increased demands on the quality of the lubricant. When using such a system, the bearing is indicated that it is self-lubricating.

Device

It is not possible to describe all the diversity. Fundamentally, this mechanism consists of an external and internal support (they can be replaced by a housing part), a sliding gasket (lubricant, a separator with rolling elements, a bushing).

The most common type is done like this:

- . two washers with grooves having the required radius of curvature;

- . balls fixed with a special device at the same distance from each other along the entire perimeter;

- . When the clips move, friction decreases sharply.

Additional fasteners

If there are high loads on the bearing, additional locking elements are required to hold the bearing in its original position. For these purposes, various fasteners are used, for example, the use of thrust snap rings for bearings. They are used both for fixation on shafts and for holes in the housing.

A very technologically advanced, convenient and inexpensive method that allows you to save space and speed up installation and dismantling - rings made of spring steel allow you to repeatedly assemble and disassemble the bearing assembly. They are called: external eccentric retaining ring and internal eccentric retaining ring.

Also, along with eccentric rings, concentric spring retaining rings are used to secure bearings: for shafts - external thrust retaining rings, for holes in the housing - internal thrust retaining rings.

Spring thrust rings. The ring designation indicates the diameter of the shaft.

Shaped thrust ring

1 – shaped thrust ring

How to assemble ball bearings: video

The process looks like this:

- . The suitably prepared clips are inserted into one another and touch at a single point. As a result, a space is formed on the side opposite to the contact through which the balls can be inserted.

- . The number of rolling elements with this design is limited. The next step is to distribute them evenly around the perimeter. In this case, the inner ring is automatically centered relative to the outer one.

- . Specially manufactured separator halves are installed below and above. The standard product is made from carbon steel. But there are varieties when fixation occurs due to a brass or plastic part. The latter consists of one part and simply snaps into place.

- . On a special machine, the two halves of the holding device are connected with rivets made of metal through a pre-prepared hole.

- . The product is washed and lubricated (with lithol, cyatim, graphite or a preservative compound).

- . Protective boots are installed. They can be metal, plastic or composite.

- . Next, the goods are marked according to GOST standards and packed in boxes.

Assembly of the support product consists of creating a separator that holds the rolling elements in certain places. The edges of the device are rolled. It is sold in the form of three parts (the upper and lower washer, and the assembly itself).

For high loads it is necessary to create more points of contact. It is impossible to place additional balls into the classic mechanism. Then manufacturers make technological recesses in the disks, through which the number of contact points becomes maximum. Subsequently, the classic riveting of the separator occurs.

One of the trusted suppliers is. It sells products based on bearings produced in Russia by factories with an ideal reputation.

Metal liners

Sliding bearings can be made from various metals and alloys. The materials of the sliding bearings meet the requirements of the standards. The following metals can be used to make bushings:

- Bronze. This type of liners is used for heavy loads and medium rotation speeds. Tin bronze alloys have the highest antifriction effect in this group. If this metal is combined with aluminum or lead, the trunnion will wear out quickly. Therefore, such alloys are mounted only on hardened varieties of the shaft support section. Alloys of bronze and lead are used if the structure is subject to shock loads.

- Babbitt alloy. It is based on tin or lead. This material is used for the manufacture of bushings in critical structures that operate under heavily or moderately loaded conditions. This is one of the best anti-friction metals, as it is resistant to jamming and works well in its assembly. But its strength is low. Therefore, babbitt is poured in a thin layer onto a solid base of a bushing made of cast iron, steel or bronze.

- Cast iron. Anti-friction types of material are used. They are suitable for use in low-speed, low-responsibility mechanisms.

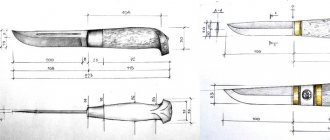

Bearing ball manufacturing technology

Ball production includes the following steps:

1. Stamping of blanks. The blanks are cut from a calibrated wire coil (rod) and processed on a cold heading machine or a helical rolling mill. The output is a ball with geometry defects (ring sagging, central protrusion).

2. Ripping. Rough abrasive processing of balls in drums with abrasive chips, during which geometric defects are removed.

3. Run-in. It is produced using disk dies, which are a lower fixed and upper rotating faceplate, equipped with cast iron disks of a special profile, resulting in semi-finished products with a tolerance of +100 microns from the required geometric size for subsequent grinding and finishing processes.

4. Heat treatment. For the production of bearing balls, steel grade ShKh15 is mainly used (bearing steel, 1.5% Cr, 0.95% C) - GOST 3722. Heat treatment is carried out in muffle furnaces and includes heating, annealing at 800 °C and quenching in oil - GOST 801-78. The balls after heat treatment have a hardness of 60-62 HRC.

5. Sanding. It is produced until the ball size is reached with a tolerance of +10 microns from the nominal one. Equipment used is similar to that used during the running-in phase, but more accurate.

6. Finishing. Used when it is necessary to obtain balls of higher precision.

As of 2016, in the process of producing bearing balls at JSC VPZ, there is no separate stage of washing finished bearing balls. The entire flushing process involves using coolant (cutting fluid) during the abrasive machining stages of bearing balls. The use of coolant is necessary for heat removal, since in the contact areas of the part and equipment the temperature reaches 1000°C; as well as abrasive. The roughness and cleanliness of the surface of the finished product depends on the coolant, since contamination of the liquid leads to clogging of the grinding equipment and, as a result, the formation of burns. The use of coolant is carried out in accordance with GOST R 52237-2004. For steel ШХ15, it is recommended to use a coolant of the following composition: 0.2% - oleic acid, 0.5% - triethanolamine, 0.2% - sodium nitrite, 6% - sulfofresol, 93.1% - water.

Design of sliding supports

Sliding bearings are calculated in a simplified way based on load (specific):

р=F/d*L, where

F – force acting on the support;

d – journal diameter;

L – sleeve length.

The value of the product of specific load and speed (circumferential) is also determined:

pv=(π*d*n/60000)*p,

where d is the diameter of the trunnion in mm;

n – shaft revolutions in 1/min.

The obtained values should not exceed the permissible values given in the reference books. This calculation corresponds to semi-fluid and boundary friction in the bearing.

Metal plain bearings dimensions table, which is given in GOST 1978-81, can serve as the main reference material for design.

When designing, it is also important to maintain the required ratio of the length and diameter of the sleeve.

Key factors are the shape, dimensions, location of the lubricant supply grooves. They are placed in the unloaded area of the liner.

Recommended fits for plain bearings:

- to ensure liquid lubrication mode H8/e8, H7/e8 at high speeds in large electric motors and turbogenerators;

- H7/f7 for light loads;

- H7/d8 at high speeds but low pressure;

- H7/c8 and H8/c9 with significant temperature changes.

Sliding bearings, due to their advantages, are widely used in mechanical engineering. They are used for high and low shaft speeds, under particularly high and low loads, for large diameter shafts, during shocks and vibrations. Moreover, with the advent of new materials and lubricants, the scope of application of sliding bearings is only expanding. They are installed in turbines, pumps, internal combustion engines, centrifuges, gearboxes, rolling mills, packaging, dosing and other equipment.

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +7 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru