When cultivating land, one of the most tedious operations is plowing it and preparing it for sowing. If you have equipment - a walk-behind tractor or a mini tractor - everything can be transferred to them, but for plowing you need a plow. Buying a ready-made one is too expensive. The prices for finished products are considerable. To save money, you can make a plow yourself. And there are two ways. First: do everything yourself completely. This is a difficult path - the shape of the plow parts is nonlinear, with bends of a certain radius, and bending thick metal at home is very difficult. The second way is to buy ready-made cases, and assemble the frame and all other auxiliary parts yourself. This is a simpler option that is relatively easy to handle.

Homemade frame for a plow on a mini tractor

Double-furrow homemade plow for a mini tractor

Installing the support wheel

Dimensions

The dimensions of different types of plows may vary. You can consider the parameters of parts using the example of a rotary specimen. It is taken into account that the rotary type of such a device is assembled from the following bases:

- side vertical part of the runner;

- horizontal plane below the skid;

- front dump part.

The most productive is considered to be a plow in which the cutting edge at the bottom of the fixed share is 20 mm below the bottom of the horizontal skid. Another correctly aligned part of the plow is the matching of the cutting edge on the side of the fixed share with the cutting edge on the side of the moldboard. The share and blade should not protrude more than 10 mm beyond the boundaries of the vertical plane on the side of the skid.

There is one more important nuance - fastening the front plane of the blade share without visible cracks and gaps, and in the same plane. If we look at these parts in more detail, they should be well polished and, like a mirror, reflect any surface. There should be no protruding fasteners under any circumstances. As soon as the plow returns from earthworks, it is advisable to clean it of settled soil and foreign particles. Elements that have been polished should be poured with oil or coated with grease. Next, the mechanisms need to be rubbed using a rag. In this way, it will be possible to protect the structure from aggressive external influences, which can lead to the formation of corrosion on the surface of the plow.

As for the 4th correctly constructed structure, it includes the flat front surface of the ploughshare, which makes an angle of 20 degrees with the flat part of the plow structure. It will be equal to the angle located at the rear of the exposed share. The cutting sidewalls-edges of the plowshare and blade will also have 20-degree angles with their bases on the side of the furrow. Moreover, the edge located on the side of the blade may be slightly rounded.

Plow for agricultural winch – video

The plow is used in conjunction with such a winch for plowing

You can find industrial motorized and electric winches for plows on sale.

- Author: Maria Sukhorukikh

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Plow dimensions

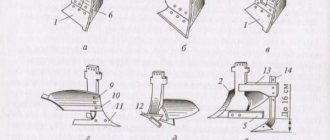

The rotary type rotary plow consists of three main planes:

- Lateral vertical plane of the skid.

- The lower horizontal plane of the skid.

- Front dump plane.

If, after dismantling the moldboard and ploughshare, the plow is placed on top of the table, pressed tightly against the wall, and its side plane is moved towards the vertical wall, then the table cover will coincide with the horizontal lower plane of the skid, and the vertical wall with the vertical side plane of the skid.

A plow is considered good if the lower cutting edge of the installed share is 20 millimeters below the horizontal lower plane of the skid.

The second correct plow design is to match the side cutting edge of the installed share in a straight line with the cutting side edge of your moldboard. Also, the blade and ploughshare do not protrude more than 10 millimeters beyond the vertical side plane of the skid.

The third correct condition is the connection of the working front plane of the plowshare to the blade without gap and in the same plane. They should ideally shine like a mirror, be well polished and should not have any protruding fasteners sticking out.

After the plow has returned from work on the site, it is recommended to clean it of soil and foreign objects, pour oil on the polished parts or grease them with grease, then rub them with a rag. This will protect the surface from environmental influences and corrosion.

The fourth correct design is the back flat surface of the share, making an angle of 20 degrees with the flat side of your plow installation, which is equal to the rear angle of the mounted share.

The cutting side edges of the blade and share also have a 20-degree clearance angle with the side of the furrow, and your blade's cutting side edge may be rounded.

Single body plow model

Such models have the simplest design. Looking at a photo of a homemade plow, which belongs to the single-hull category, you can see that it only includes a ploughshare.

Suitable only for soils that are light. It is impossible to use it for working in virgin lands or, for example, in difficult soil.

There is also a type of plow consisting of two bodies. They look like two frames that are fastened together, and this design is also topped with plowshares.

This type not only plows, but also harrows the soil. At the same time, the quality of soil cultivation increases significantly.

How to properly set up a plow on a walk-behind tractor? We plow simply, quickly and easily.

Having become the proud owner of a walk-behind tractor of one brand or another, we are faced with the problem of choosing a plow and related elements for plowing our gardens and fields. Spring is a hot time for all people who are not indifferent to the earth, the topic of environmentally friendly nutrition, summer residents and gardeners. How to make work easier, more enjoyable and more useful? This article will discuss how to properly set up a plow, select a hitch, and work on your mistakes. Everything in order:

As a person living in a rural area, I have watched tractors work in the fields since childhood. Plow - what’s so surprising, I thought when I went to buy this attachment for my Agat walk-behind tractor with a 6.5 hp engine. In a specialized store it turned out that not everything is so simple. There are many options for plows, depending on the power of the walk-behind tractor. The choice was made on the advice of the seller, I did not argue, because... there was no point in it. This was followed by the accompanying purchase of a hitch (at that time I imagined it as one whole)

Having installed this attachment on the walk-behind tractor, I rushed on the road with wrenches in my hands for adjustments. We are plowing the land for the first time in our lives—an experimental run. Of course, I consulted with neighbors and acquaintances. Tips in the style: “place the walk-behind tractor on a brick, two fingers under the heel, angle of attack. “All this advice seemed simple, and that’s what frightened me. I had to watch the work of walk-behind tractors when plowing - everyone was sweating, either pushing the walk-behind tractor or running after it - without strength, arms or legs. At first it seemed to me that this is exactly what plowing on a walk-behind tractor looks like. But all this was the result of incorrect plow settings.

I will try to tell you in simple terms and share my experience on the correct setup of the hitch and plow, in which you can easily cope with any volume of plowing on a walk-behind tractor of any brand. The understanding of this came after one season - there is no need to rush anywhere.

First: The plow plows in a position strictly perpendicular to the plane of the ground; we carry out this adjustment after the first and subsequent passes, since the wheel goes into the rut. Everything is simple - as in the photo:

Second: What is the angle of attack? This is how deep the plow will go into the ground before its heel - bottom part takes a position parallel to the line of movement. The greater the angle of attack, the deeper the rut, the larger the blade, the higher the bed))) This is the most common mistake - too large an angle of attack on a light and weak walk-behind tractor - the result is sore hands and back for the one who controlled it. Additionally, you can use weights, but this increases the load on the axle and engine - don’t overdo it, everything is within reasonable limits. In the photo I schematically indicated with lines:

Thirdly: An error in which the walk-behind tractor tends to run either to the left or to the right. If you look at the walk-behind tractor from the top point, the hitch should be in a position strictly perpendicular to the axis of the walk-behind tractor. It’s easy to understand - imagine you are sailing on a boat - how do you steer? You guessed it - everything here follows the same principle. Schematically marked with lines in the photo:

If you follow all these rules for adjusting the plow, then the work will be a joy, the walk-behind tractor will help you, and not be a burden.

But all these adjustments are meaningless if the hitch is of poor quality. And this is the most important mistake! We choose a high-quality, reliable - strong coupling in order to quickly and easily make adjustments, while the reliability of the fastenings should not be questioned while working with the plow.

In the photo, the hitch is black - it has proven itself reliably - the metal is a decent thickness, does not move around in the fastening areas, does not break threaded connections

In the photo, the red hitch is of satisfactory quality - it bends, moves, and the thread on the adjusting pin gets knocked out.

How to install a plow on a walk-behind tractor

Before you start setting up the plow, you need to prepare the walk-behind tractor itself and install the plow on the walk-behind tractor. To do this, the walk-behind tractor is placed at the work site, the wheels with rubber tires are removed and steel lug wheels are installed. This is done in order to reduce the slipping of the walk-behind tractor when plowing due to soil resistance.

After this, they begin to attach the existing walk-behind plow to the attachment. The fastening nuts should not be fully tightened in order to be able to adjust the unit. Then the unit is fixed to the mounting bracket of the walk-behind tractor with two steel pins. Once these operations are completed, the plow adjustment operation can begin.

Equipment manufacturing methods

A homemade unit can be made in two ways.

- In the first case, a steel pipe is used to make the dump, the diameter of which is 55-60 centimeters and the wall thickness is 0.4-0.5 centimeters. Initially, you need to make a template from thick cardboard. For this purpose, appropriate drawings are used. If you have sheet-bending rollers at hand, then the workpiece can be given the required shape as simply as possible. The blade blank is cut out using scissors. When feeding it to the rollers, an angle of 20 degrees is maintained. After bending it, modification is done using a hammer.

- The second option is a rather labor-intensive way to make the unit yourself. To make it, you need to heat the workpiece in a forge or in any other convenient way. Next, it is bent along the matrix. For this purpose, the blade from the attachments of the T 25 tractor is most often used. Sheet steel is used as a raw material for the production of the body. The next stage involves placing the template on the pipe while maintaining an angle of 20 degrees. The outline of the dump can be drawn using chalk. Next it needs to be cut off. For this purpose, gas welding is most often used. The contour is processed using sandpaper. If the need arises, the blade contour is modified using a hammer.

Manufacturing technology

Initially, the elements of the unit are manufactured from thick cardboard. For this you must also use drawings. In order to make a homemade plow as correctly as possible, it is necessary to maintain the appropriate angles. If the parameters of the unit suit you, then you need to make it out of metal.

After manufacturing the metal elements of the plow, it is necessary to use a steel sheet to assemble them, the thickness of which will be from 2 to 3 millimeters. You need to step back from the edges of the sheet and put a corner on it. In order to make a plow with your own hands, you need to install the plowshare on a metal sheet.

- Correct manufacturing of attachments for the T 25 tractor requires the use of welding to fasten the ploughshare to a metal sheet. Next, you need to place the side shield of the rack under the plowshare. This is done in such a way that it is located in a vertical position and extends beyond the edge of the ploughshare by about 7 centimeters. It also needs to be attached to the metal sheet and plowshare. Welding is most often used for this purpose.

- In order to correctly make a plow for the T 25, it is necessary to fit the moldboard to the ploughshare. It requires maximum tight joining with the canvas. The plowshare blade and the top edge must be at the correct angle. Otherwise, they will need to be finished with a hammer.

- In order to properly manufacture a homemade unit for the T 25, it is necessary to attach the spacer bar to the side shield by welding. If you don't know how to do this, you can watch the video on our website. The shield, plowshare and side sheet must be connected to each other by welding.

The work of a homemade plow

In order for the T 25 plow to independently hold the furrow, a two-wheeled block is fitted to it. The width of the furrow wheel should be 4-5 centimeters, and the diameter should be 32 centimeters. The diameter of the field wheel should be 20 centimeters. The axle for the plow wheels on the T 25 tractor is made from a pipe whose size is ¾ inches.

On one side, the pipe must be bent 90 degrees and a bushing must be welded to it, on which the furrow wheel will later be installed. The field wheel is mounted on the other side of the pipe. The wheel axle is manufactured as a composite one. The pipe itself is attached to the attachment beam by welding.

Setting up the plow

In the video you can see the plow in action (second option)

The depth of soil plowing with a tractor plow ranges from 20 to 24 centimeters. The same distance should be between the field wheel and the toe of the ploughshare. If you provide the ability to move the field wheel vertically, the plow can be adjusted according to the depth of plowing and the width of the soil during work. If you don’t know how to enable wheel movement, then you can watch a video on this on our website.

Making attachments yourself is not very easy, but it is still possible. The main thing is to choose the right material and adhere to the production technology as accurately as possible.

DIY plow drawings

After I got a self-made agricultural winch, which is used for plowing the garden, the question became: should I buy a plow or make it myself? Walking through the shops and bazaar of Smolensk, you get a strange feeling that the plows produced by the industry for walk-behind tractors are a sad sight.

And these industrial creations are suitable only for “picking” and not for plowing the land, and even with the rotation of the layer, and regarding the depth and width of plowing, we can conclude that for planting potatoes with a distance between rows of 60 cm, not one of the proposed ones is suitable in the plow trade. Either our manufacturers are saving money, or the power of the most popular walk-behind tractors is not enough to work with a normal plow with a working width of 30 cm. When planting potatoes, you shouldn’t plow one furrow three times. And the price wants to leave the best - under 2 thousand. rubles (for a couple of pieces of iron from a scrap metal collection point).

The next step to find something useful is to search the Internet. To my surprise, there are 3-4 original descriptions with drawings floating in the vastness of the Russian-language network (this fact surprises me very much). The next step is to look at what those around you are using. It was not possible to buy a suitable plow; the decision was made to make a plow with our own hands. Based on the fact that the plow was supposed to be used for planting potatoes with a winch for plowing, the following requirements are imposed on it:

1. Plowing width – up to 30 cm.

2. Plowing depth -10-20cm.

3. The plow must hold the furrow itself, without digging in or jumping out of the furrow. The geometry of the plow must ensure movement with the specified parameters without the help of a plowman.

4. Possibility of adjusting the depth and width of plowing.

5. Minimum weight and sufficient strength.

My uncle has been using his homemade motorized winch for plowing for more than 10 years and has tried several options. For the last few years, he has settled on an option optimized for a homemade motorized winch for the garden, namely for planting potatoes with a distance between rows of 60 cm. There is also a homemade hiller for a motorized winch and a homemade potato digger, all this can be viewed on the corresponding pages of the site.

Plow drawing

Field board drawing.

The blade is bent according to this template until the two profiles coincide and then welded at an angle.

Using a drawing of a homemade plow, you need to draw a template for the plow pattern on thick paper, and then transfer the picture to metal and cut out the blank with a grinder. Personally, I used stainless steel material with a thickness of 1.8 mm. Many often use a sheet of 2-3 mm. The cutting part of the plow is reinforced with a strip of thicker metal. Someone suggests using a disk from a circular machine for these purposes, or a spring from a “Muscovite”. From personal experience, if you plow a summer cottage plot for a family of 4 people in the spring and fall, cultivating six acres, you shouldn’t strive for super-strength. It is more profitable to make a plow that is light but strong enough for its tasks. It’s better to repair or replace something after 10 years, and only if necessary, than to carry around the heavy structure of a homemade plow for 10 years. There is no need for excess weight.

Read also: Concrete mixer 120 liters solution proportions

This is what the plowing width adjustment system looks like. By rearranging the large wheel, you can change the plowing width within significant limits. When I plant potatoes, I set the grip to 30 cm, in two passes the distance between the rows is 60 cm. For autumn plowing of the garden or when plowing virgin soil, I use a smaller grip. The small wheel is made so wide that the plow does not press into the ground.

Having looked at the pictures below, you can imagine the basic principles of operation of a homemade plow, or rather a guide system that allows the plow, without the participation of a plowman, to move strictly in a straight line at the established plowing depth and width. The plowing width is regulated by moving the large wheel, which, when the point of application of the traction force is shifted as shown in the figure, is pressed against the furrow, which allows the plow to repeat the direction of the previous furrow. The plow turns slightly, which increases the plowing width. In fact, the width of the nose in the direction perpendicular to the axis of movement of the plow is less than 300 mm, however, the specified width is available for plowing.

The plow wheel runs along the bottom of the plowed furrow and this situation is observed from the previous furrow to the next. As a result of the application of traction force, a force is exerted to deepen the plow until the plow is aligned with the axis of the wheel, as shown in the figure, as a result, all forces are balanced, and the system operates very stably. Rough adjustment of the plowing depth is carried out by selecting the appropriate difference in wheel diameters, and smooth adjustment is carried out by adjusting the tilt of the plow. At this stage, there was no longer any need to use handles to control the plow, except for some special plowing conditions.

Plows not only loose soil as in the video, but also virgin soil

Plowing with a horse plow

Plowing is a process that requires the plow to cut away soil, rhizomes, vegetation, and gently turn side soil.

Basic requirements for plowing:

- It is better to carry out plowing immediately after harvesting crops, while the soil retains enough moisture;

- the turf layer is thoroughly wrapped and crumbled as finely as possible;

- the surface is desirable to be continuous and dense, without the formation of voids or irregularities;

- mineral fertilizers, manure and turf are completely plowed;

- The furrows should be straight, or with a slight deviation from the norm, with a minimum gap between them.

The fundamental thing when plowing is to loosen the fertile layer, remove the turf and turn it around completely for further reheating to a state of humus.

Sometimes you have to deal with stones and other natural barriers that are too strong for one horse, so for increased resistance, two-horse and multi-horse teams are used. Medium and heavy-duty walk-behind tractors cope with this task quite simply.

Plowing with a walk-behind tractor

Plowing with a single horse

Plowing with one horse is quite a comfortable process, provided that the plow depth and width are adjusted properly. Only in this case, it goes exactly along the furrow, smoothly without additional resistance other than the rise of the ground. The horse moves at an even pace.

As a rule, the draft power of one horse is used on previously plowed areas, or on turfy, weed-free soil.

Cultivating the land with a horse-drawn plow with one horse

Plowing with steam horse harness

Heavy loamy soils, as well as virgin soil and areas where greater traction force is needed, use two-horse and multi-horse harnesses.

What does the harness consist of?

When harnessing horses together, the defining moments are:

- competent selection of animals and crowding;

- character and endurance;

- haste at work and the strength of the animal.

For the plow to work smoothly, it is necessary to determine the amount of traction force in order to calculate the number of animals for work. This takes into account not only the width and depth of the layer, but also the qualitative composition of the soil.

Plowing with a horse plow using a walk-behind tractor

Today, the walk-behind tractor is an indispensable “iron friend” for many farmers and summer residents. The plow is attached to the walk-behind tractor with a hooking device. After which it is necessary to balance its work. To do this, make a control pass in first gear and look at the depth of the furrow (15-20 cm), and whether the tiller is correctly secured and adjusted.

- For heavy walk-behind tractors, a plow with a 23 cm grip is suitable.

- For medium walk-behind tractors, a plow with a grip of 18 cm is suitable.

Plowing with a walk-behind tractor is not difficult, the main thing to remember is that the plow always pulls to the left, so the first row must be marked with markings. In the second aisle you will be able to navigate along the first row. The distance between the ridges should not exceed 10 cm.

Universal horse-drawn plow for walk-behind tractor and horse-drawn carriage

When adjusted correctly, the unit moves smoothly, without jerking or deviation to the side. Only after the furrows begin to turn out smooth can the speed be increased.

Setting up a plow on a walk-behind tractor

If the area to be plowed is large, carry out this process in several stages to avoid overheating the engine.

Homemade plow: existing types, their pros and cons, manufacturing technology

Cultivation of land is the most labor-intensive task for rural residents and summer residents. Preparing the soil for sowing and cultivating the land after harvesting are the most difficult types of manual work. A plow can greatly facilitate the performance of these works.

A plow is an agricultural tool with a wide metal blade that is used to plow the ground. In addition to tillage, plows are used for underwater work, for laying cables, and when searching for oil.

At the first stages of using the plow as an agricultural tool, people dragged it behind them , a little later they began to use livestock (oxen, horses) for this, today this hard physical work has been transferred to agricultural machinery - the tractor.

The main task of this tool is to turn over the top layer of soil. This procedure (ploughing) largely frees the soil from weeds. During the plowing process, the root system of weeds that have already begun to grow, but are not yet strong enough, is damaged.

In addition, along with the overturned layer of earth, the seeds of weeds that have not yet germinated are moved deep into the soil, which, of course, complicates their further germination. Many weed seeds are completely destroyed during the plowing process.

During the plowing process the soil loosens , becomes softer and more pliable, which subsequently makes sowing more effective and has a good effect on the germination of cultivated plants.

Modern agriculture uses different types of plows to cultivate the soil. These agricultural implements differ according to two characteristics:

- by aggregation method;

- according to the method of plowing.

According to the method of aggregation, plows are trailed, mounted and semi-mounted. Each type has its own advantages and disadvantages.

The trailed plow can only be driven using transport wheels. It is rarely used in modern agriculture, because the majority of tractors are equipped with a mounted system with a built-in hydraulic cylinder.

The advantages include the fact that, according to agronomists, after cultivating the soil with a trailed plow, the arable land is smoother and more uniform.

The disadvantage of such a tool is the rather large rotation angle, which prevents the use of this plow along with mounted and semi-mounted ones in the same paddock.

Drawings of a plow for a walk-behind tractor

Using the experience of craftsmen who made a plow for a walk-behind tractor with their own hands and left drawings, the ploughshare should be made in such a way that it can be removed, this will make it easier to sharpen it before plowing.

Alloy steel 9ХС, from which I make blades for hand saws, is considered an ideal material for the cutting part of a plow.

Suitable steel grade 45, when hardened, brought to a hardness of HRC 50-55. If you only have ordinary steel on hand, say carbon St5ps, which is not subject to heat treatment, then by beating the cutting edge on an anvil and sharpening it, it is quite suitable for cultivating the soil.

Plow blade for walk-behind tractor

The moldboard of the plow is the part that takes the earth to the side.

The first method of making a blade:

The working surface of the blade must be given a curved shape. If you have a metal bending machine or sheet bending rollers, then giving the workpiece the desired shape will not be difficult.

A metal blank with a thickness of 3-5 mm is required, the rollers are directed at an angle of 20-22 degrees, as shown in the drawing, and the desired bend is given.

Second way:

Here, prepared. A pipe with a diameter of 600-650 mm can serve (this is the diameter that will require less labor, since the bend of the pipe will maximally repeat the desired bend of the future dump) and a thickness of 3-5 mm. We make a template from cardboard and apply it to the pipe, not forgetting the angle of 20-22 degrees, as shown in the drawing below.

We outline the template with a pencil or chalk and cut it out using gas. welding, if necessary, grind the workpiece and bring it to the desired condition.

Third way:

Probably the most difficult method of making a moldboard is when the workpiece is heated and, using a matrix, given the desired shape, which can be a moldboard from another plow.

The material of the plow body is steel sheet grade St3 - St10 with a thickness of 3 mm.

Drawing of plow parts for walk-behind tractor

a – ploughshare made of alloy steel;

b – side shield of the rack, St3;

c – spacer plate, St3;

d – plow base plate, St3;

d – field board, corner 30x30 mm;

e – stand, pipe with a diameter of 42 mm

We advise you to first make the plow parts from cardboard and attach them to each other at the required angles. Thus, the values of the angle α on different parts of the plow body will be from 25° to 130°, the values of the angle γ - from 42° to 50°. If the homemade model of a cardboard plow suits you in all respects, you can move on to working with metal.

When the metal parts of the plow are ready, you need to find an additional sheet of steel 3 mm thick, 600x600 mm in size, it will be needed to assemble the plow, and a welding machine (preferably an inverter). On this sheet we retreat 40 mm from the edges and measure the angle γ0.

Plow assembly

1 – ploughshare;

2 – side shield of the rack;

3 – additional sheet 2-3 mm

Using wedges with an angle α0=25 degrees and an angle γ0=42 degrees, a ploughshare is installed on the additional sheet and tacked to the sheet by welding, pointwise on both sides.

The side shield of the rack is connected to the ploughshare vertically so that its edge extends beyond the ploughshare by 4-7 mm, while the raised shield should be higher than the blade of the ploughshare (that is, higher than the additional sheet) by 6-8 mm, so as not to interfere with the ploughshare, cut the ground. The shield is also attached to the ploughshare and to the additional sheet.

Next, the blade is attached to the ploughshare very tightly, without leaving a gap, so that their surfaces are one whole. The angle between the upper edge of the blade and the ploughshare blade is equal to (γmax − γ0) = 6-8°.

Mounting the plow share

– ploughshare;

– countersunk head screw M8;

– dump;

– base plate;

– corner 30x30x90 mm;

– M8 nut

If it is found that the corners and/or surfaces do not correspond, the blade is adjusted using a hammer. After fitting the blade to the ploughshare, it is welded from the back to the ploughshare and to the side shield. Then the side shield is welded to the spacer bar and the base plate; the thrust corners for the ploughshare are attached to the latter by welding.

Followed by. Inspect the finished plow again, and if everything is clearly welded completely. Add. the sheet is separated from the body with a chisel or LNA. All welds are ground.

Structure and types of plows

To make a plow with your own hands, you need to have information about its structure and the purpose of its parts. General purpose arable implements are most often used. It consists of several parts, which can be divided into working and auxiliary:

- workers: body - consists of a stand to which a ploughshare with a blade and a field board are attached;

- knife - the main cutting part;

- skimmer - an additional cutting part that cuts the turf layer of soil;

General purpose plow design

- frame - the base on which everything is mounted, consists of longitudinal beams, stiffening beams and spacers;

How does this plow work? The skimmer removes the top layer of soil with plants growing on it, turns it over and places it at the bottom of the furrow, which is the result of the work of the body. The body with the equipment cuts off part of the soil from the side of the furrow, loosens it, turns it around a certain angle (depending on the design), and lays it on top of an inverted layer of turf (laid with a skimmer). To level the furrow wall, a knife is placed in front of the last plow body.

General purpose plows can provide a plowing depth of 20 cm to 30 cm, plowshares - from 16 cm (they also do not have a knife and skimmer).

Housings

According to the number of bodies, plows are single-body, double-body and multi-body. The body consists of several parts:

- rack;

- working surface - ploughshare and blade;

- field board. Body with share and blade

The ploughshare and blade are the working surface - this part is responsible for the quality and type of plowing. The soil layer is cut with a ploughshare, along which it rises to the dump. Here the soil crumbles and turns over. The degree of formation rotation depends on the shape of the dump. A field board is attached to the bottom of the body. Its task is to prevent the plow from moving towards the already plowed area.

If you are going to make your own plow, you need to choose a design based on the type of soil you are going to cultivate. Plow bodies are:

- Dump. For plowing with full or partial rotation of the formation. Such plows promote soil formation (grown plants are cut and placed at the bottom of the furrow, where they rot), and enrich the soil with oxygen (due to loosening). cultural - used for long-cultivated lands, crumbles the soil well, wraps to a medium degree;

- semi-screw moldboard bodies are used for cultivating virgin soil, plowing heavily turfed soil, it wraps the soil well, crumbles it moderately (models with an elongated feather wrap the layer completely);

- screw - good for cultivating virgin soil - the layer is completely wrapped;

Types of plowshare plow bodies

When planning to make a plow with your own hands, the design of the plow body is chosen based on the type of soil and the goals set. Sometimes the choice depends on the type of plantings being grown. For example, root crops require enhanced loosening, which none of the above plow bodies provides. Then a special one is used - combined. It has a shortened blade and share, as well as a rotor. When plowing, the rotor additionally crushes the soil that comes from the ploughshare.

Blade

The plow blade is one of the working parts of the plow (a component of the body). His job is to cut off a layer of soil from the wall, crumble it and turn it over (turn it around). That is, how well the soil will be prepared largely depends on the quality of the dump. When making your own plow, this is worth remembering.

Shape and drawing of a blade made of 3 mm thick sheet steel

The blade is made from sheet carbon steel or special three-layer steel. It has a complex curved shape, on which the degree of soil grinding and its turnover depend. Structurally, a plow moldboard is distinguished between a chest and a wing (spout).

The blade breast cuts off a layer of soil from the wall of the furrow, crushes it, and begins to wrap the cut layer. The blade wing finishes its revolution. As you can see, the chest does most of the work, and therefore wears out, on average, twice as fast. Therefore, the blade is made of two parts. In this case, if there is severe wear, the blade breast can be replaced. Another nuance: at the factory, to reduce friction between the formation and the surface, it is polished.

Types of dumps

There are four main moldboard shapes, each of which imparts specific plowing characteristics:

- Cultural dump. It crumbles the layer well and wraps it quite completely. It is used for plowing large areas of long-developed land.

- Cylindrical. It crushes the soil well, but does not wrap well. As a result, plant residues in this case are evenly mixed with the soil. A similar blade is used on light soils.

- Half-screw and screw. They wrap the layer completely (plant residues are laid upside down), but crumble very poorly. After plowing with a plow with such a moldboard, the field has pronounced “waves”. Before sowing, it must be further processed - leveled (harrows, cutters, etc.).

When choosing materials, keep in mind that both the blade and the plowshare must have almost the same thickness: the permissible “step” size is 1 mm. Also, the gap at the junction of the plowshare and the blade can be very small - no more than 0.5 mm.

ploughshare

To make a plow with your own hands, you need to decide on the shape of the ploughshare. A ploughshare is a part that cuts a layer of soil; along it, the cut layer of soil also rises and ends up on the dump. High-strength hardened steel is used for its manufacture.

Position the ploughshare as follows:

- to the bottom of the furrow at an angle of 22-30°;

- the choice of inclination angle relative to the furrow plane depends on the type of blade: for a cultural dump - 40°;

- cylindrical - 45°;

- screw and half-screw - 35°.

This arrangement provides the least resistance when moving, while the blade cuts roots well and breaks up lumps of earth that slide along its surface.

Shapes of plowshares

Ploughshares come in different shapes (pictured above). When making a plow with your own hands, they are chosen depending on the type of soil and the complexity of production:

- Trapezoidal. The easiest to make, the good thing is that when used, the bottom of the furrow is smooth. The disadvantage is rapid wear and difficulty in deepening. Therefore, trapezoidal shares are most often used on long-cultivated lands. To compensate for rapid wear, a certain supply of material is made on the reverse side - a magazine. The next time it is pulled back, part of the reserve goes away.

- Toothed and with retractable chisel. These types of plowshares are used on heavy soils (clay, loams) and where there are a lot of stones.

- Chisel-shaped. It is distinguished by the presence of a sharp, forward protrusion-nose. This protrusion protrudes towards the field by 5 mm and downwards by 10 mm. Such a bend ensures that a plow with such a plowshare penetrates deeper better and faster and goes smoother. To compensate for wear, they also make a “magazine” - a reserve of length. Plows with chisel-shaped shares are used on heavy soils.

Of all these types, chisel-shaped shares are the most common. They are more stable in operation, there are no problems with them when going deep: the plow easily lowers to the desired depth.

Dimensions of a blade made of a thick-walled pipe with a diameter of 50-60 mm (a gas cylinder is suitable)

As they wear, the plowshares pull back and sharpen the cutting edge. This is done regularly, since with a dull blade (width more than 3 mm), the resistance of the plow increases by 50%. Therefore, it is more profitable to inspect and maintain equipment on time.

Preparing and setting up the plow for work

Assembly work is carried out in the following stages:

- Open the packaging and select spare parts; they should be put aside. We lay out the main components in a convenient order.

- We bring the frame into locking mode and install it on the prepared stand.

- The housing is hung and inserted into the stiffening beam and the rack with a bolt. The housing stand is mounted to the frame using locknuts.

- On the left, the skimmers are screwed to the body in front of the body holders using brackets. There is no need to tighten the staples at this stage.

- We secure the support wheels using brackets and spring washers. They are attached to the outside of the structure.

- The support wheels are lowered all the way; to do this, turn the screw nut at the end counterclockwise).

- We tighten all the brackets until they stop and remove the plow from the stand.

- The scraper is mounted to the wheel bracket using washers and nuts.

- The hitch is mounted on the plow frame using bolts, which must be tightened until they stop.

- We screw red reflectors to the back of the main beam.

The plow is assembled and ready to be set up. The tincture is carried out in the following steps:

- Before using for the first time, inspect the equipment. Lubricate the wheel bearings and all rubbing parts with grease.

- Set the skimmer to the required plowing depth. The gap between the coulter shares and the body must be at least 250 mm. Using the protrusion on the holder, we adjust the depth of tillage.

- Tighten the skimmer clamps completely. In this case, the field edge of the skimmer covers the edge of the body.

- The PLN plow has a soil grip of 105 cm, so the track should be 1560 mm. To prevent shortfalls when plowing, the right wheel of the machine is placed in the furrow.

- The slanting rods of the mounted part are adjusted after the plow is installed on the ground.

- The braces are placed in the front holes of the rod.

- Before work, it is necessary to adjust the limit chain. The longitudinal rods should swing freely horizontally by 120-130 mm in different directions. To do this, the chain is built with a slight slack.

- Before plowing, it is necessary to adjust the depth by adjusting the traction of the mounted part and the support wheel. Initially, according to the timing of the front wheel, the average depth value is set and the first row is passed. Next, the flash depth is adjusted for each type of soil individually.

- When working, the right side of the frame should always be slightly higher than the left. As the furrow passes, it will break out and be strictly parallel to the soil.

- After passing the furrow, make sure that the plowing is uniform and completely covers the plant residues. There is an adjustment on the left side of the plow that will help make the plow for the MTZ 80 tractor more stable. If the plow moves to the side, then the canopy is moved back.

- If the frame warps, then you need to lengthen the brace.

- You can adjust the plowing depth of the front part of the body using the right link slants from the mounted unit, the rear part using the top one. In this case, the support wheel is placed at the required plowing depth and the position is fixed using a support bolt in the holder.

High-quality plowing can be determined by several criteria:

- The plowing depth of all plow bodies is uniform, the furrows are the same.

- When plowing forever, the adjusted units remain in the same position.

After moving to new fields, with a different type of soil, the plow must be adjusted in a new way.

Rules for plowing with an adjusted plow

After passing the first row, you need to adjust the plow to the desired depth.

For uniform and correct plowing, a number of rules must be followed:

- When moving from one furrow to another, the plow rises to the transport position.

- Circular plowing can only be done with a reversible plow.

- The plow turns smoothly.

- When transporting the working body, it is necessary to control the ground clearance. The distance from the road to the plow must be constant.

- When using a power deepener, the support wheel is removed from the plow. The depth is adjusted automatically.

- When plowing with power control, remove the support wheel from the plow. In this case, the specified plowing depth is maintained automatically using a power regulator.

The price of a new plow for the MTZ 80 tractor is presented in the table:

How to do it?

Modern models of walk-behind tractors can be equipped with a reliable plow made by yourself. Varieties of this element: double-turn, reversible, two-body, rotary or Zykov’s product. There are quite a lot of design options. There are even options in which the body is made of a gas cylinder. It’s not difficult to make a high-quality plow for motorcycles yourself if you follow certain rules.

Rotary

The manufacturing of the structure can be divided into several main stages.

Prepare a good dump in the shape of a cylinder. This must be done exclusively in accordance with the drawing. The part is made of alloy metal

It is important to follow the drawing when making the structure yourself. They put out the ploughshare. The wedges are inserted into the iron sheet (3 mm) at an angle of 45 degrees. Connect the ploughshare to the shield on the side

Be sure to ensure that the blade of the ploughshare is located just below the shield itself (1 cm, no more). Attach the blade to the ploughshare. The working half with the ploughshare is welded to the metal tube, which serves as the base, using a welding machine. On the opposite side - fasteners for motorcycles. When the plow is ready, you can weld an axle with wheels in its lower half.

Turning

The rotating type of plow is rightfully recognized as one of the most functional and practical. This design is an excellent assistant for plowing land on a site, because it can cover a fairly large area. The plow is also good because you don’t have to waste time with it after each approach. You will only need to turn the plow and move in the opposite direction. The productivity of equipment will increase significantly. The main actions are performed in the same way as in the case of a rotary mechanism, but in this case the cutting elements must be below the skid (at least 2 cm).

Disk

It is possible to assemble a disc plow for machinery with your own hands. A similar model is assembled from the following parts:

- disks;

- fist;

- axles;

- bracket;

- scraper;

- drive beam;

- pens;

- screeds.

The disks for the device can be taken from an old “seeder”, if you have one in your arsenal. These elements are installed at an angle to increase work productivity. The hiller is hung on the equipment through the coupling bracket. The T-shaped leash from the plow is screwed to it using bolts and a stopper. At impressive speeds, the hiller may begin to slip, so you will have to work exclusively at low speeds or with twin wheels.

Video tutorials on making plows

This problem probably occurs for many gardeners and vegetable gardeners. There is a small plot of land - one or three acres, and it needs to be plowed. It’s a chore to shovel, the horse is nowhere to be found now, the tractor won’t get in. Buying a cultivator for a buck and using it for an hour a year is a toad's crush. I started digging around the Internet - is it really a hand plow, just our invention - and what did the greedy bourgeoisie come up with?

It turns out that the bourgeoisie had such a device for a long time, but they used it only for subsequent improvements to the land - surface cultivation, shallow hilling, making furrows during planting. That is, to manually pull a plow over the turf instead of a horse by two people, this is not observed there. It’s probably better for several owners to come together in the area and buy a walk-behind tractor. This is how collective farms and socialism appear, which is also not encouraging. And this is how they plowed; women in a Dutch field 1919 Use hand plows to make furrows for planting poppies:

At the beginning of the 20th century, hand plows with large wheels were made almost en masse:

The bourgeoisie used the same principle to make hand cultivators.

Now let's look at our handicrafts. Due to the increasing need for hand plows, they began to be produced at almost every factory. The designs of such a product are almost identical for all and are intended for use as a burden for an over-aged child, who will do physical exercise on one hundred square meters and help his parents. It looks like this:

These designs are constantly being improved by both enterprises and craftsmen. Rollers and discs are installed, and either a rope or a pipe with a cross member is used as traction. A bicycle frame can be used:

A very interesting Belarusian homemade product, I liked the shape of the hand plow – hiller:

In parallel with such searches, I found an antique American manual lawn mower. Everything is primitive - a pair of knives, two wheels. And also the hand harrow of the old cowboys. Maybe someone will try:

Here it is, a drawing of a hand plow:

See also:

Repairing an electric trimmer I will write another article in the do-it-yourself repair series. This time we are repairing a lawn mower trimmer. The start button on this important summer power tool has broken down; it was probably mowed down by a hare.

How to clear snow There is snow all around. It is vital to ensure access to your home. You need to find the strength within yourself and replace your computer with a snow shovel. It’s even better to organize the younger generation for such work and provide for it yourself.

How to choose a trimmer I will not get into an argument about which is better, a trimmer or a lawn mower. They are tools designed for different purposes. And if you have more than three acres of lawn with trees, then it’s better.

Plow design

If we talk about the Neva walk-behind tractor, several types of plows are installed on it, each of which has its own design features.

Nowadays the land on personal plots is cultivated with plows of the following designs:

- single-hull;

- negotiable;

- rotary.

The most popular are single-hull guns. In addition, such a plow is considered the most optimal for plowmen without skills.

At the top of the reversible plow there is a curved feather, which allows you to immediately turn over the layer of earth during the plowing process. This feature makes the design an excellent option for cultivating hard soils. Since the design of such a plow is quite complex, only an experienced person can make it.

The rotary plow is the most difficult to manufacture. In design, it is more reminiscent of a cultivator, since there are several shares on one axis. When cultivating the soil, the axis rotates, causing the soil layer to turn over. The advantage of the design is that the soil can be cultivated to a depth of up to 30 cm with little effort. With the help of a rotary plow, plowing of the site can be done along different trajectories.

So, the single-hull plow is the most widely used, and anyone can work with it, even those not familiar with mechanized plowing. The advantage is that this tool is quite easy to make with your own hands.

Rotary plow for walk-behind tractor, homemade

The rotary plow is universal, used on walk-behind tractors, and contains a manual rotary mechanism on a standard single hitch. As you know, when plowing the soil with a conventional plow, in one pass the layer of soil is turned over by the ploughshare in one direction. In order for the soil of the next row to turn over in the same direction, you have to return to the beginning of the previous row and start from the same side of the plot.

A rotating plow will allow you to plow much faster - at the end of the row, after turning the walk-behind tractor, you simply turn the ploughshare in the other direction and continue cultivating the soil.