The marking implies a special license plate that describes the main functional characteristics of the hardware. This degree of discrimination is necessary for applying fasteners to a drawing or for recording some information for documentation. By using fastener markings, confusion due to incorrect reading of the markings disappears.

Digital designations printed on fasteners are determined in accordance with the approved GOST R52627-2006. Marking of hardware can contain such information about the element as:

· Trademark;

· Strength class.

Fasteners include all types of hardware, including nuts, bolts, studs, screws and washers.

Strength class in marking

One of the main indicators used in marking is the strength class. Such indicators can be defined by the following symbolism:

| Strength class | 3.6 | 4.6 | 4.8 | 5.6 | 5.8 | 6.6 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 |

| Marking symbol | 3.6 | 4.6 | 4.8 | 5.6 | 5.8 | 6.6 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 |

The “a” indicator corresponds to the number 12 on the watch dial. This is the control mark. It looks like a dot and defines the trademark.

The “b” indicator corresponds to the strength class and is indicated by a double stroke. To highlight the strength class, the dot designation is used.

Conventional designations of coatings

All coatings have their own markings, which are marked on the packaging, but understanding the intricacies of technical symbolism is not easy. You need to know the numerical designation of the coating:

| Zinc, chromated | C. hr | 01 |

| Cadmium, chromated | Kd. xp | 02 |

| Multilayer: copper-nickel | M. N | 03 |

| Multilayer: copper-nickel-chrome | M. N. H. b | 04 |

| Oxidized, oil-impregnated | Chem. Oks. prm | 05 |

| Phosphate, oil impregnated | Chem. Phos. prm | 06 |

| Tin | ABOUT | 07 |

| Copper | M | 08 |

| Zinc | C | 09 |

| Oxidic, filled with chromates | An. Oks. NHR | 10 |

| Oxidic from acidic solutions | Chem. Pass | 11 |

| Silver | Wed | 12 |

| Nickel | N | 13 |

In addition, the thickness of the spraying is of great importance, which is also written on the packaging and is calculated in microns. It is always noted after the type of spraying.

Examples:

- Nut М12×1.25-6Н.05.40Х.016 GOST 5915-70;

- Screw A2M12×1.25-be x60.58.S.019 GOST 17473-80.

The numbers 016 and 019 are general information about the coating and its thickness. 01 - zinc chromated coating. And the third number (6 and 9) indicates that these types of spraying have a thickness of 6 and 9 microns, respectively. There are also letter variants that would look like “Ts.khr6” and “Ts.khr9” in these cases.

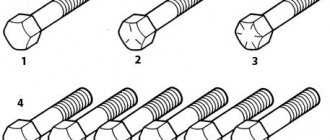

Star and hex head on fasteners

This type of fastener is marked with a strength class and the manufacturer’s trademark. These are the necessary indicators that should be on the product.

Functional designations are applied to the side of the fastener. The place of application is the head. If it is not possible to apply numbering on the head of the element due to its absence, then the markings are applied to the flanges of bolts and screws.

Hex bolts have their own marking characteristics. Especially if their diameter is higher than 5 mm. Marking the head of such fasteners is mandatory during their manufacture.

a— Trademark. b— Strength class.

How are protective coatings for bolts, screws, studs, and nuts designated?

There is a unified corrosion protection system developed and outlined in GOST 9.306-85. According to this interstate standard, each type of coating is assigned its own letter and number designation. The table shows examples of the main types of protective and protective-decorative coatings for fasteners:

Having such a table at hand, you can easily determine the type of fastener coating and draw a conclusion about the degree of protection of the product from corrosion, and evaluate its suitability for certain conditions of use.

Hairpins

As for bolts and screws with a diameter greater than 5, as a rule, the strength class corresponds to 5.6 or 8.8. Sometimes the strength class can be higher. The marking of such products necessarily includes strength class indicators. Numbering is applied to any place on the product that does not have a thread.

If there is not enough space on the product, other symbols may be used.

| Strength class | 5,6 | 8,8 | 9,8 | 10,9 | 12,9 |

| Marking symbol |

Basic methods of protecting hardware by coating

It seems that it is easy to get confused in the complex intricacy of various classifications of such coatings, but upon closer study we can find that there are only two types: mechanical and electromechanical processing of the surface of the hardware.

Mechanical. It is the isolation of the hardware material from the external environment with a layer of a protective composition, which realizes its potential only with uniform coverage and the absence of cracks, chips and other damage.

Electromechanical. Implies the presence of electromechanical potential between two metals. Sputtering made of negatively charged material is called anodic, and is produced by treating it with zinc, chromium, aluminum and magnesium. In contrast, there are cathode coatings that have a positive potential. This coating is done using silver, gold, tin and copper.

Anodic coatings. They are characterized by mechanical and electromechanical protection; cathodic ones can provide only mechanical protection.

Fasteners: types, coatings and markings of fasteners.

Steel bolts and nuts are the most common and familiar fasteners. | Fasteners are the most important engineering parts used in all branches of mechanical engineering. There are many types of fasteners. A variety of definitions of structural types of fasteners are standardized by GOST and other standards. |

Marking of high-strength bolts according to GOST 22353-77

Strictly speaking, GOST 22353-77 today has already lost force in the Russian Federation. Instead, bolts are now made according to GOST R 52644-2006, which we will talk about below.

But, since bolts manufactured according to this GOST are still found in practice, let's see what markings were made on them and what it means.

It consists of two parts: at the top there are some alphabetic symbols, at the bottom there are numbers.

So what do the numbers and letters on the head of the bolt mean according to GOST 22353-77?

1. The letter designation at the top, which comes first, is the manufacturer’s mark (D, OC, L, Ch, WT, etc.)

2. A series of numbers following the letters is the temporary resistance of the bolt in MPa, divided by 10

3. Climatic version HL (for cold climates)

4. Melt number.

If the thread on a bolt is left-handed, then such a bolt is additionally marked with an arrow (counterclockwise), if the thread is right-handed, then the bolt is not marked with any arrow.

Marking of high-strength bolts according to GOST R 52644-2006

And this is what the markings on the bolts look like according to the new GOST:

Marking values on the hex head of a high-strength bolt:

- 1. Manufacturer's mark;

- 2. Strength class for GOST R 52644-2006;

- 3. Climatic version HL (for cold climates);

- 4. Heat number;

- 5. The letter S is a designation for a high-strength hex head bolt with an increased wrench size

Structural forms of fasteners

Basic Fasteners

Figure 1. Types of fasteners for threaded connections of various designs: a) bolt, nut and washer; b) screw; c) stud, nut and washer; d) screw, insert and washer

Among threaded parts, the most common are the following basic fasteners :

- screws (including bolts ),

- hairpins,

- nuts,

- inserts,

- washers.

A bolt (Figure 1, a) or a screw (Figure 1, b) is understood as a rod with a head and one threaded end.

A screw is a fastener that has a rod with an external thread and a head. The screw connects to a nut or mounting hole.

Figure 2. Stainless steel bolt DIN 933

Screws are classified according to purpose into two types:

- fastening screws used for detachable connections of parts (for example, for detachable flange connections of pipelines);

- installation screws used for mutual fixation of parts.

A bolt is a fastener that has a male threaded shank at one end and a head at the other. A bolt forms a connection using a nut or threaded hole in the product being connected. Unlike a screw, a bolt necessarily has a head to transmit torque.

The hairpin (Figure 1, c) has two threaded ends and does not have a head.

Figure 3. Stainless steel nuts.

The insert (Figure 1, d) is shaped like a helical spring made of rhombic wire, screwed under tension into a threaded hole.

A nut is a fastener with a threaded hole and a structural element for transmitting torque.

A washer is a fastener with a hole placed under a nut or the head of a bolt or screw. The washer serves to increase the supporting surface or to prevent them from unscrewing themselves.

In our country and abroad, standards have been developed for the most common types of parts for general purpose threaded connections.

Marking of fasteners

Marking of fasteners.

Types of fasteners

Before deciphering the markings on a specific “stud”, you should decide on the types of fasteners. There are quite a lot of them: fasteners differ in purpose, design, material, coating. In addition, within the same type, fasteners differ in size (length, diameter), and sometimes in shape.

The main and most common types of fasteners include:

- threaded fasteners – bolts, nuts, studs, screws, screws;

- auxiliary elements (most often used in combination with threaded fasteners) - washers, cotter pins, retaining rings/half rings;

- fasteners installed with tension into solid material - nails, dowels, anchors, reinforcement fasteners;

- rivets (for creating permanent connections);

- various fixing elements - clamps, ties, brackets, etc.;

- rigging, cables, tapes, wire;

- specific plumbing fasteners;

- and other types.

*A variety of adhesives, mastics, and sealants are also widely used to connect parts of structures. However, these materials still do not belong to fastener elements (presuming the presence of individual products measured in pieces).

In addition to types (i.e. classification based on design characteristics), there is a widespread, although not entirely “academic”, division into metric and inch fasteners. For example, pipe thread sizes, due to historical tradition, are always indicated in inches. Although this does not prevent us from classifying this fastener as a threaded fastener.

Fastener material

Another characteristic difference between fasteners is its material. All common types of structural materials are used for the production of fasteners: steel, non-ferrous metals, wood, plastic. The last type of material is the most promising. And in some cases it actively displaces the “classics” - metals of various types. With comparable strength characteristics, synthetic polyamide has a significant advantage over steel products - primarily, its resistance to corrosion. That is why the difference in material is present not only for different types of fasteners (such as a steel nut and a copper rivet), but also for products of the same type - the same bolts made of steel or polyamide.

However, despite the progress in the field of synthetic materials, steel, alloys and non-ferrous metals remain the main ones for the production of fasteners. The choice of material grade for fastening a specific design is dictated by:

- workload requiring a certain strength of fasteners;

- environmental conditions - temperature, the presence of aggressive chemical influences (which requires the selection of fasteners that are resistant to temperature and corrosion);

- the presence of a dynamic component of the load - vibration (fasteners must have significant fatigue strength);

- requirements for the magnetic properties of the material - or, conversely, for their absence;

- physical characteristics of the material (specific gravity, density, lack of tendency to spark during impact contact, etc.);

- quite often - aesthetic properties and design considerations.

These and other factors impose strict restrictions on the choice of the type of materials for fasteners in each specific case. Therefore, if a batch of spare parts contains titanium fasteners, it is unlikely that it will be possible to decipher the “steel” grade in its markings!

Types of protective coatings

Another category of properties of fasteners is the presence/type of protective coating of the material. A thin layer of coating not only provides protection against corrosion or mechanical stress (contact abrasion), but also has a beneficial effect on increasing the fatigue strength of fasteners (in the presence of a protective coating, the effect of surface compression is comparable to mechanical hardening by forging).

The thickness of the coating is determined by the size and type of fasteners. For example, for elements with a thread pitch of less than 0.4 mm, the thickness is 3-6 microns. For threads with pitches above 0.8 mm – 9-12 microns. Zinc, cadmium, copper-nickel alloy, chromium, tin, oxide films, etc. are used for coating. All technical requirements for the type and characteristics of the coating are regulated by GOST 1759.4-87.

Fastener marking

Some types of fasteners are not subject to mandatory marking. However, for a number of fasteners (primarily threaded ones), marking is an indispensable requirement. Must be marked:

- bolt fastener with hexagonal head;

- socket/hexagon socket screws;

- hex nuts;

- threaded rods.

In this case, the labeling must contain information about:

- strength class of fastener material;

- design dimensions;

- left-hand thread (if the fastener has one);

- presence/type of protective coating;

- manufacturer of the fastener (a stamp or trademark is applied).

The strength class designation is deciphered as follows. For example, there is a hex head bolt with a strength class of 5.6. The first number (multiplied by 100) is the ultimate breaking load. In our example, it is at least 500 N/mm2. Exceeding this load means guaranteed destruction of the fastener material. Consequently, this number characterizes the maximum load-bearing capacity of a threaded fastener as part of an assembly unit.

The second part of the designation (the number multiplied by 10) is the ratio of the yield strength to the tensile strength (encoded by the first number). In our example, the bolt will pass the elastic deformation limit and approach the yield point at a load of 6•5•10=300 N/mm2

Thus, the strength class marking contains all the main characteristics of the material. Based on the markings, it is easy to compare fasteners with each other and choose the one that is suitable for a specific design. For example, bolts marked 4.6 and 4.8 have the same tensile strength (400 N/mm2). However, the yield strength of the first is lower (occurs at a load of 240 N/mm2, while for the second - at 320 N/mm2). Can we say that the bolts will withstand the same load, for example 300 N/mm2? In the limit, yes - none of them will collapse. But the second bolt will work in the plastic deformation zone. And whether this is acceptable for a particular design should be carefully assessed.

The strength class is usually marked as a separate number in the lower semicircle at the end of the hexagonal head of the bolt. At the top there is an alphanumeric code of several characters:

- the first letter is always the mark or code of the manufacturer;

- the next group of numbers is the value of tensile strength (divided by 100);

- followed by the letters of the climatic version (ХЛ means “cold climate”);

- the number next is the heat number;

- if the bolt thread is left-handed, the “counterclockwise” arrow icon closes the marking.

For stainless bolts, the strength class is preceded by the steel grade - A2 or A4. In this case, the strength class is encrypted with a two-digit number (50, 60, 70, etc.). Multiplying this number by 10 will give the tensile strength in MPa.

Hex nuts are also divided into strength classes: 4, 5, 6, 8, 10, 12. If the number in the marking is multiplied by 100, you get the strength limit of the bolt with which the nut can be used. For example, a class 6 nut can be safely used with class 6.6 bolts.

In general, the rules for marking fasteners, as well as their decoding, are regulated by GOST 27017-86. The standard outlines the terminology, nomenclature and designations of various types of fasteners. At the same time, GOST allows modification of designations (adding new information to the standard characteristics, more accurately revealing the features and properties of fasteners).

The most recent standard for bolted fastenings is GOST R 52644-2006.

Fastener materials

According to the fastening standard GOST 1759.4-87 “Bolts, screws and studs. Mechanical properties and test methods" (“Bolts, screws and studs. Mechanical properties and test methods”), the mechanical characteristics of carbon and alloy steels used for the manufacture of bolts, screws and nuts, as well as the steel grade, must correspond to those indicated in Table 1.

Table 1. Mechanical characteristics of corrosion-resistant (stainless), heat-resistant, heat-resistant and heat-resistant steels (at normal temperature) for the production of screws, bolts, studs and nuts.

| Fastener steel grade | tensile strength σв, MPa | yield strength σt, MPa | relative elongation δ5, % | impact strength, aH, J/cm2 | |

| Bolts | Nuts | no less | |||

| 12Х18Н10Т | 12Х18Н9Т, 10Х17Н13М2Т | 520 | 200 | 40 | 40 |

| 20Х13 | — | 700 | 550 | 15 | 60 |

| 14Х17Н2 | 20Х13, 14Х17Н2 | 650 | 12 | 60 | |

| 10Х11Н23Т3МР 13Х11Н2В2МФ | — Х12Н22Т3МР | 900 | 550 | 8 | 30 |

| 25Х1МФ | 25Х2М1Ф 20Х1М1Ф1ТР | 750 | 10 | 30 | |

The use of Bessemer steels for the manufacture of fasteners is prohibited, since such steel fasteners have increased brittleness due to the high content of phosphorus and nitrogen absorbed from the air during purging.

When there are strict requirements for corrosion resistance, strength, dimensions and weight of the connection, fasteners made of titanium and beryllium alloys, high-strength and heat-resistant steels and alloys are used.